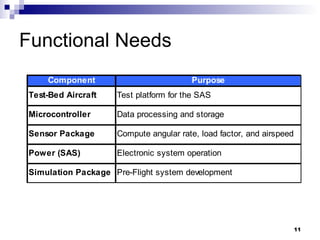

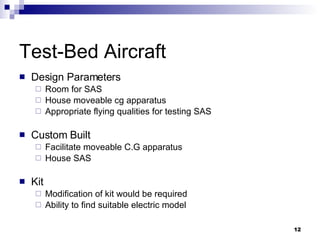

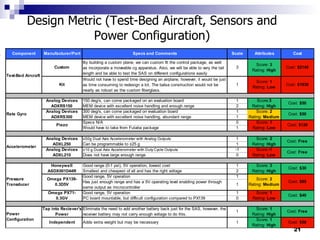

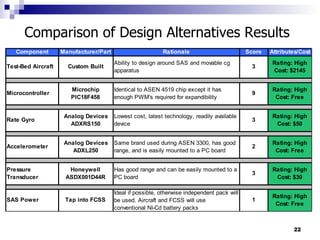

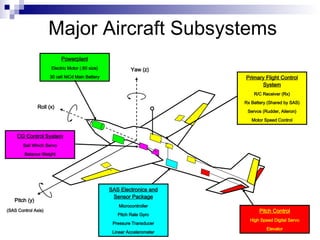

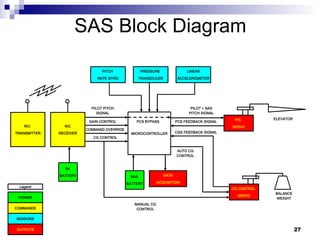

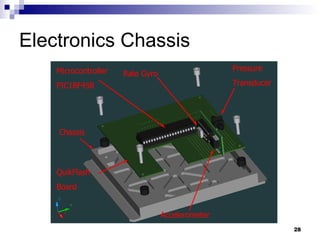

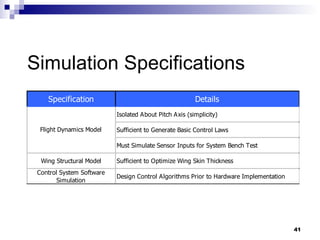

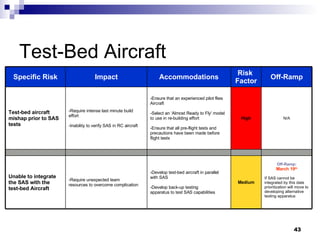

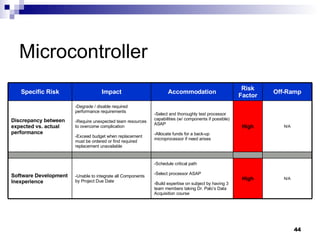

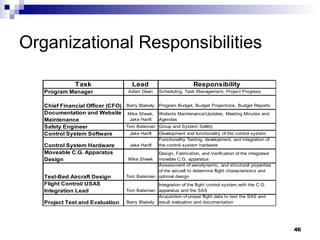

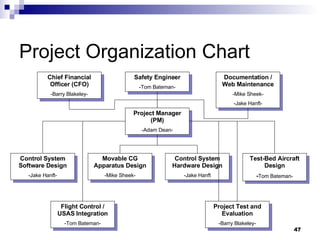

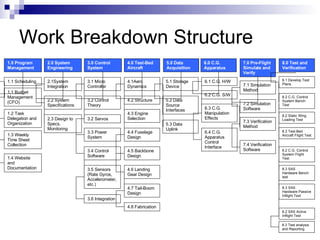

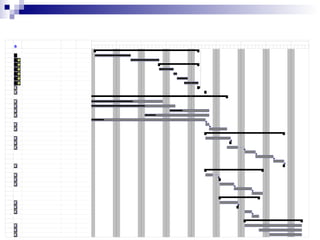

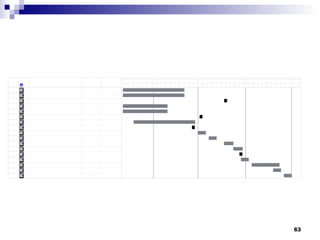

The document outlines a project to develop an artificial stability augmentation system (USAS) for unmanned aerial vehicles. It discusses the mission objectives, an overview of design alternatives, specifications for the system design, and a risk assessment plan. A project plan is presented, including an organizational chart, work breakdown structure, schedule, cost estimates, and required facilities and resources.