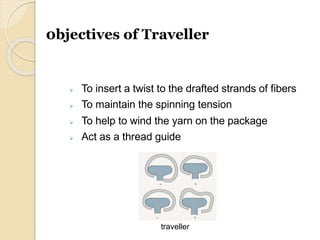

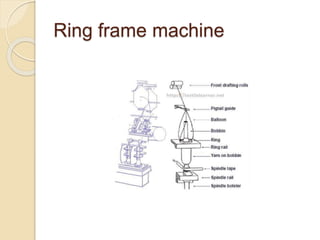

Ring spinning is the most widely used spinning method for producing yarn from fibers like cotton, flax, and wool. It was invented in 1828 and improved through the late 19th century. The key components of a ring spinning machine are the creel, drafting system, traveler, ring, spindle, and winder. It drafts roving into yarn, imparts twist using the traveler moving around the ring, and winds the yarn onto bobbins. Common yarn counts produced are 5-200 Ne. While versatile, it has limitations like low speed, production, and bobbin size compared to newer methods.