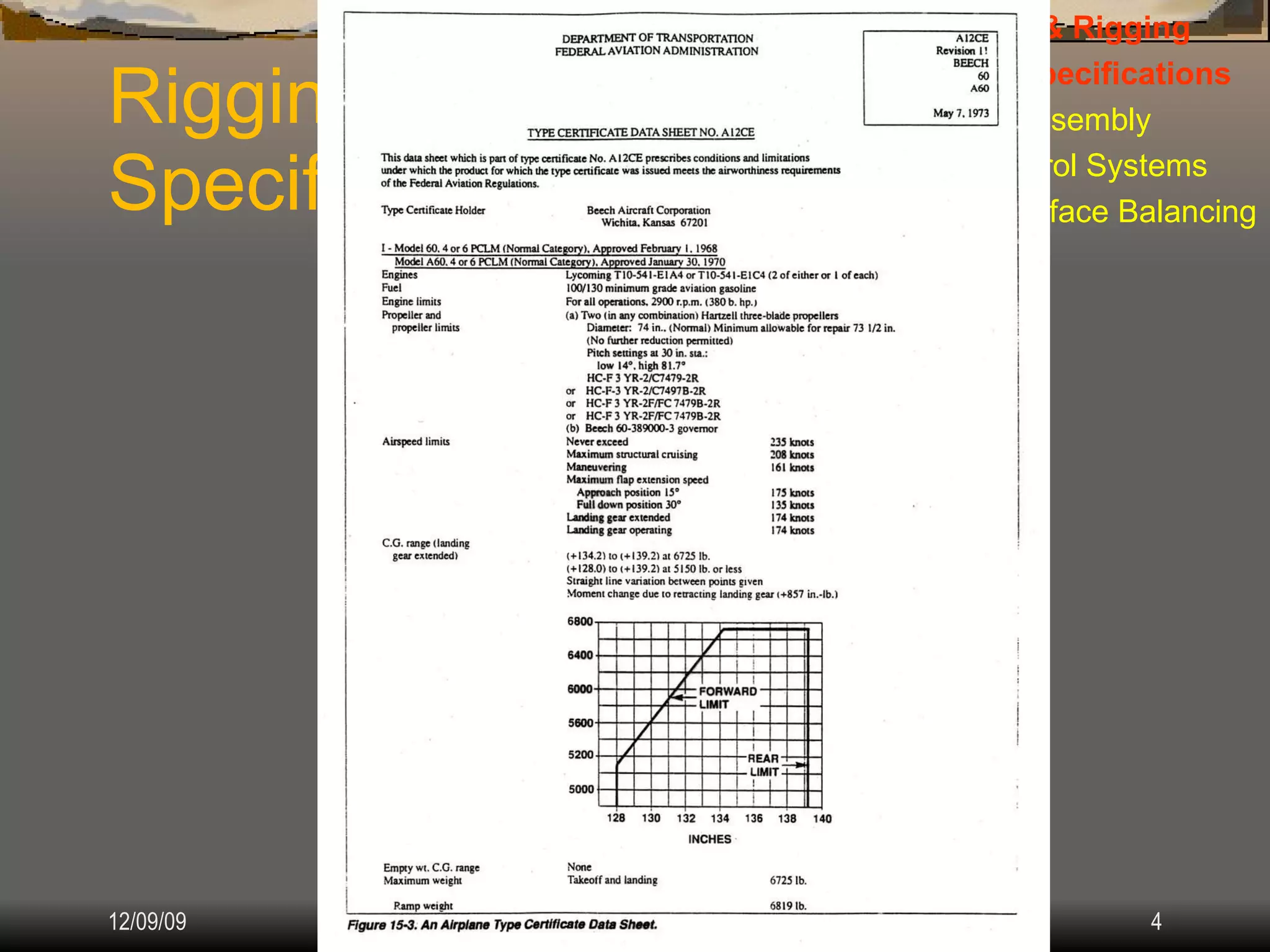

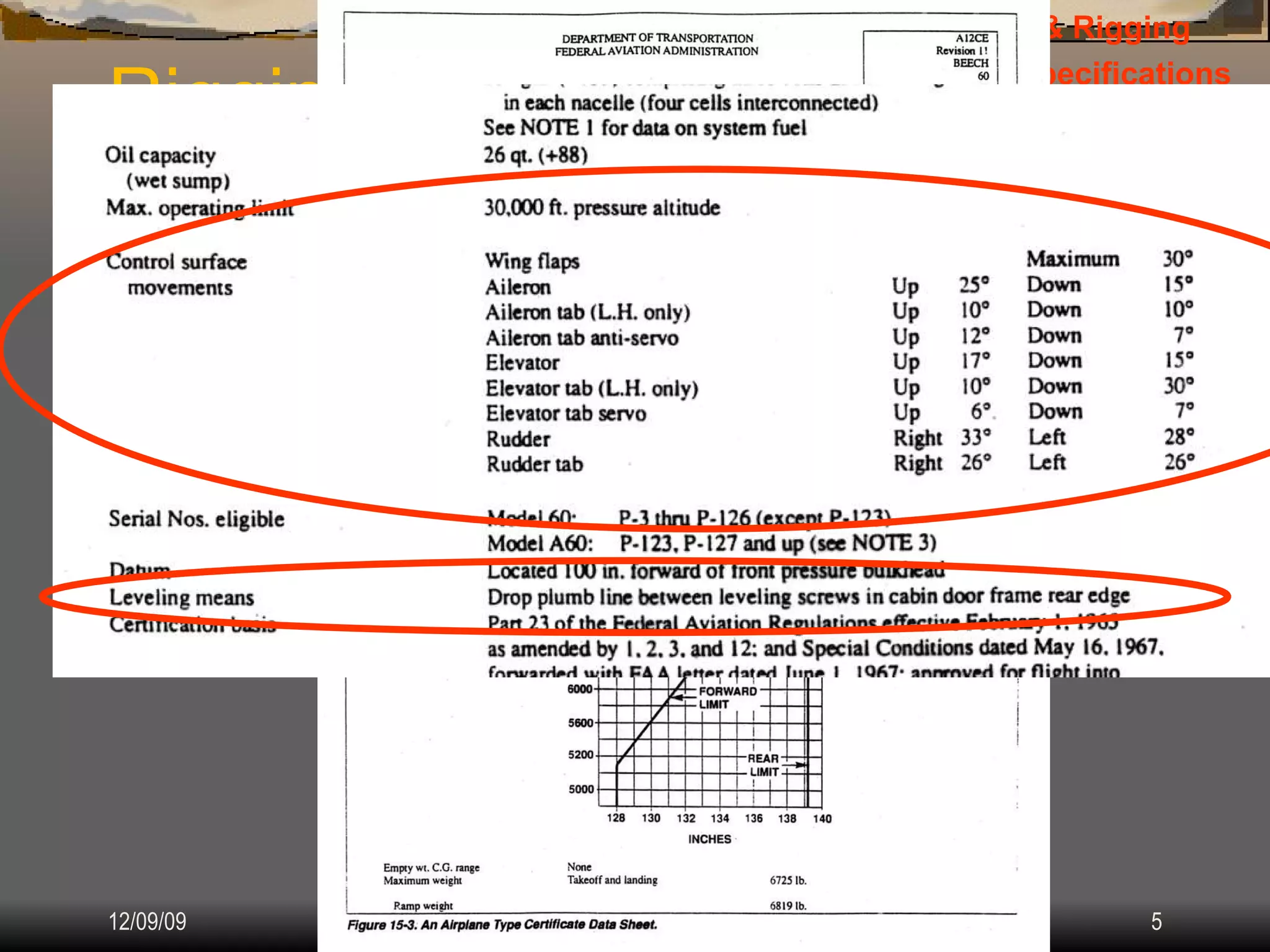

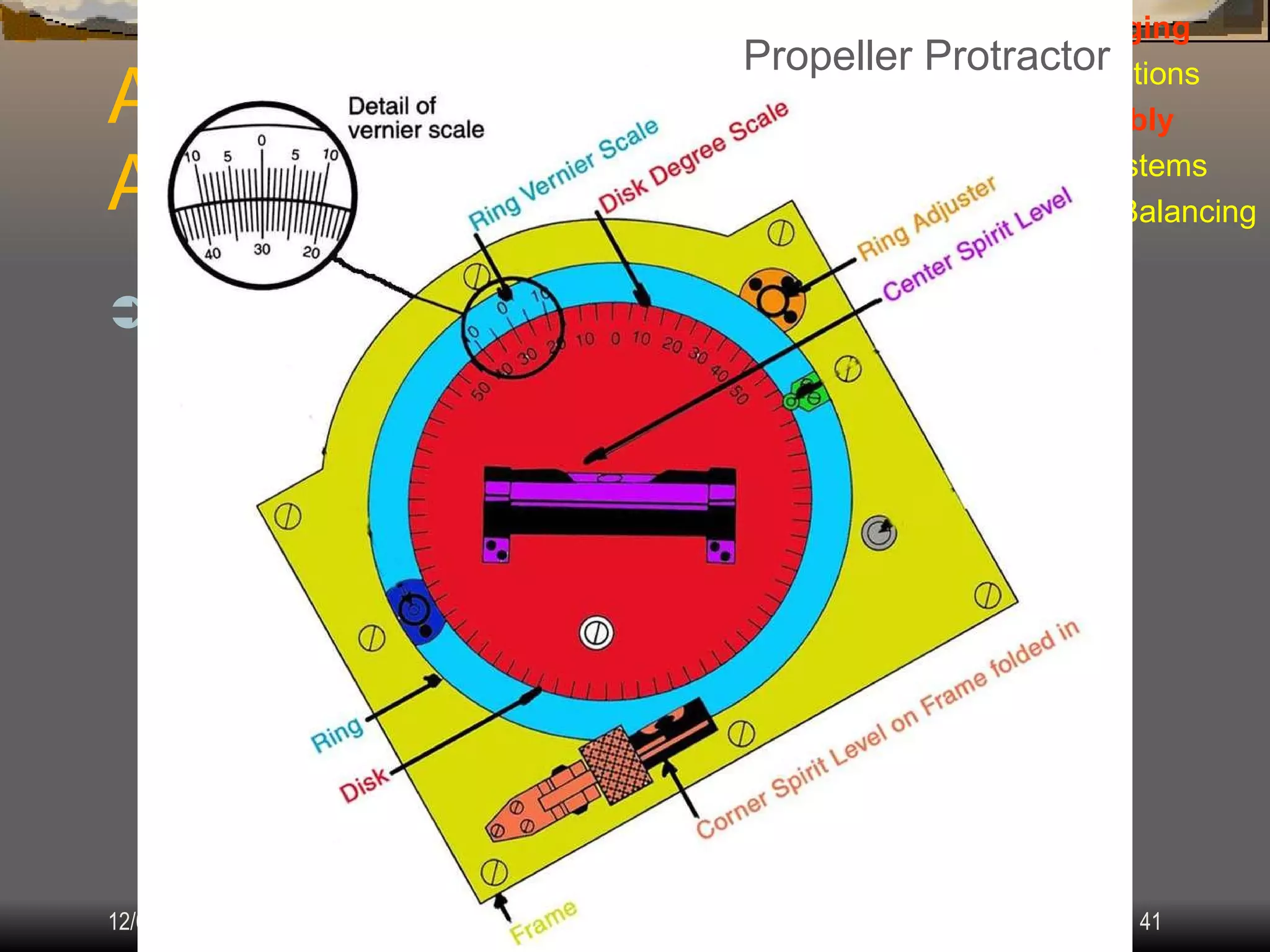

The document discusses rigging specifications and procedures for aircraft assembly and flight control systems. It provides details on:

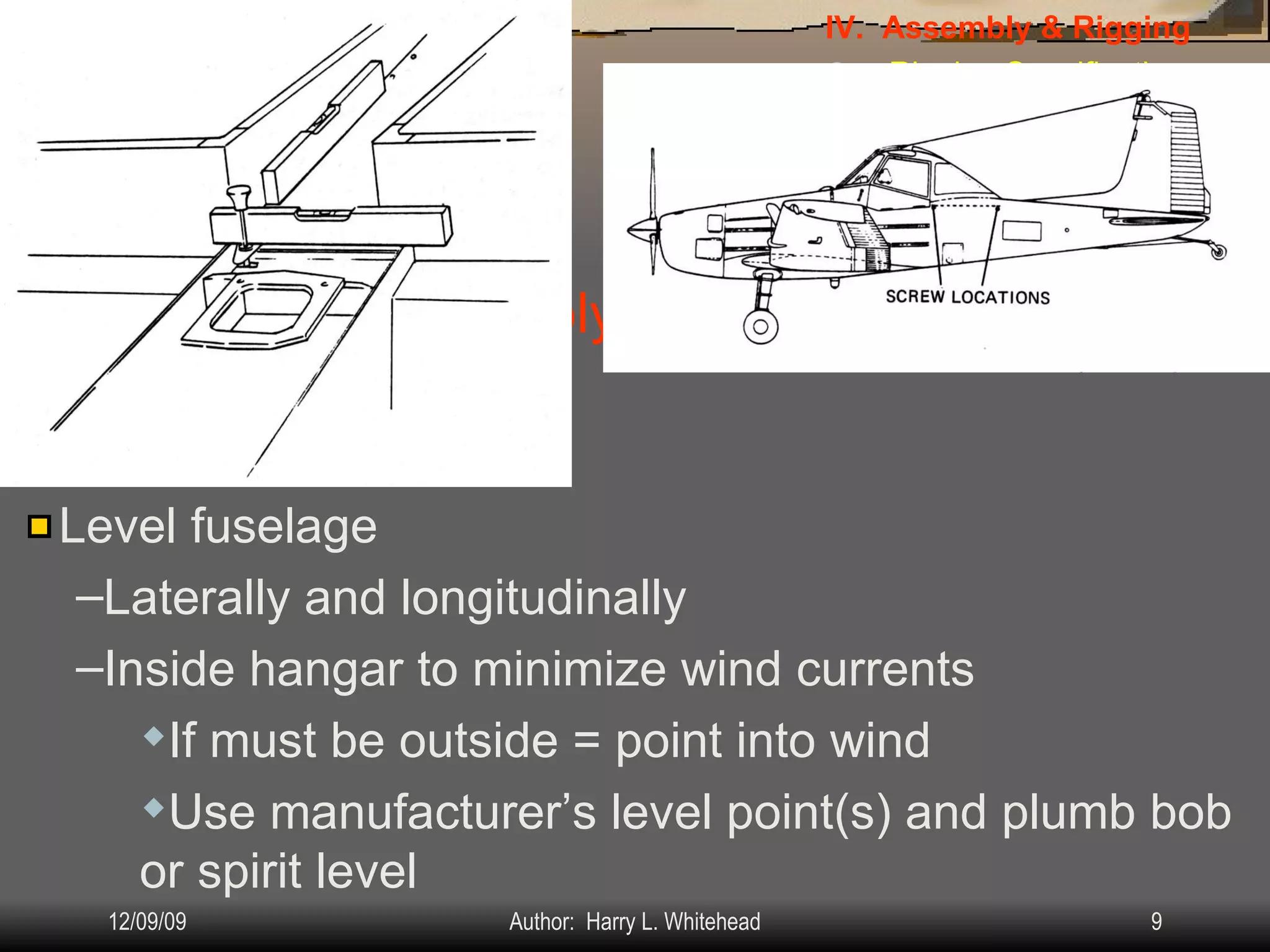

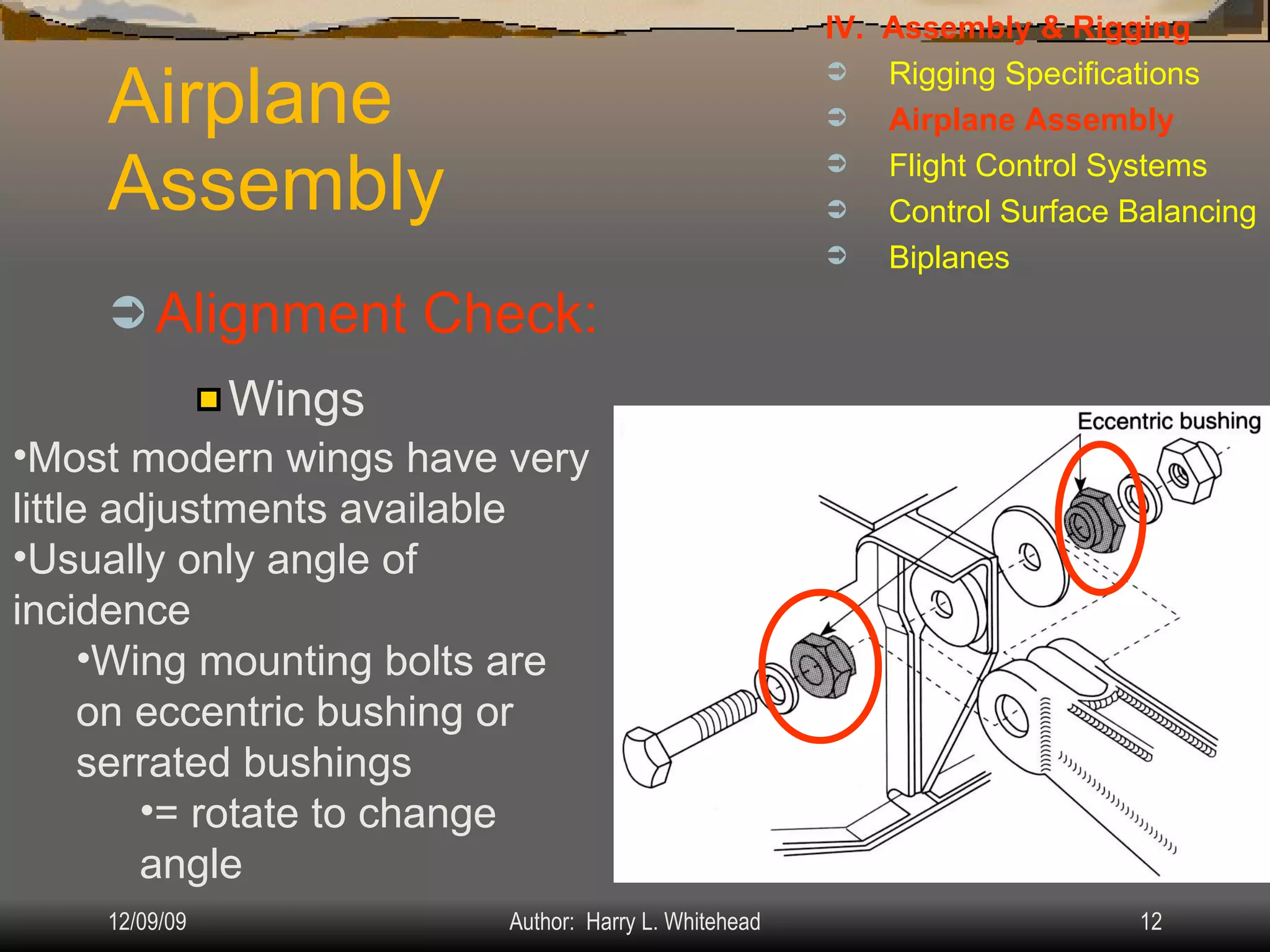

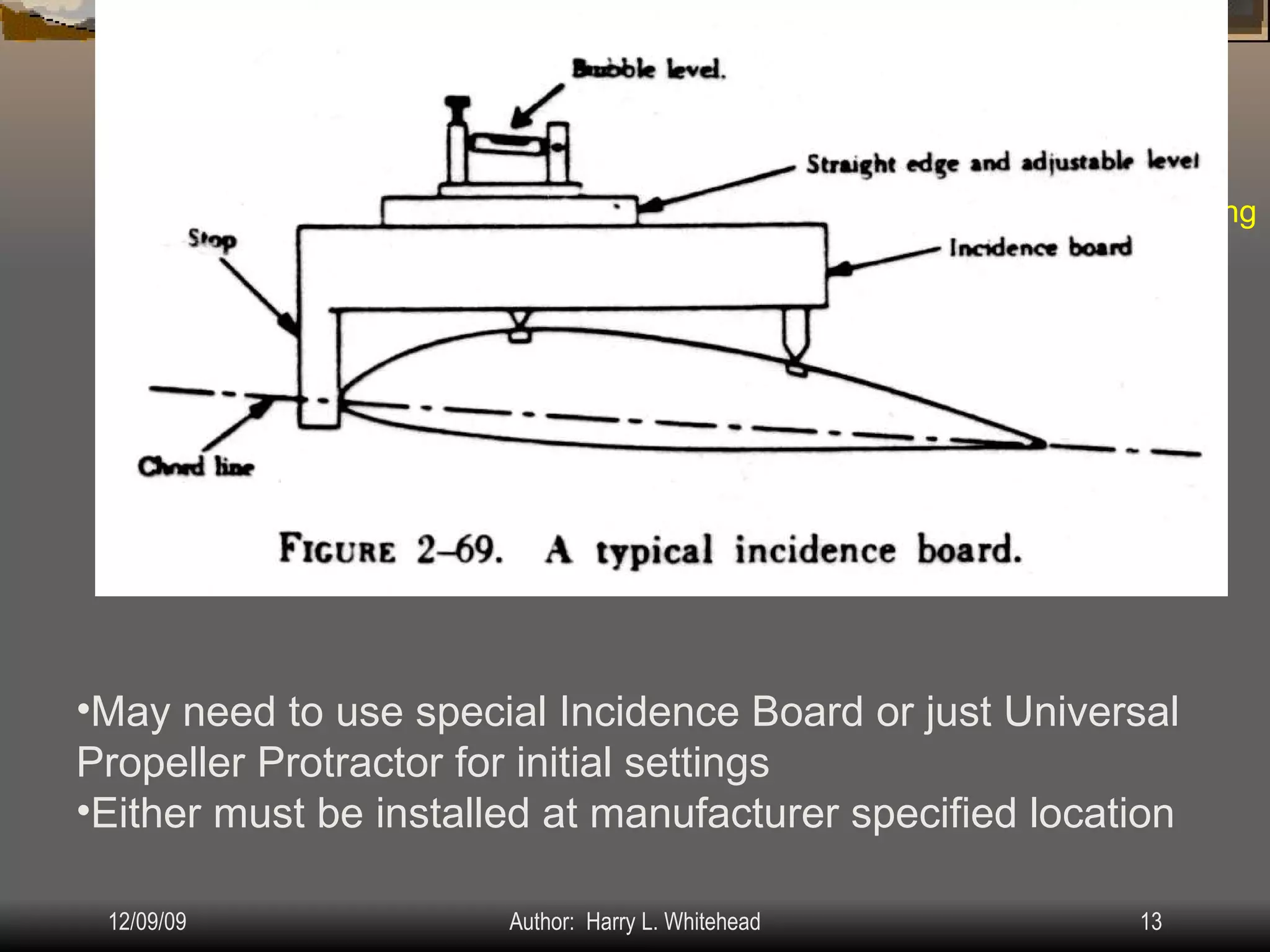

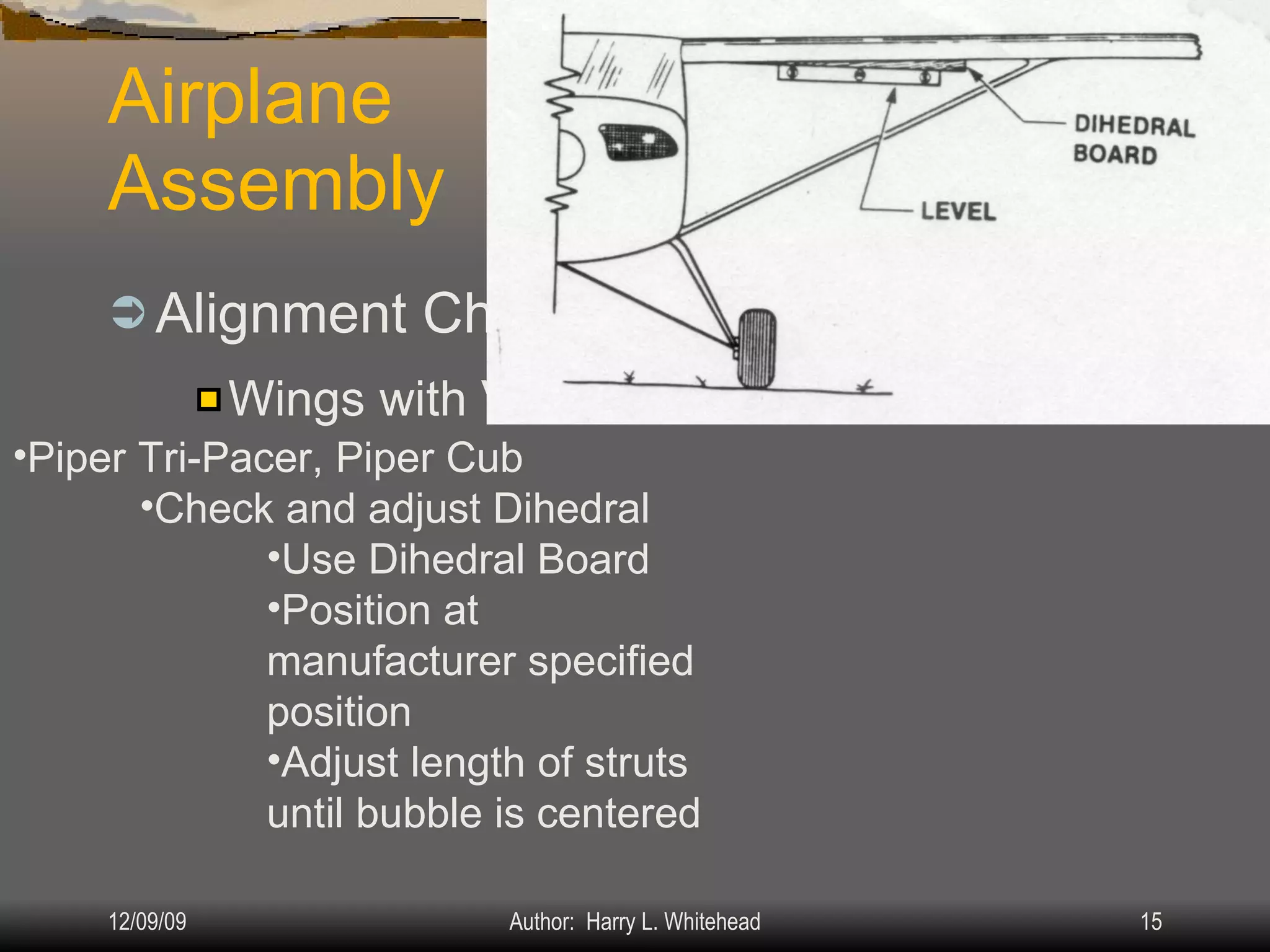

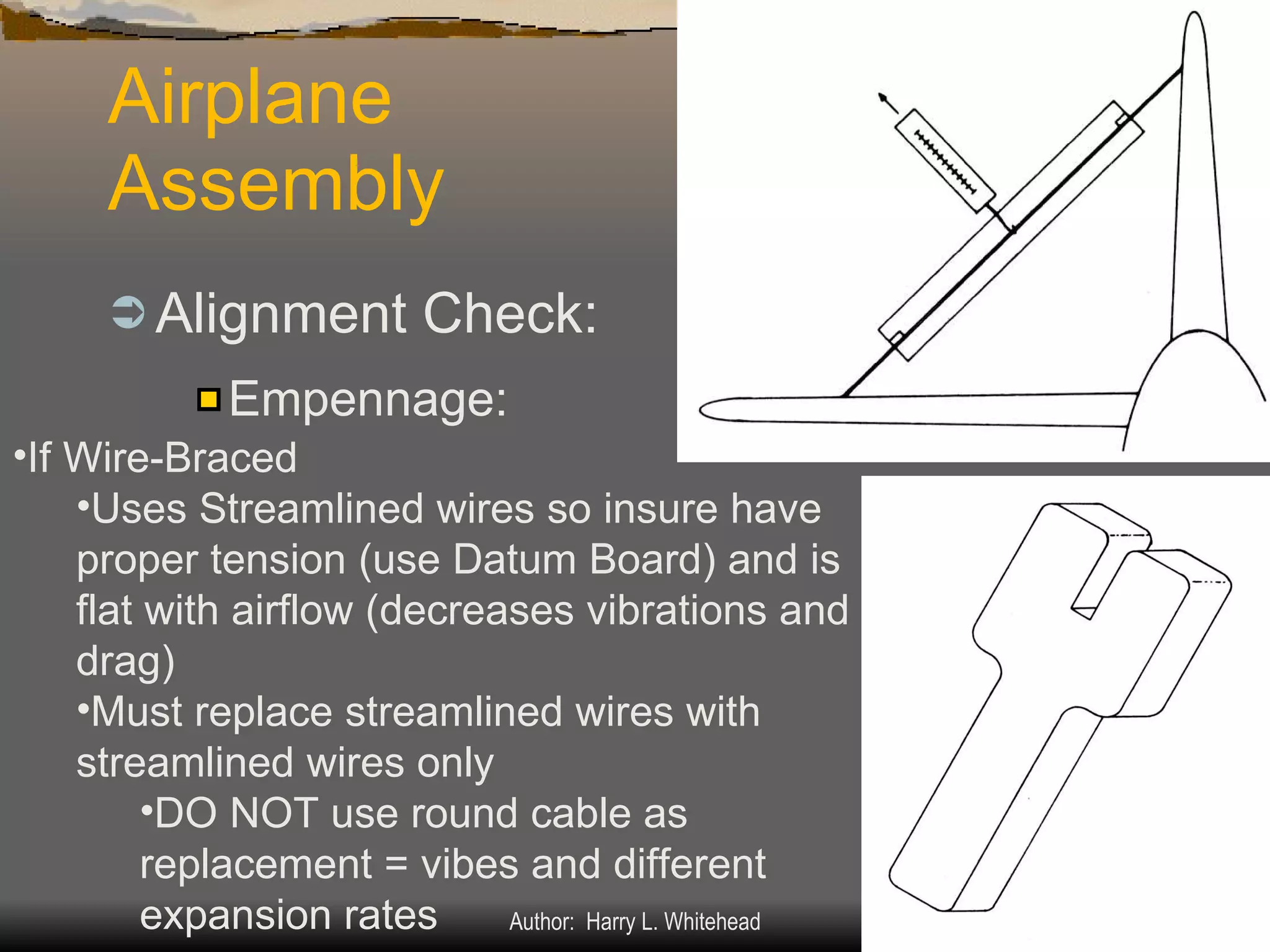

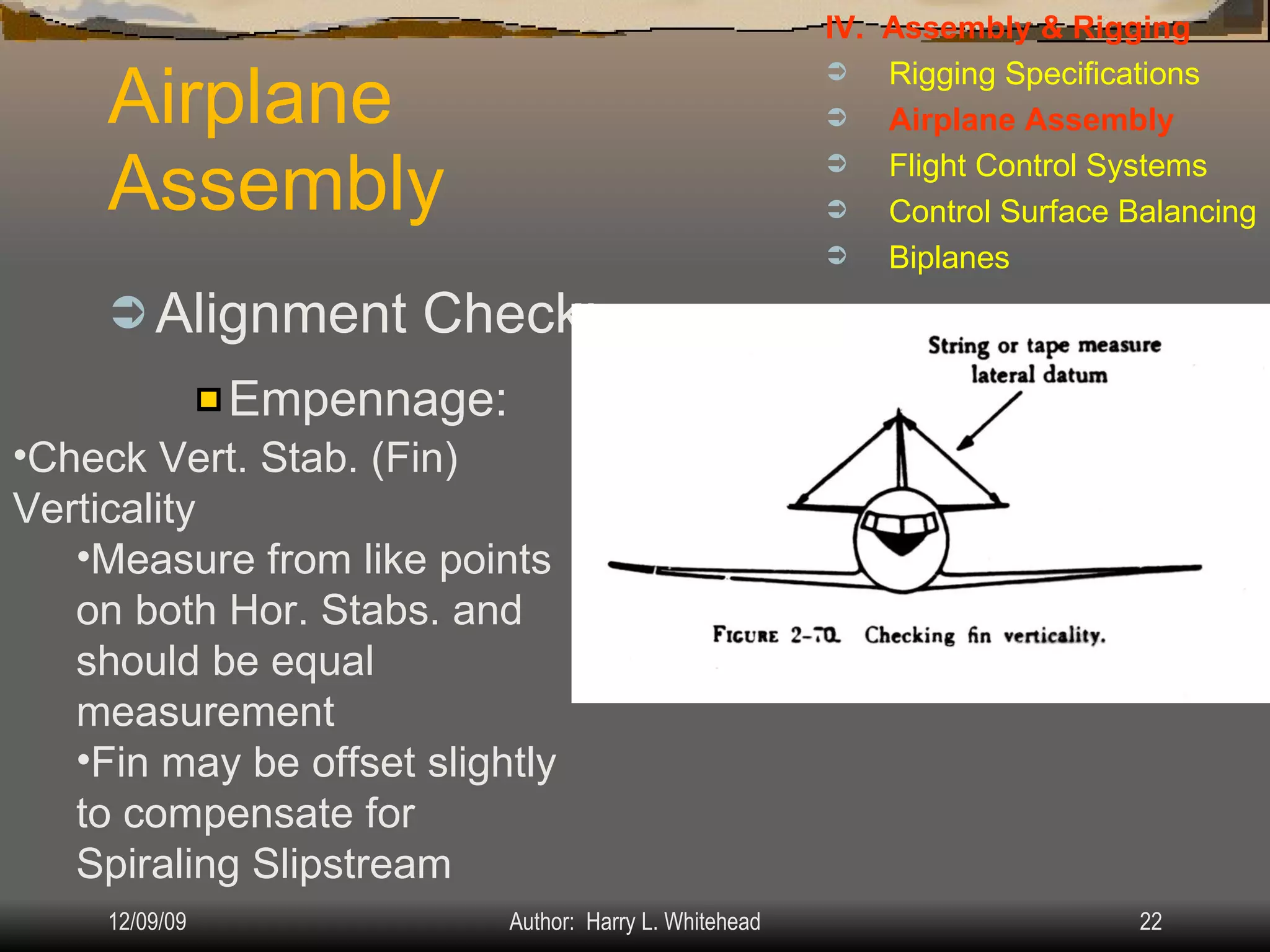

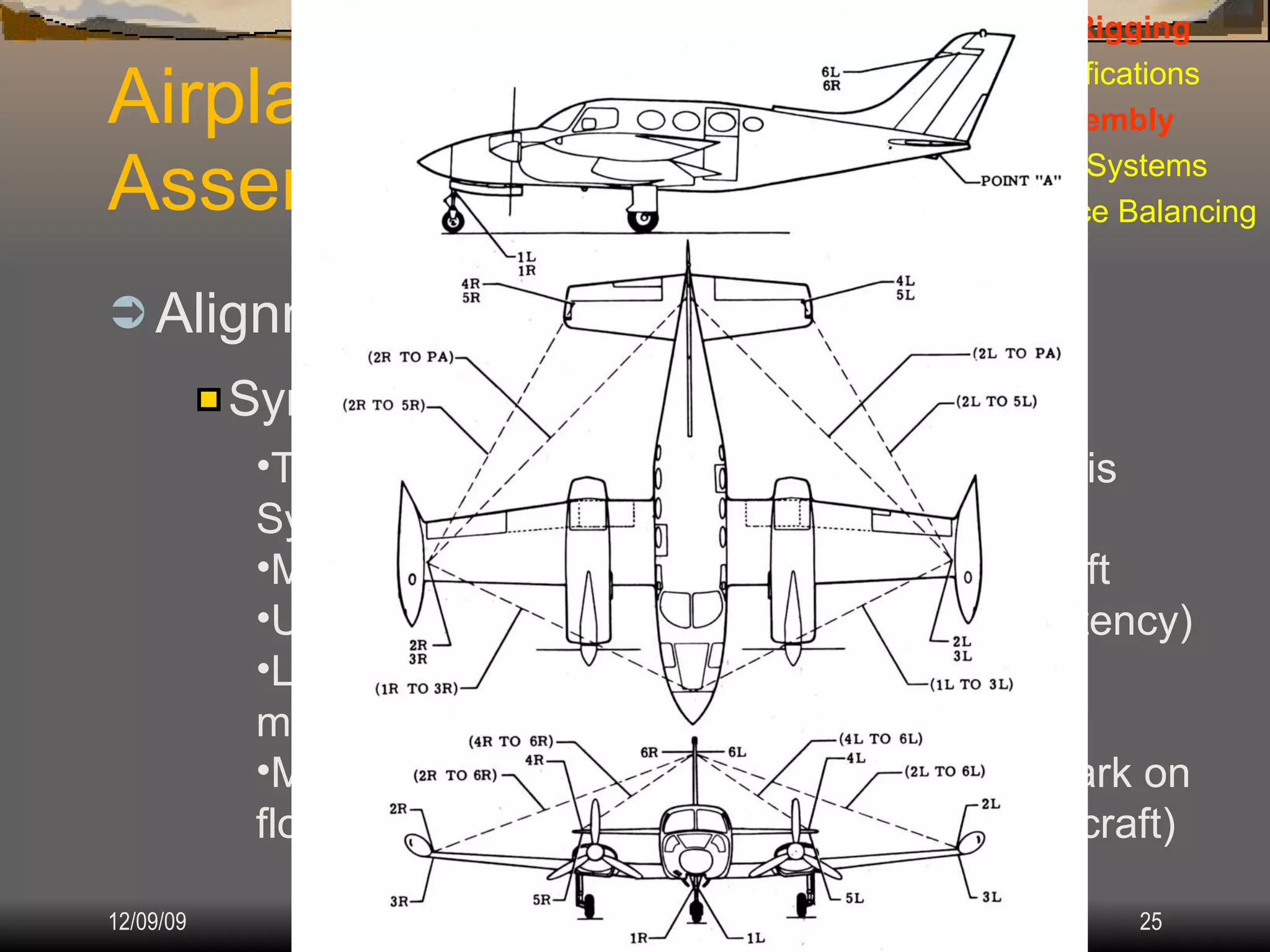

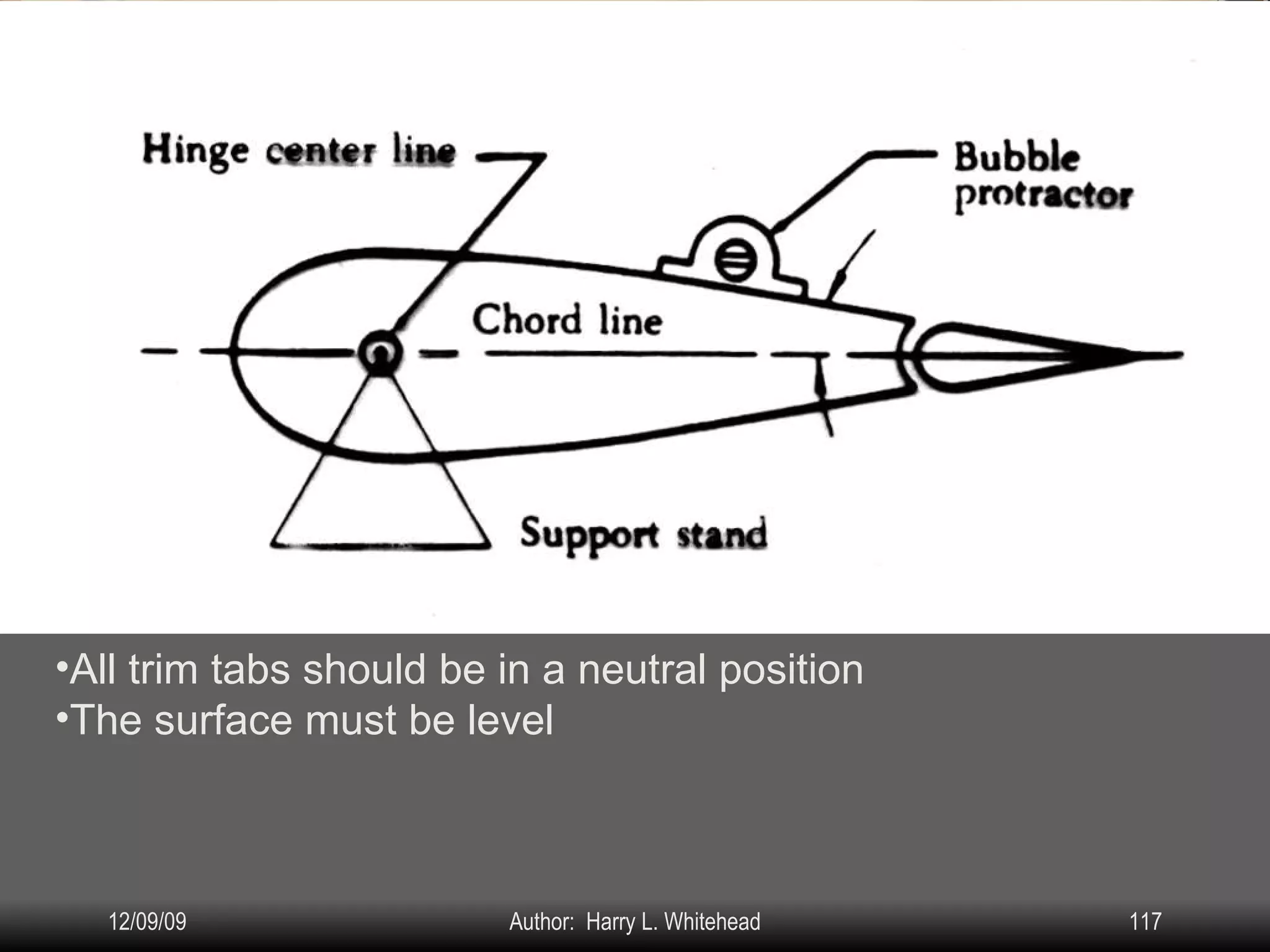

1) Aligning and leveling the fuselage, wings, empennage and other components during assembly according to manufacturer specifications.

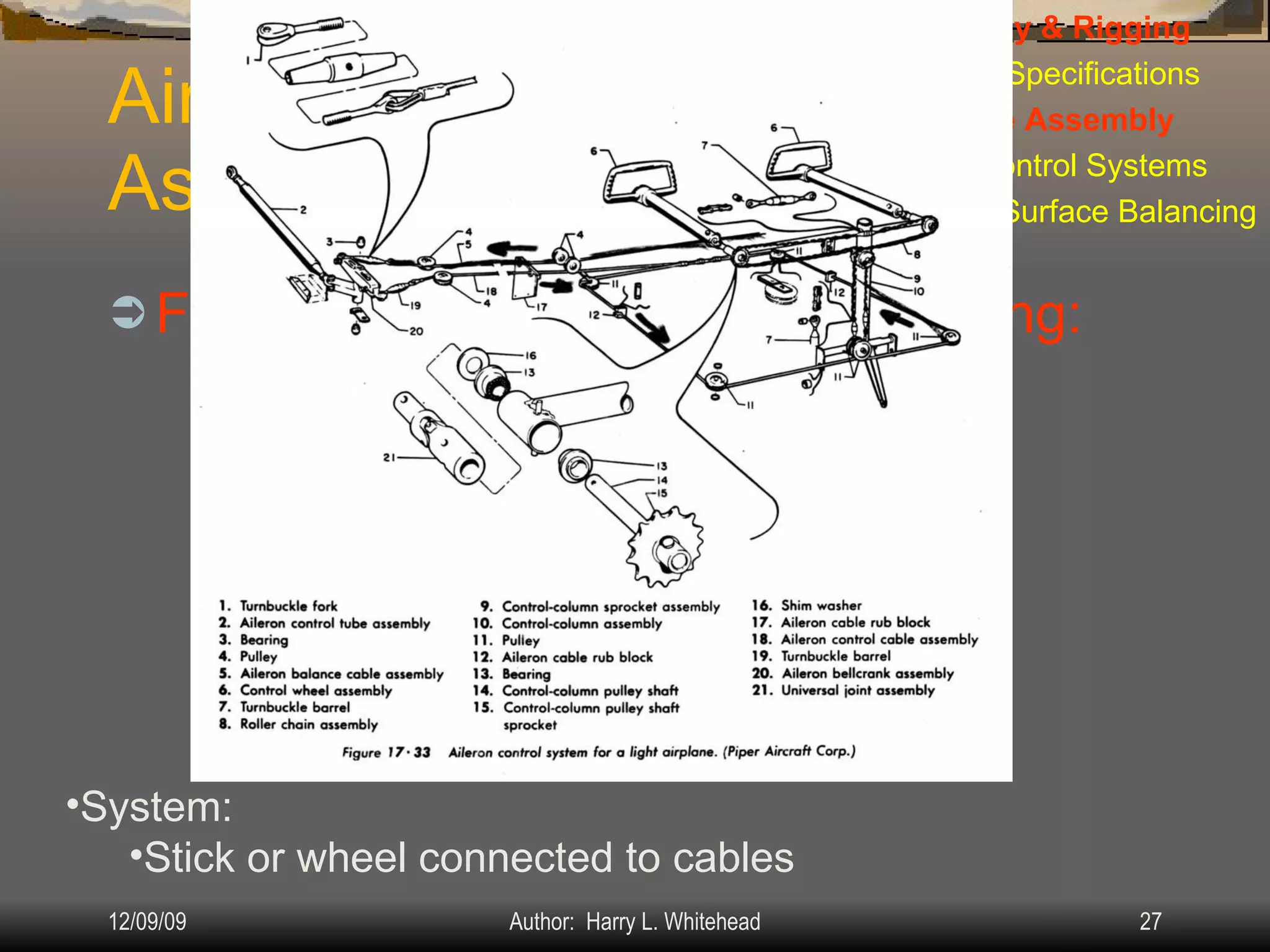

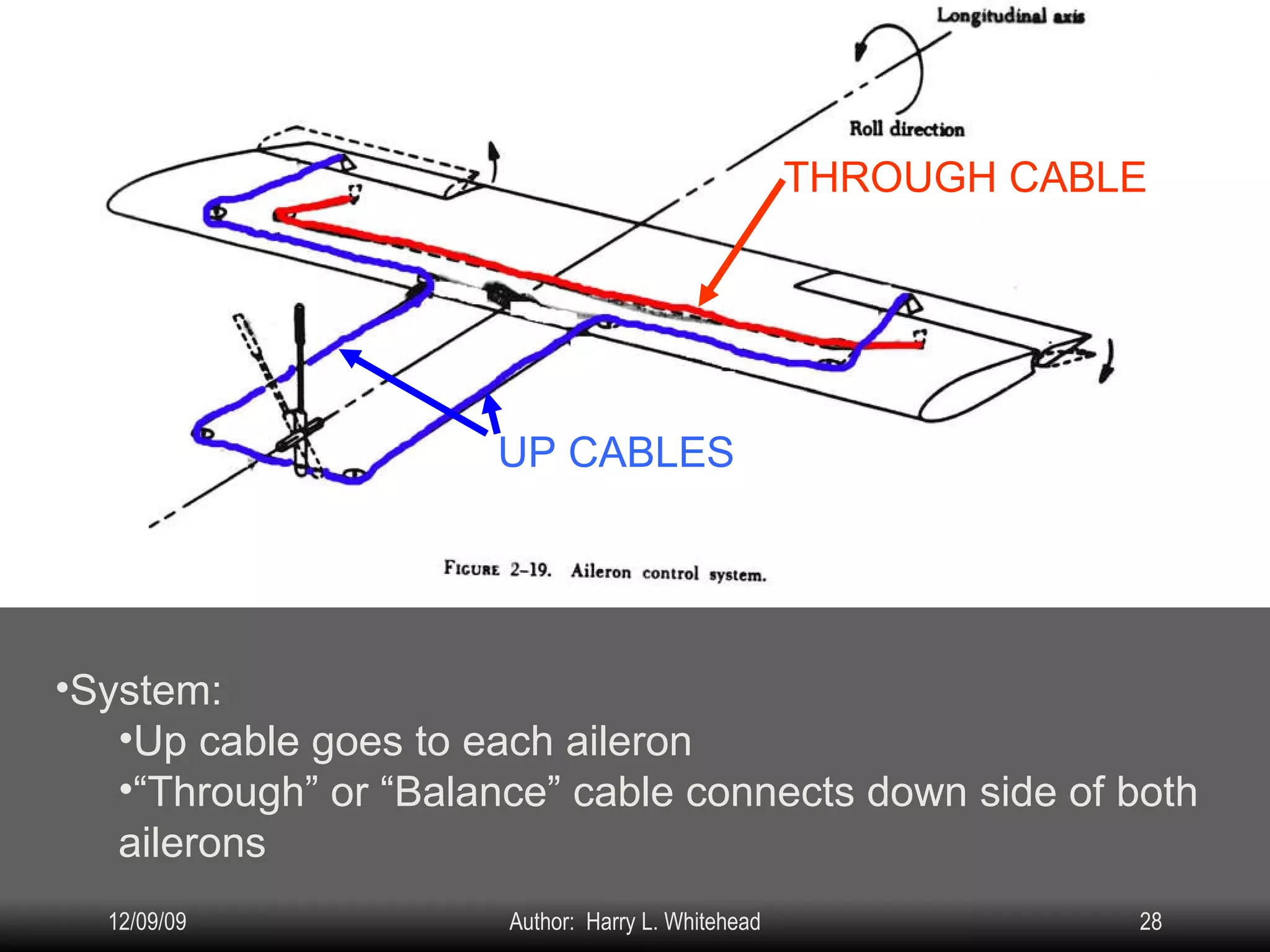

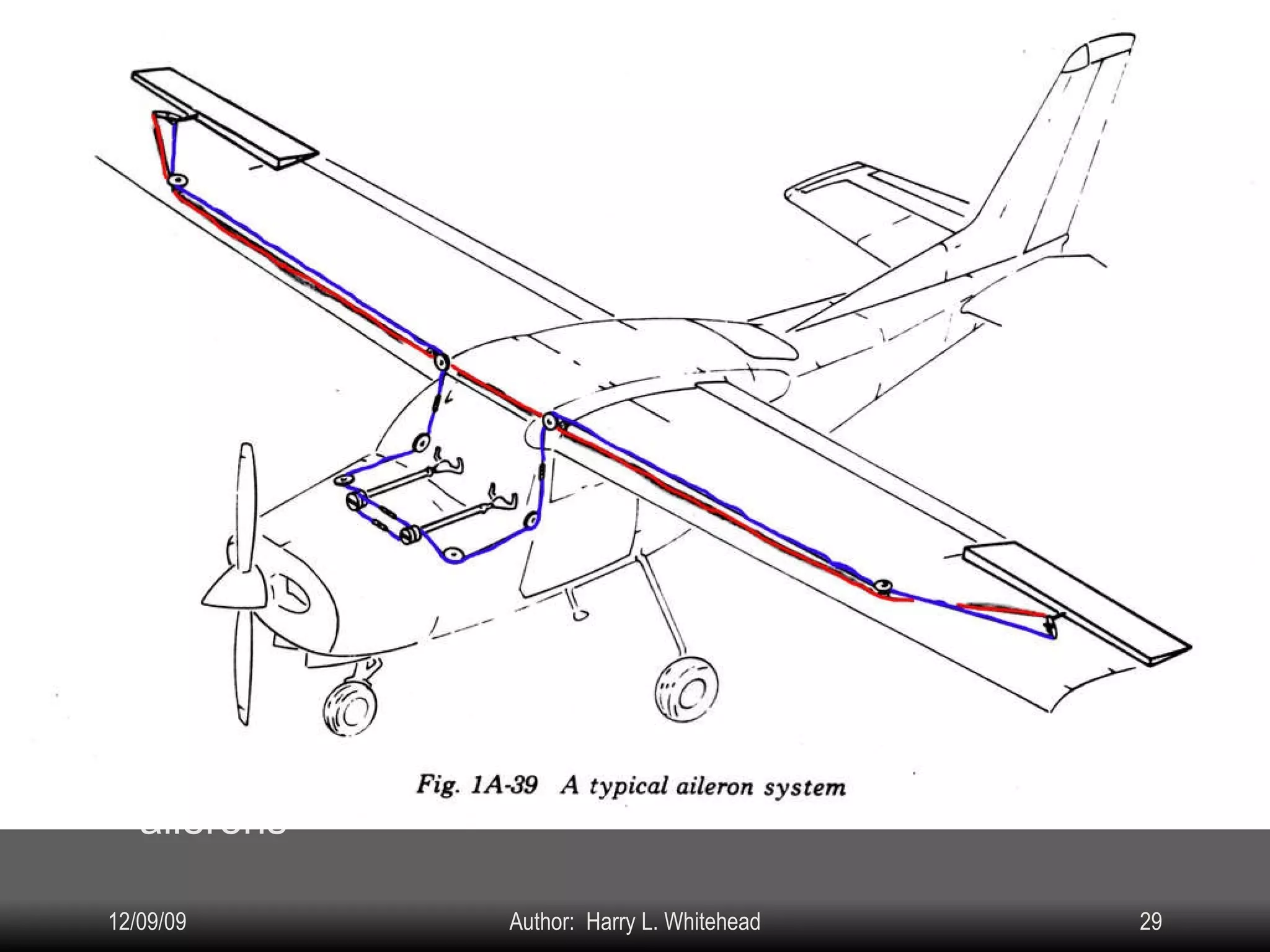

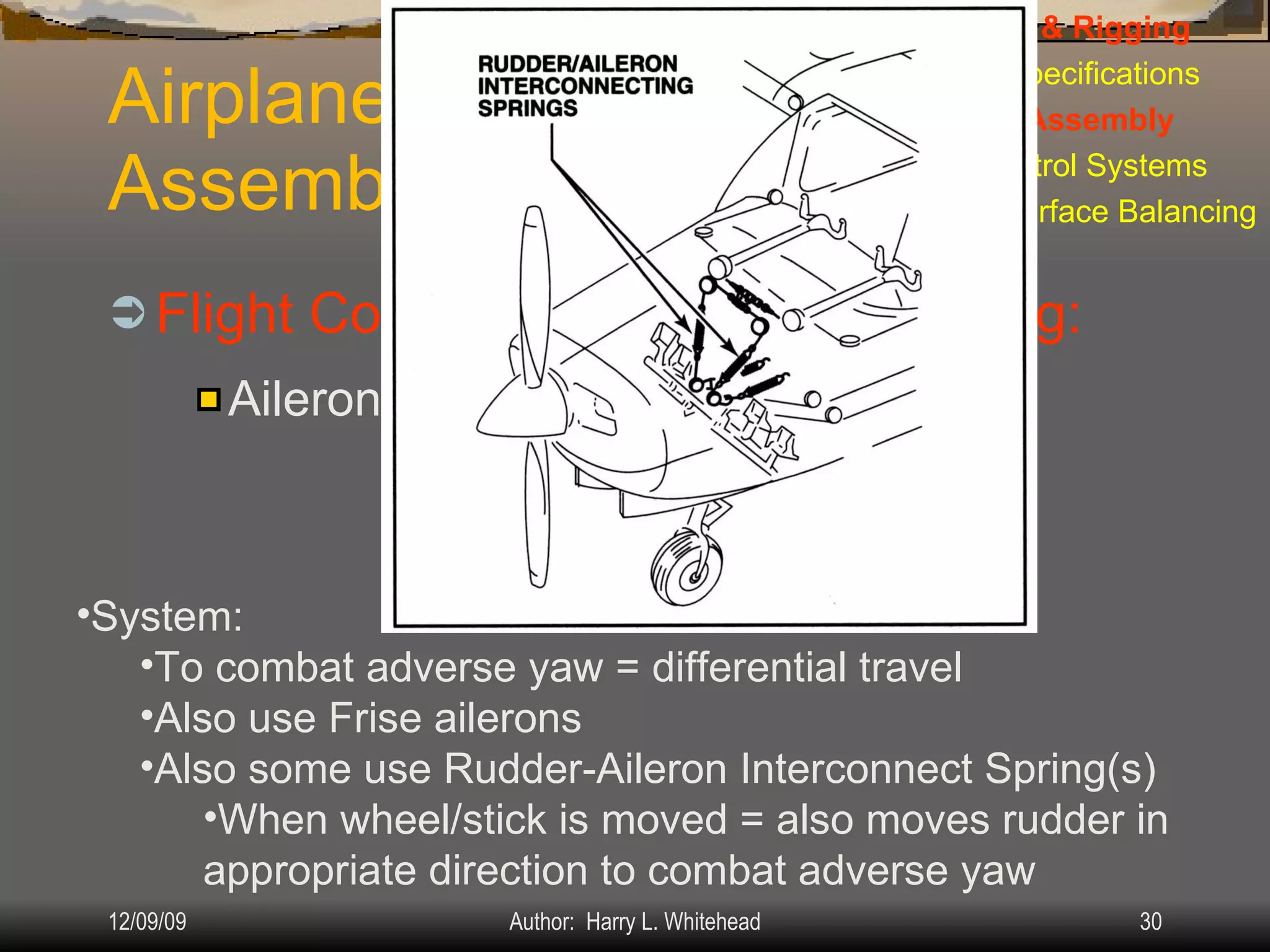

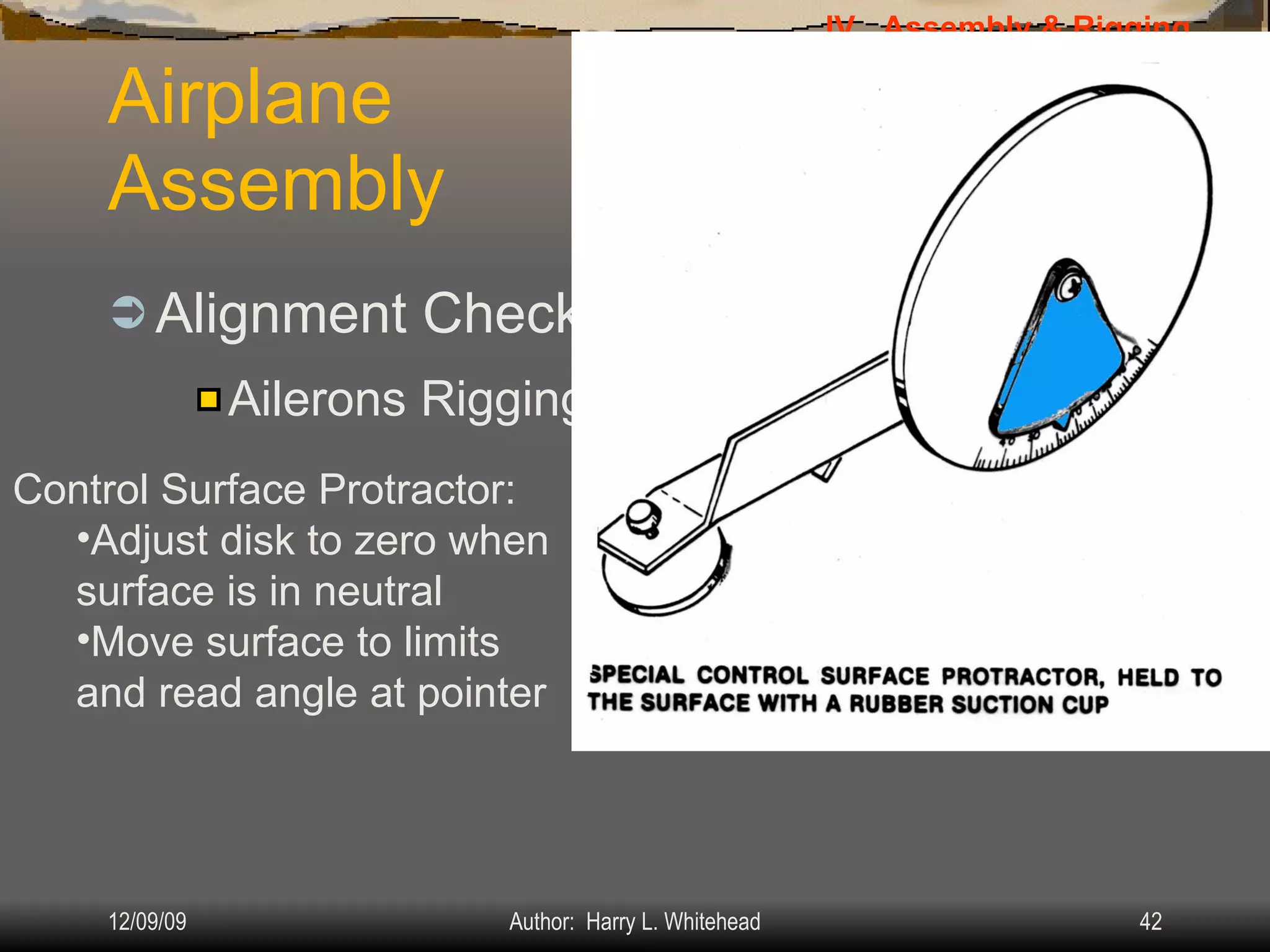

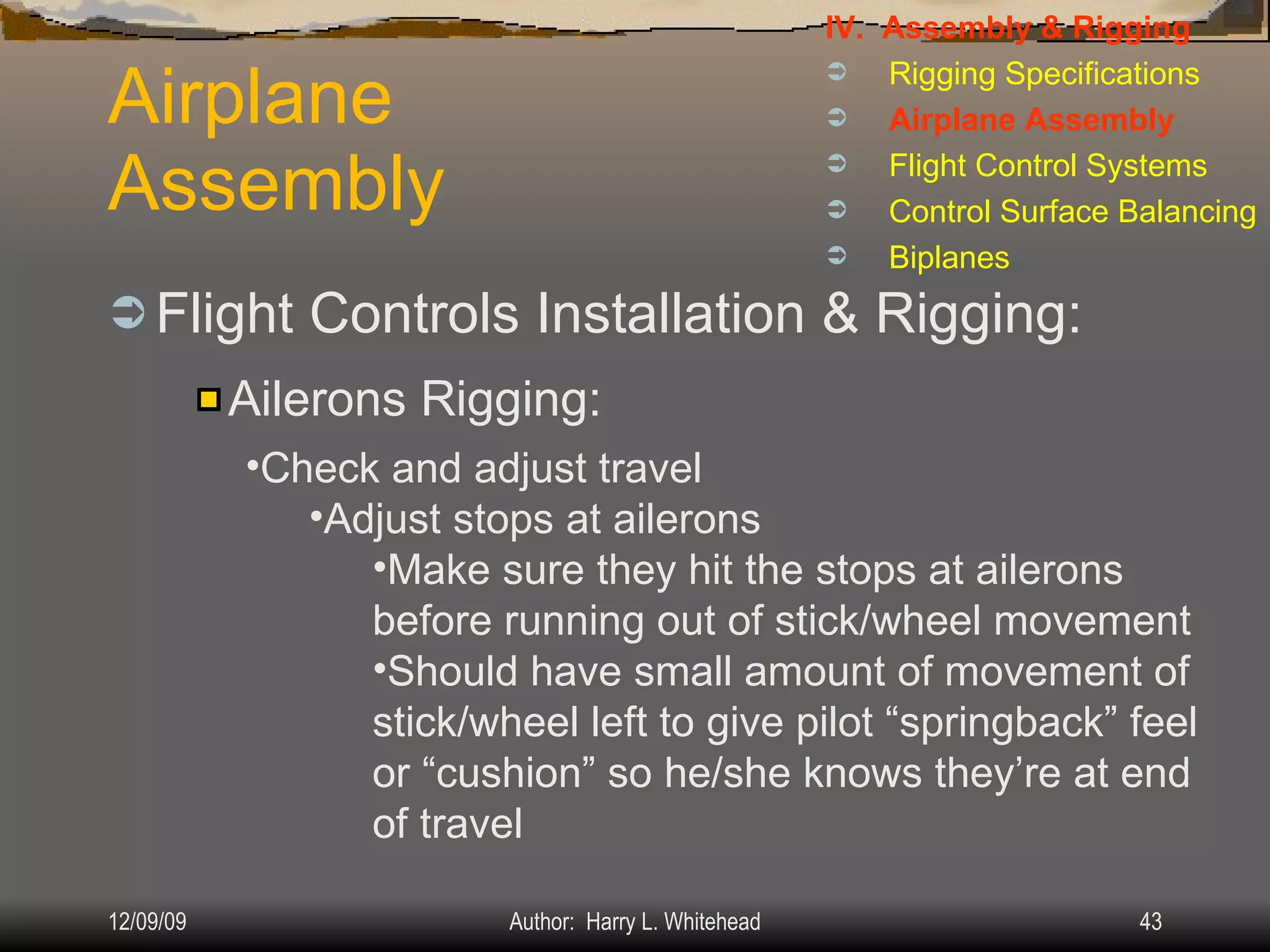

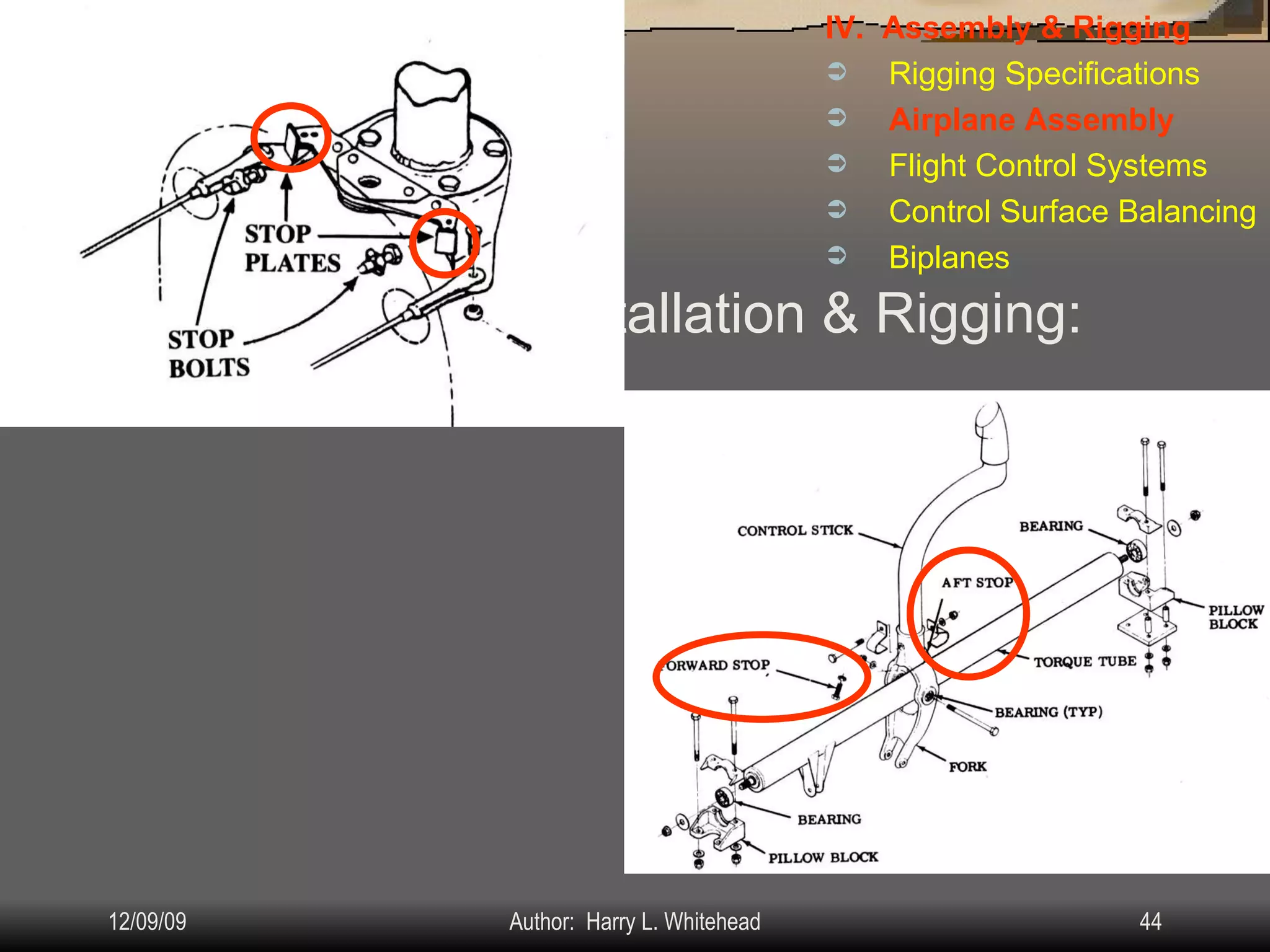

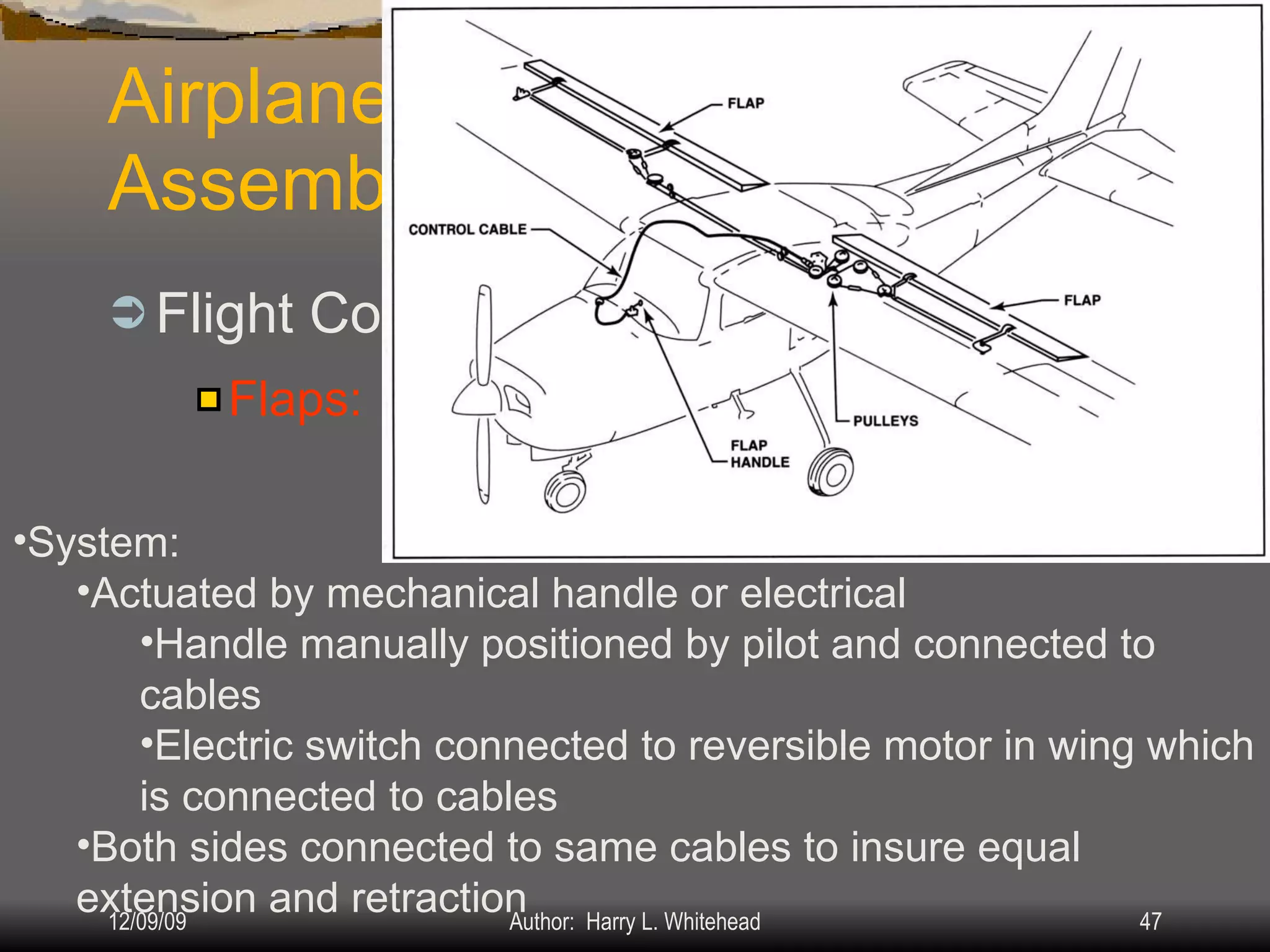

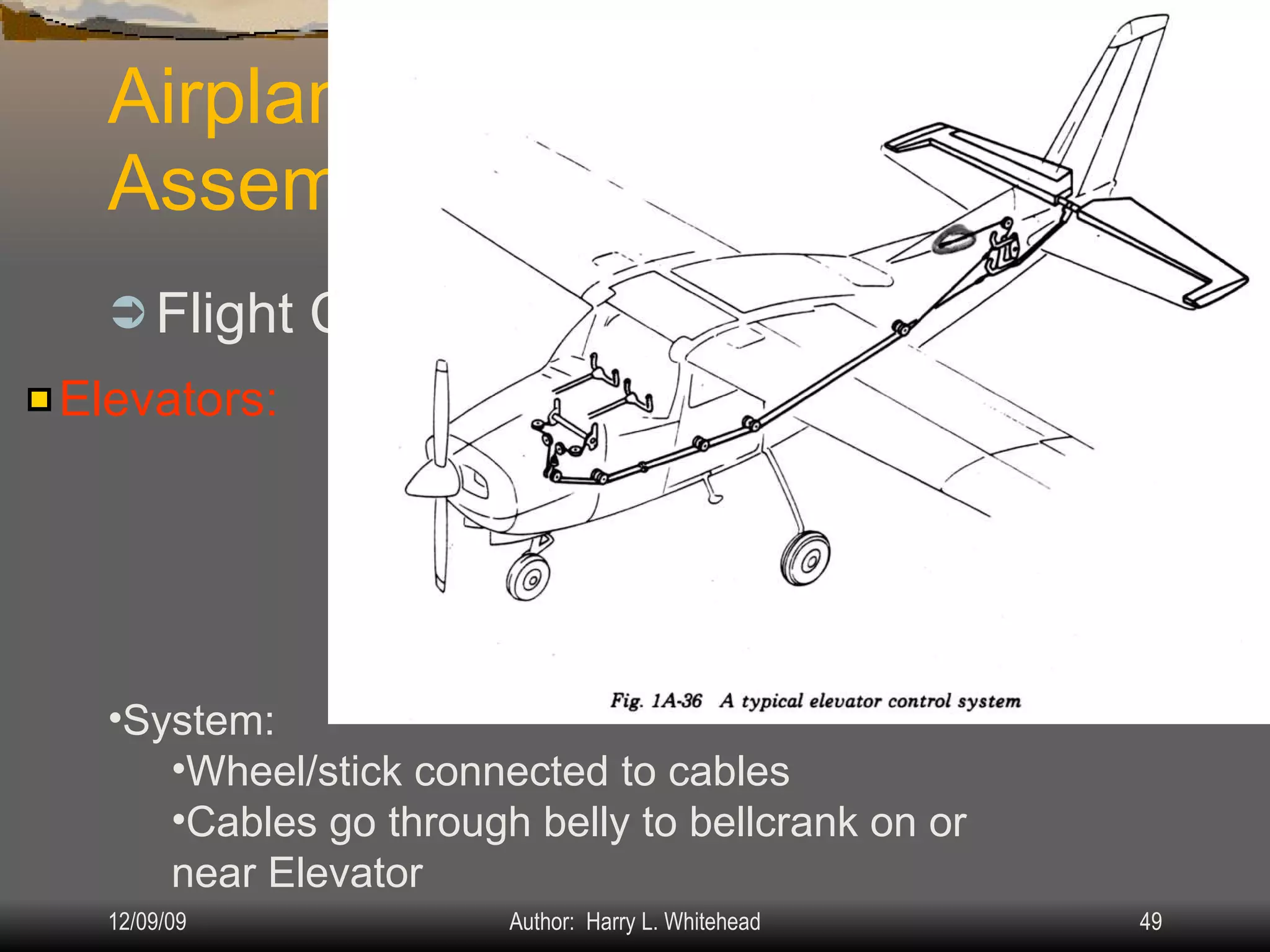

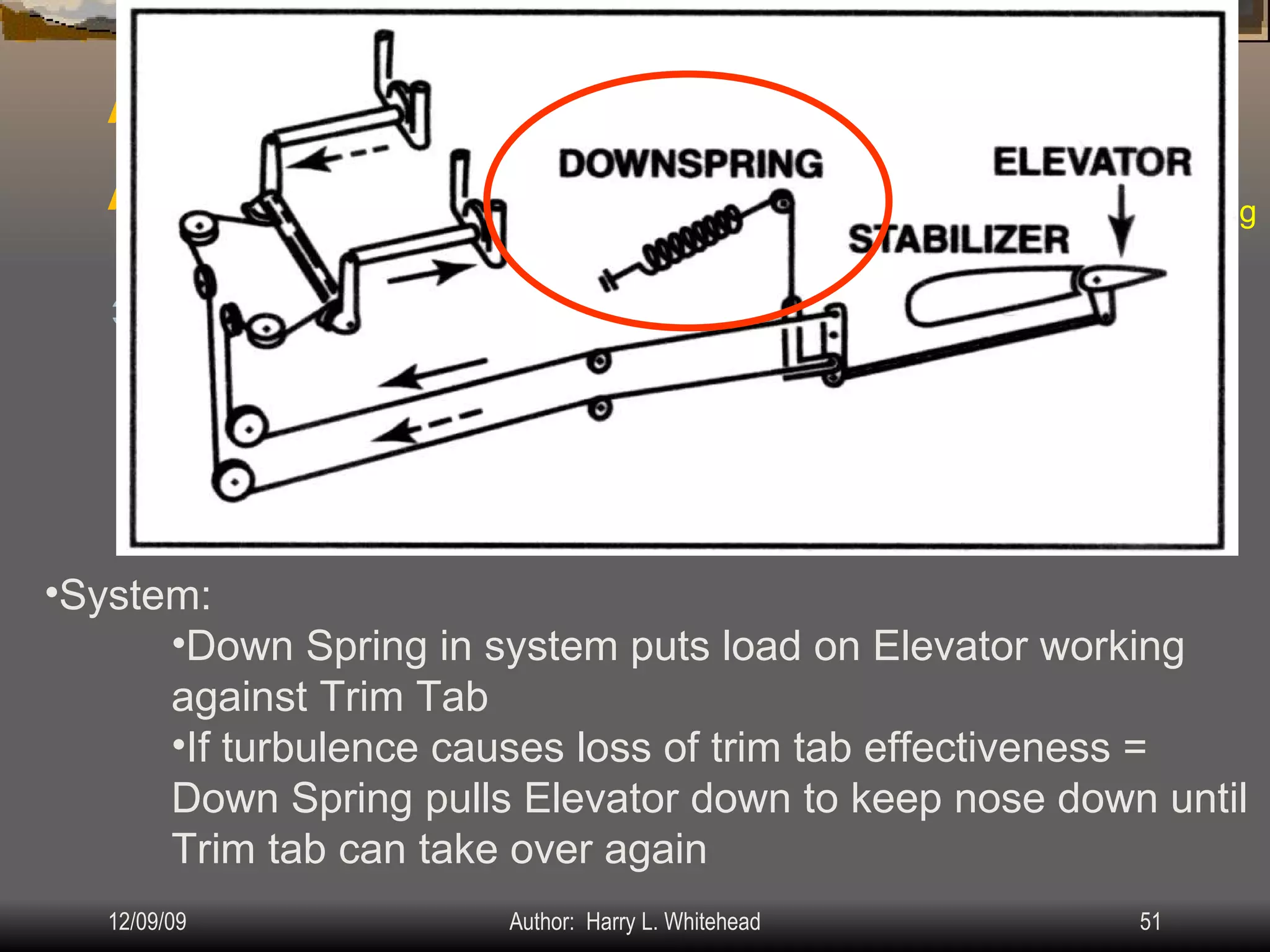

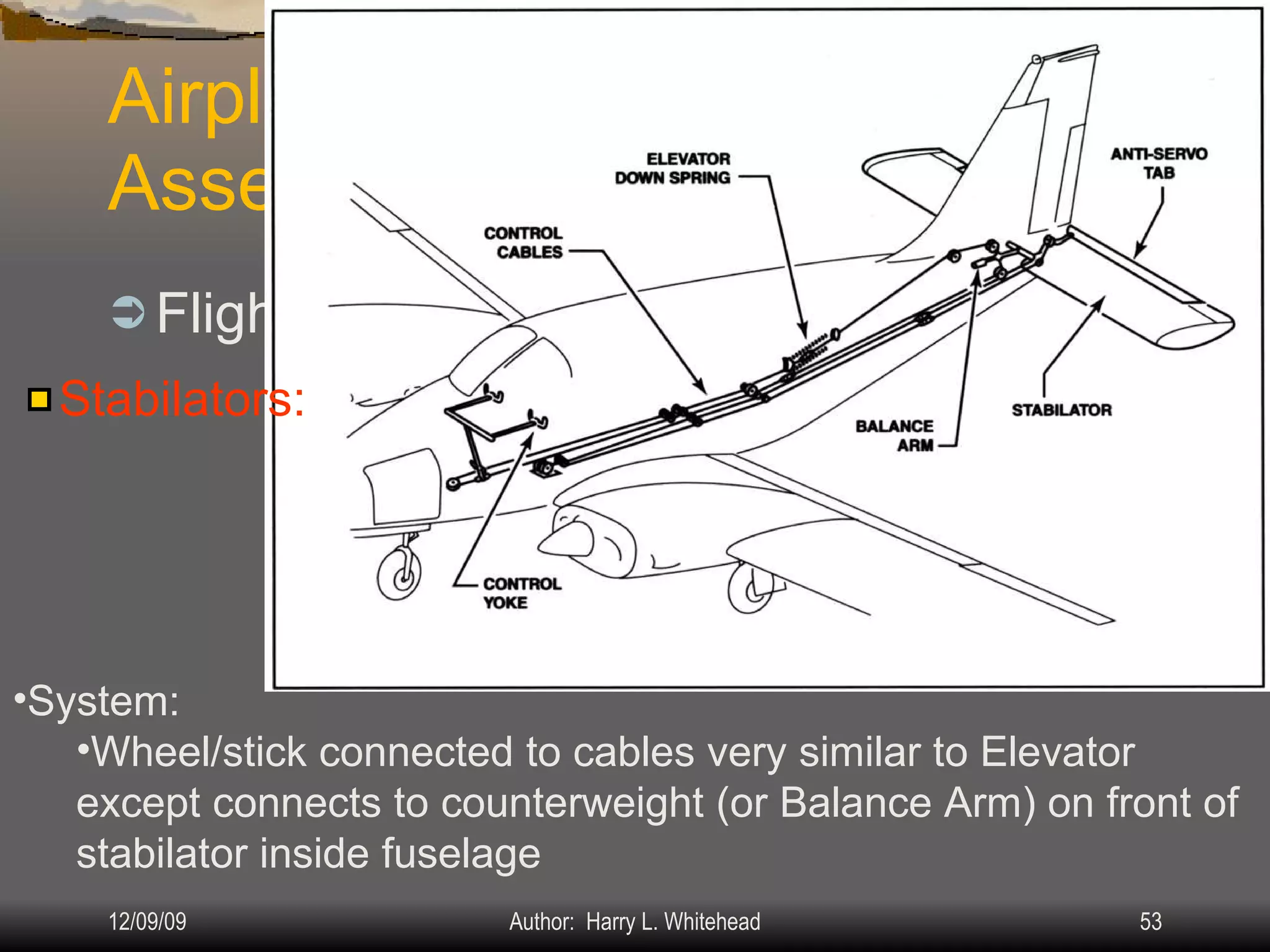

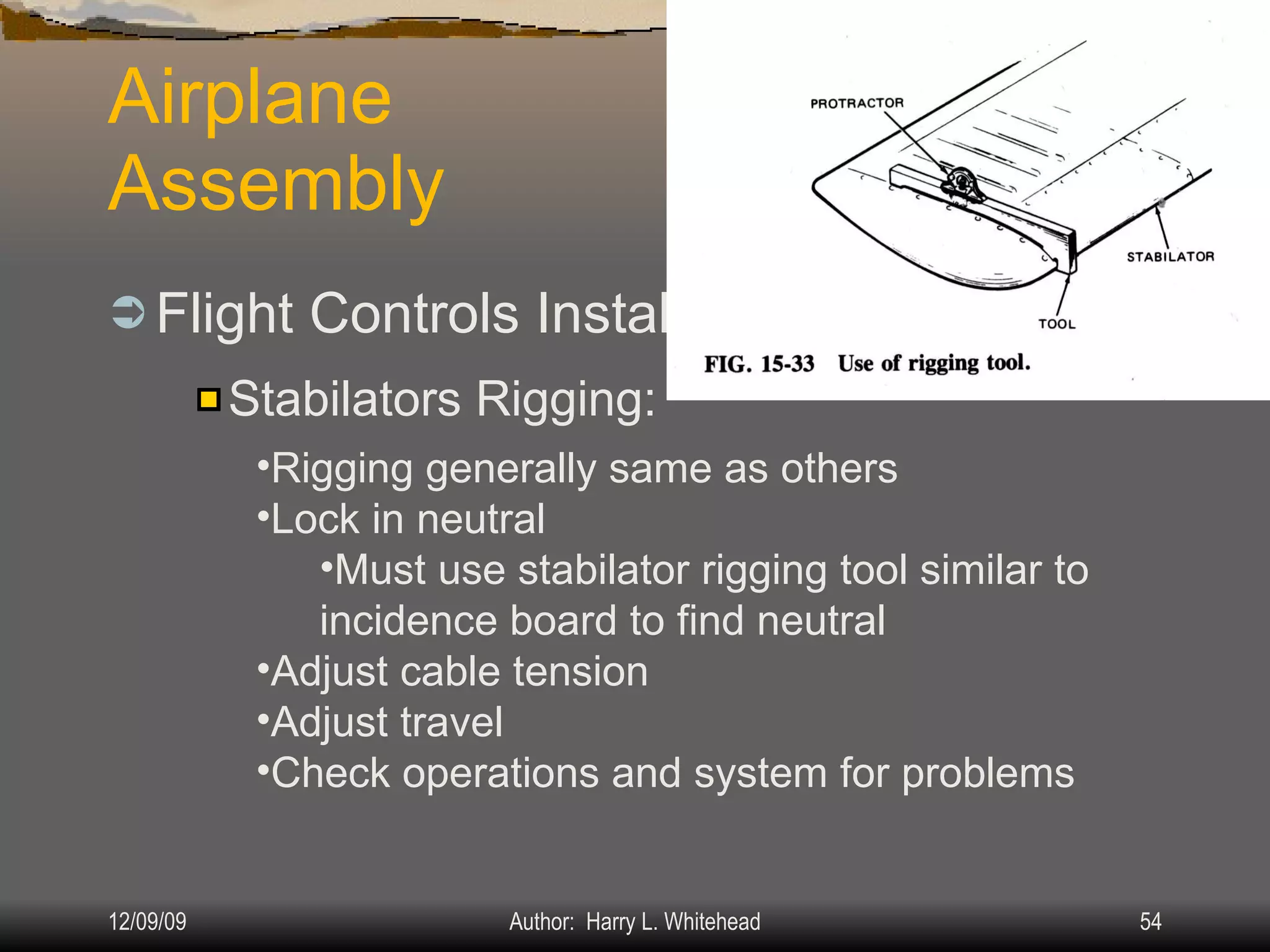

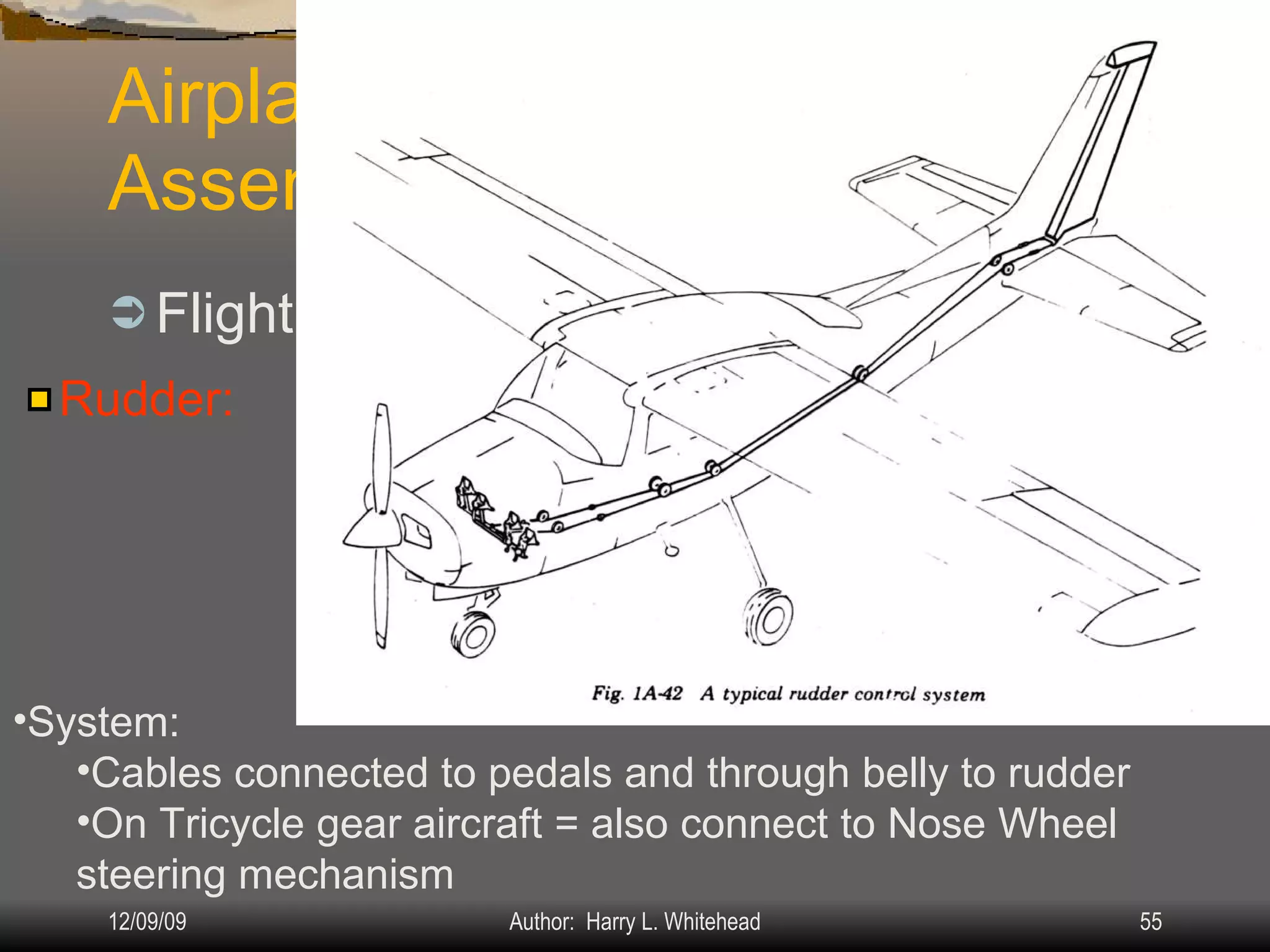

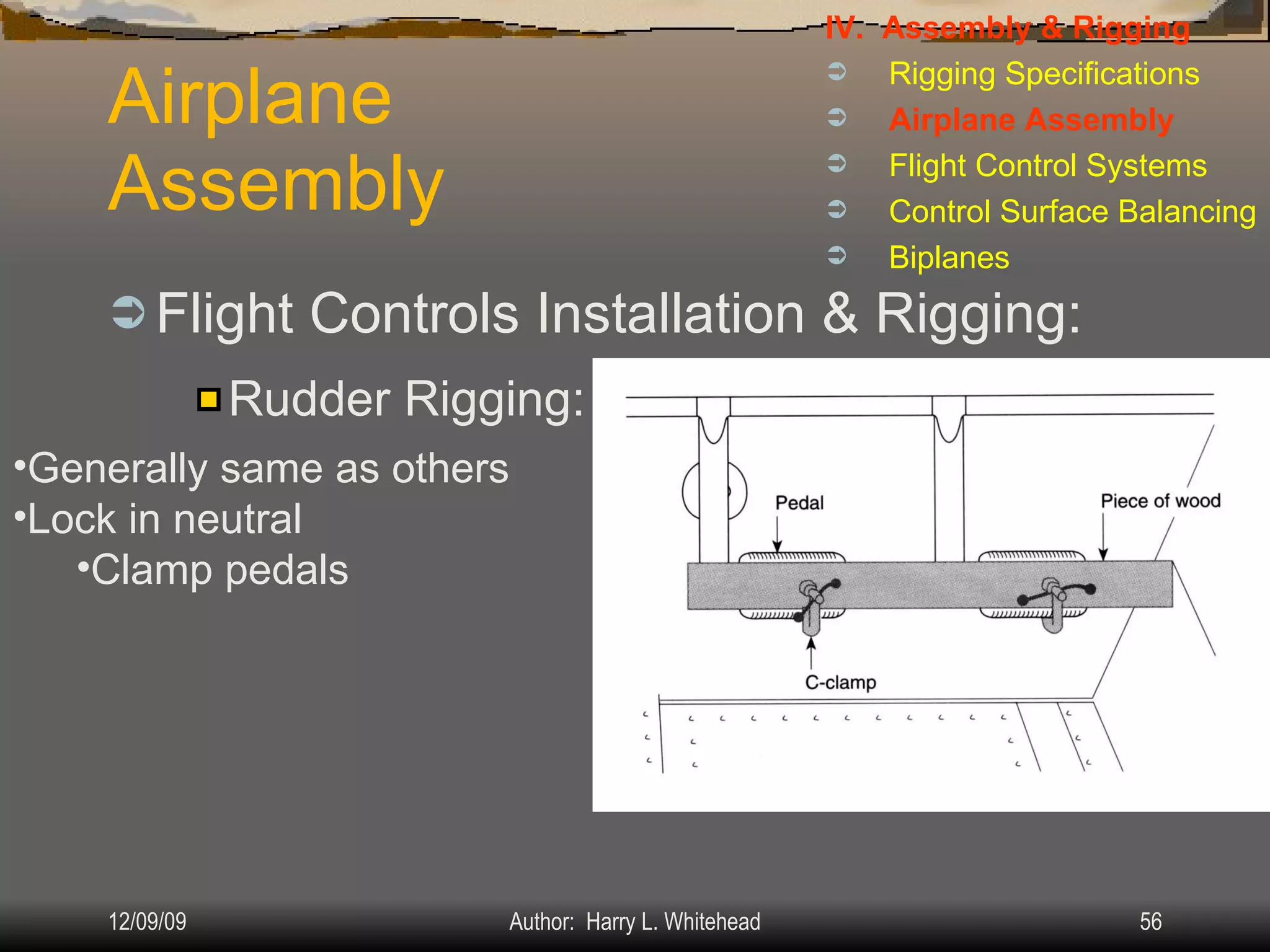

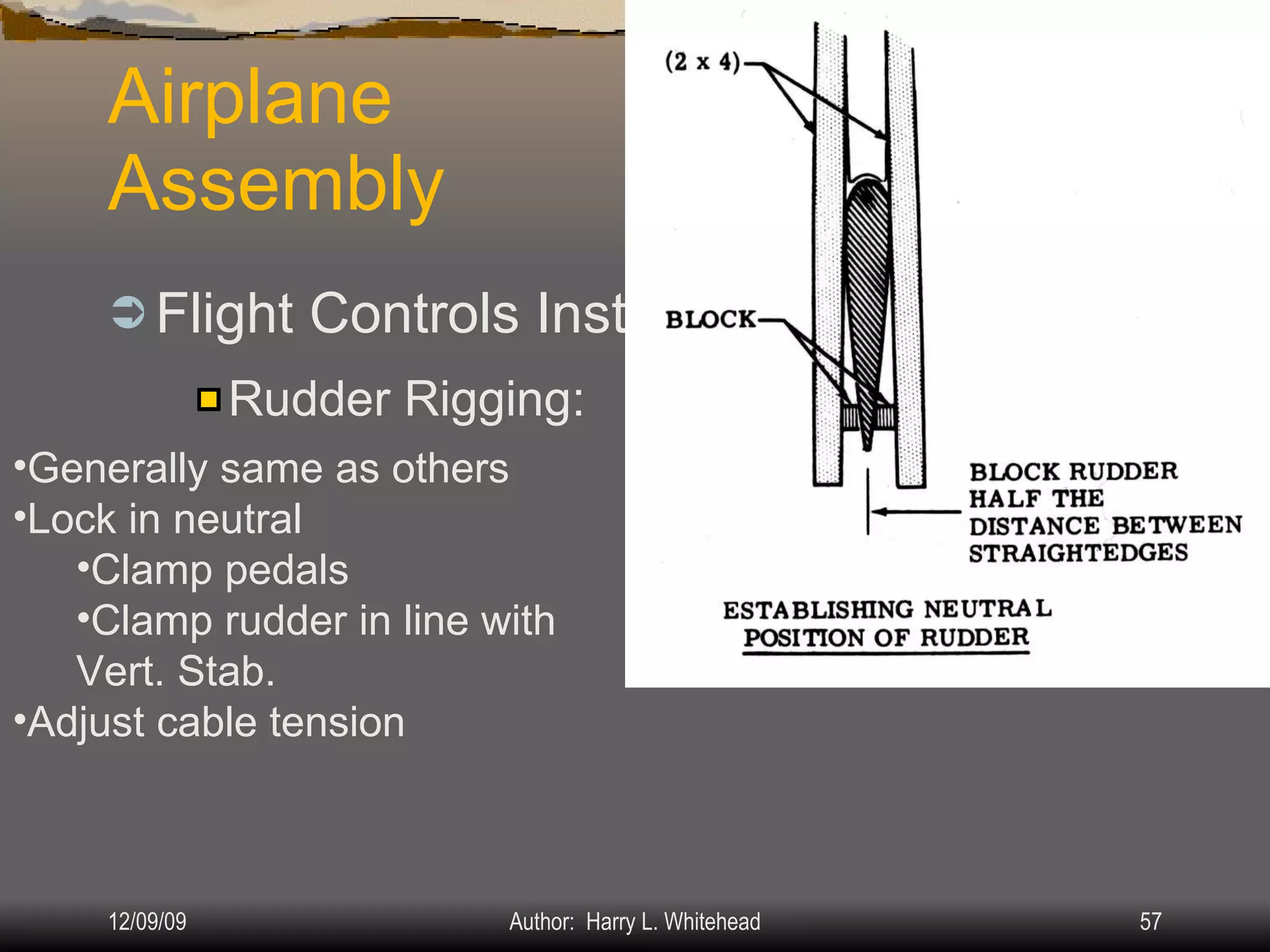

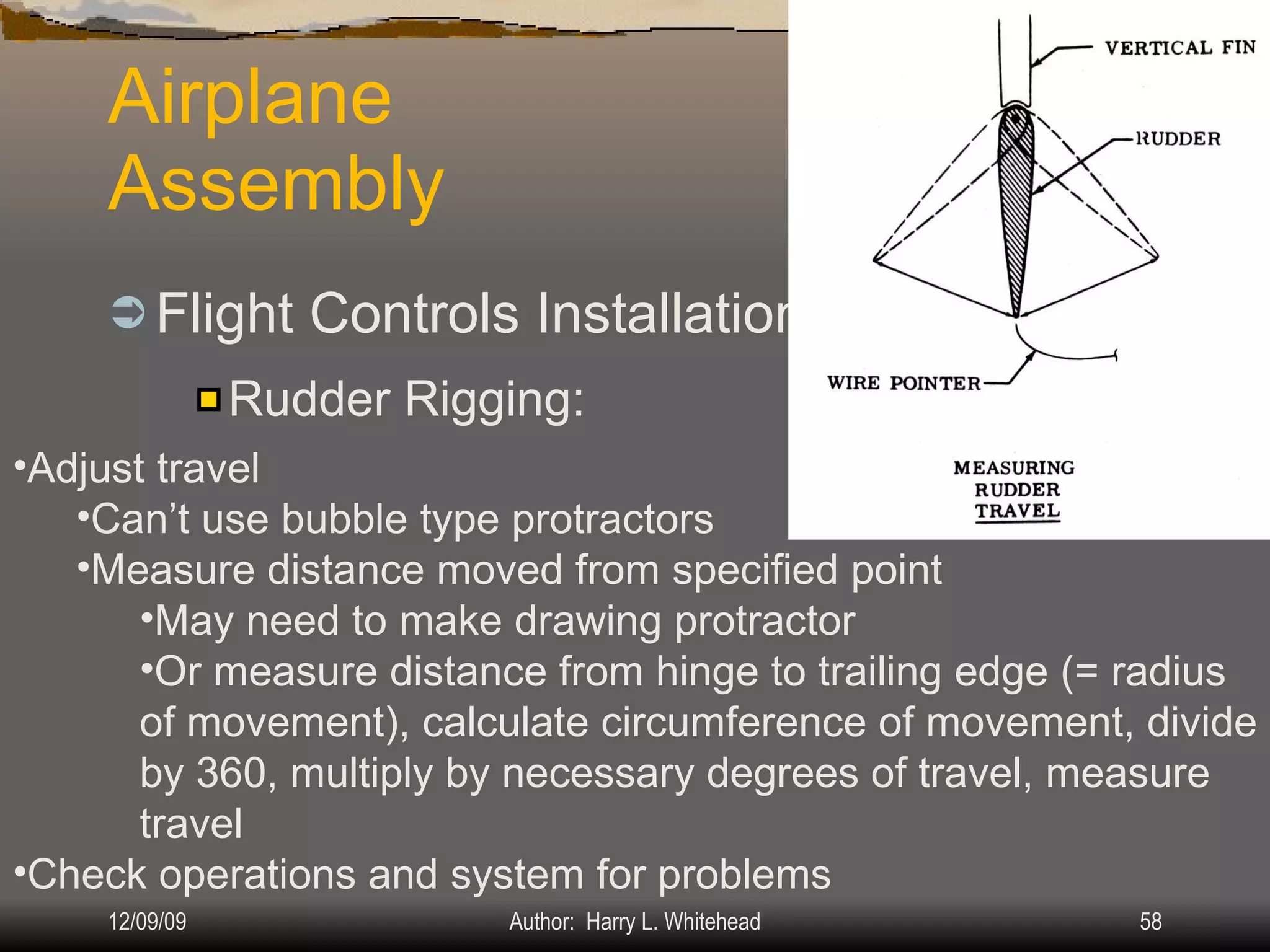

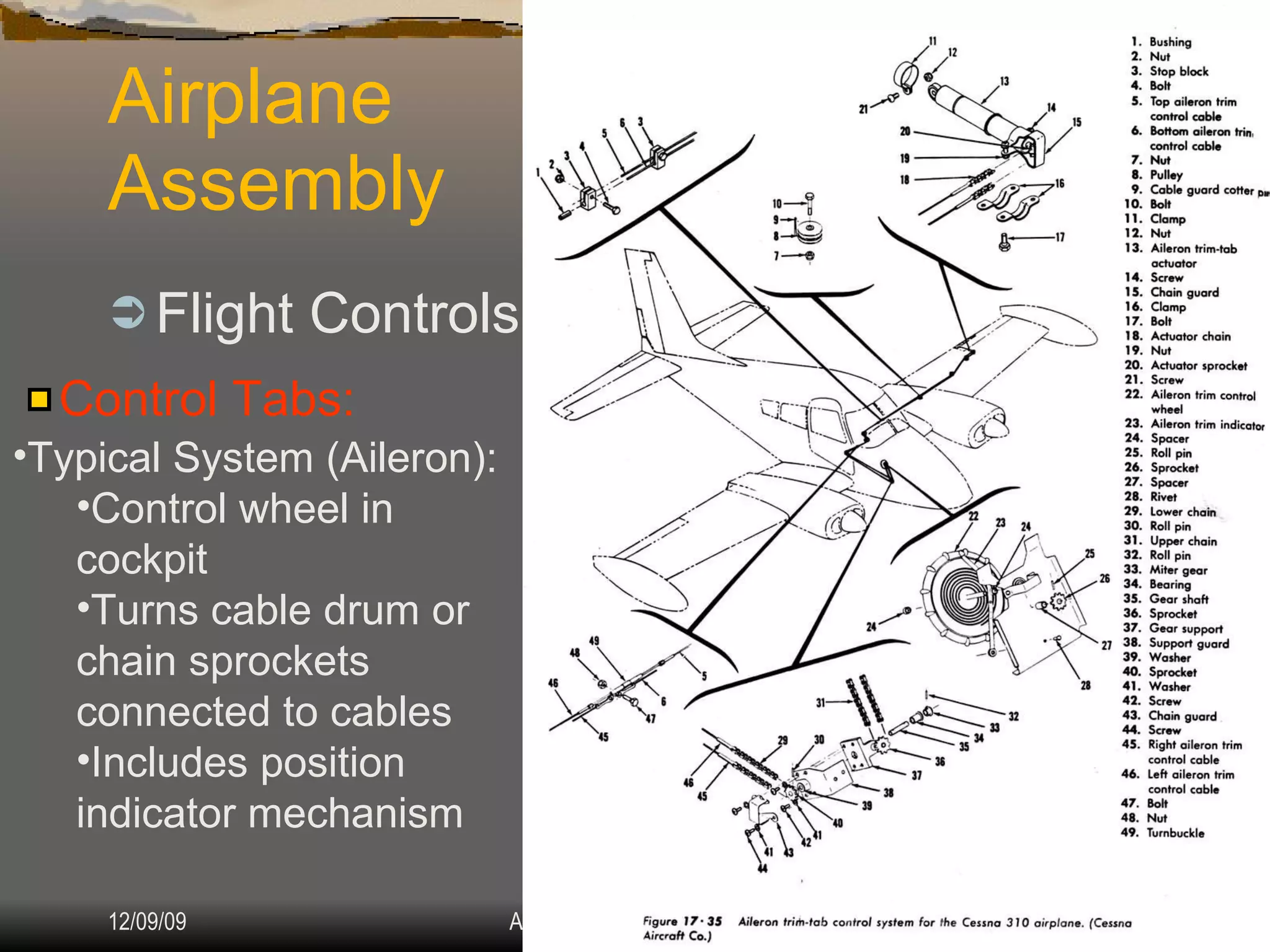

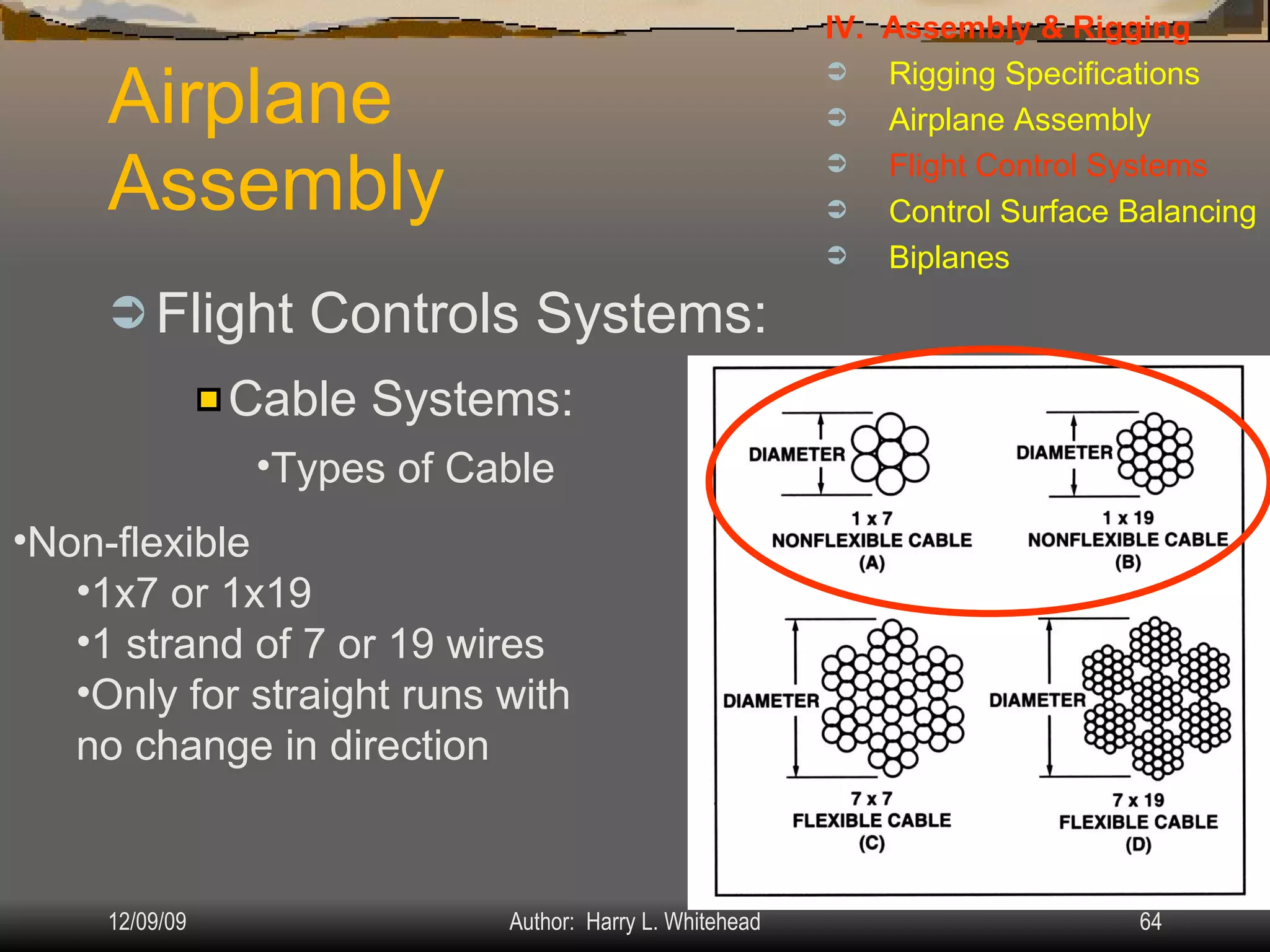

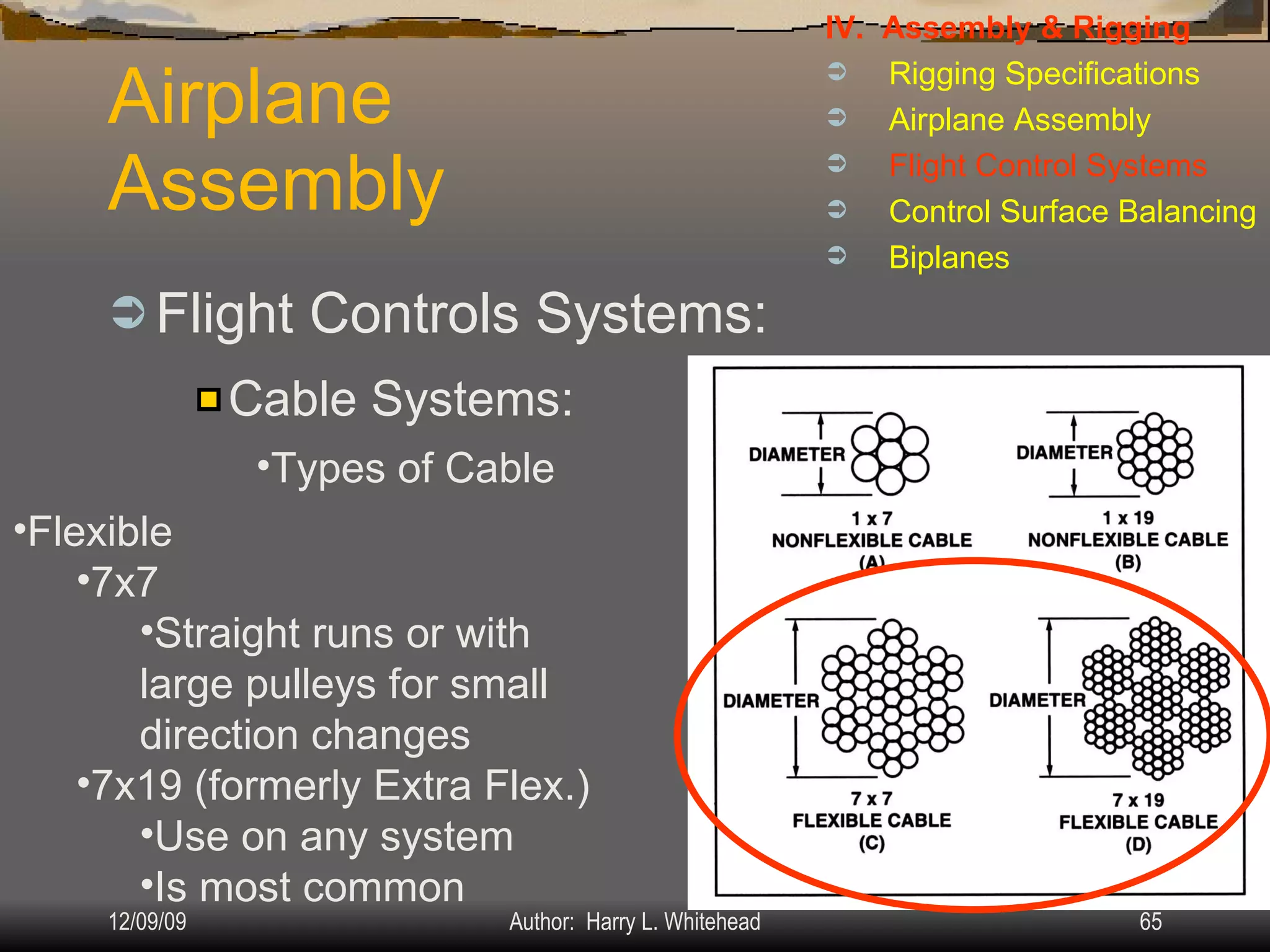

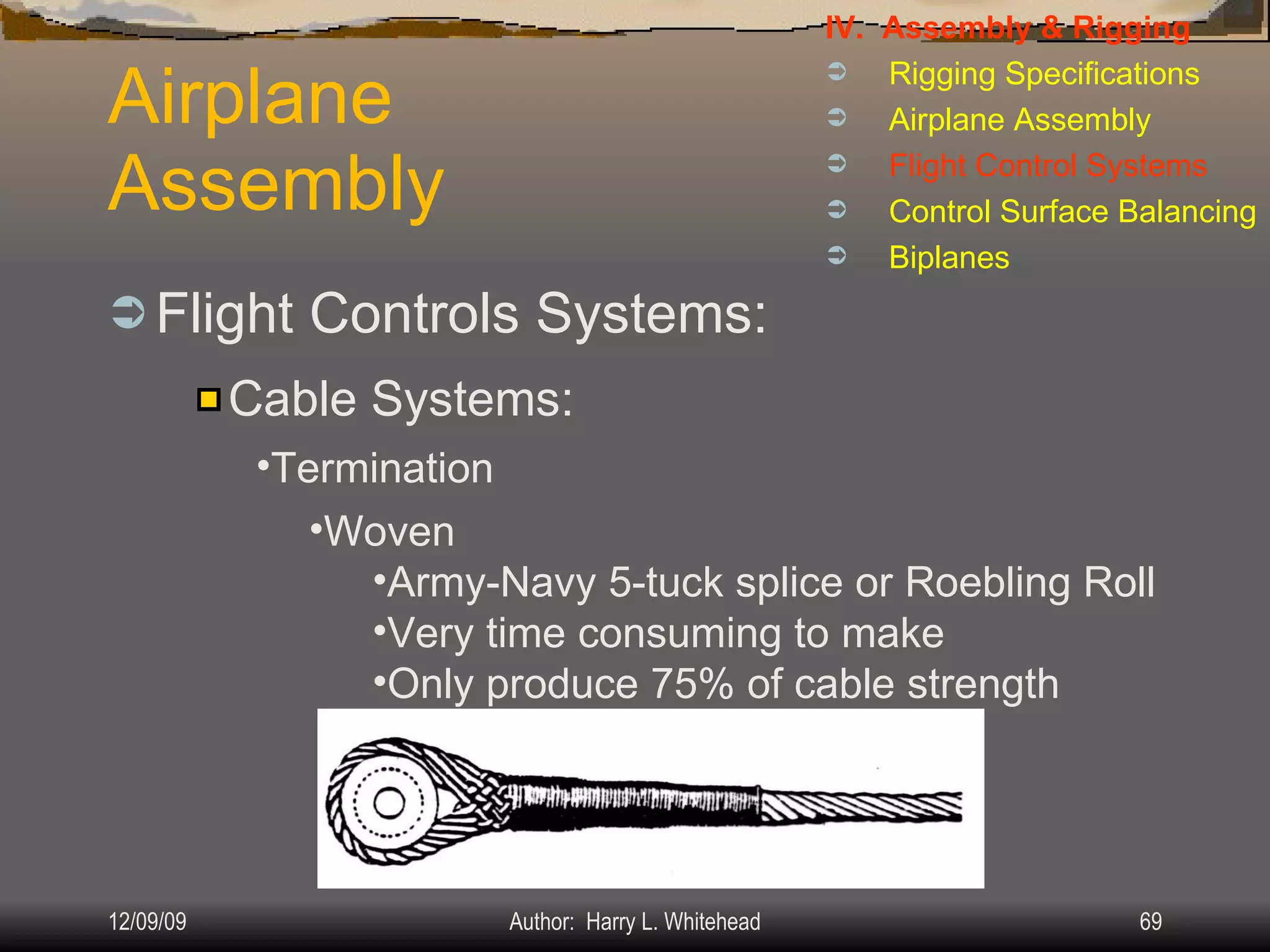

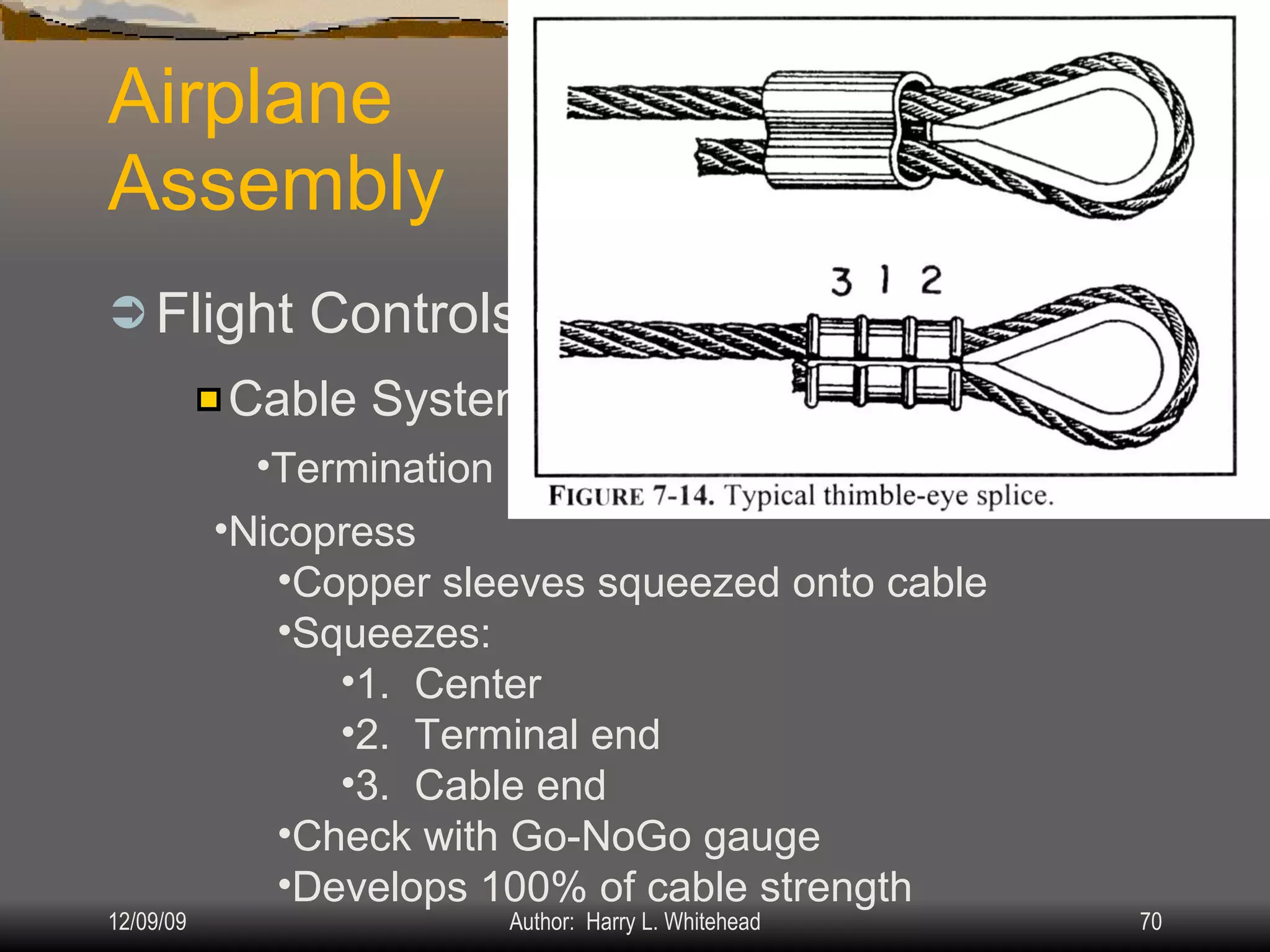

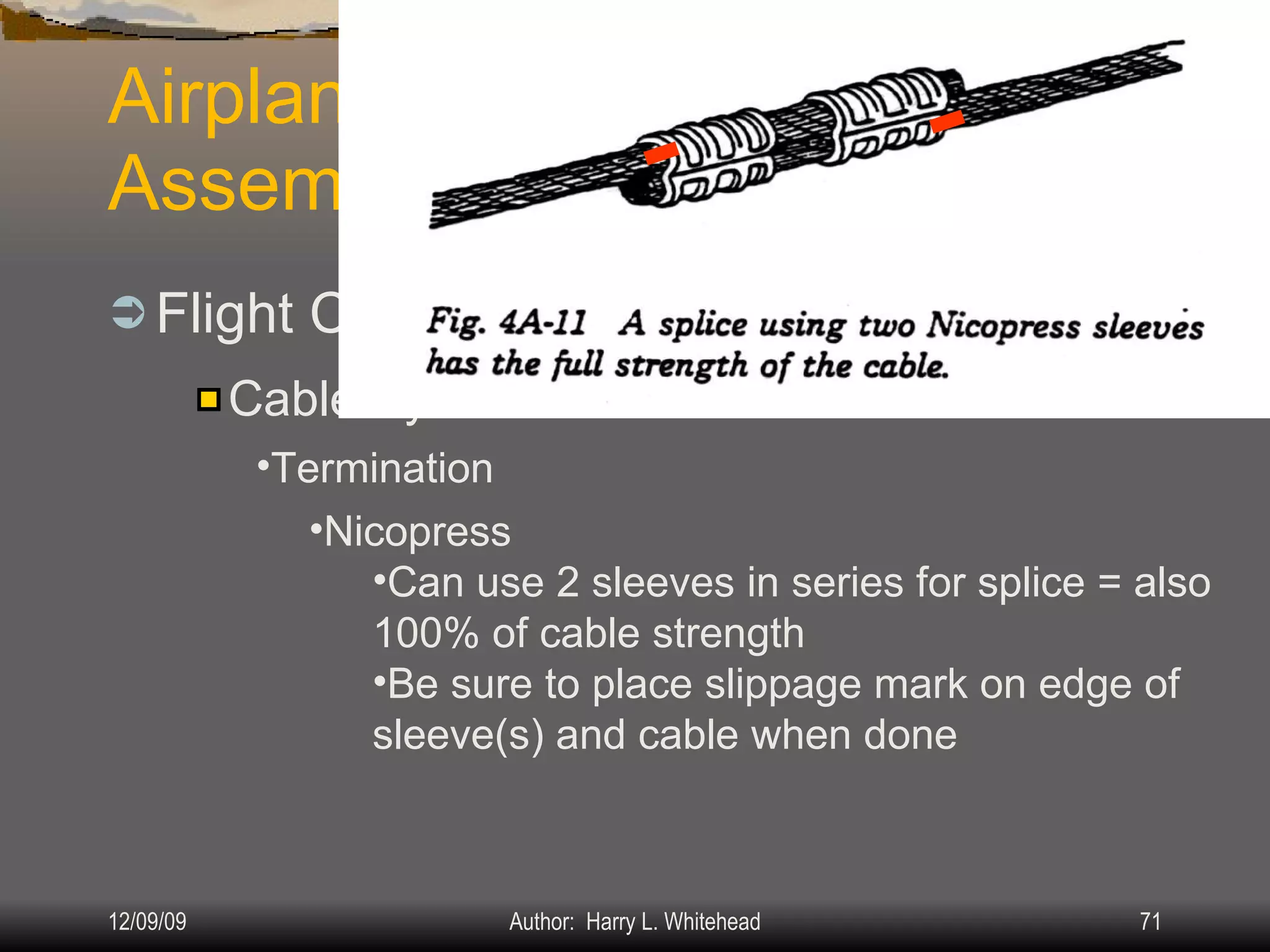

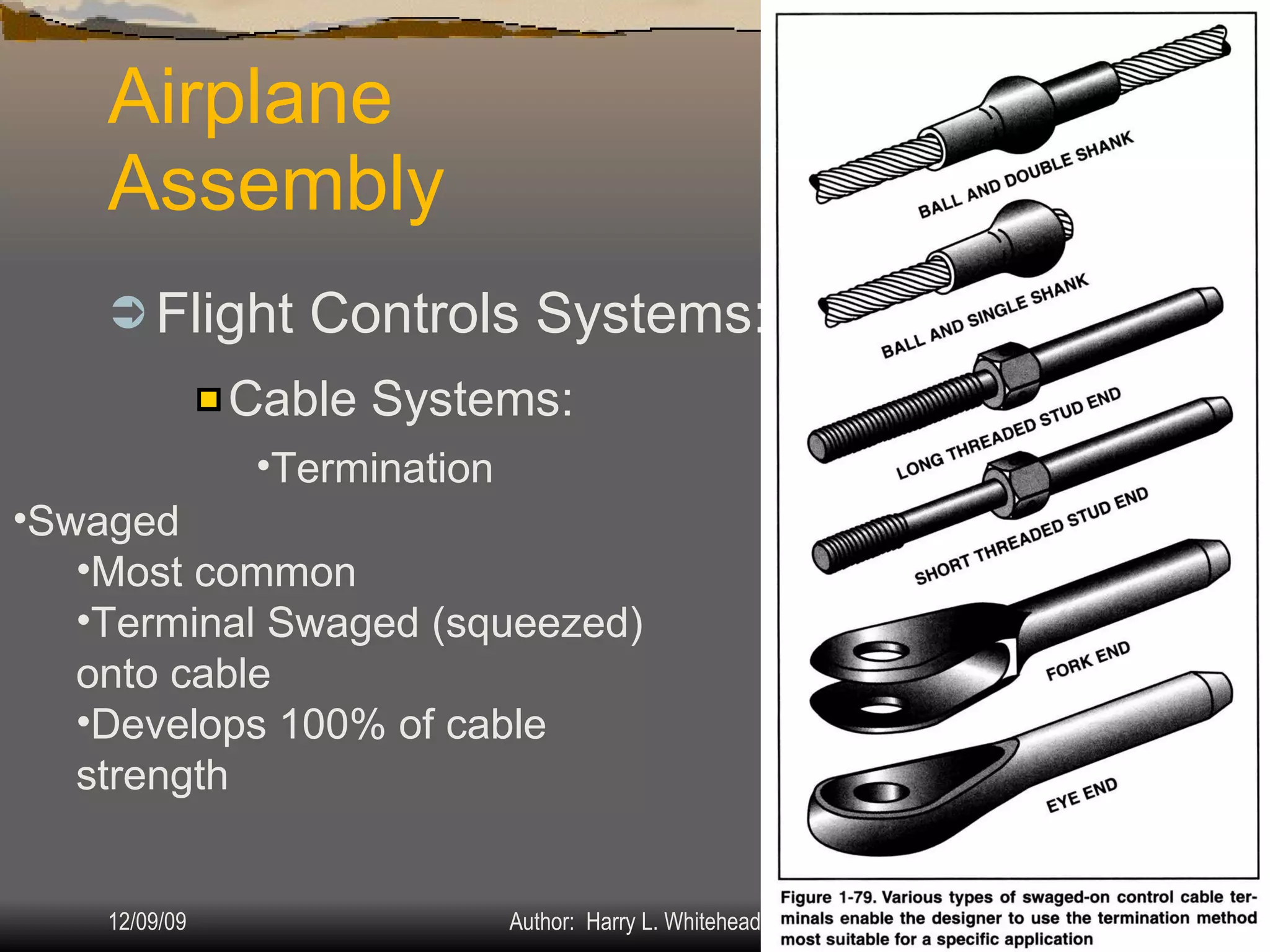

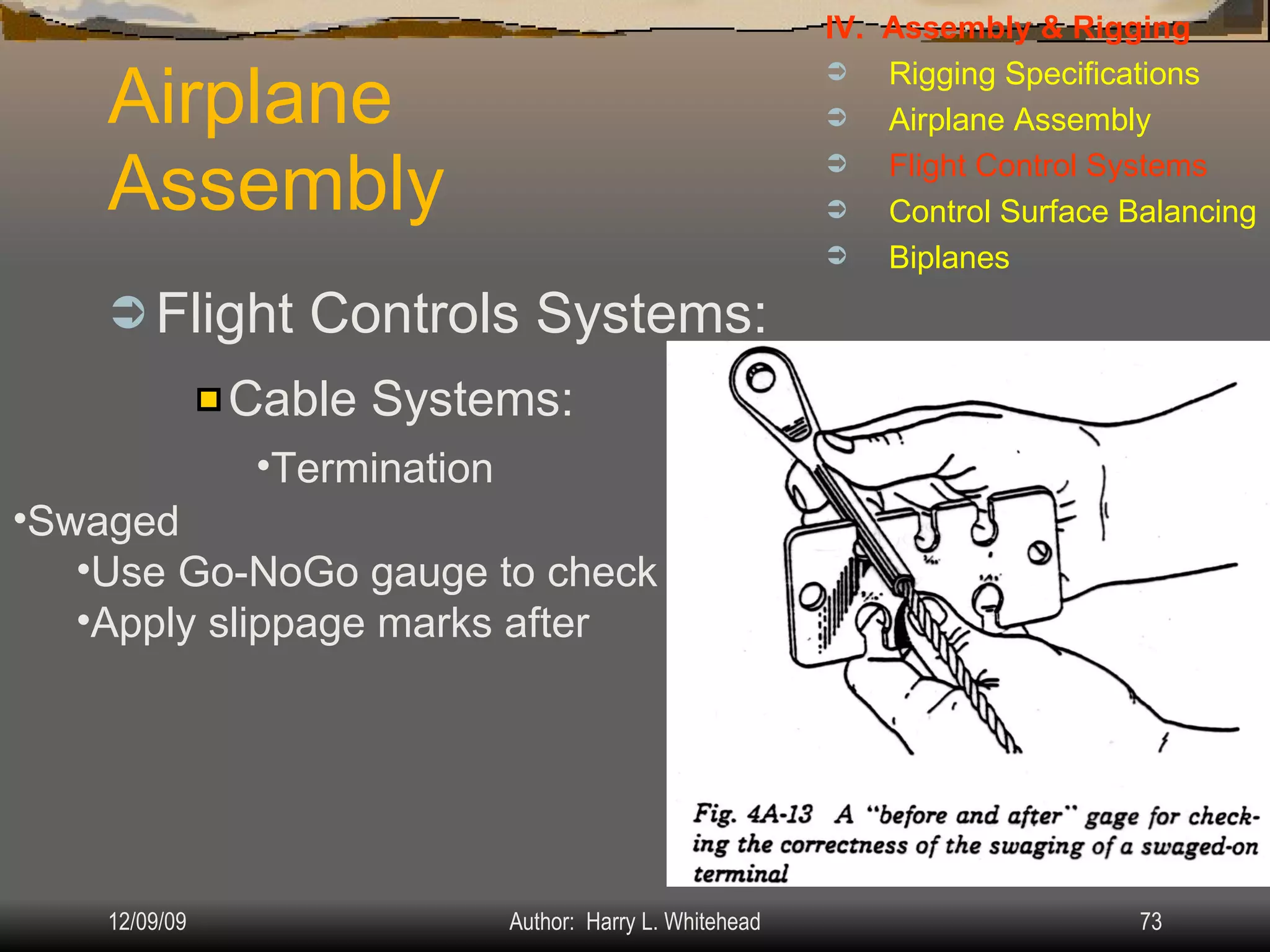

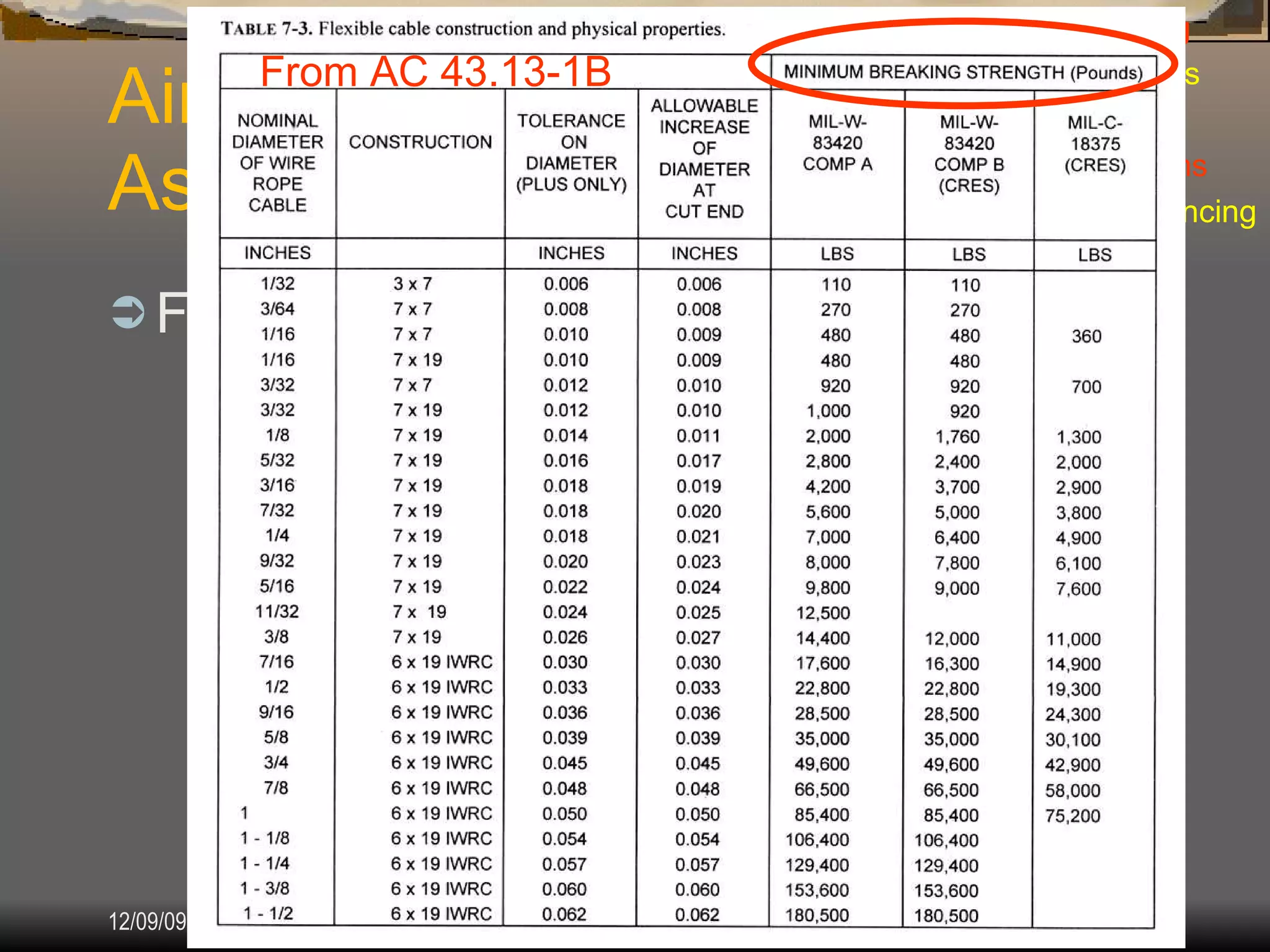

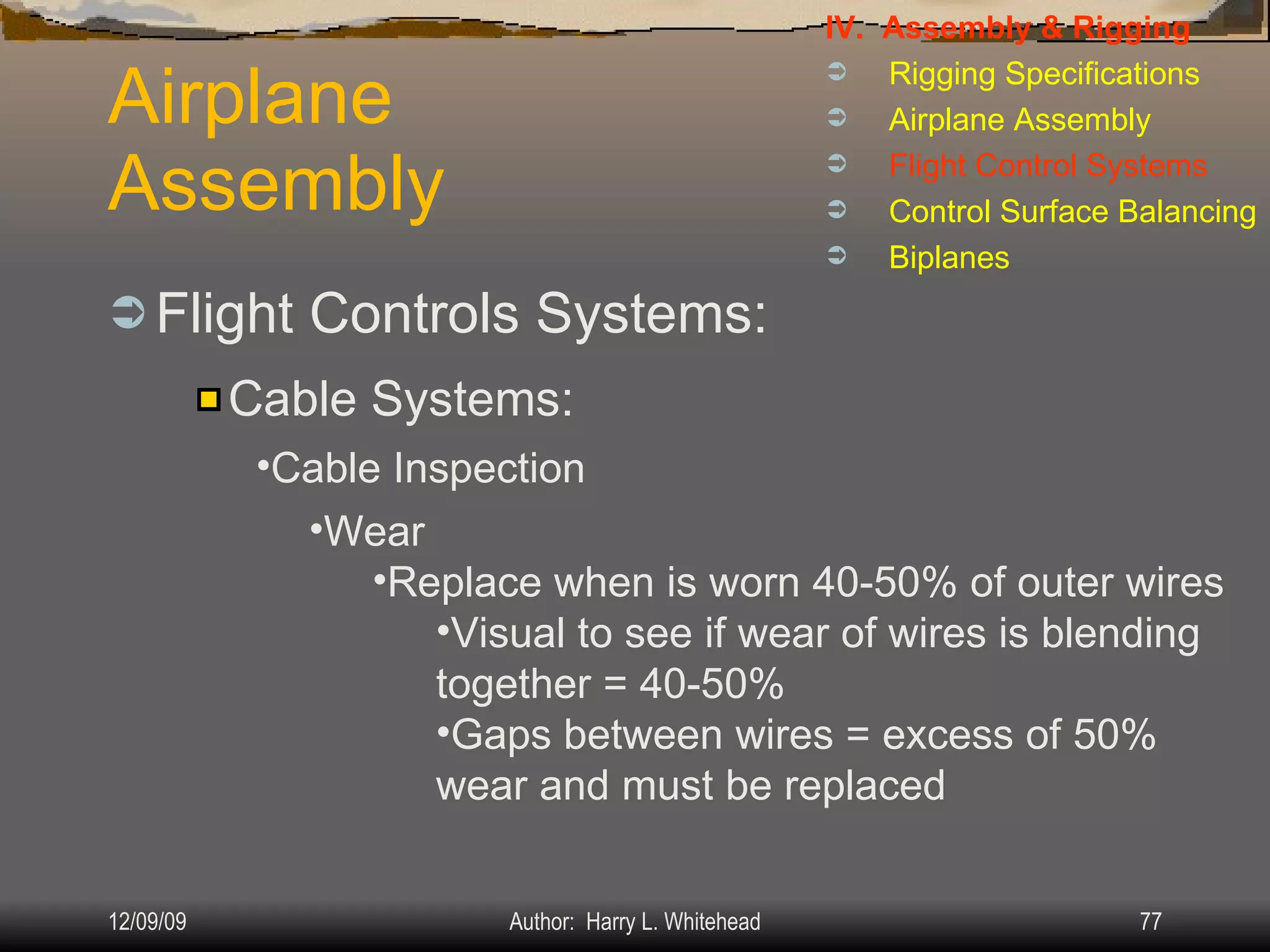

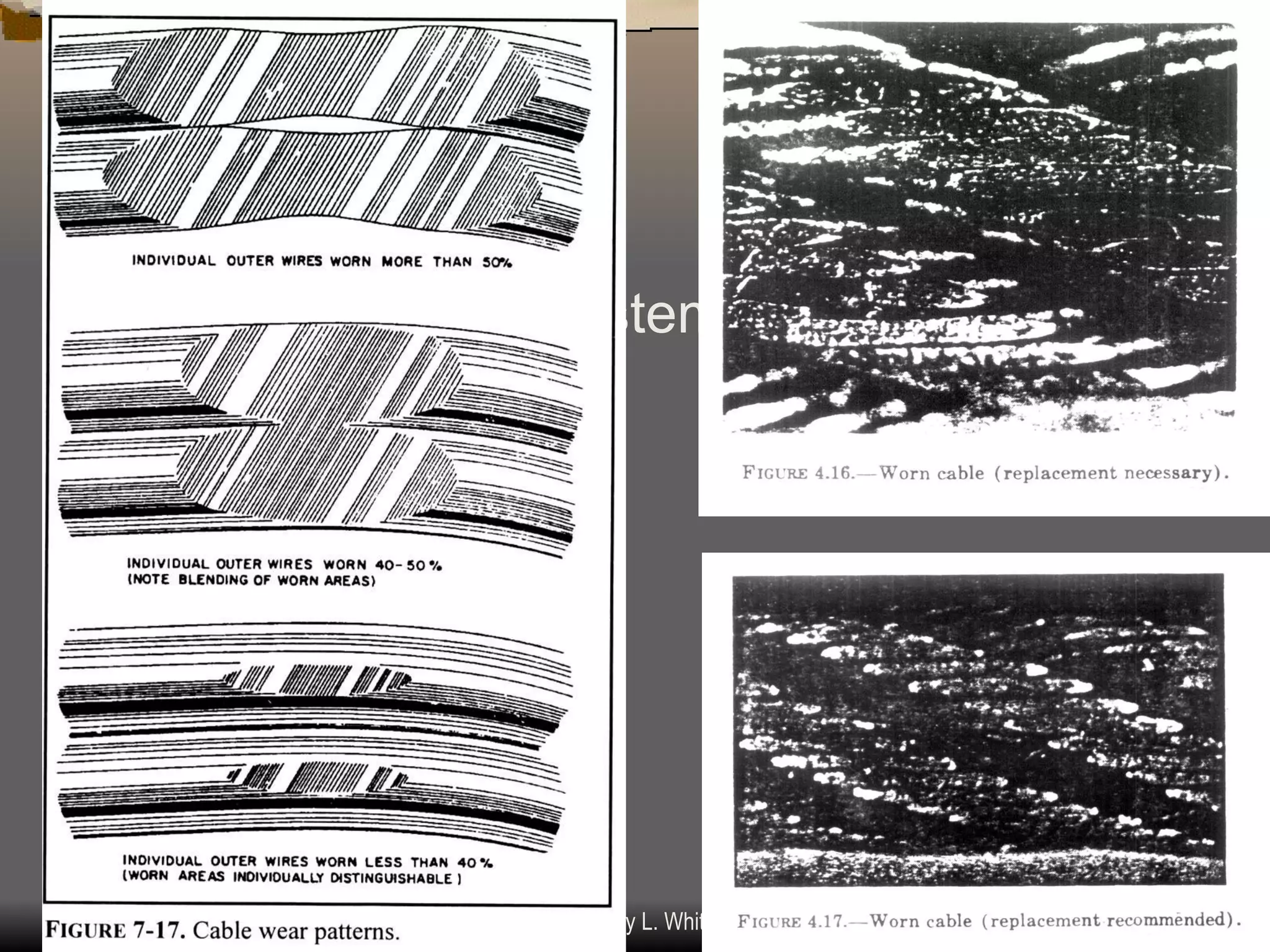

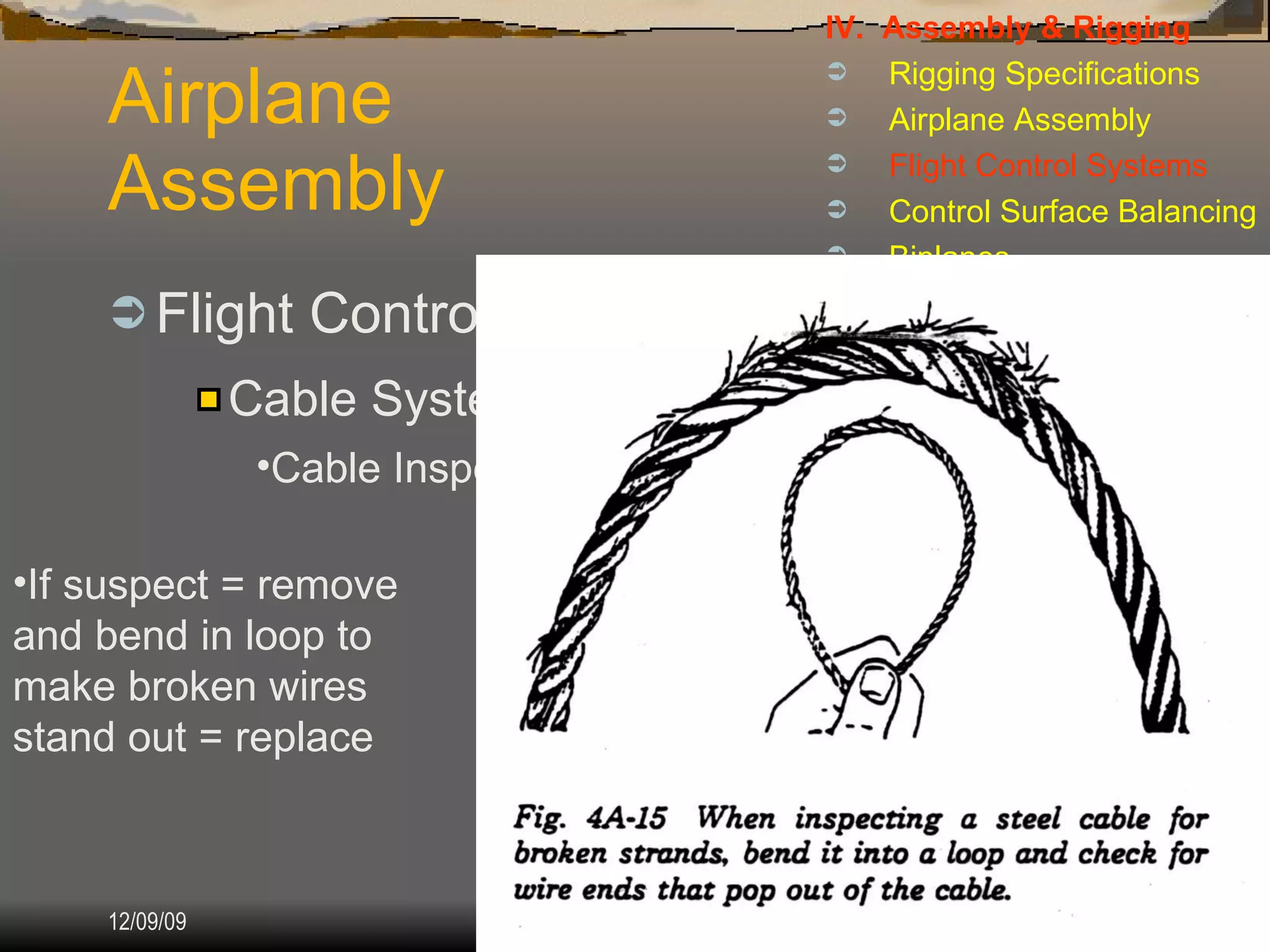

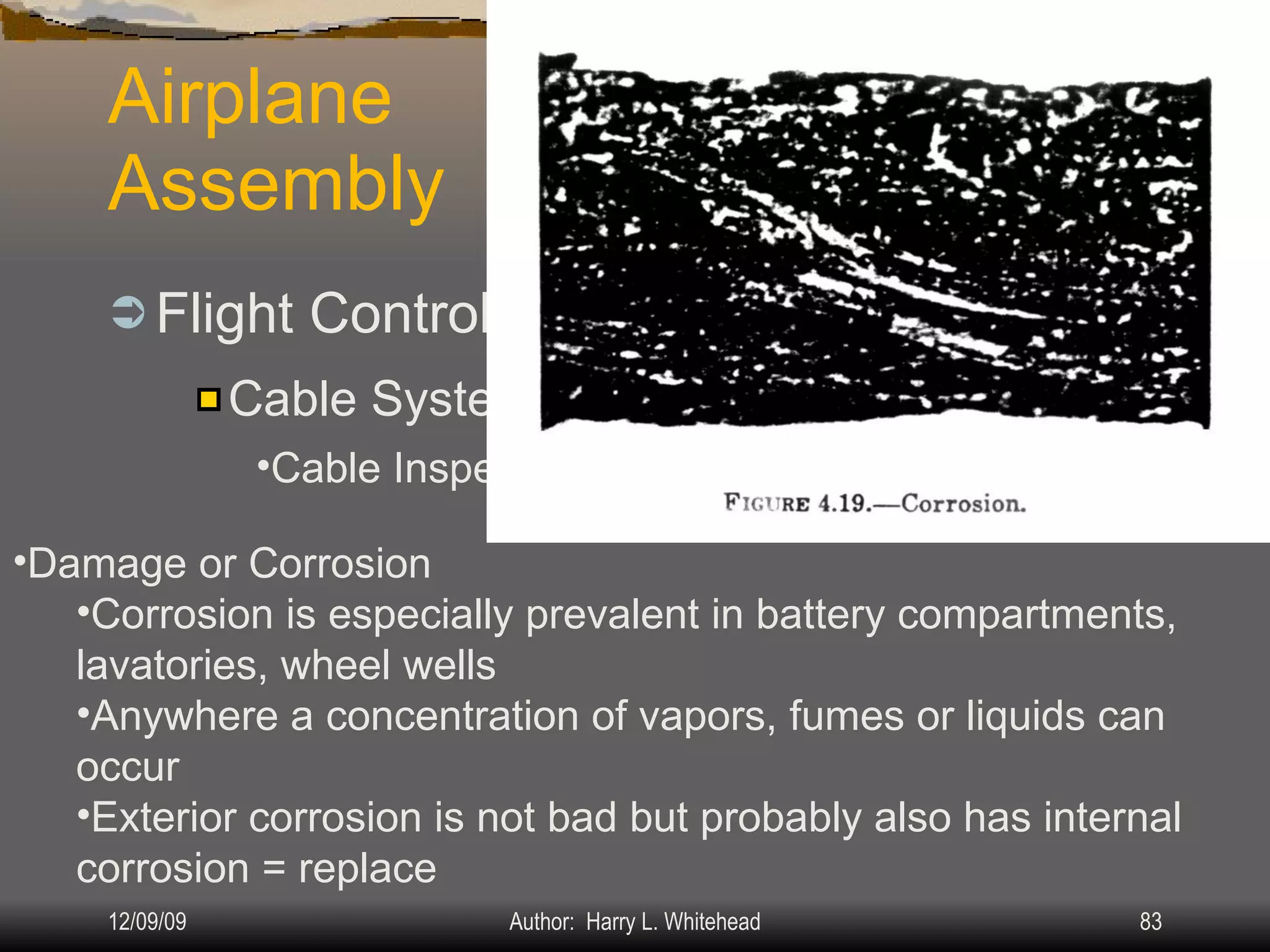

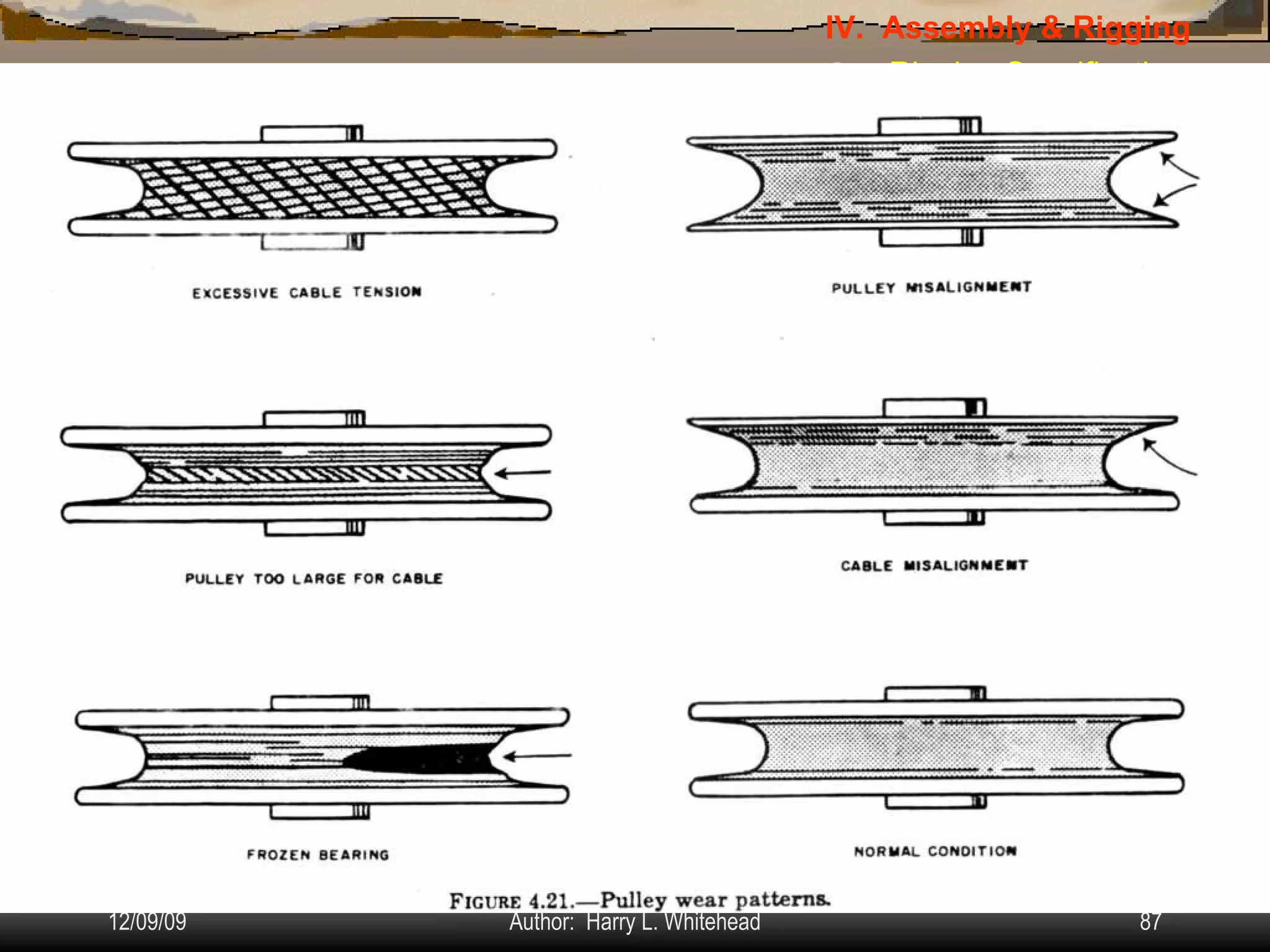

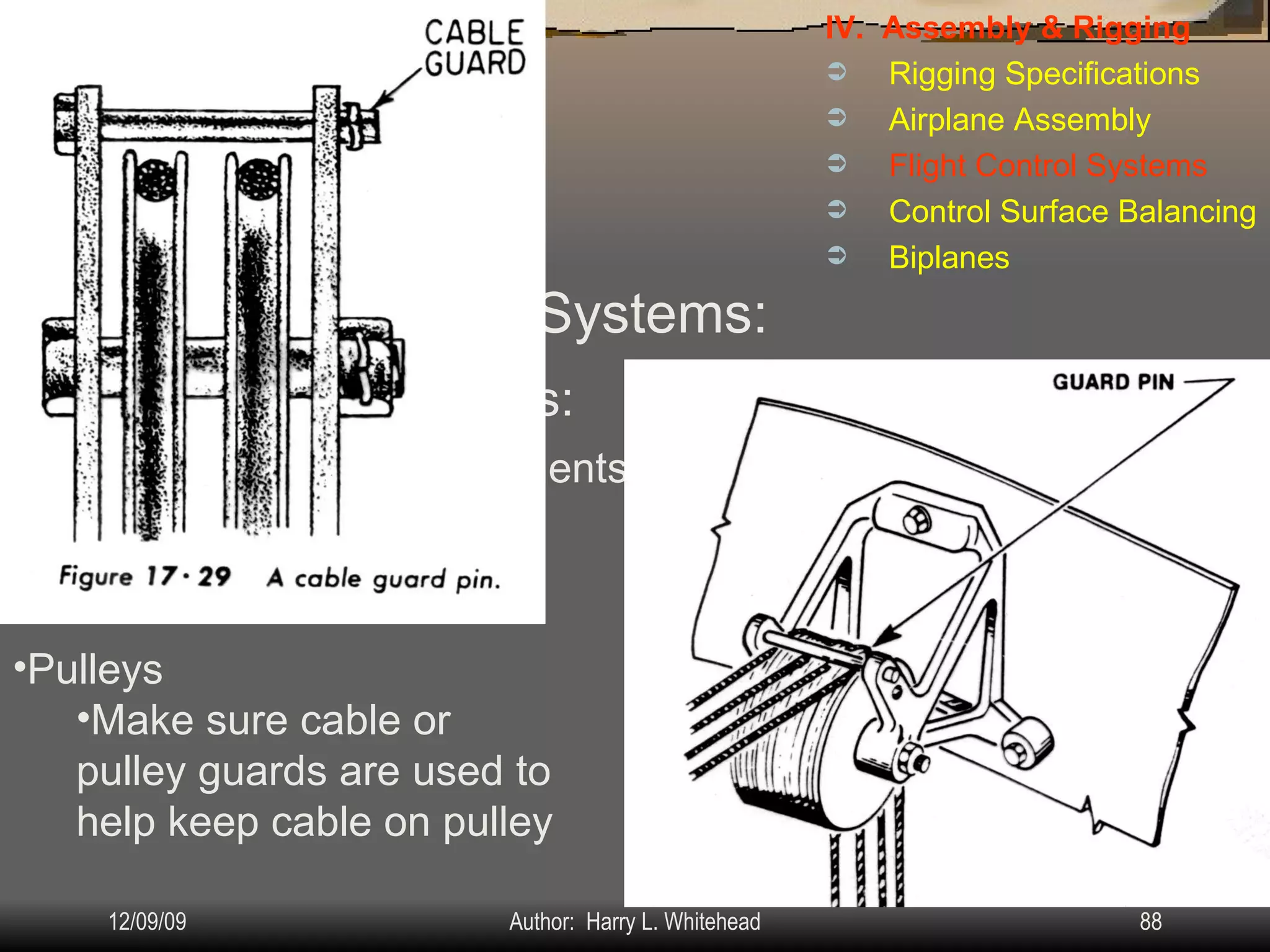

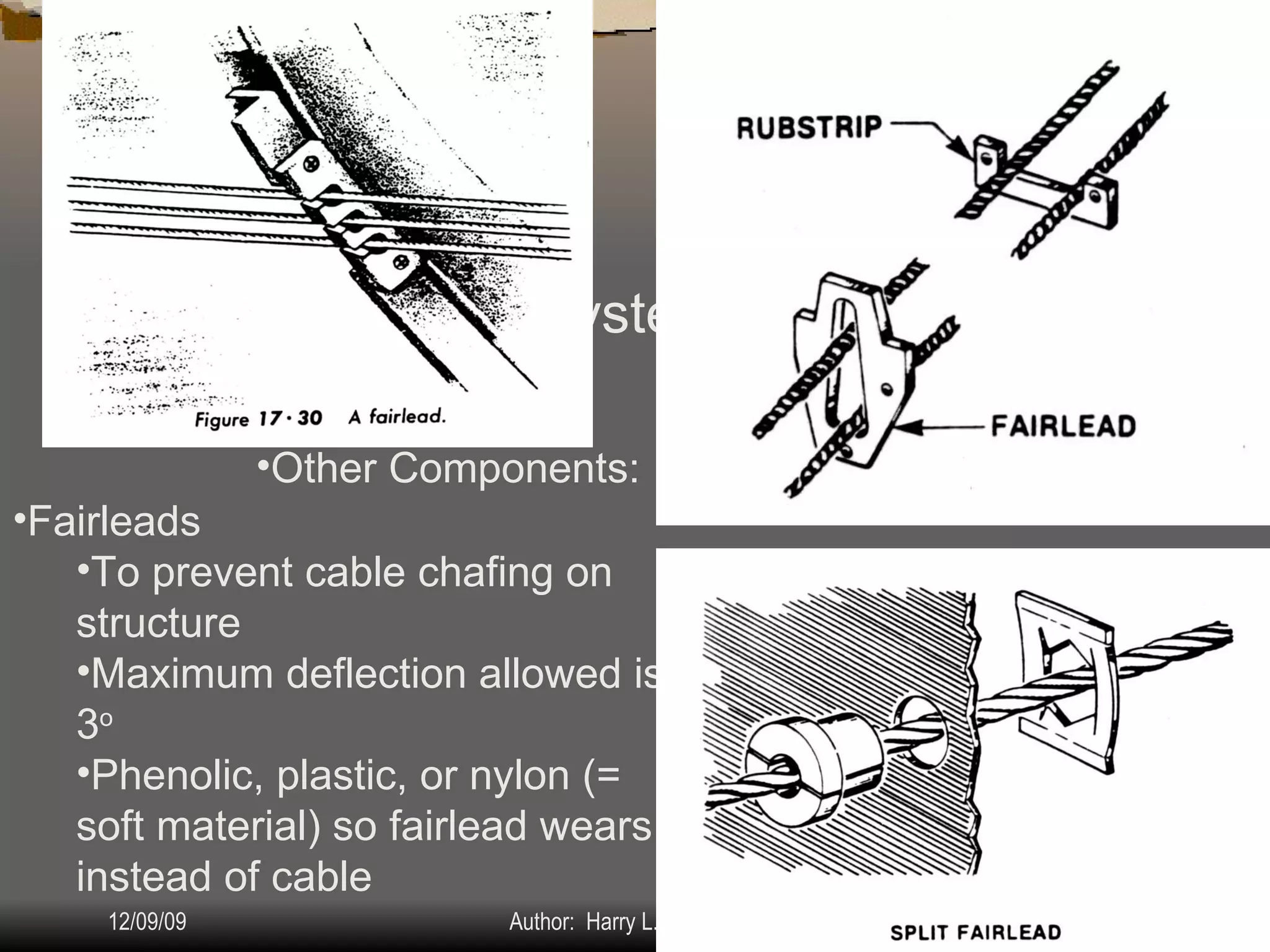

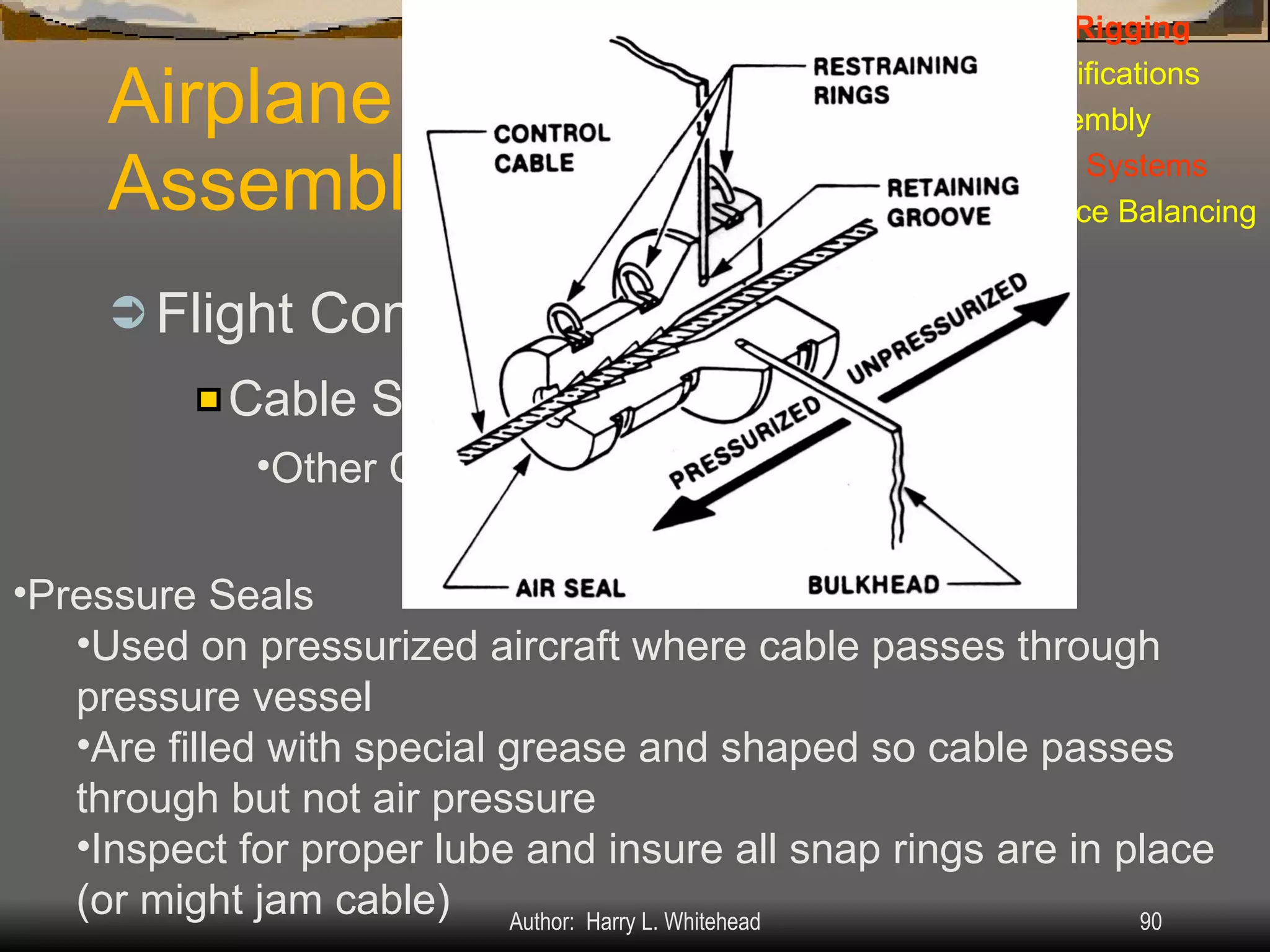

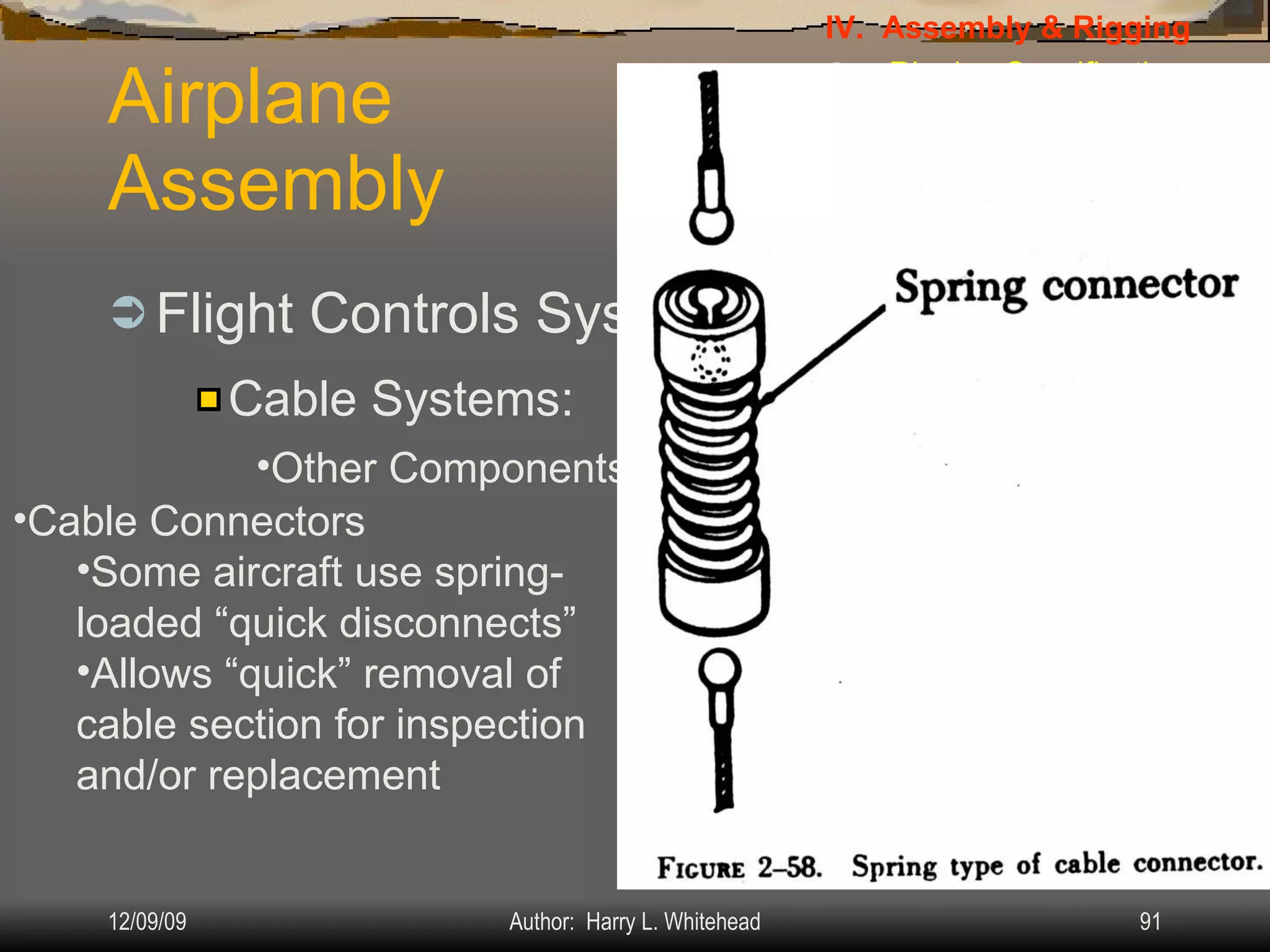

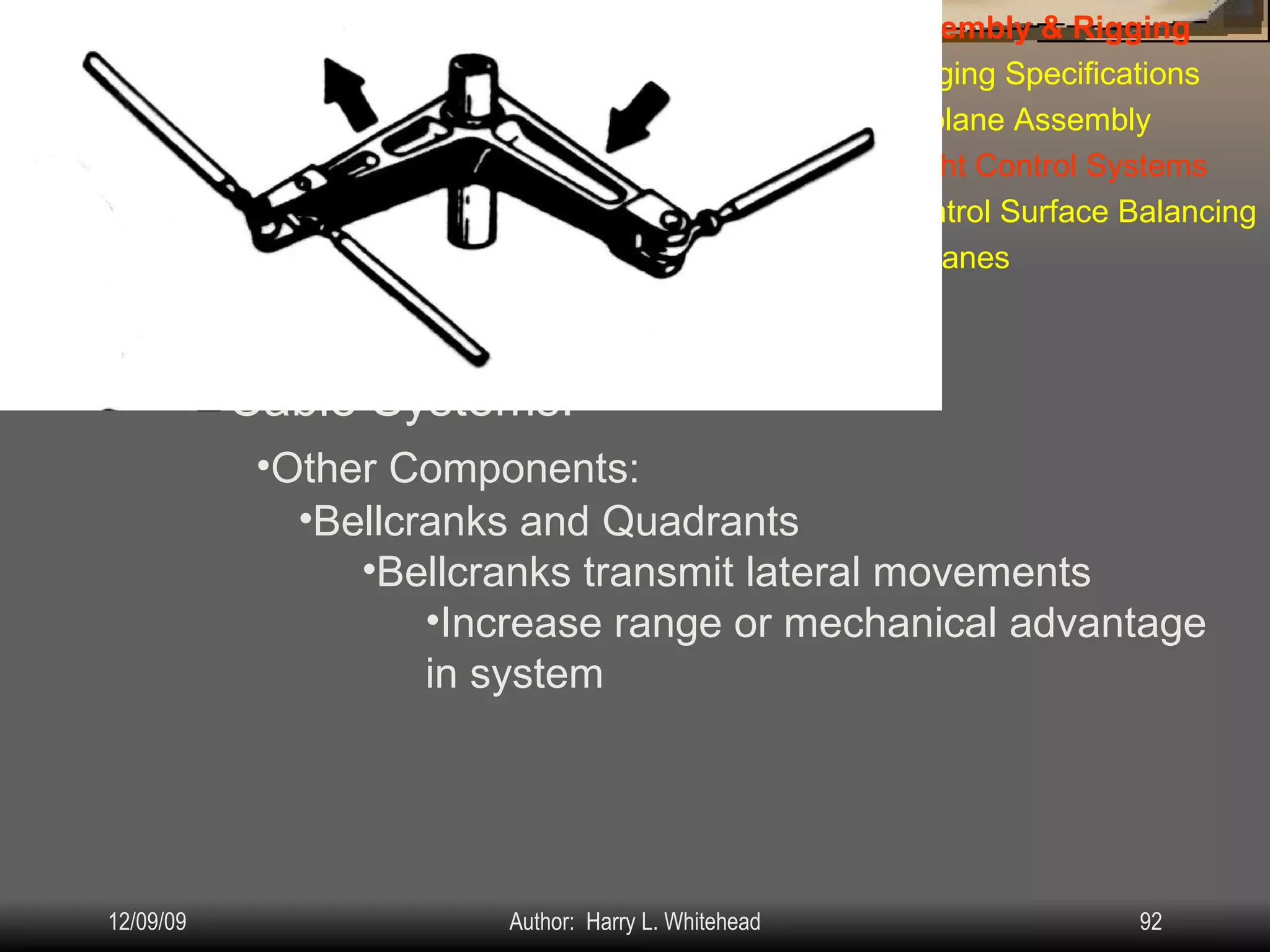

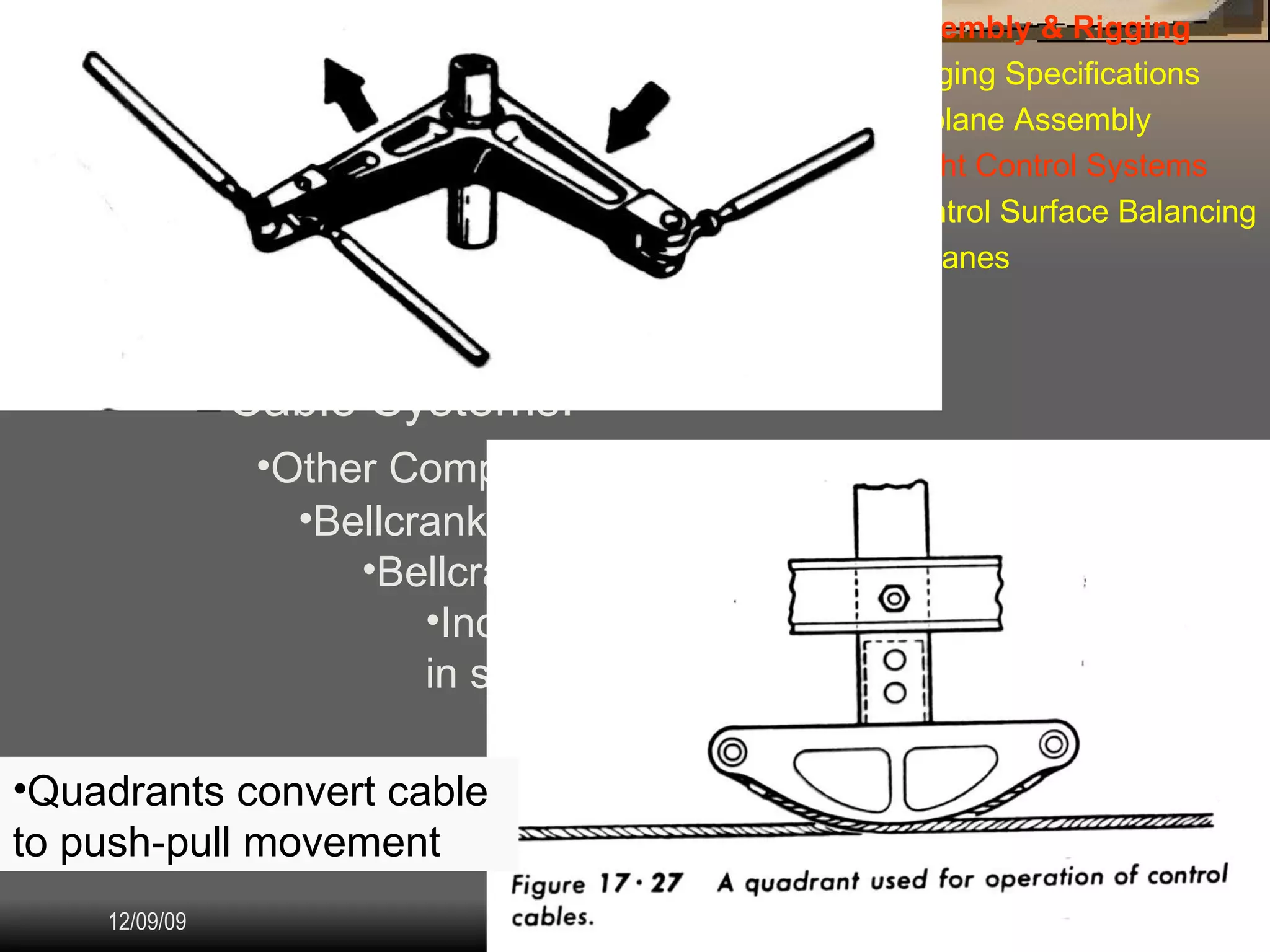

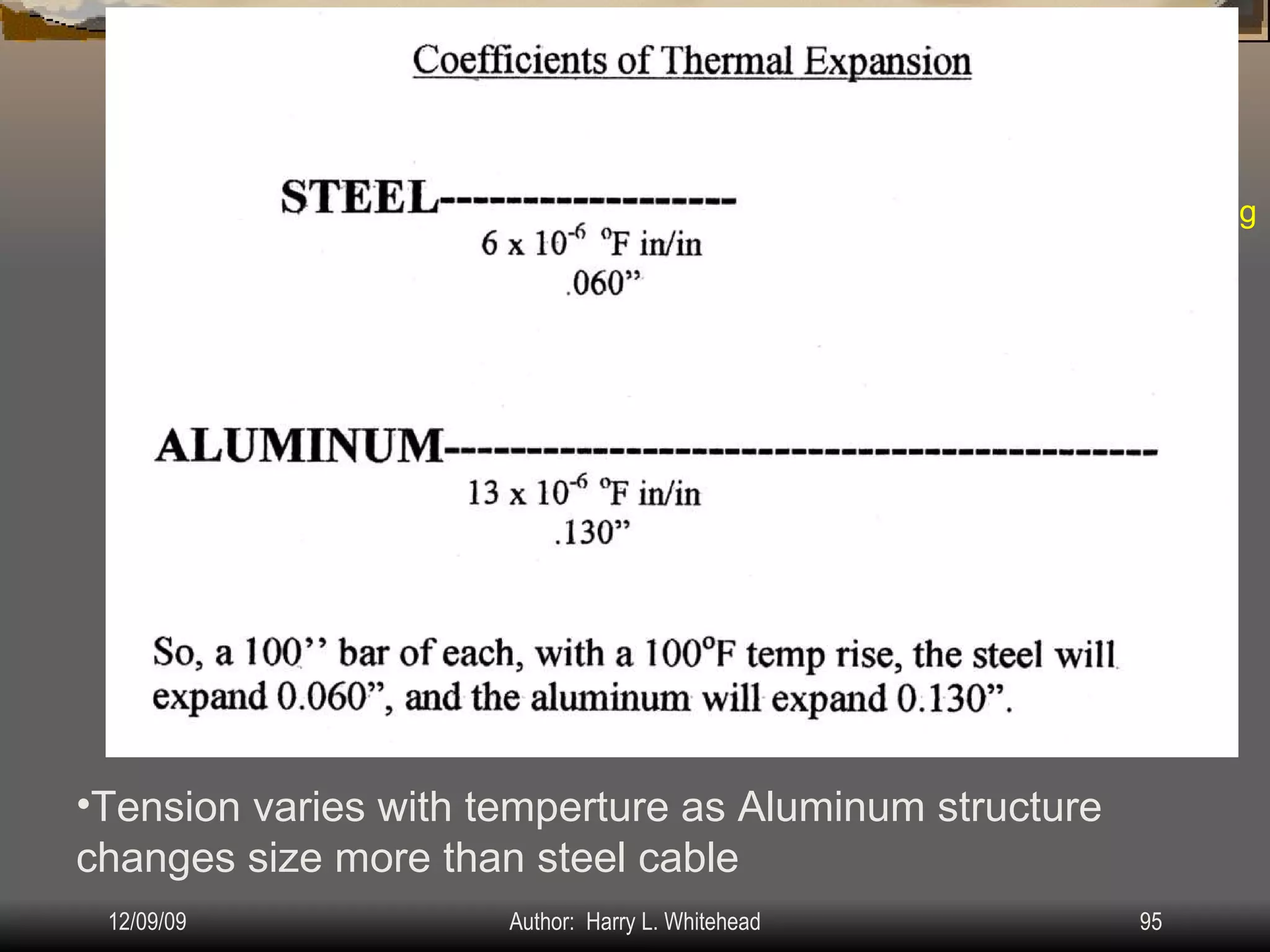

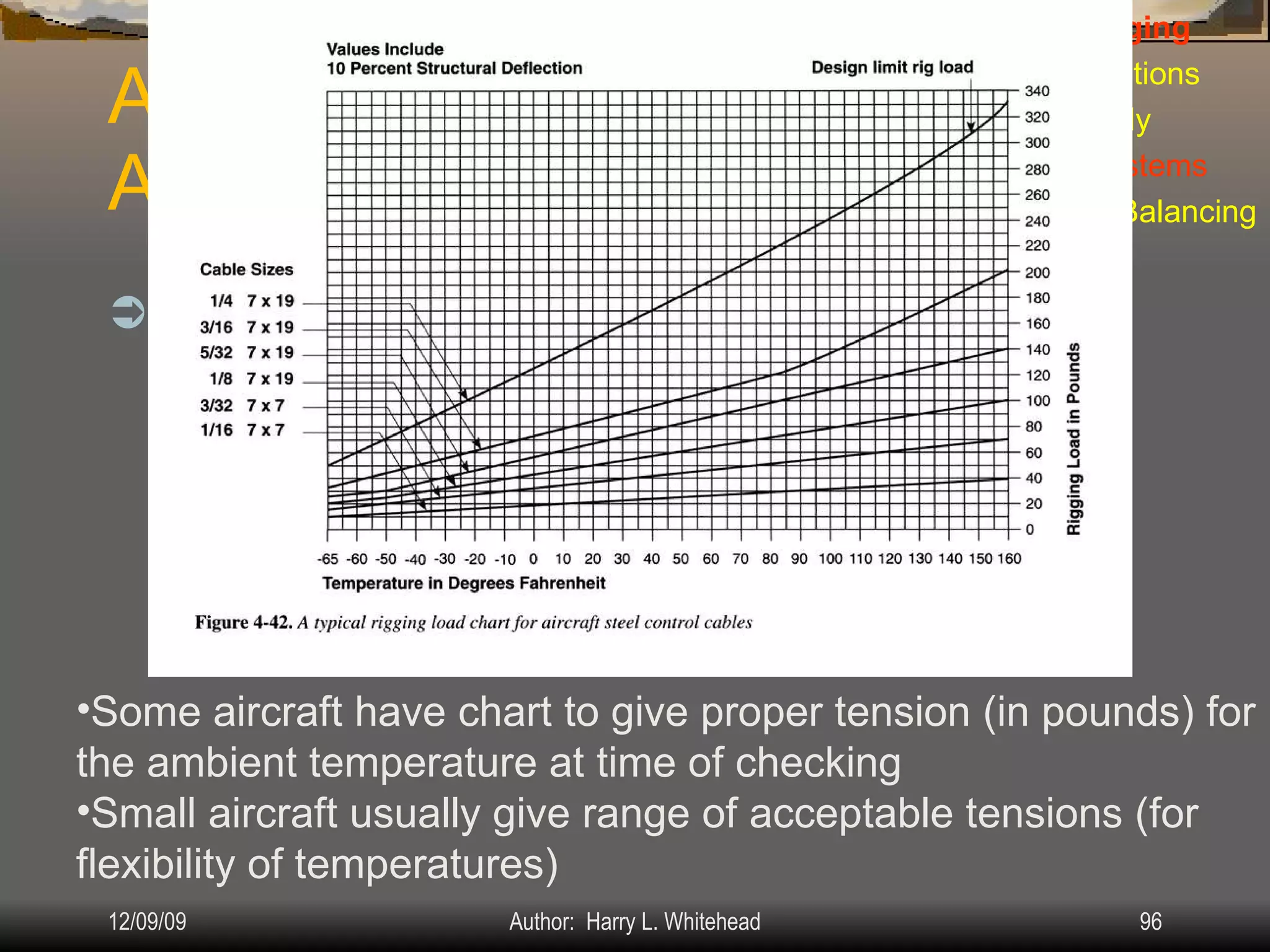

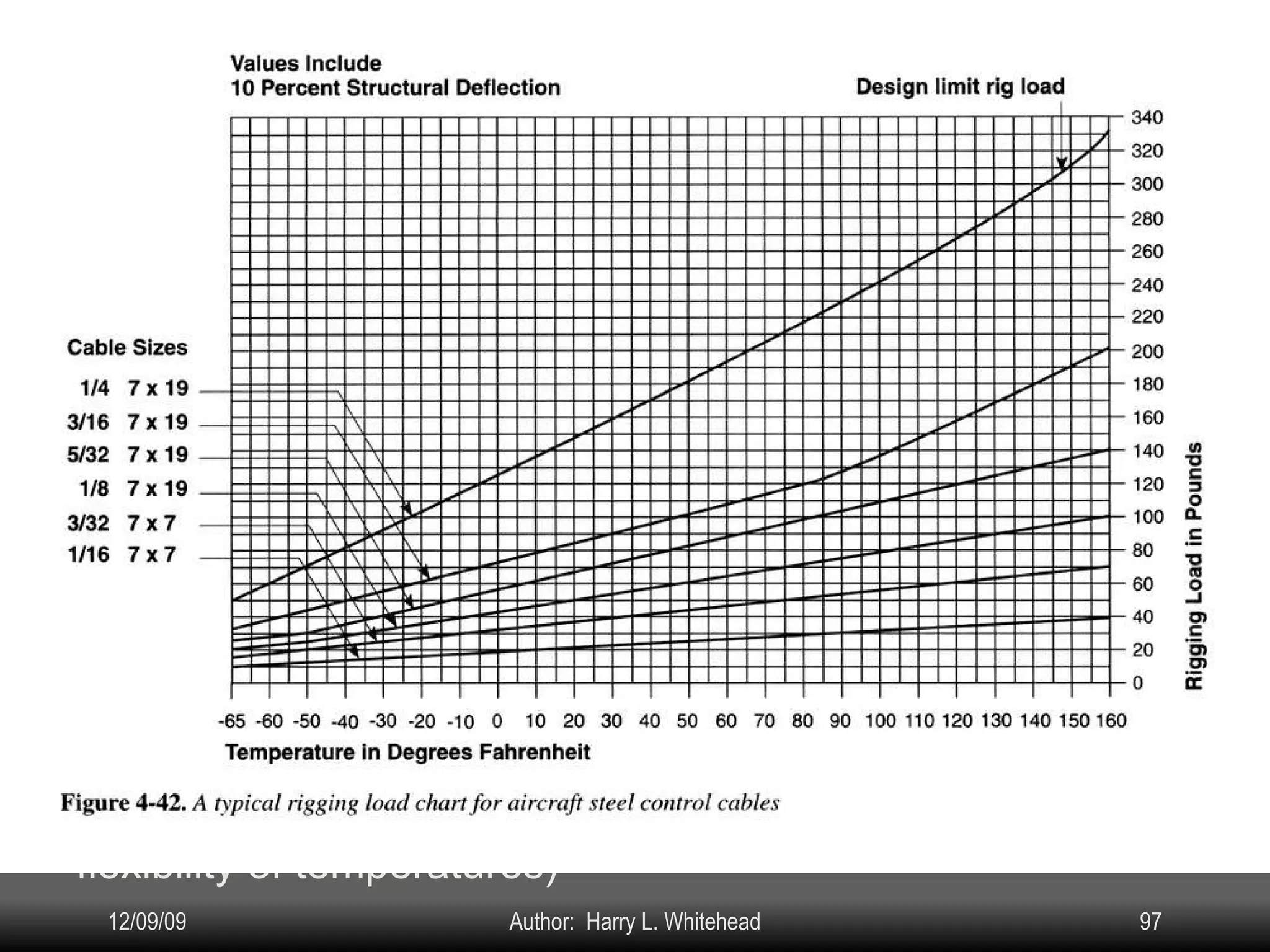

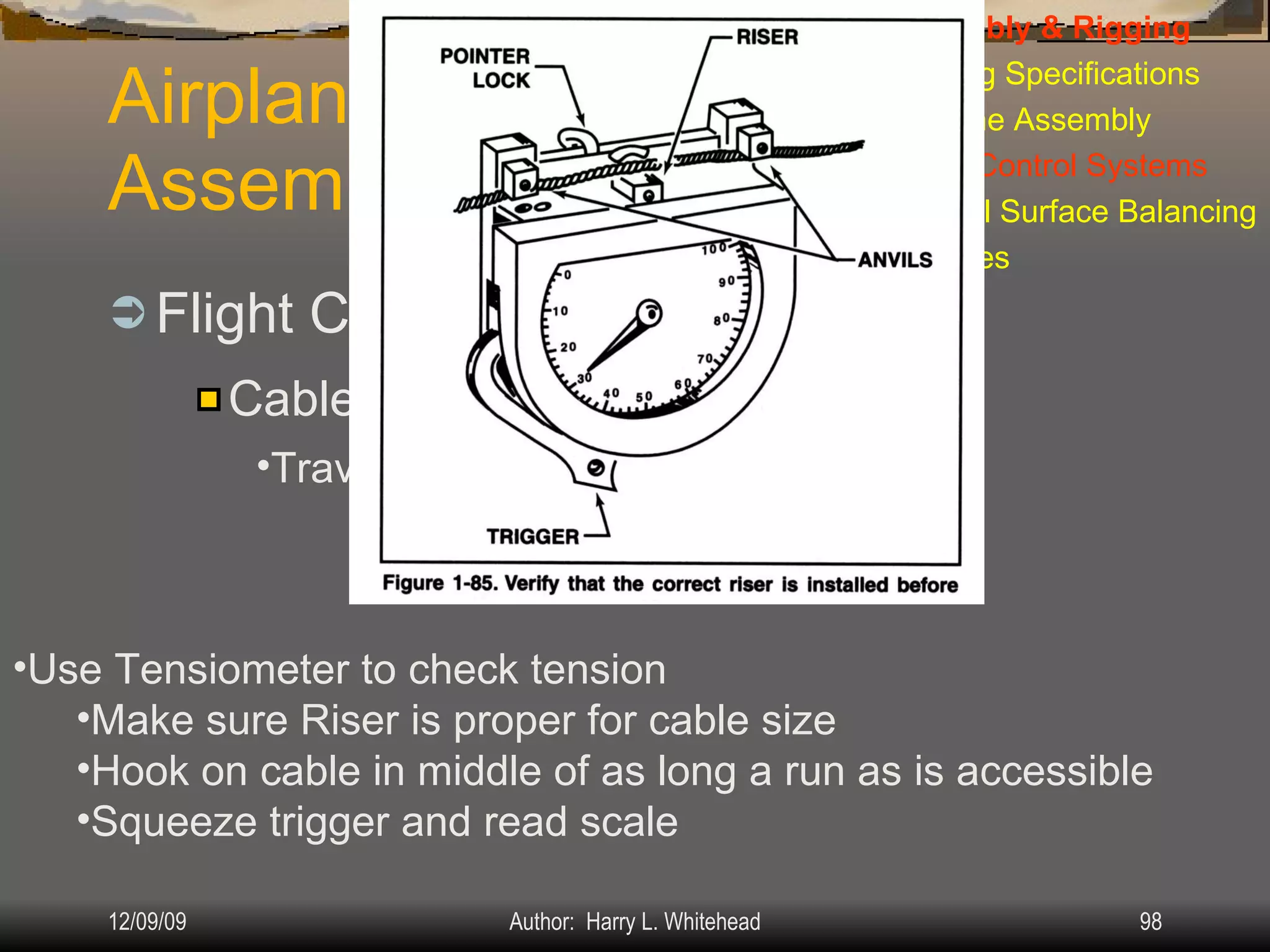

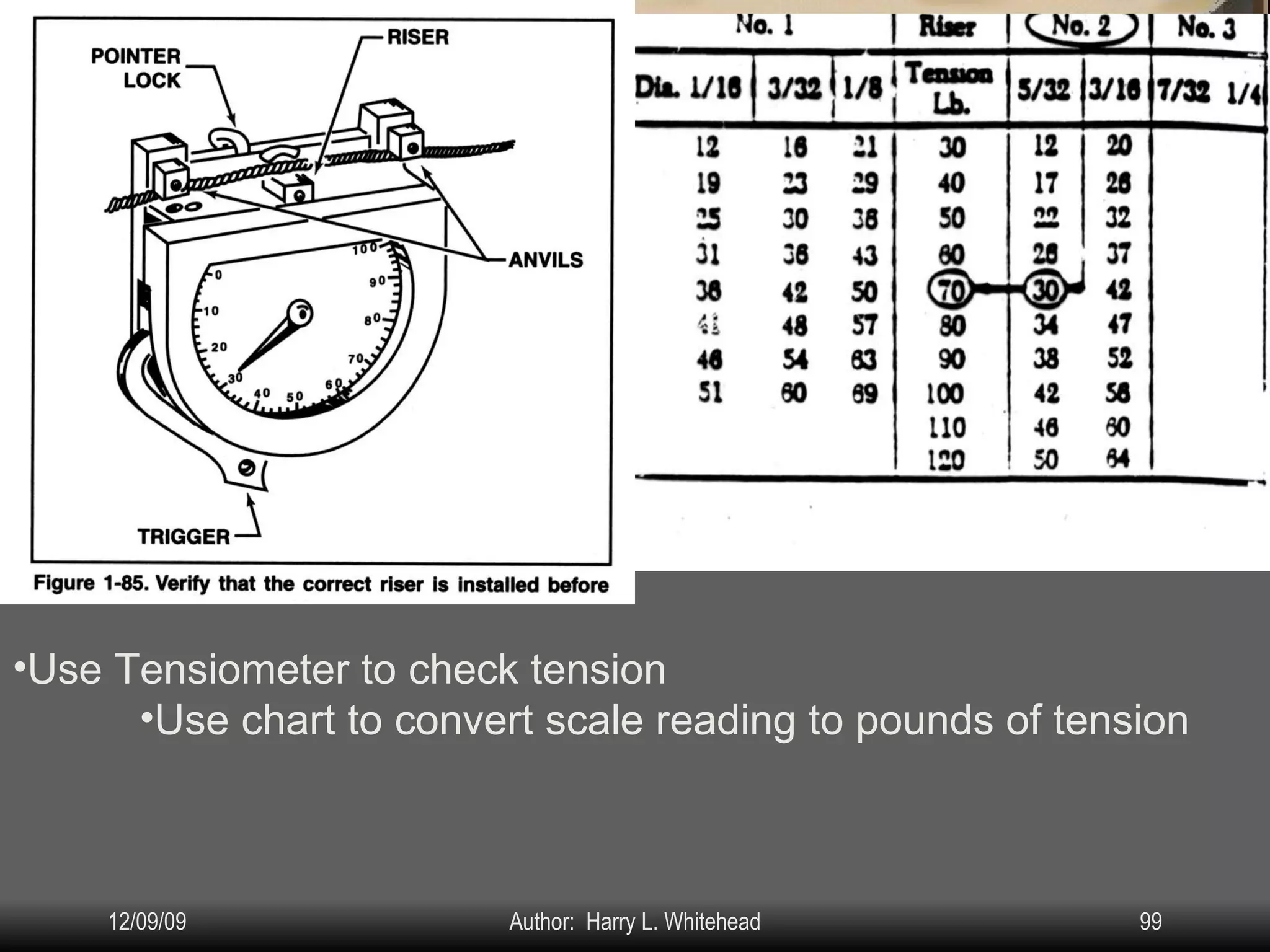

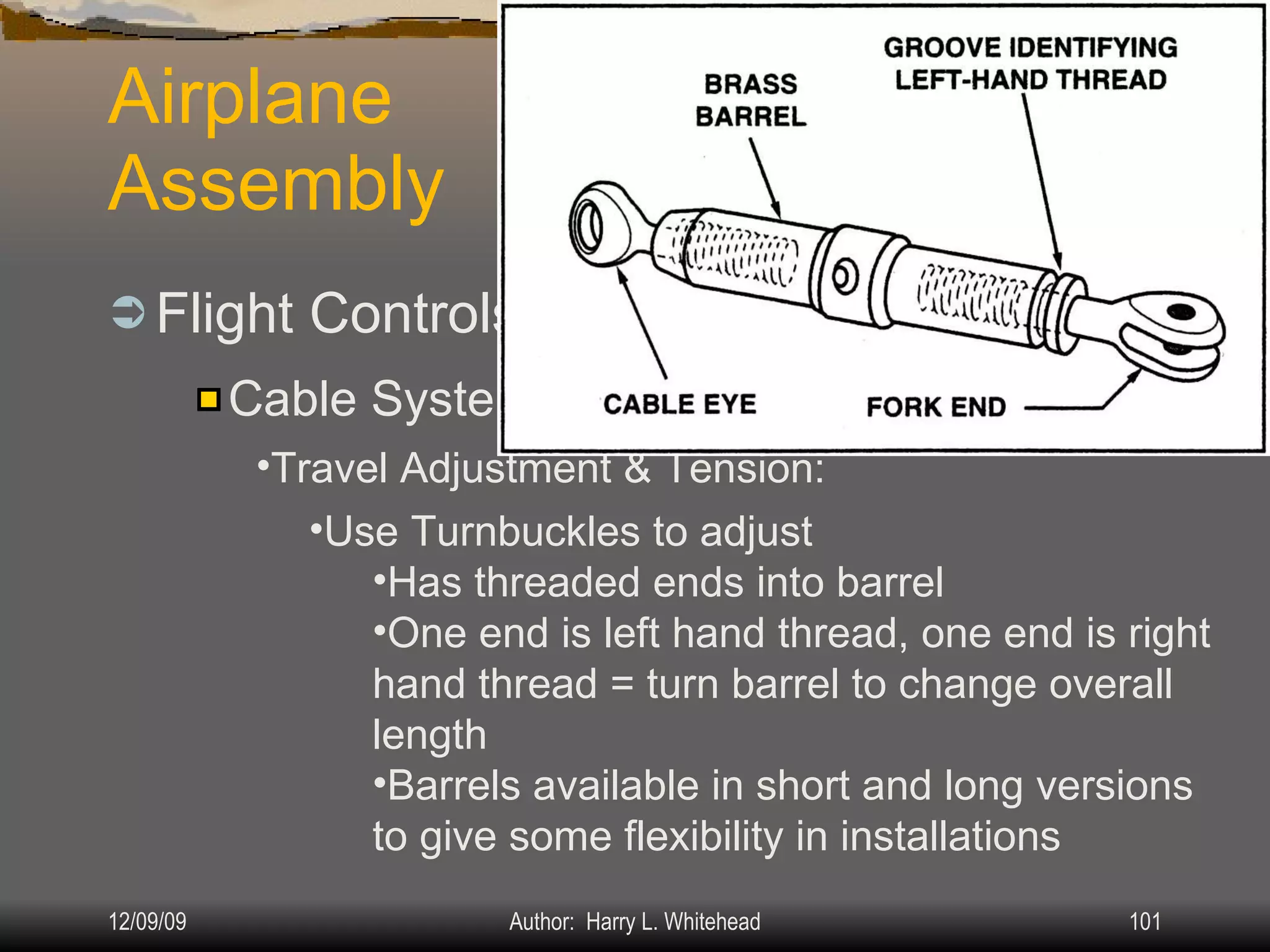

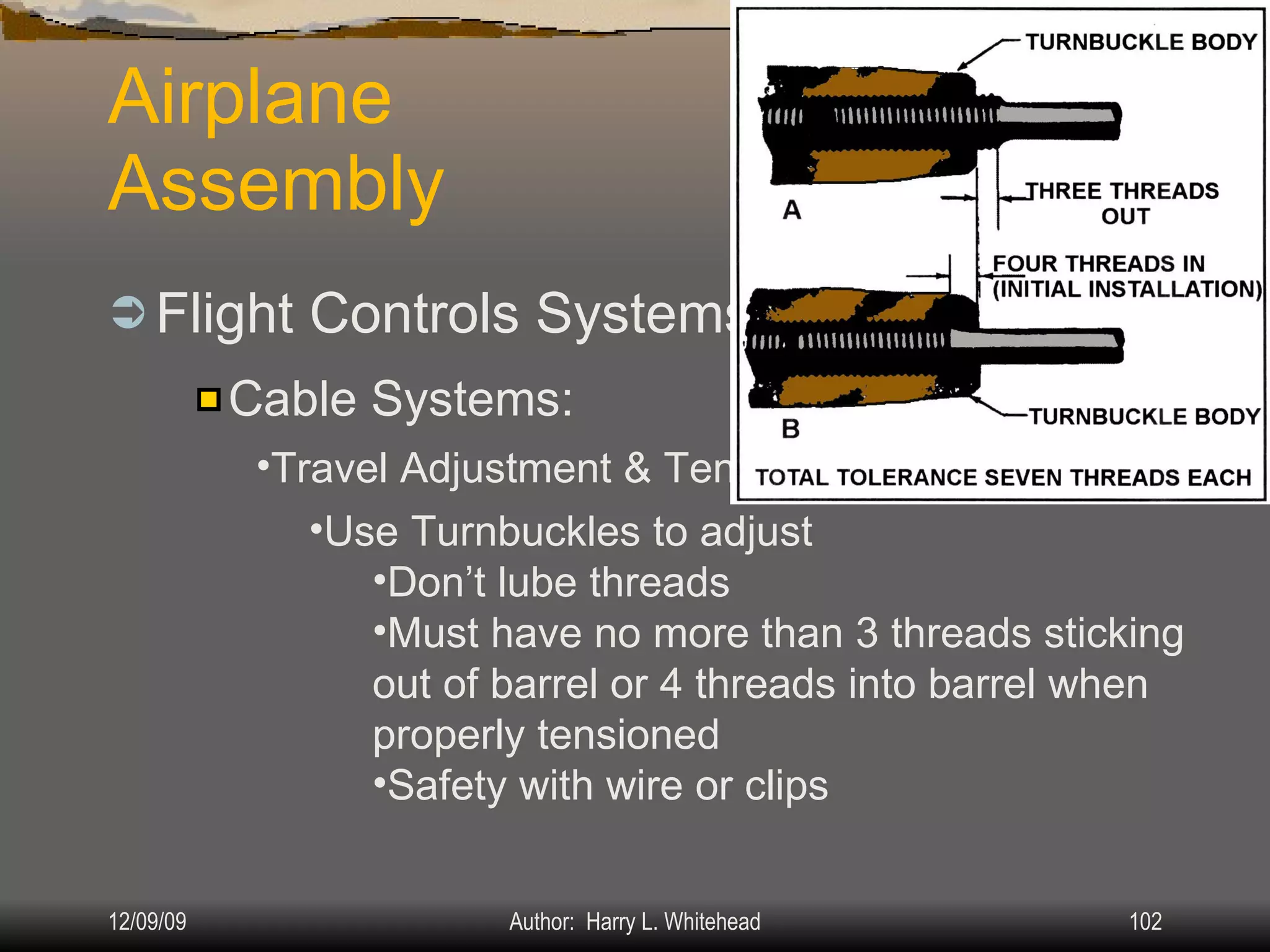

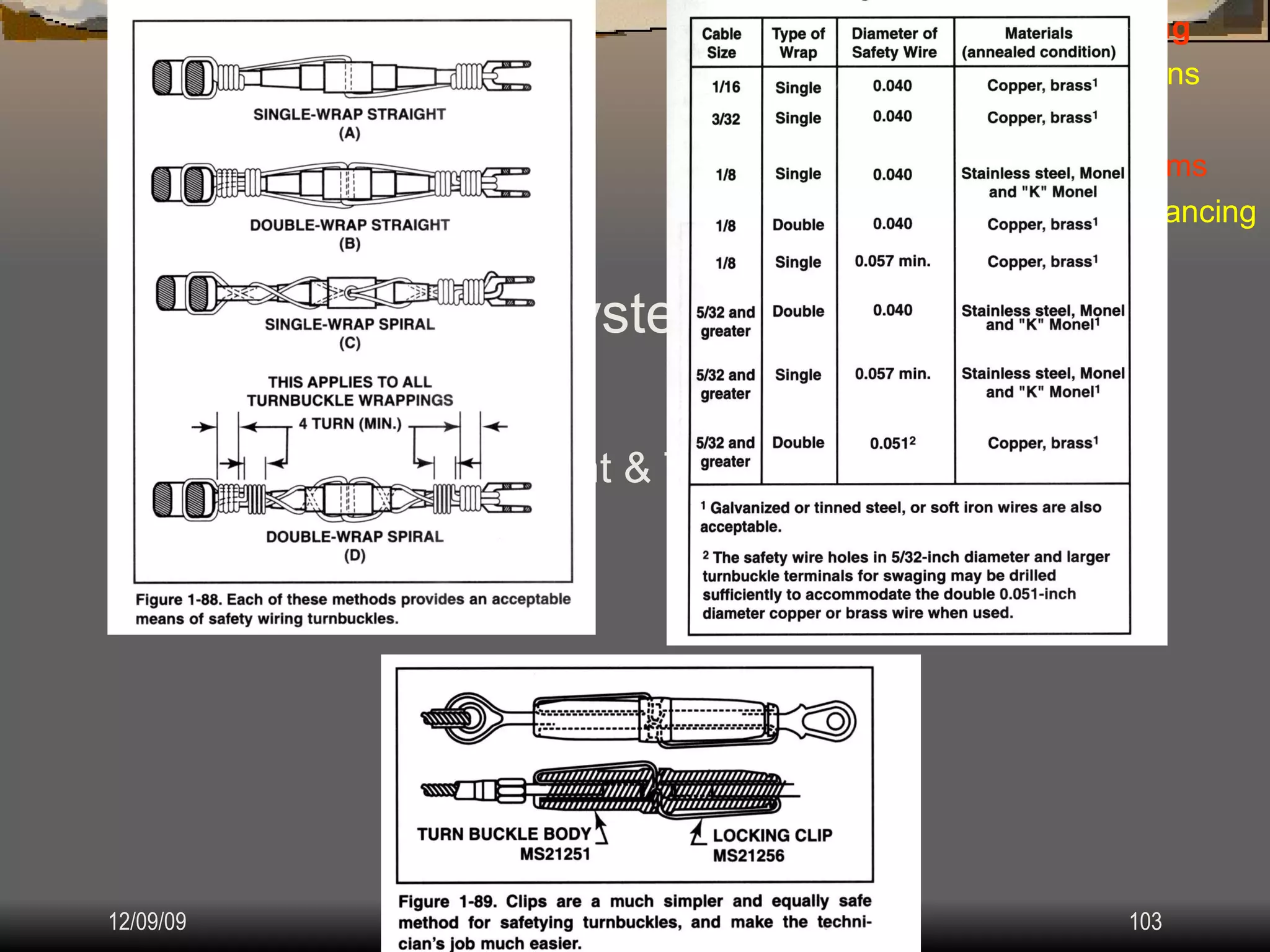

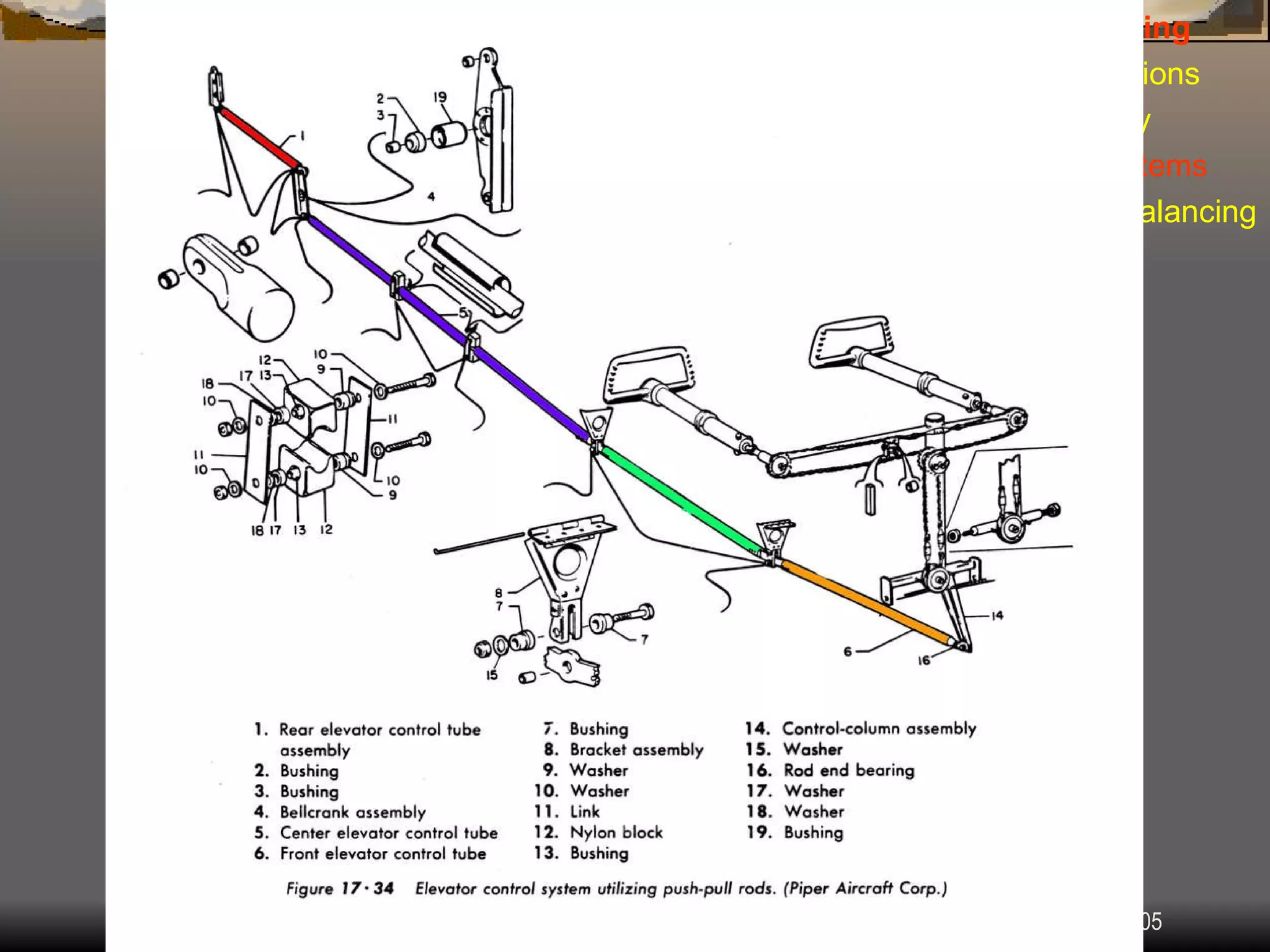

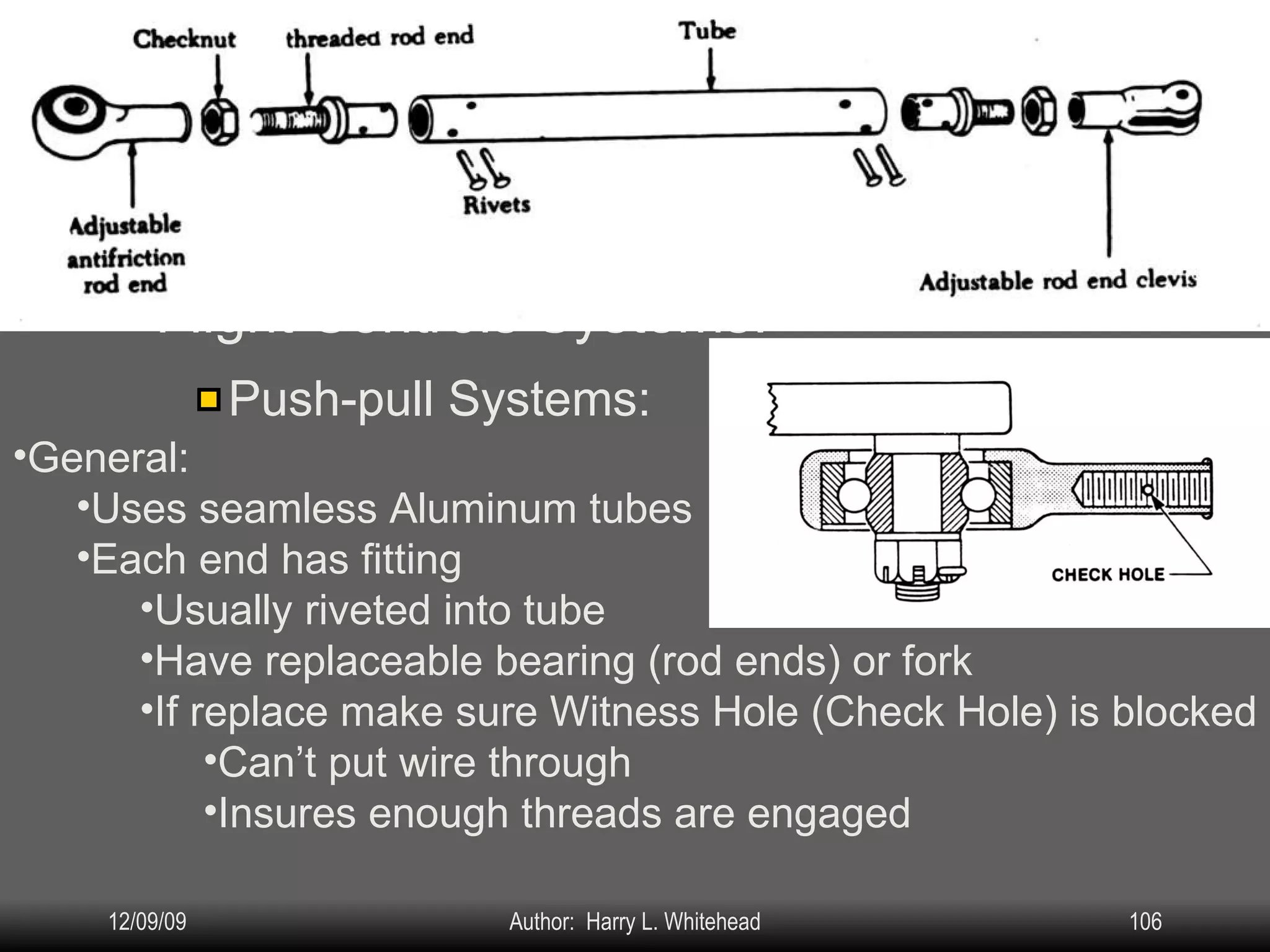

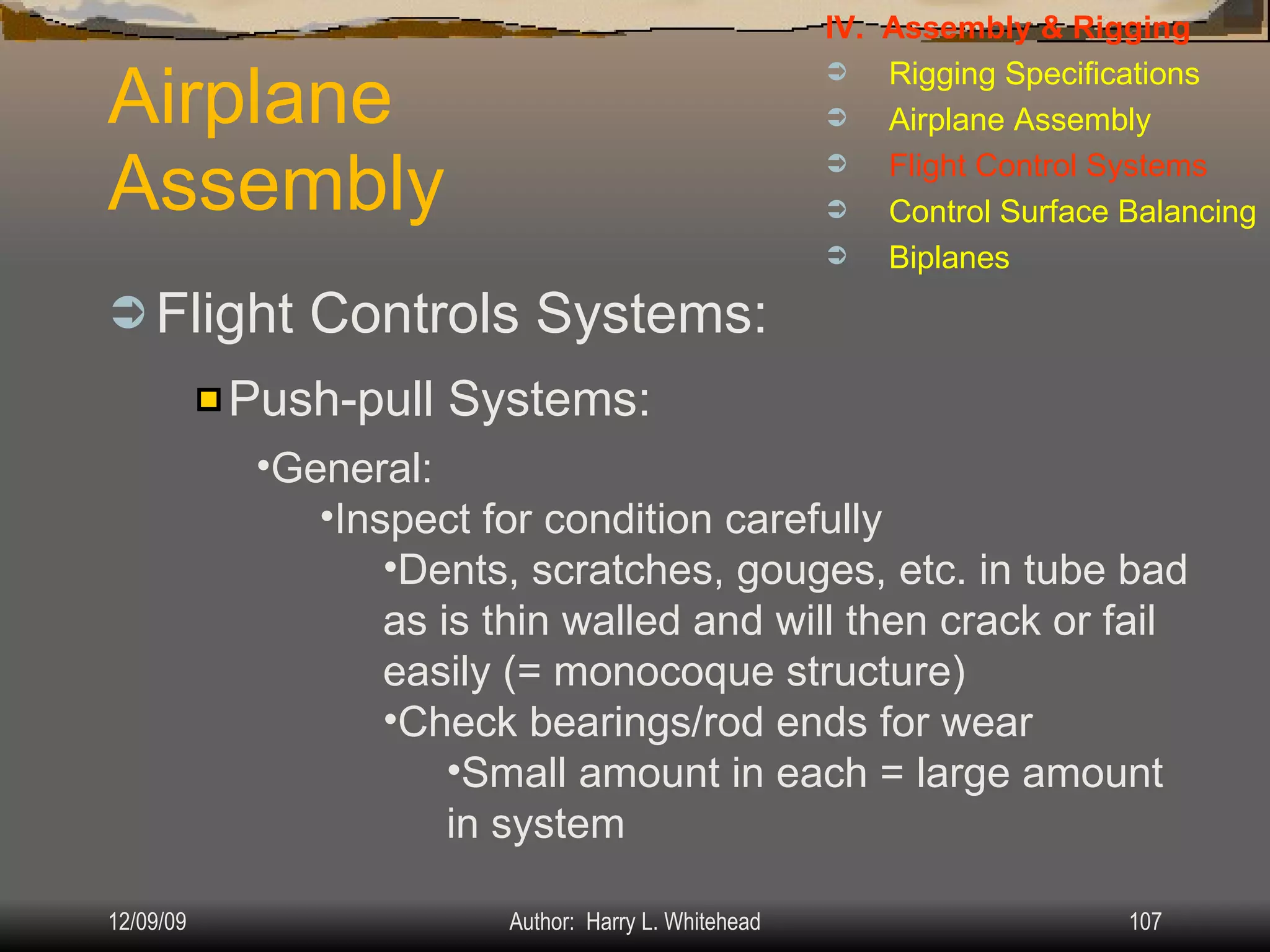

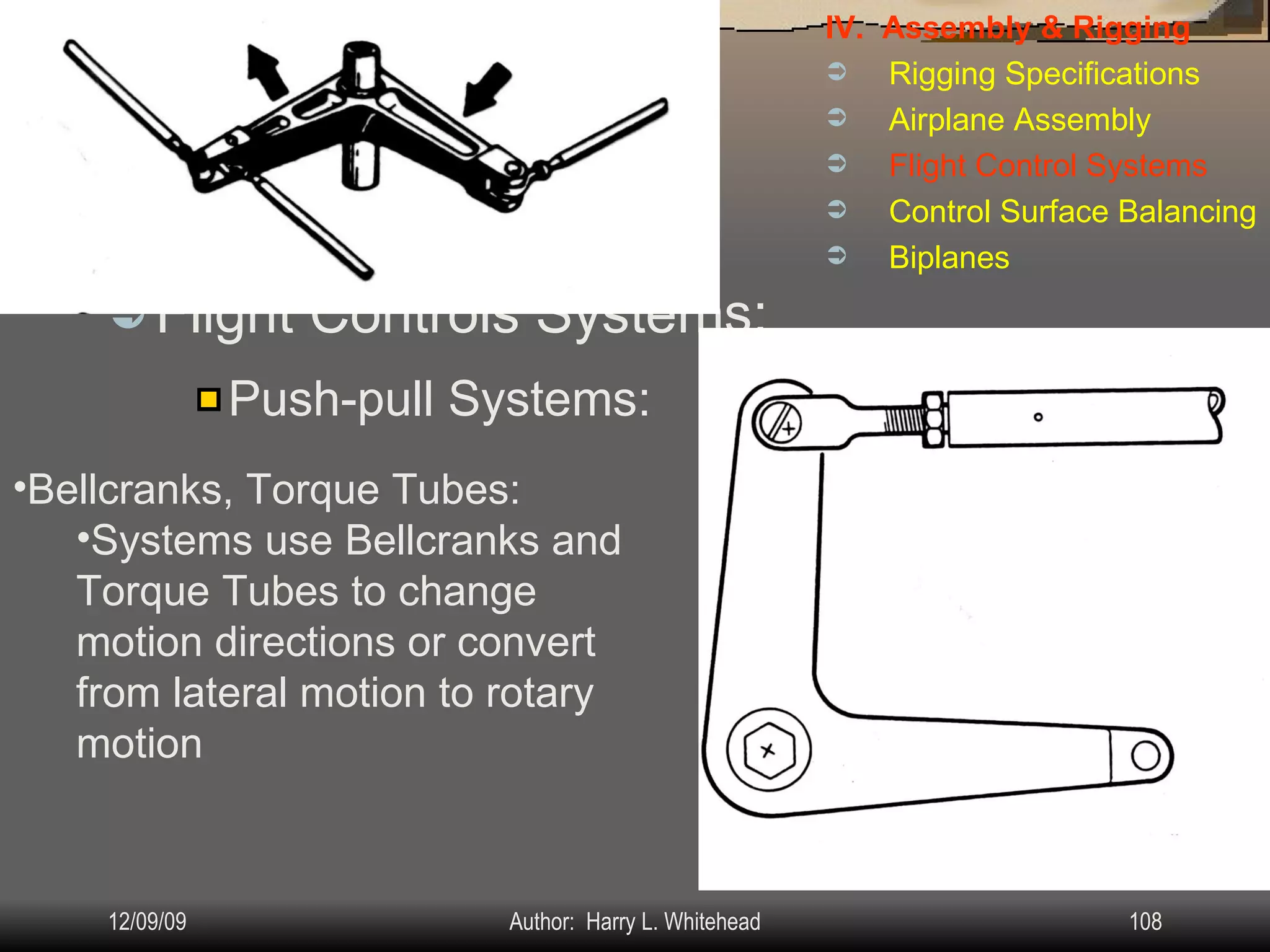

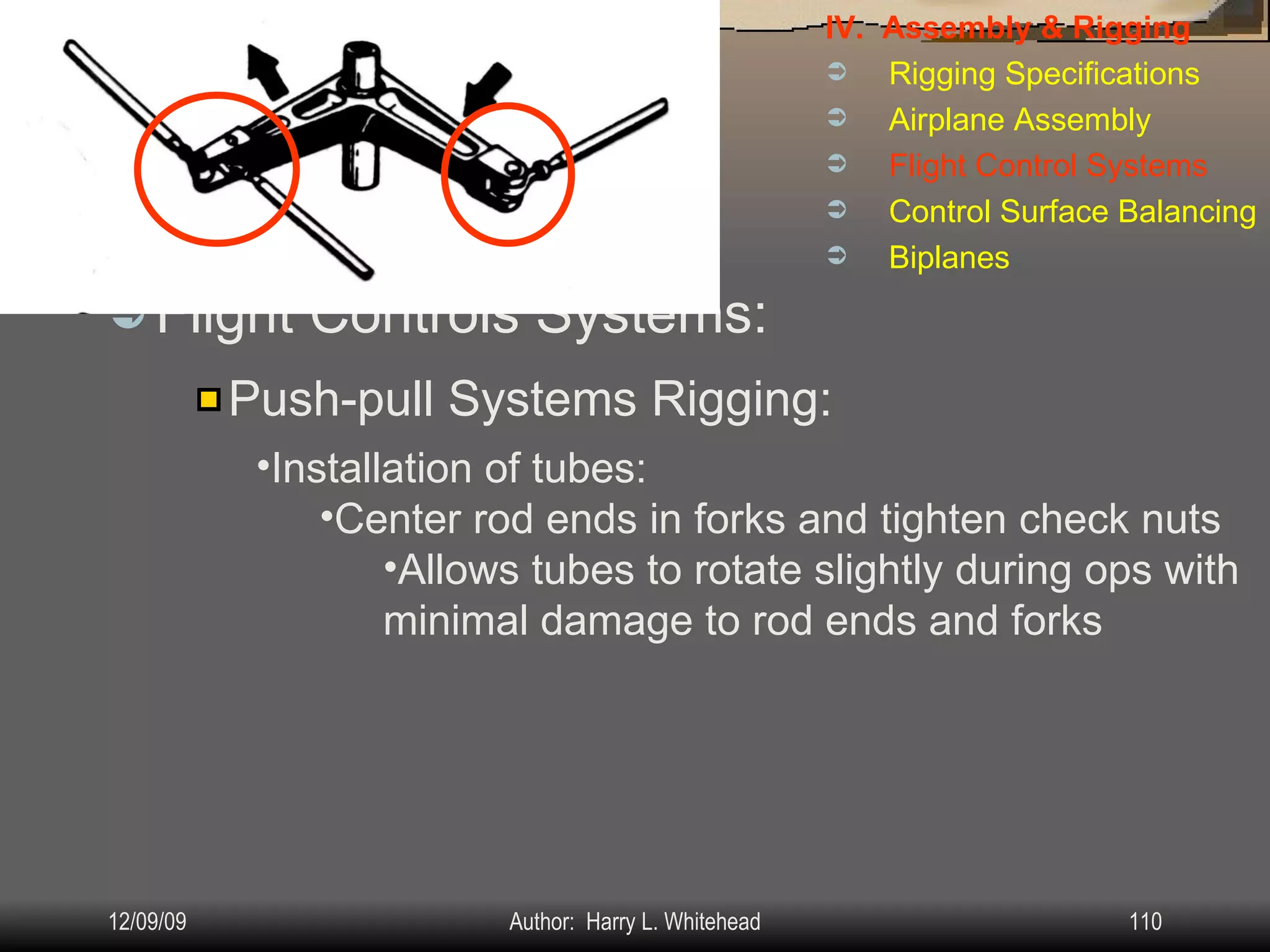

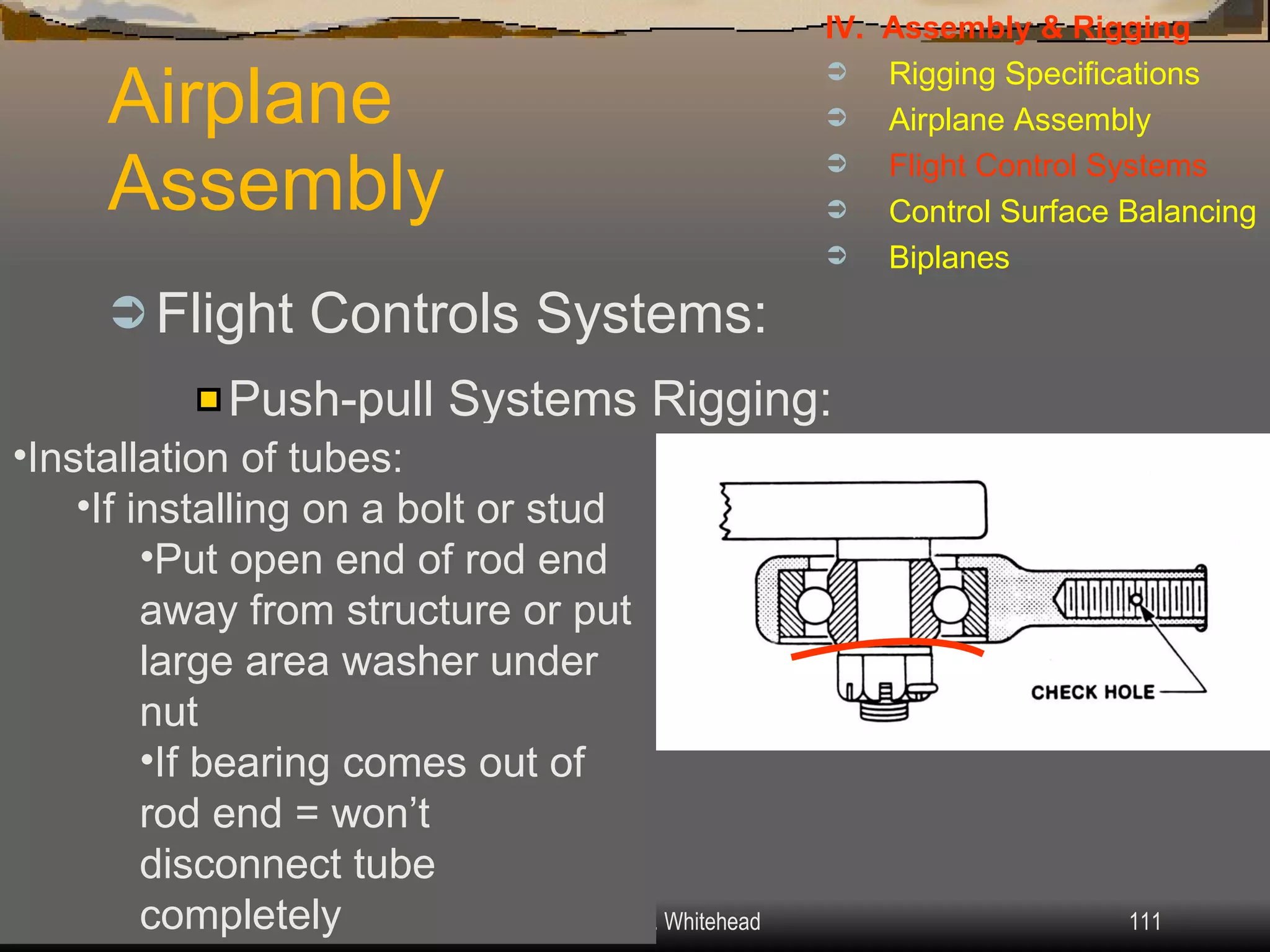

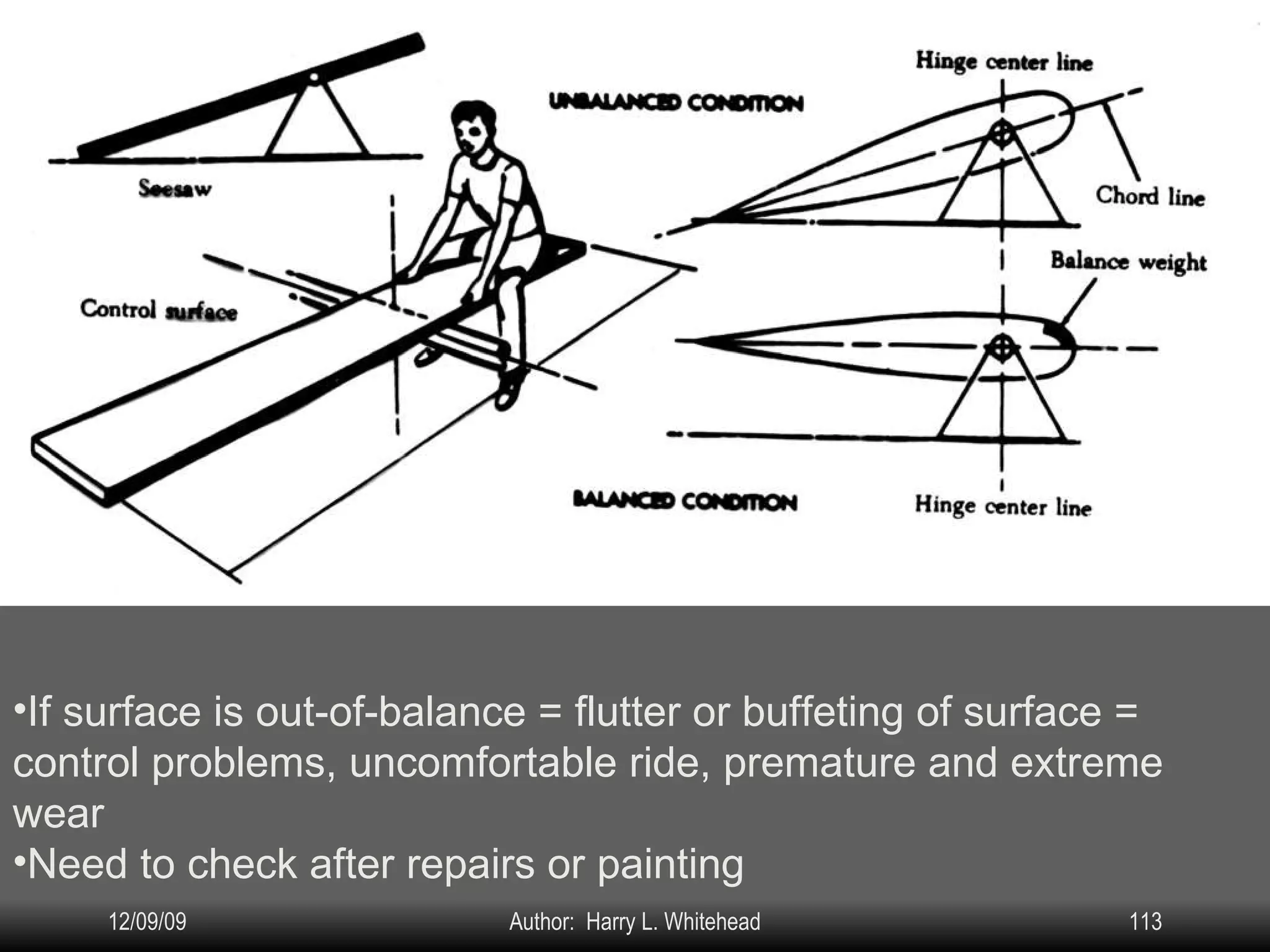

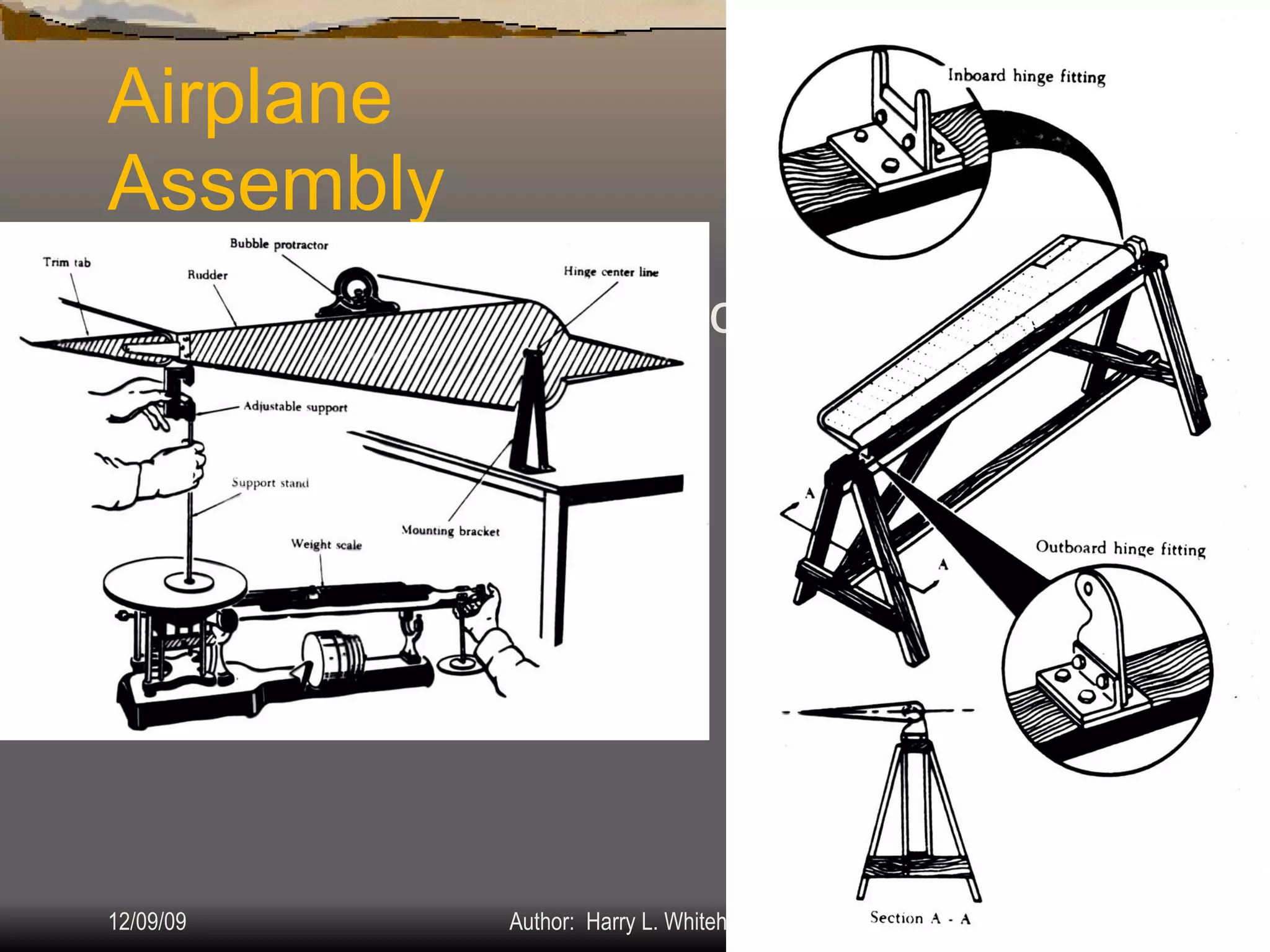

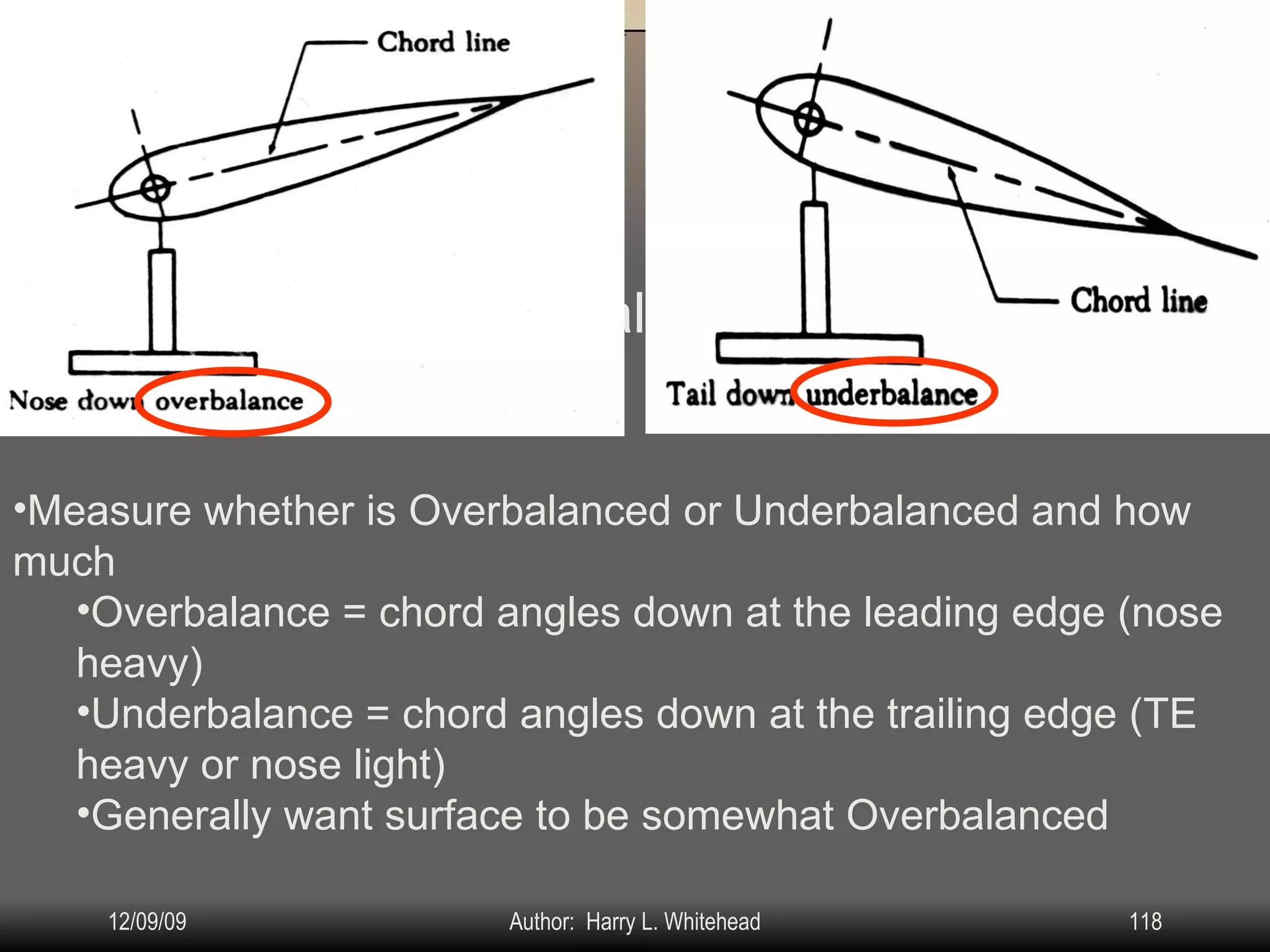

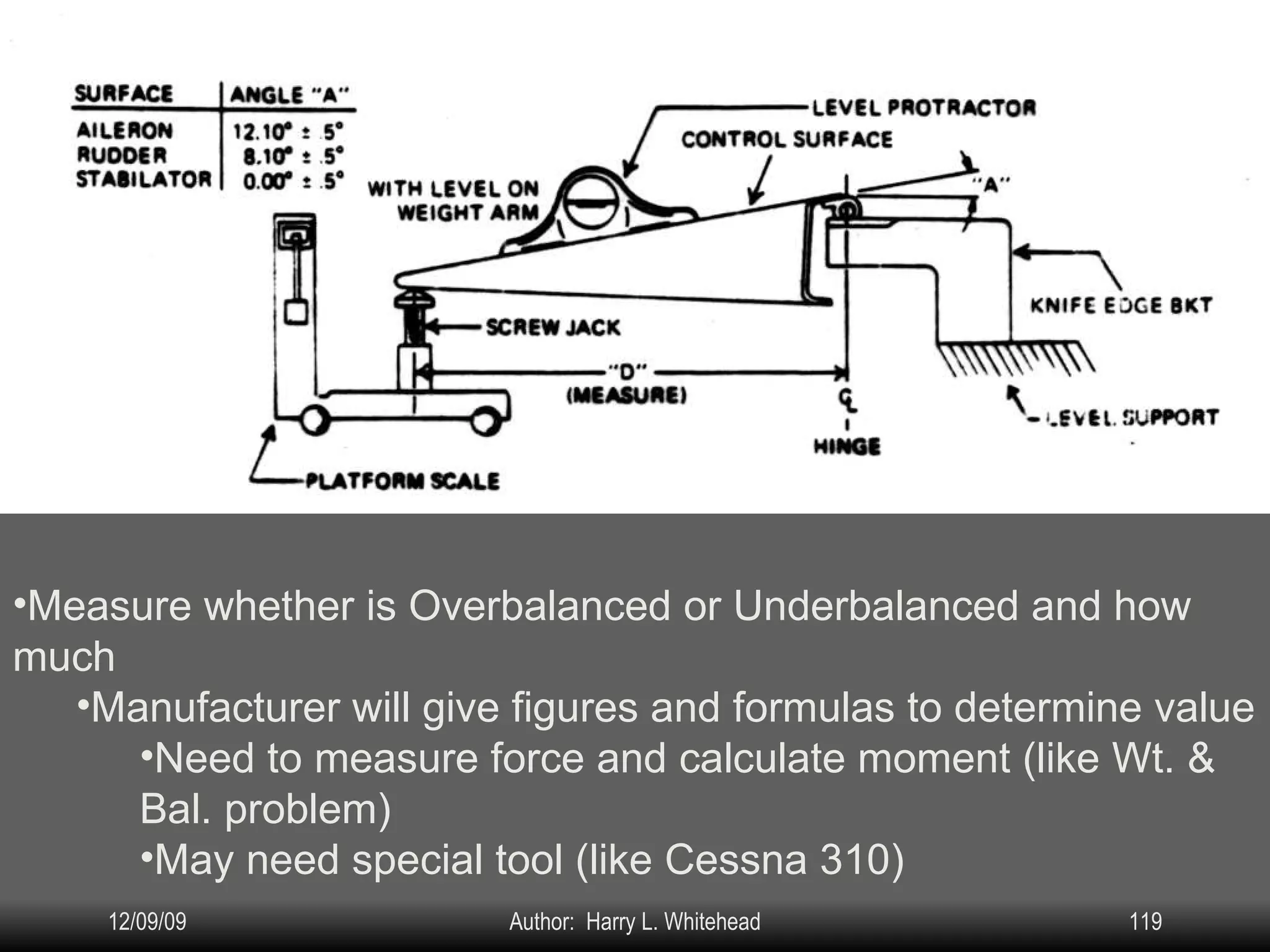

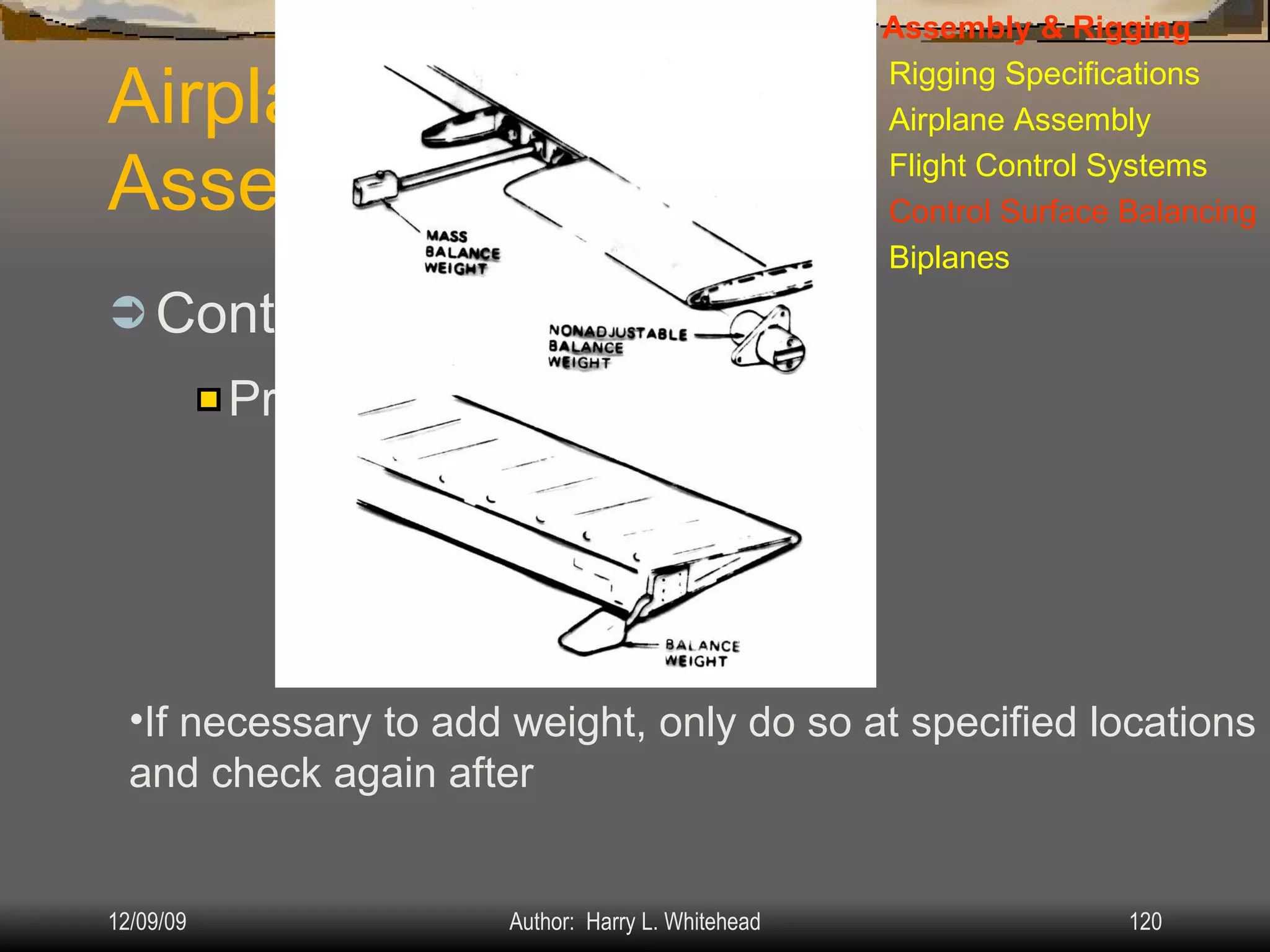

2) Installing and rigging the aileron, elevator, rudder and other flight control systems, including adjusting cable tension and travel to manufacturer standards.

3) Checking control surface movements and aircraft symmetry after assembly and making adjustments as needed.