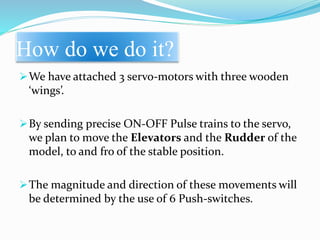

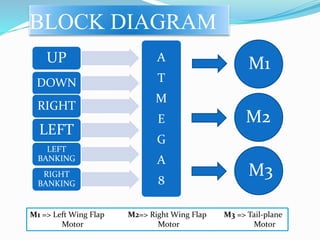

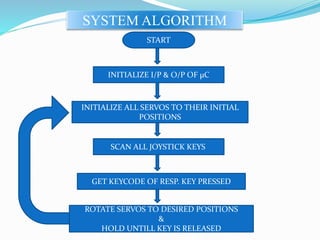

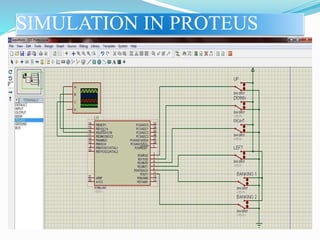

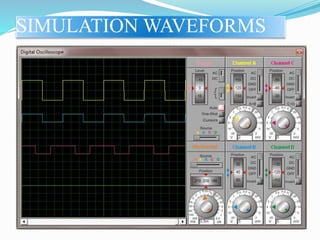

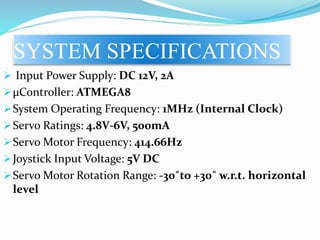

This document describes a student project to design and fabricate a fly-by-wire system for flight control using an ATmega8 microcontroller and three servo motors. The system takes input from pilot controls like the steering column and foot pedals and sends electronic signals to actuators controlling the flight surfaces. The students' prototype controls the yaw, pitch, and roll of a model aircraft using push switches and servo motors attached to wooden wings to simulate flight control surfaces like elevators and rudders. Simulation and testing confirmed the system could control the servos to rotate between -30 and +30 degrees based on input signals.