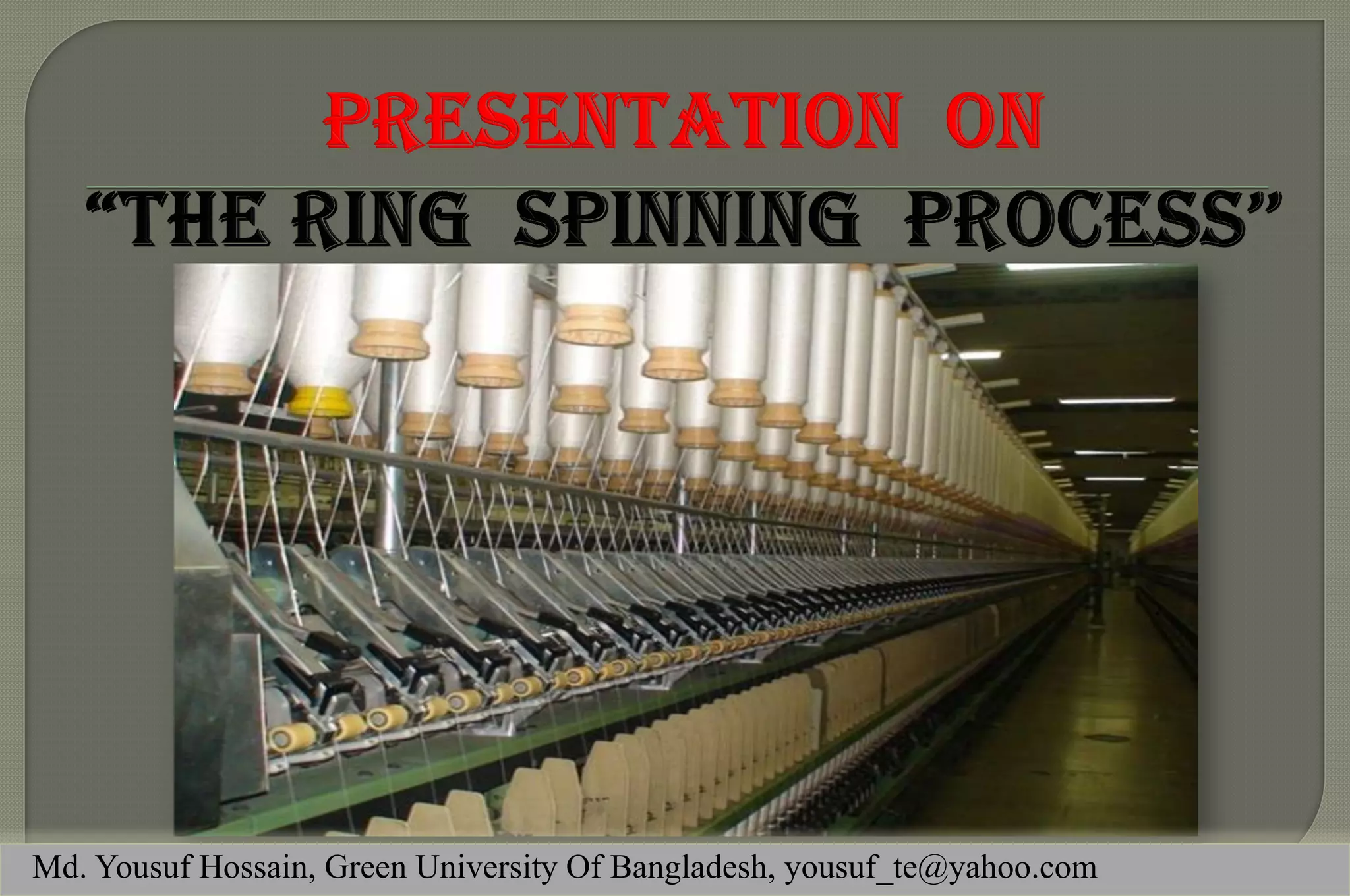

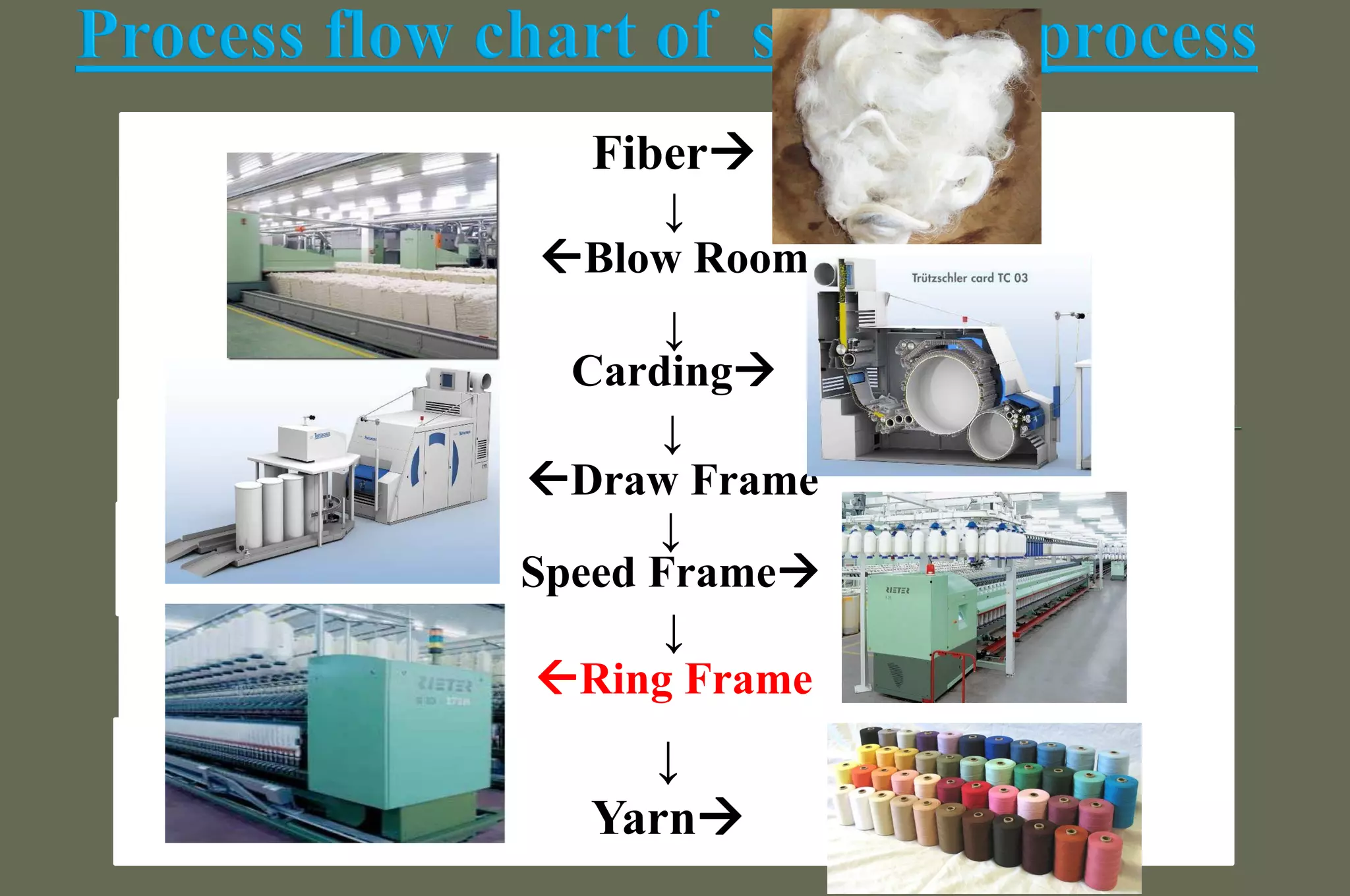

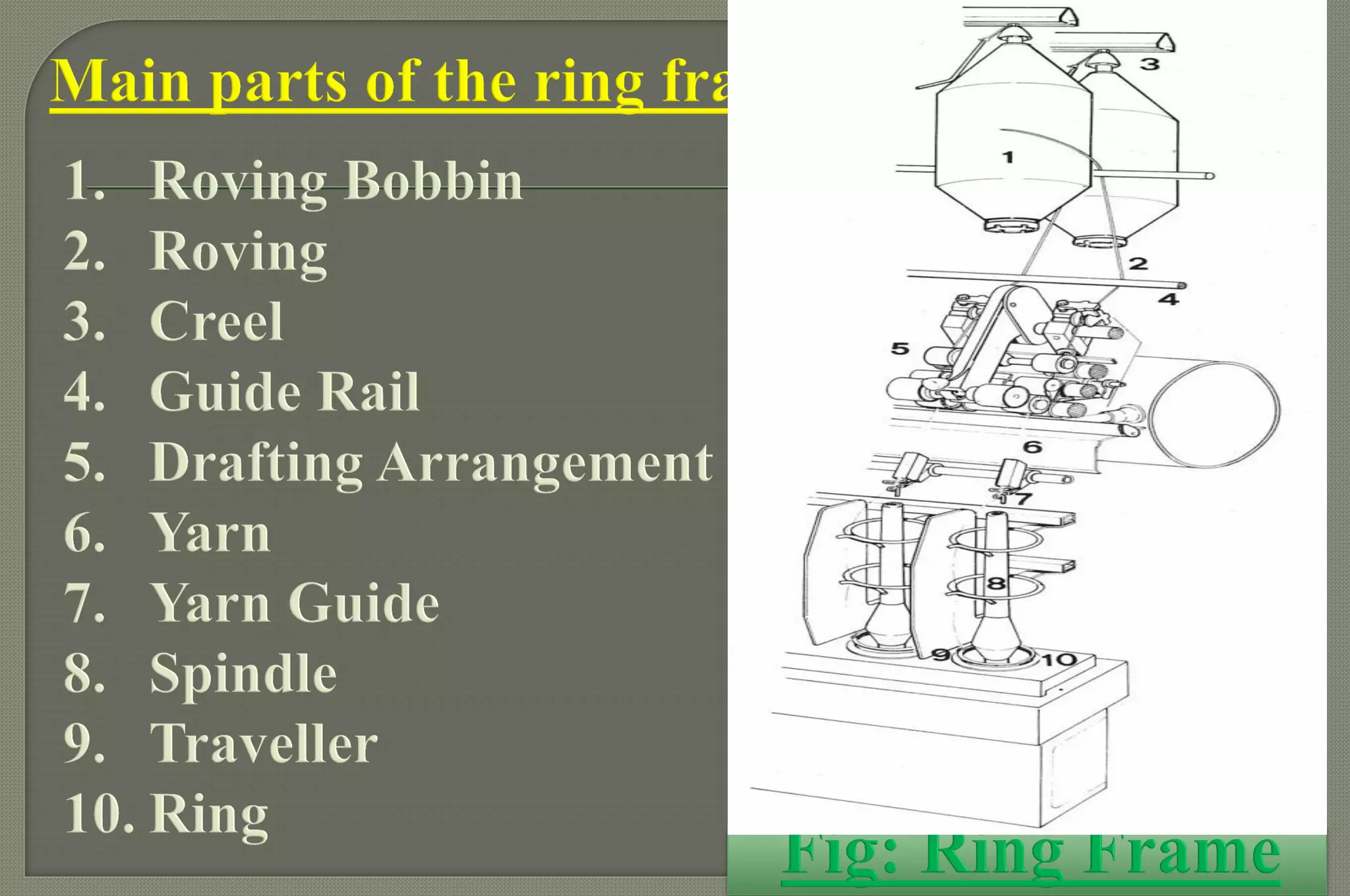

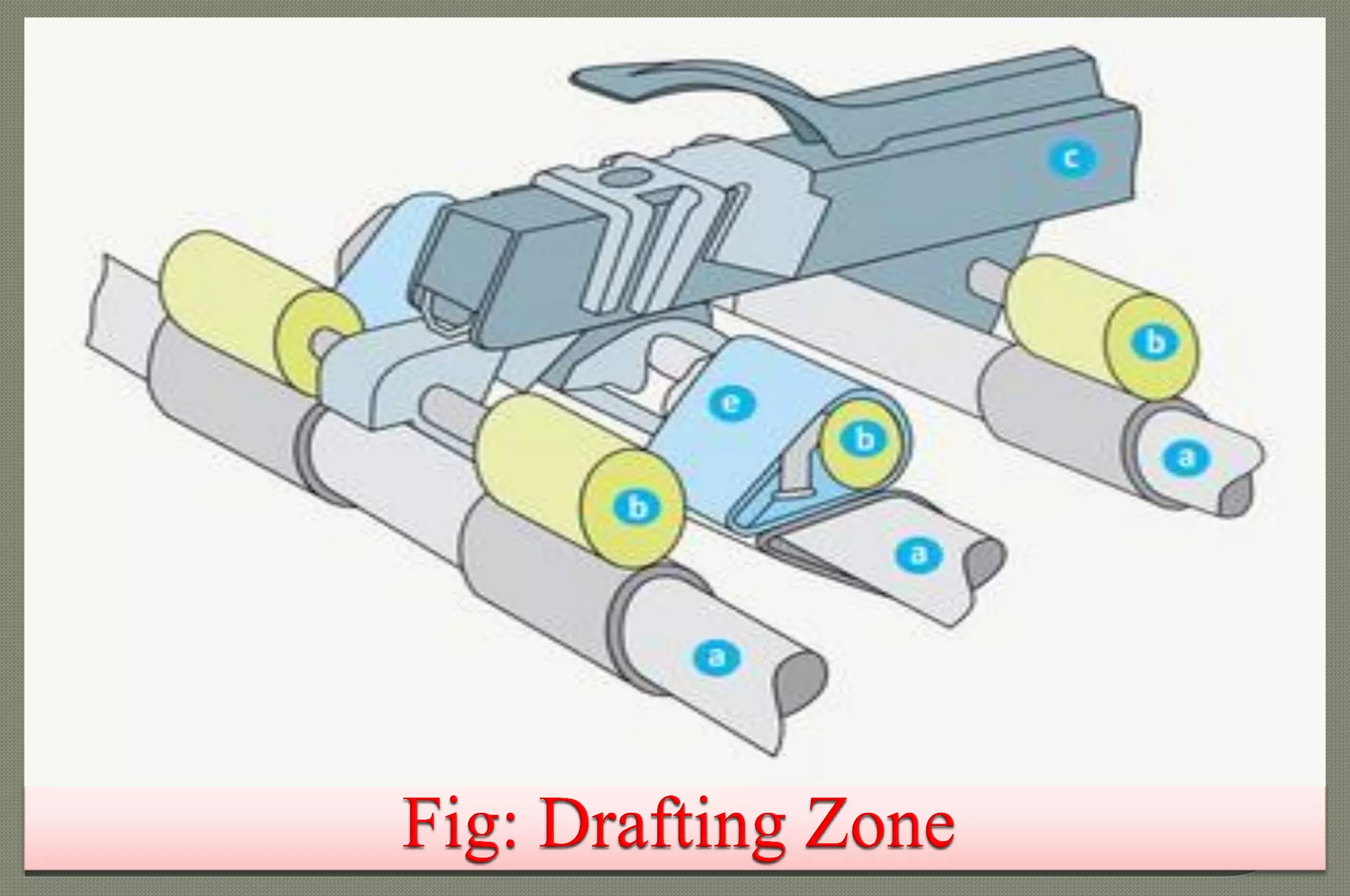

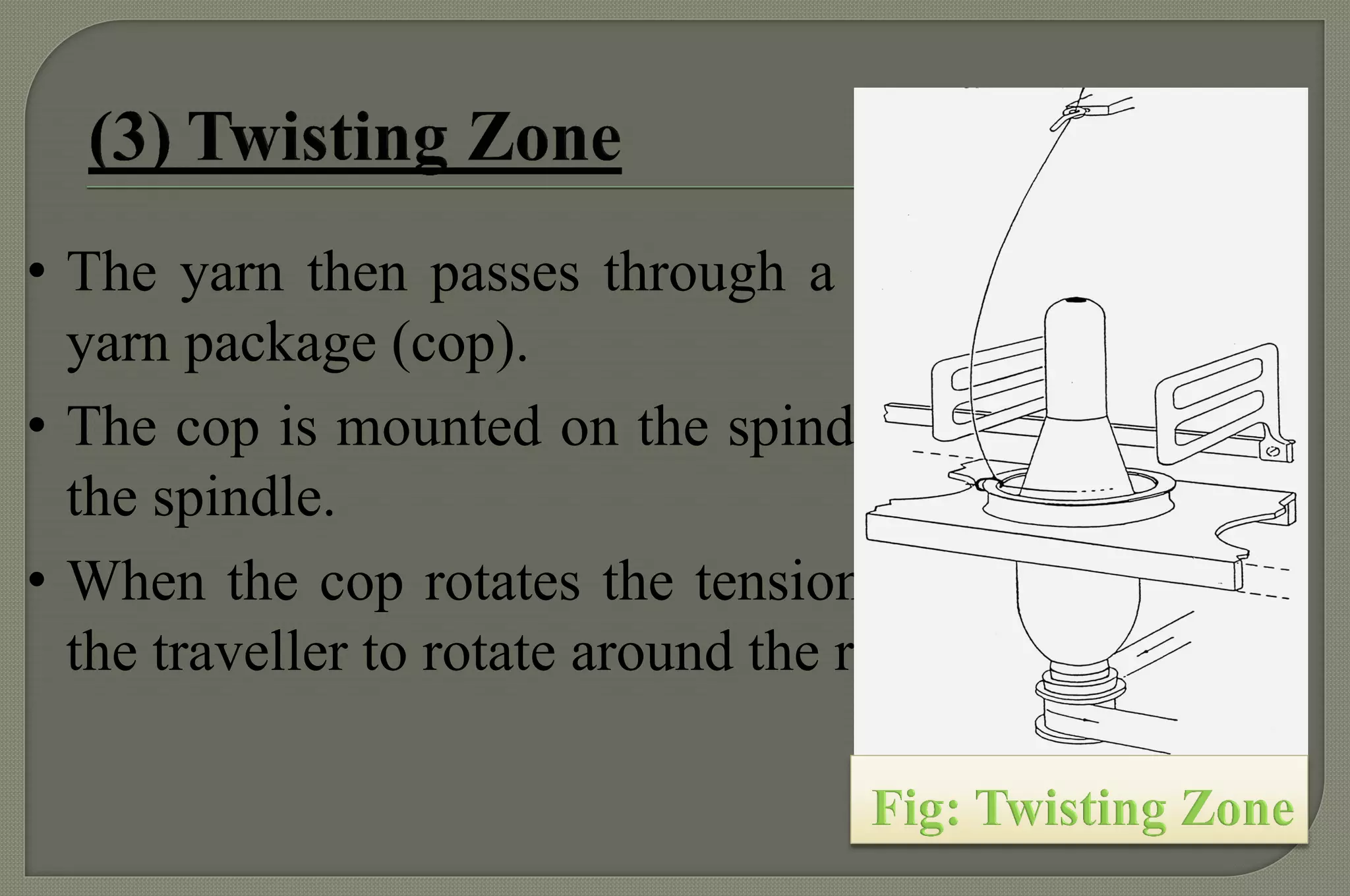

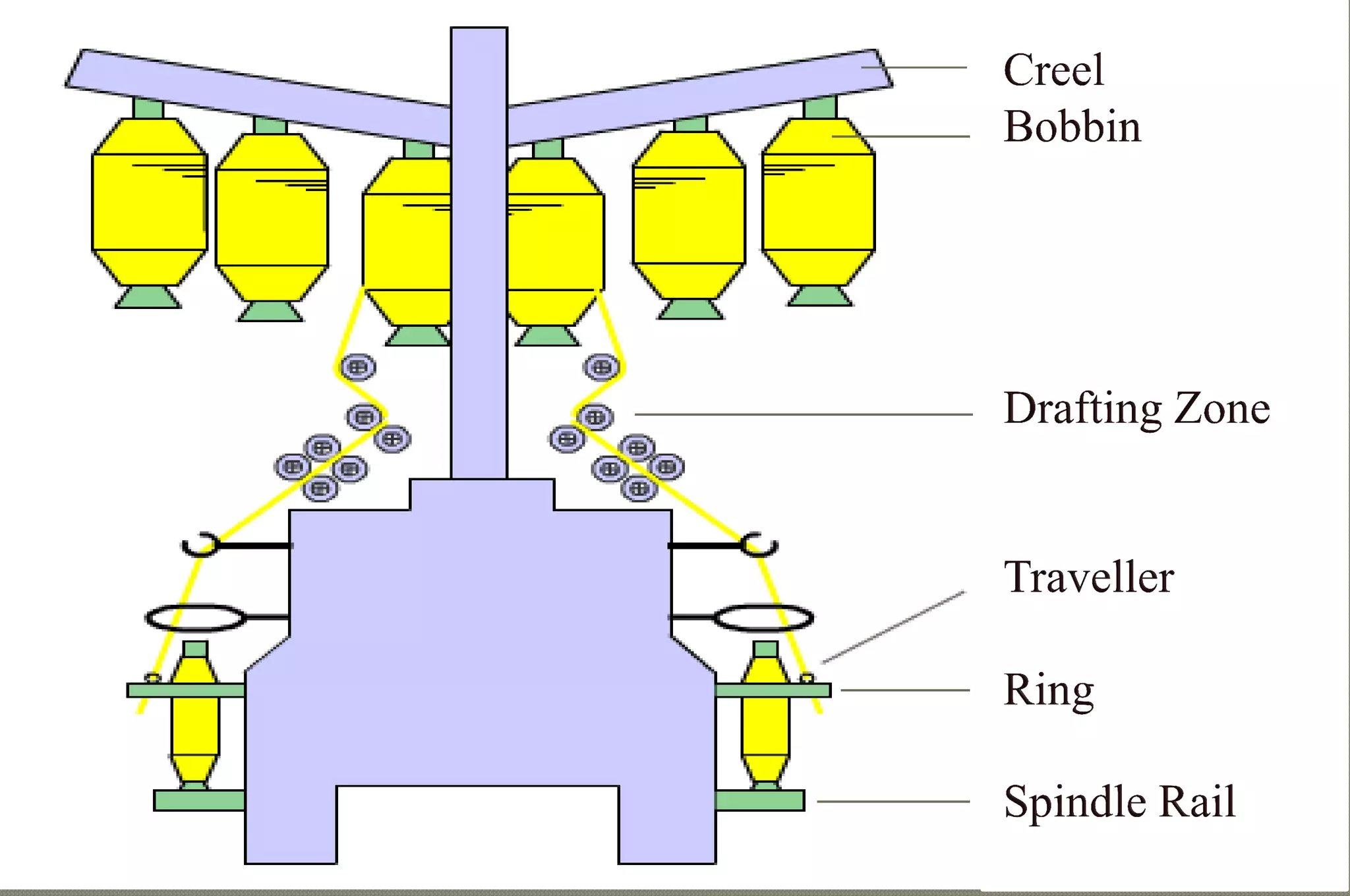

This document presents information about ring spinning. Md. Yousuf Hossain from Green University of Bangladesh introduces the topic and defines key terms like fiber, spinning and yarn. It then describes the ring spinning process which involves blow room, carding, draw frame and speed frame before the roving reaches the ring frame. Here, it is drafted and twisted to produce yarn, which is then wound onto bobbins. The document focuses on the drafting zone of the ring frame and explains how higher drafts are applied. It also provides details about how the yarn travels through the traveller and onto the cop during winding. In closing, advantages and limitations of ring spinning are mentioned.