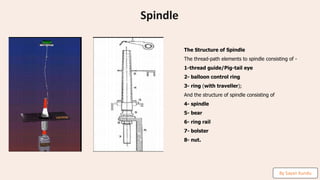

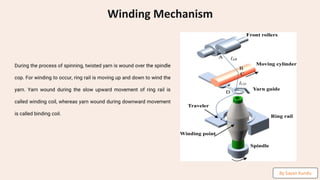

The ring frame, also known as the ring spinning machine, is the most widely used and essential machine in the textile industry for the final stage of yarn manufacturing, where the roving delivered from the speed frame is transformed into fine, strong, and high-quality yarn by the processes of drafting, twisting, and winding, all executed simultaneously in a continuous and highly controlled manner. This machine is considered the heart of the spinning section due to its critical role in determining the final yarn's properties, such as strength, uniformity, elongation, hairiness, and overall spinnability, which in turn influence the quality and performance of the finished fabric. The ring spinning process begins by feeding the roving from bobbins placed in the creel, which passes through a drafting system made up of three or four pairs of rollers, each set rotating at progressively higher speeds, thereby attenuating the thick roving into a finer strand. This drafted fibre strand, still relatively weak, is given the necessary strength and structure by the insertion of twist using a traveller-and-ring mechanism, wherein the spindle rotates at high speed and the traveller, which is a small metal clip, moves around a stationary ring, imparting twist to the yarn as it is simultaneously wound onto a bobbin. The high spindle speeds—often ranging from 15,000 to 25,000 revolutions per minute—allow for the production of a continuous yarn with a well-defined twist that ensures strength and cohesion of fibres, making ring spinning the most reliable method for producing yarns of fine to medium counts used in various applications like apparel, home textiles, and industrial fabrics. The balance between twist and draft, along with the accurate winding of yarn on the bobbin, is crucial, as any inconsistency can lead to defects such as thick and thin places, neps, or excessive hairiness, which affect downstream processes like weaving, knitting, dyeing, and finishing. The quality of the yarn produced is highly influenced by parameters such as twist per inch (TPI), spindle speed, traveller weight, break draft, draft ratio, tension control, and roller settings. Modern ring frames, manufactured by companies like Rieter, LMW, Zinser, and Toyota, are sophisticated, high-speed machines that incorporate automation, sensor-based monitoring, and electronic control systems to maintain consistent yarn quality and operational efficiency. Features such as auto doffing (automatic removal and replacement of bobbins), yarn break sensors, auto-piecing (automatic joining of broken ends), centralized lubrication, and real-time production monitoring systems have significantly enhanced the productivity and ease of operation of ring frames while reducing labour dependency. Additionally, energy-efficient motors, inverter drives, and ergonomic machine designs have contributed to sustainability and operator comfort in modern spinning mills. Despite advancements in alternative spinning method