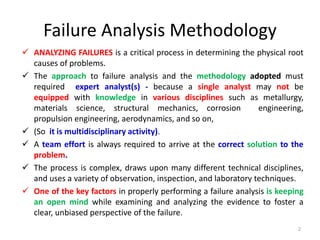

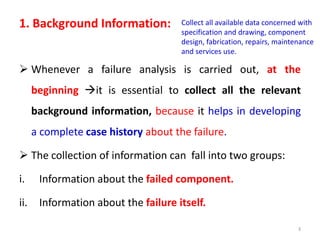

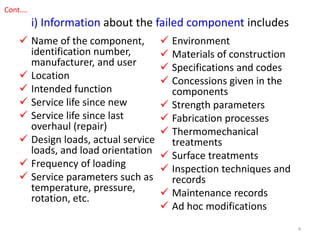

This document provides an overview of the methodology for conducting failure analysis of materials and components. It discusses collecting background information on the failed component and failure details. Key steps in the process include examining the failure site, documenting locations, collecting specimen samples, performing laboratory tests, analyzing test data, and preparing a report detailing the root cause failure mechanism. The methodology is a multidisciplinary approach requiring expertise across various engineering domains to properly analyze failures and prevent future occurrences.