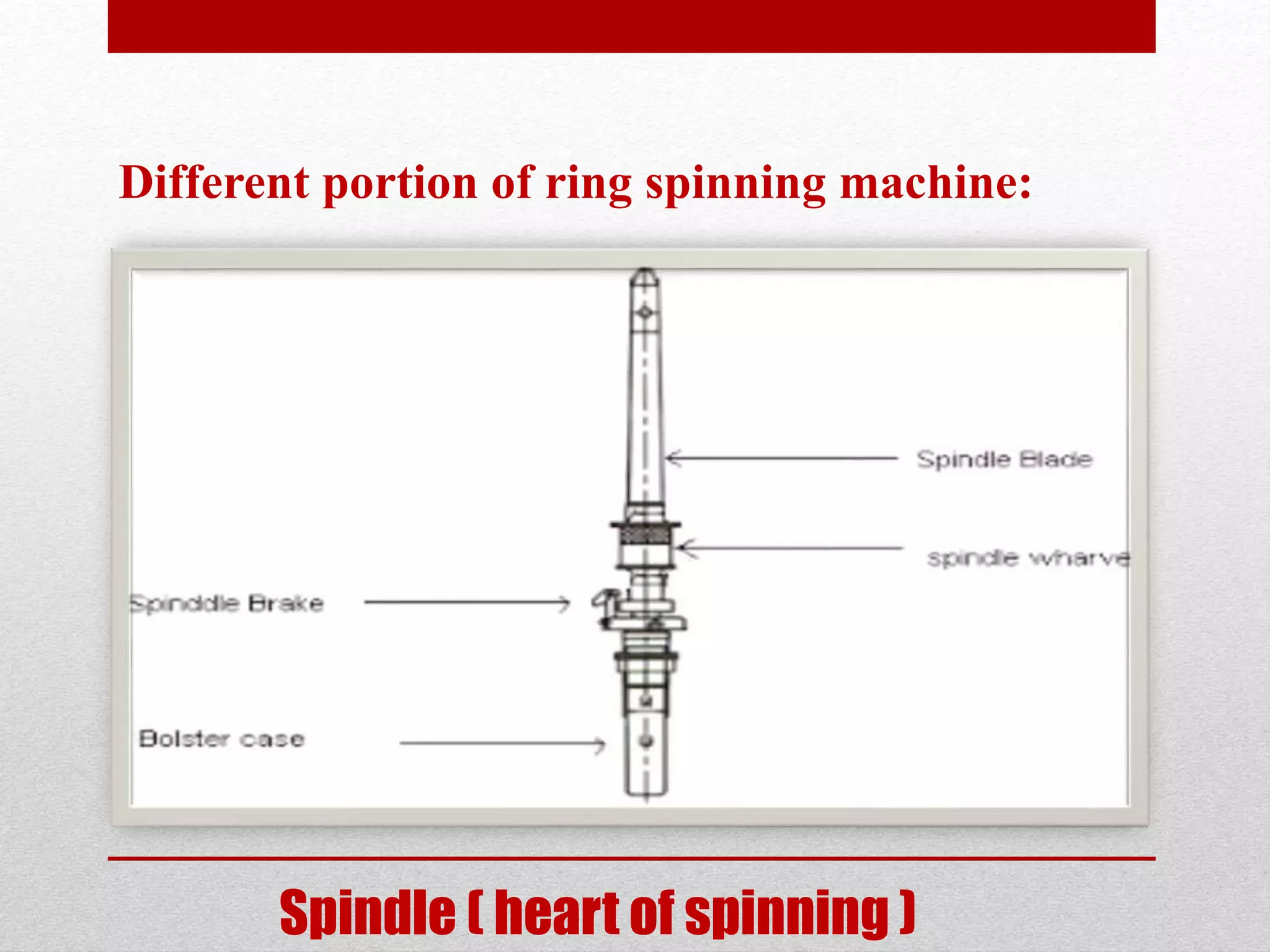

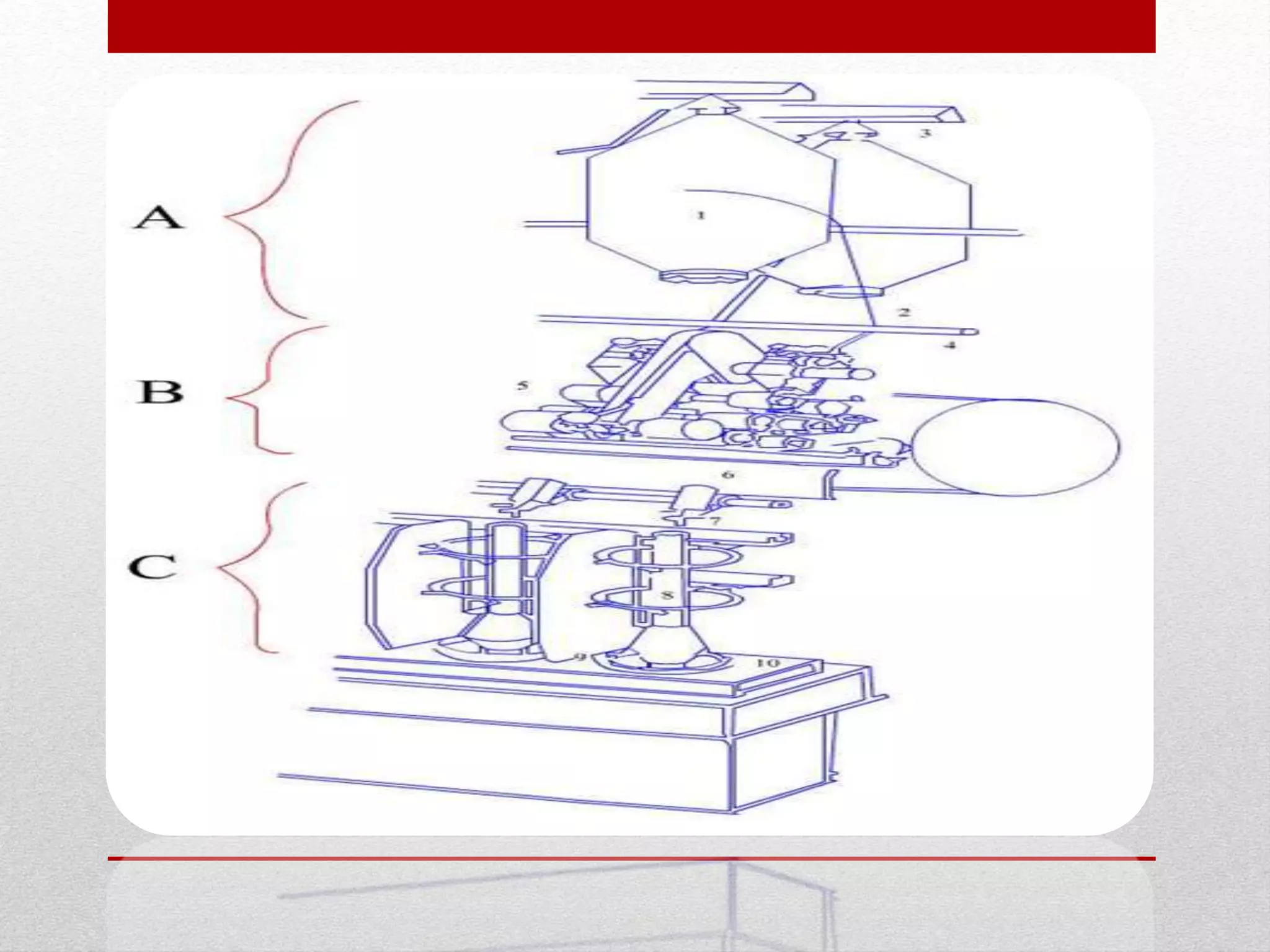

Ring spinning machines are the most commonly used spinning machines in the world. They consist of a spindle that twists the yarn and a ring and traveler that maintain tension. The key operations are creeling, drafting, twisting, winding, and doffing. Drafting draws out the fiber through three rollers. As the traveler circles the ring at high speeds, it picks up fibers from the front roller and twists them onto the spindle. Ring spinning can produce fine to coarse yarns from 5-1000 tex with good strength suitable for many applications. However, it has limitations such as low production rates and frequent doffing requirements.