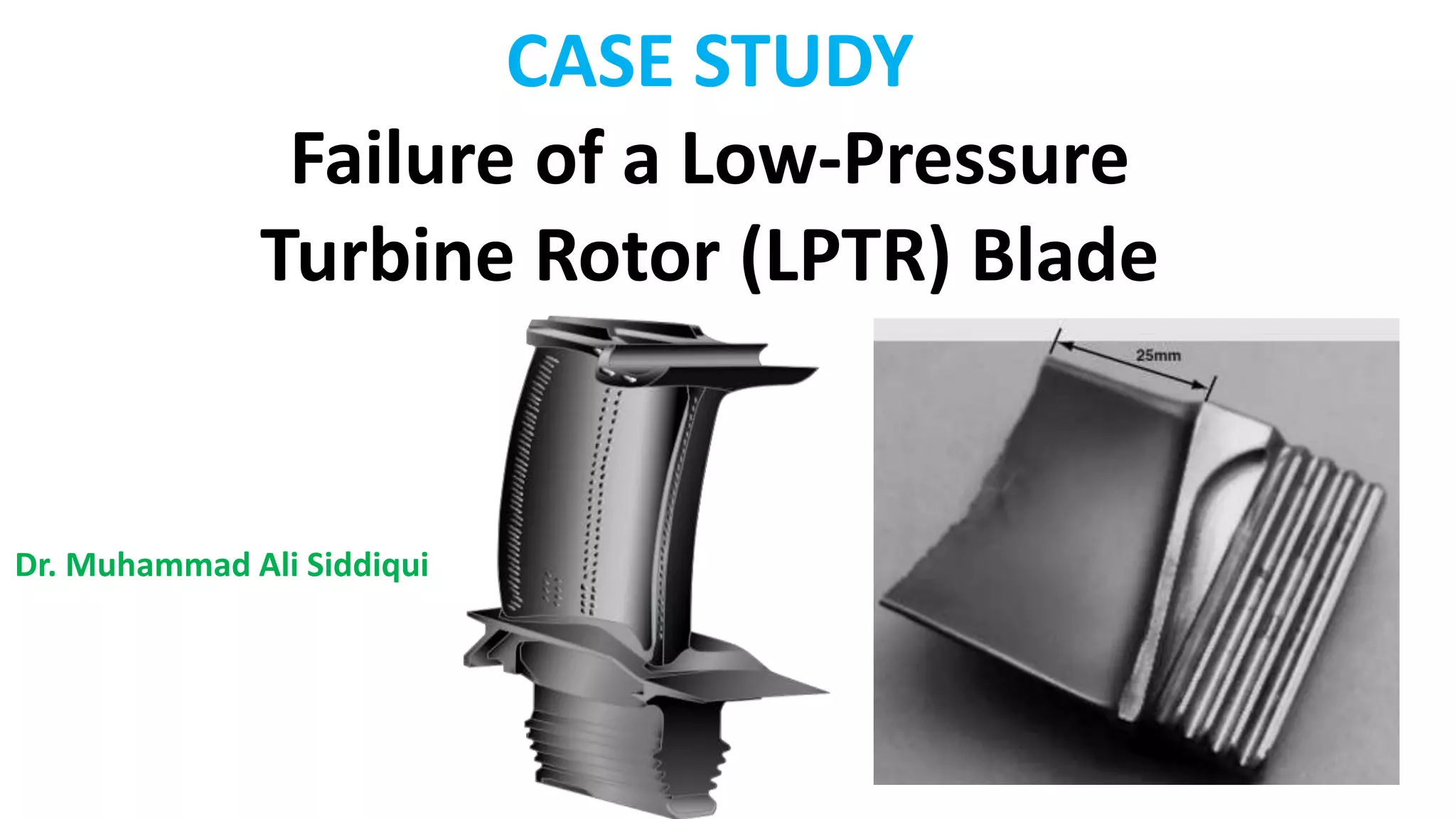

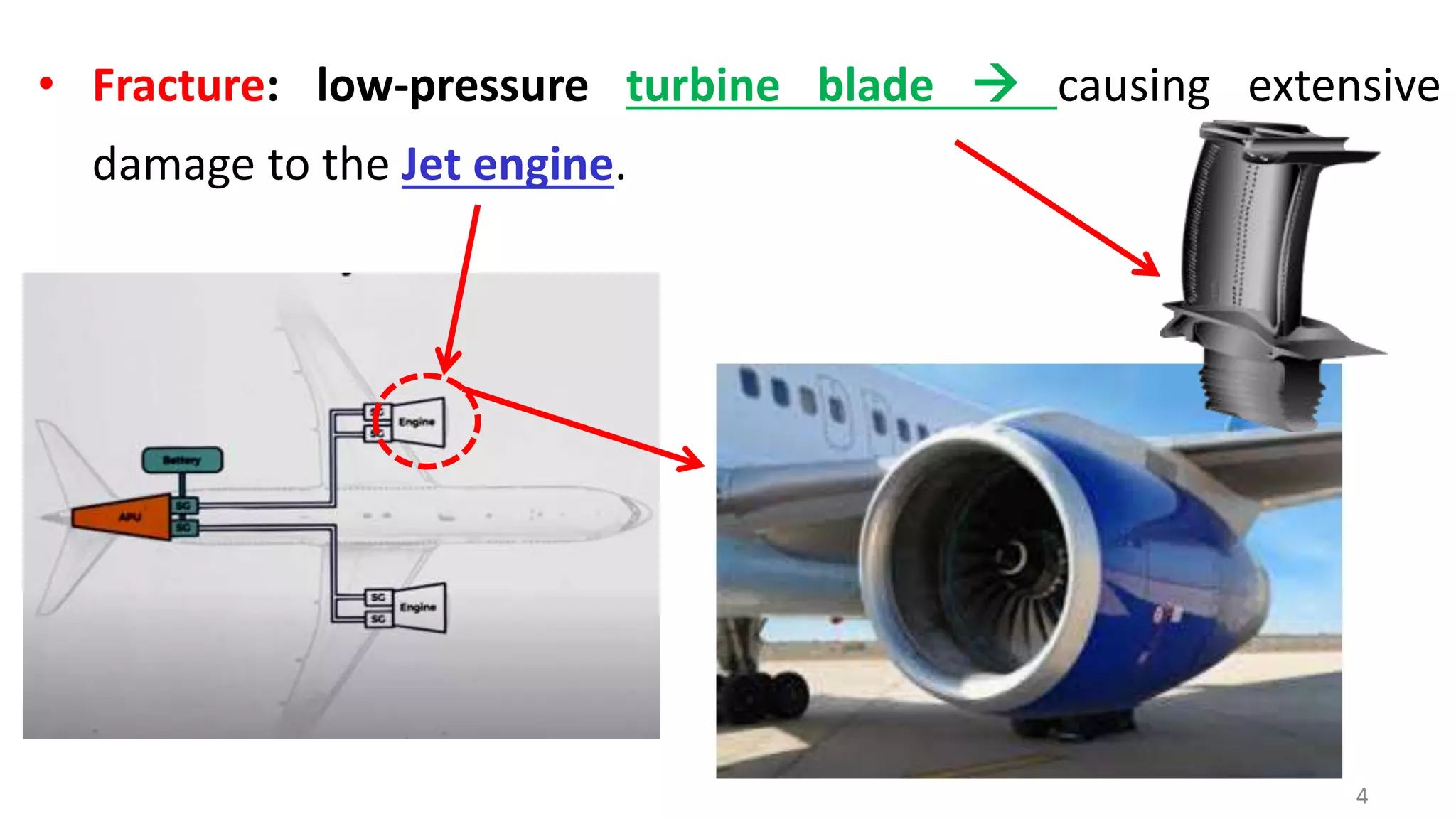

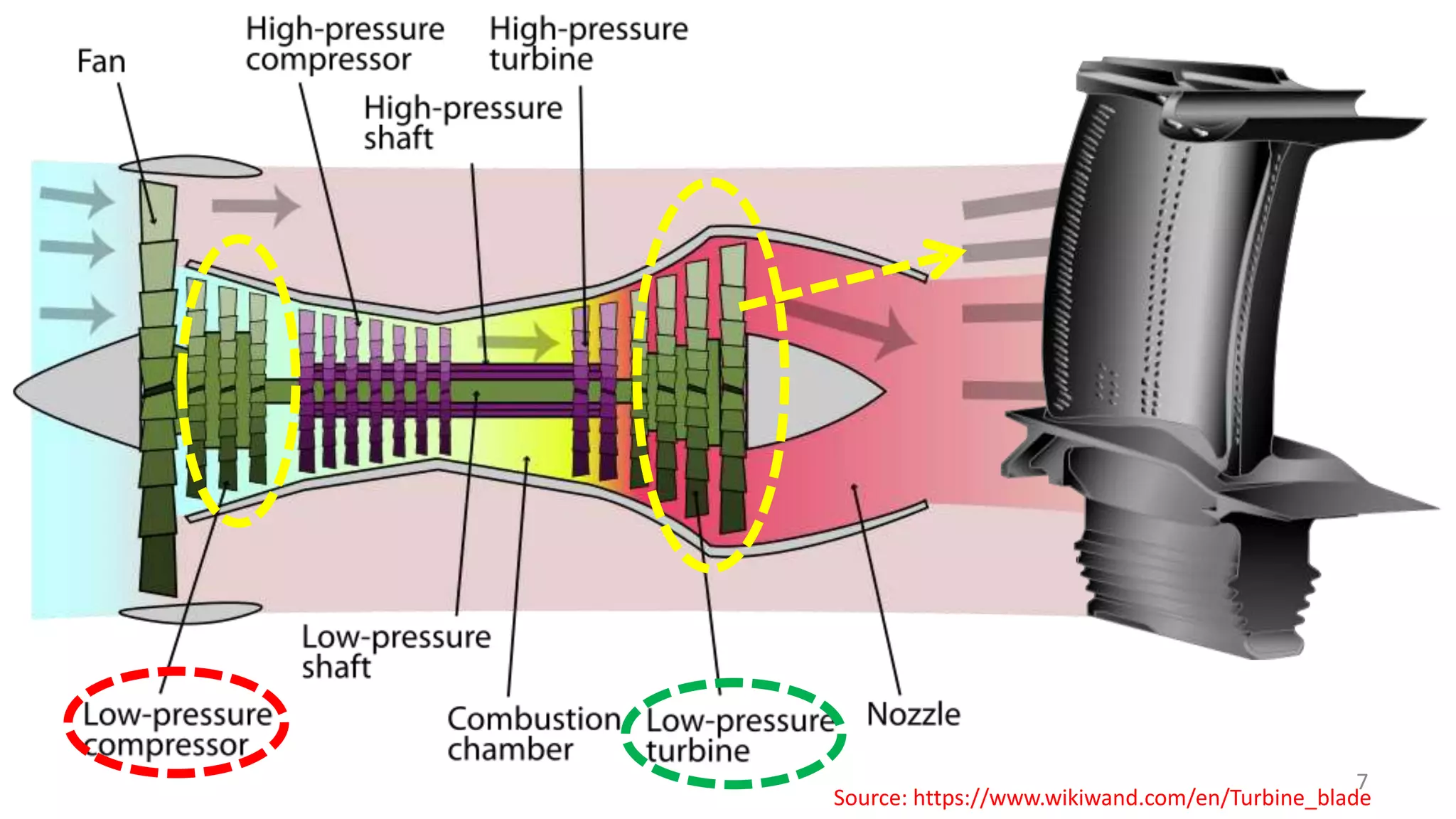

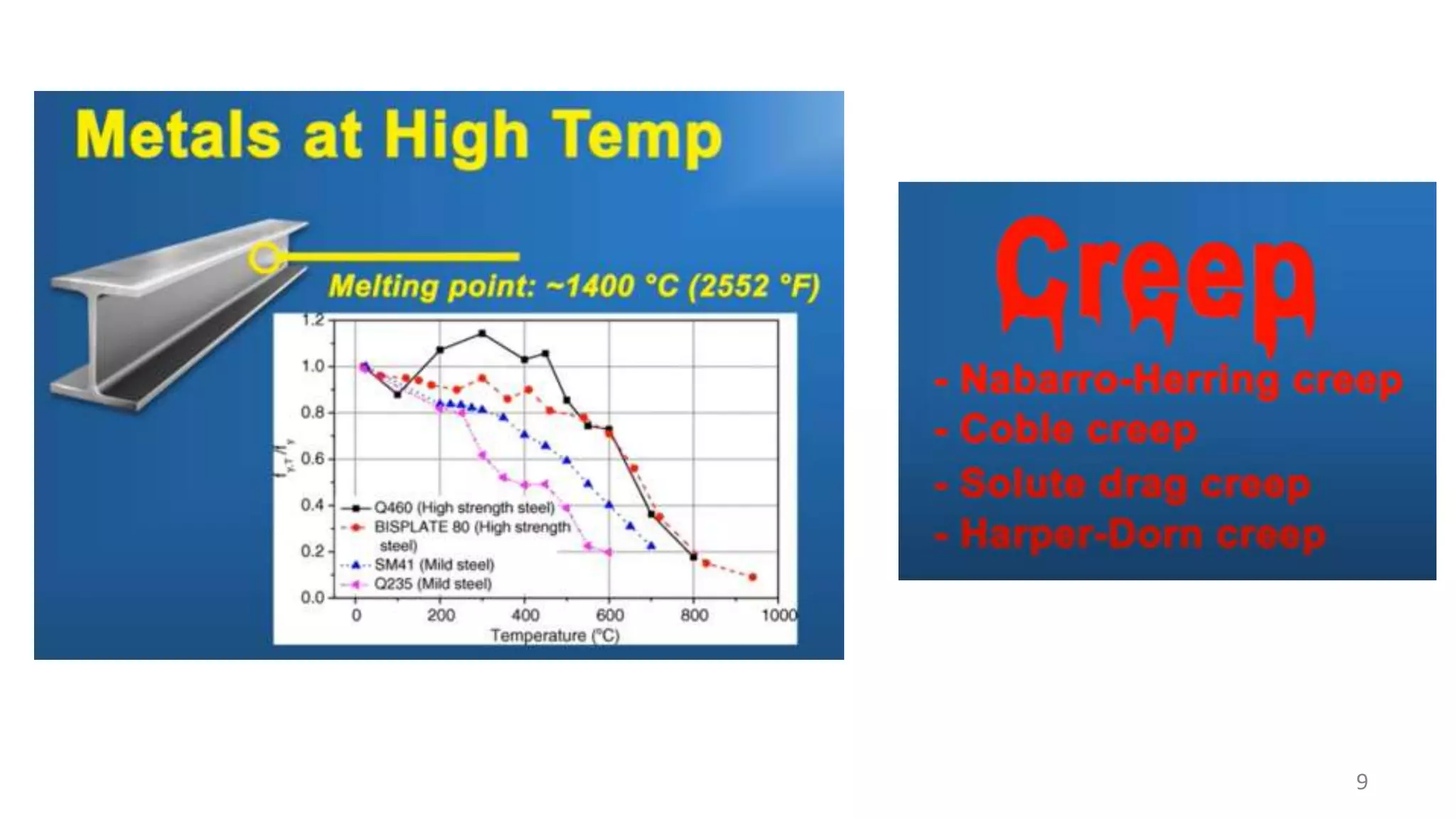

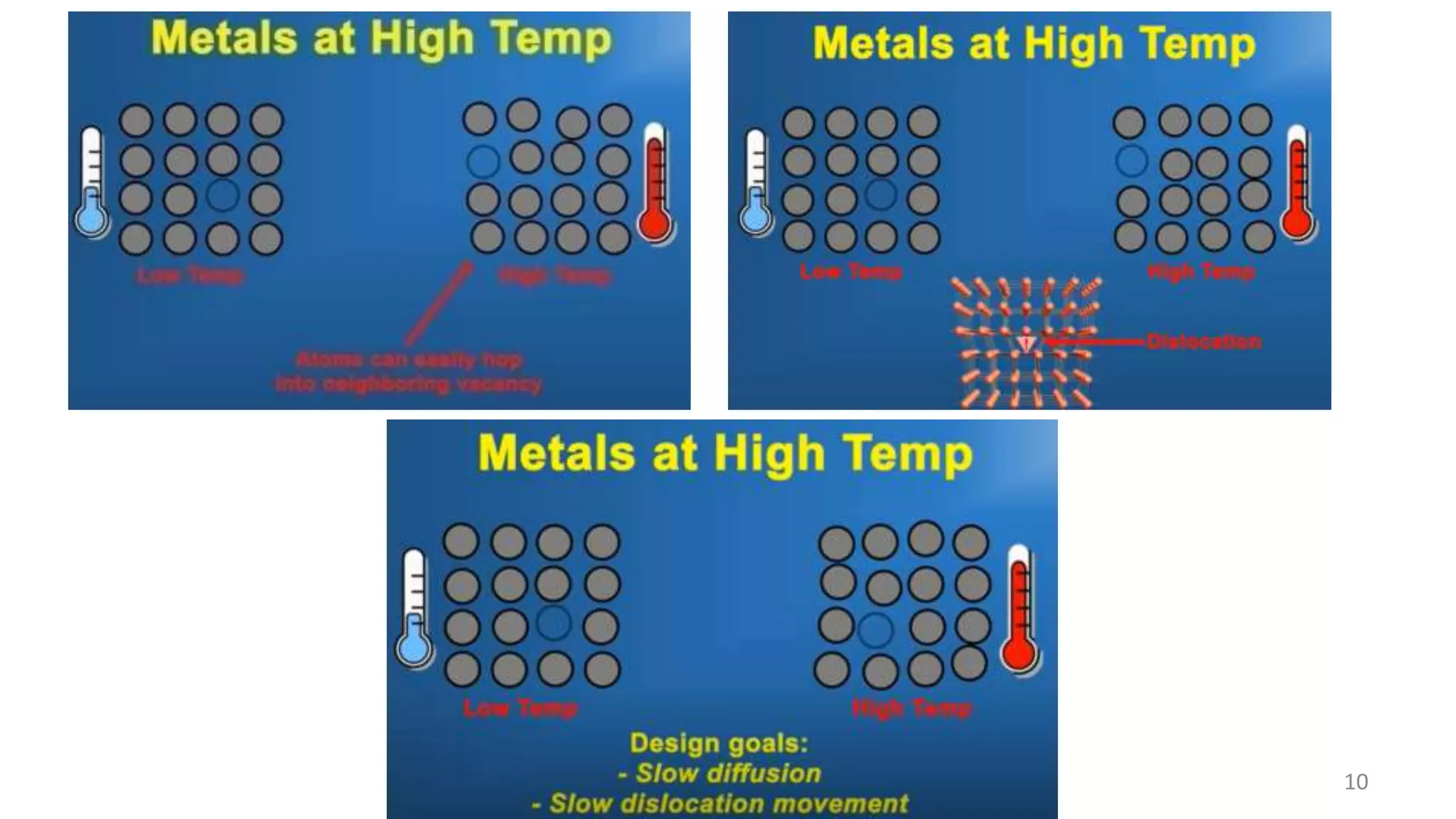

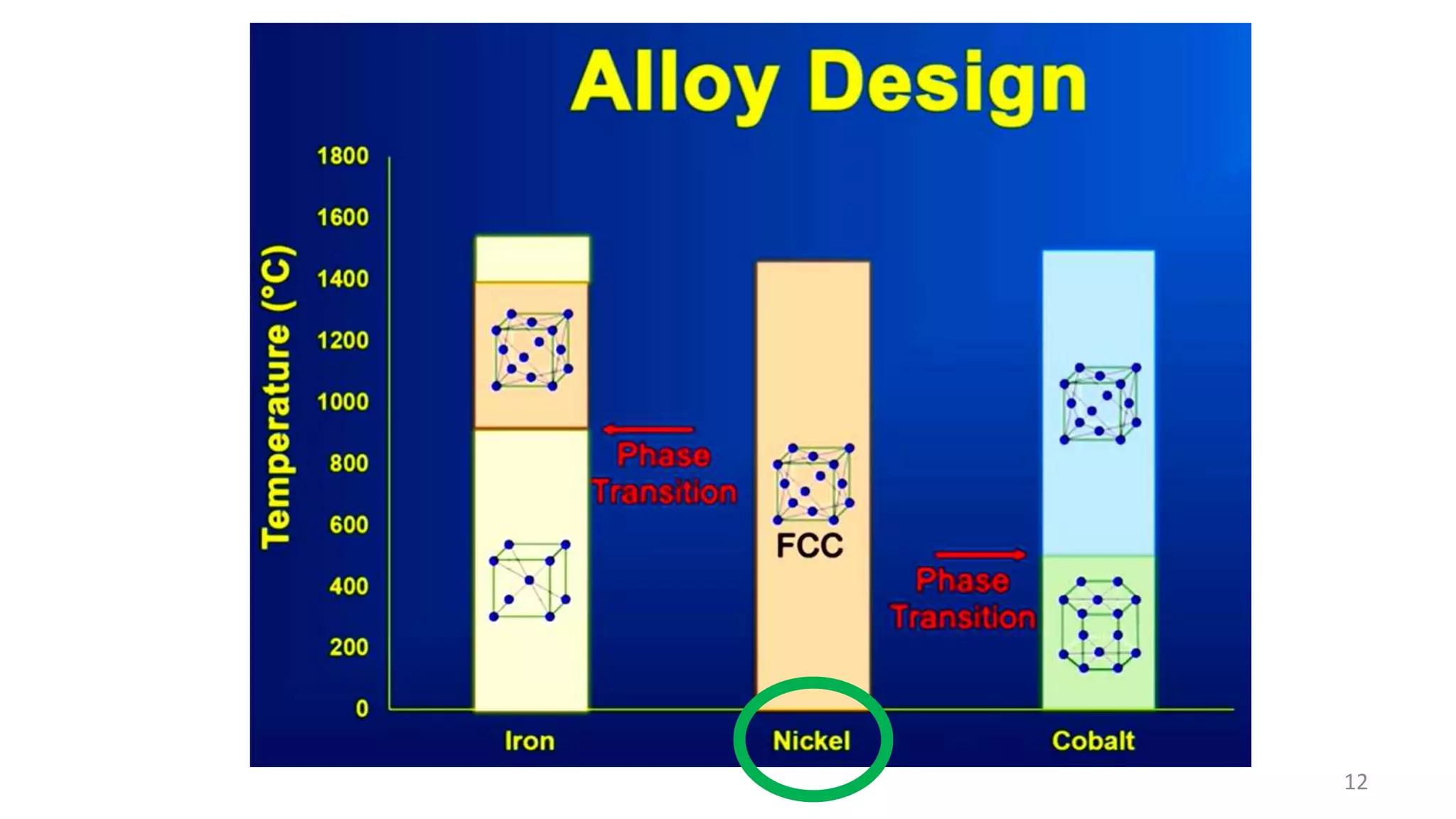

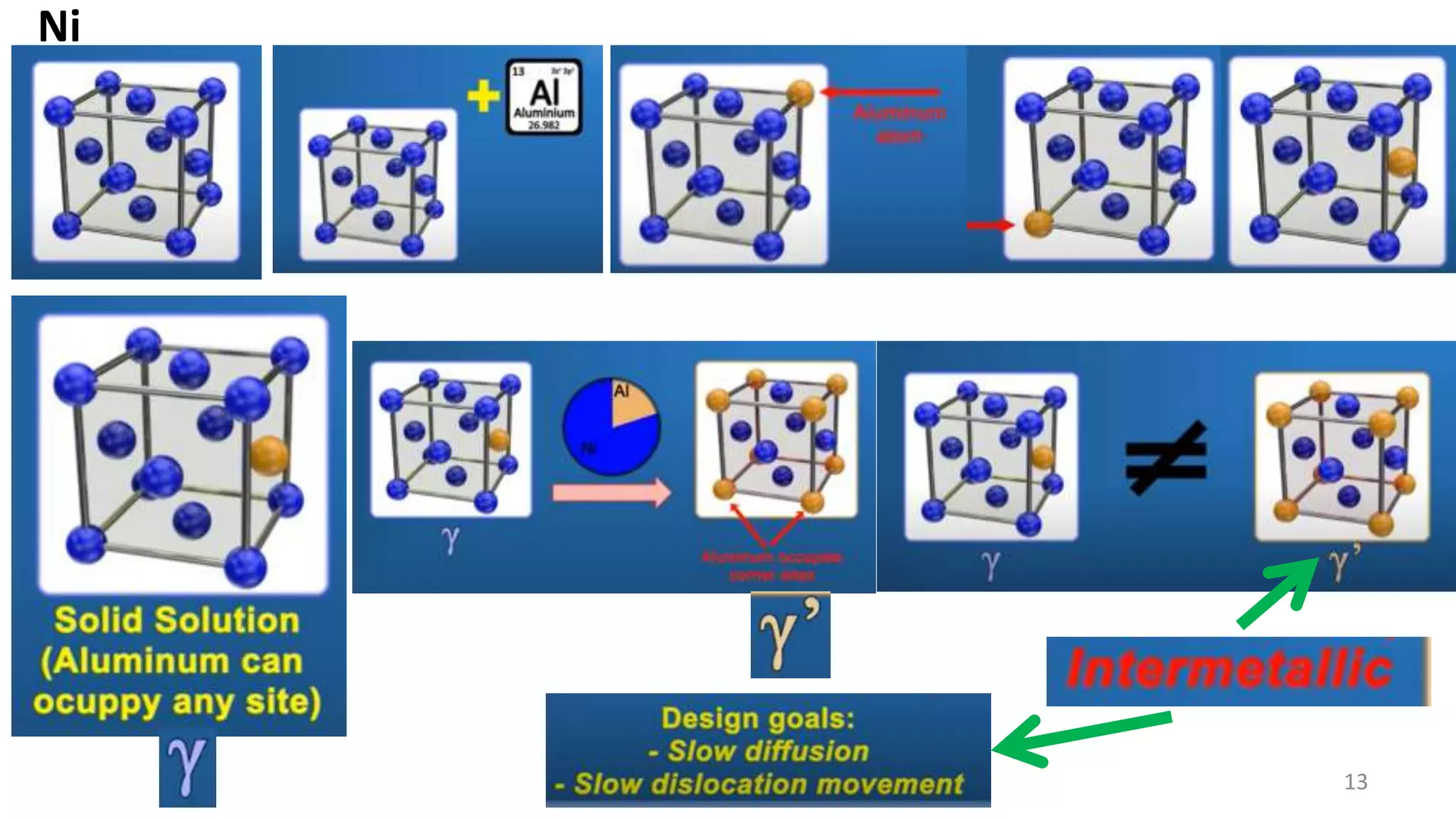

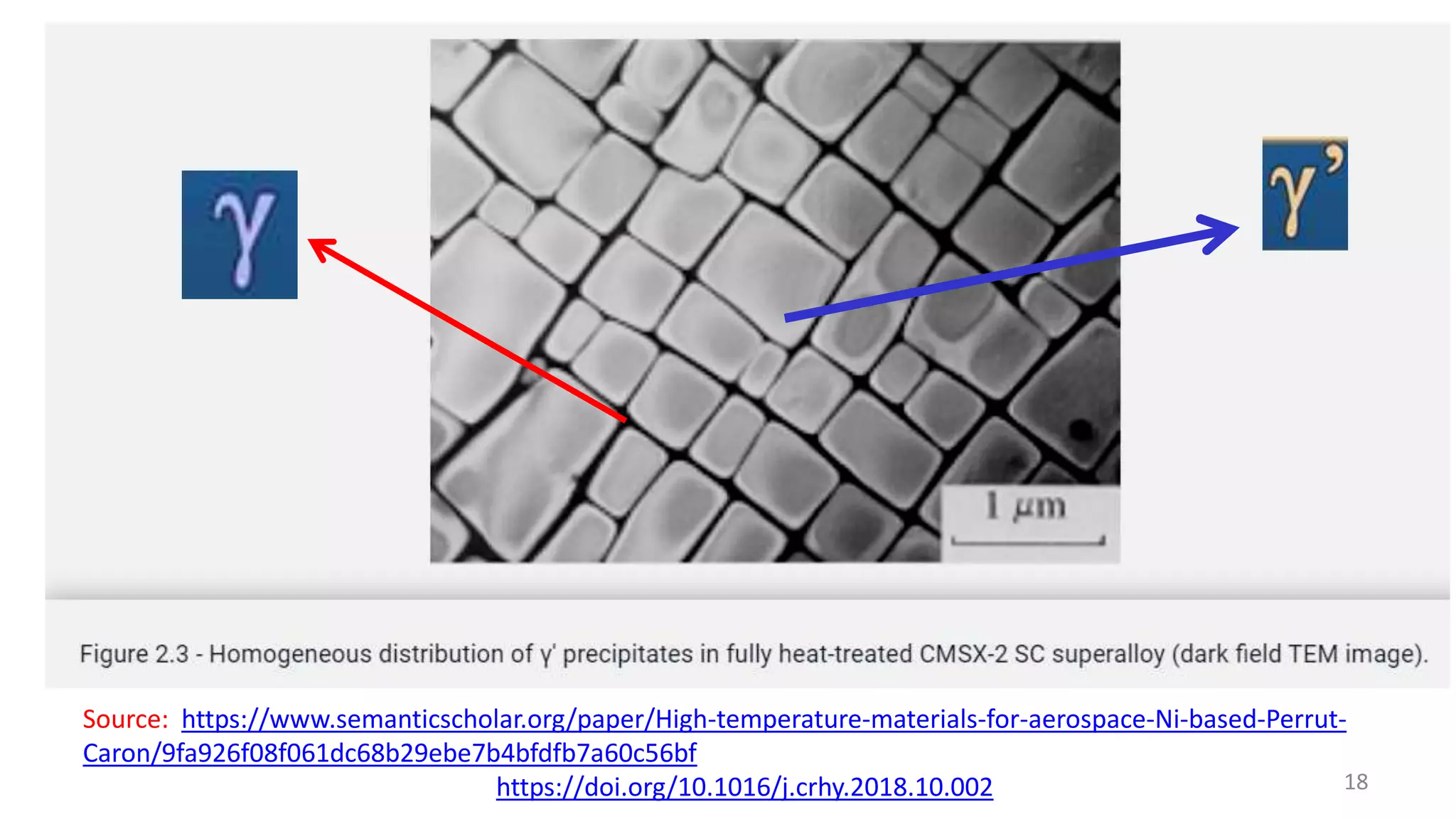

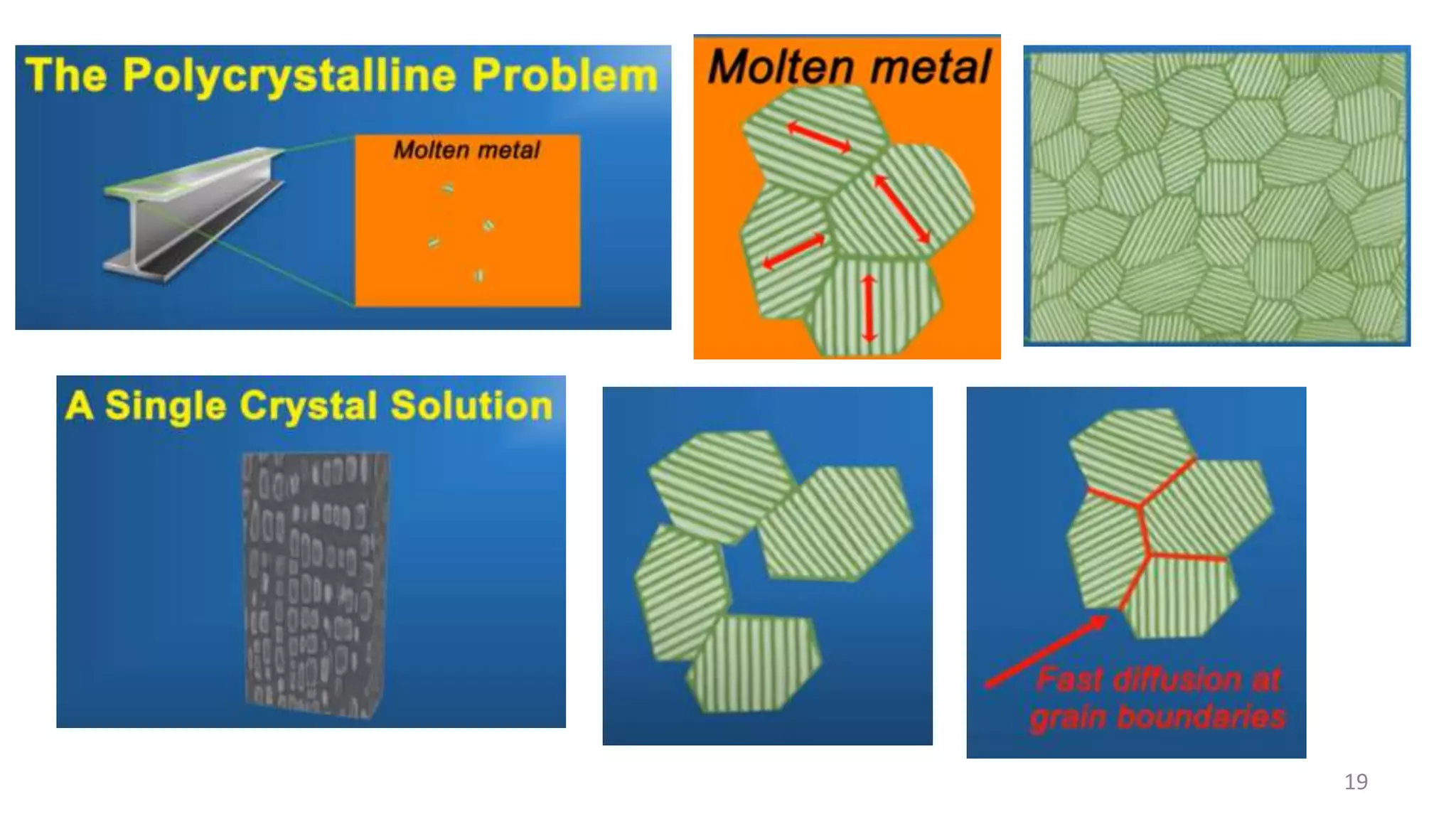

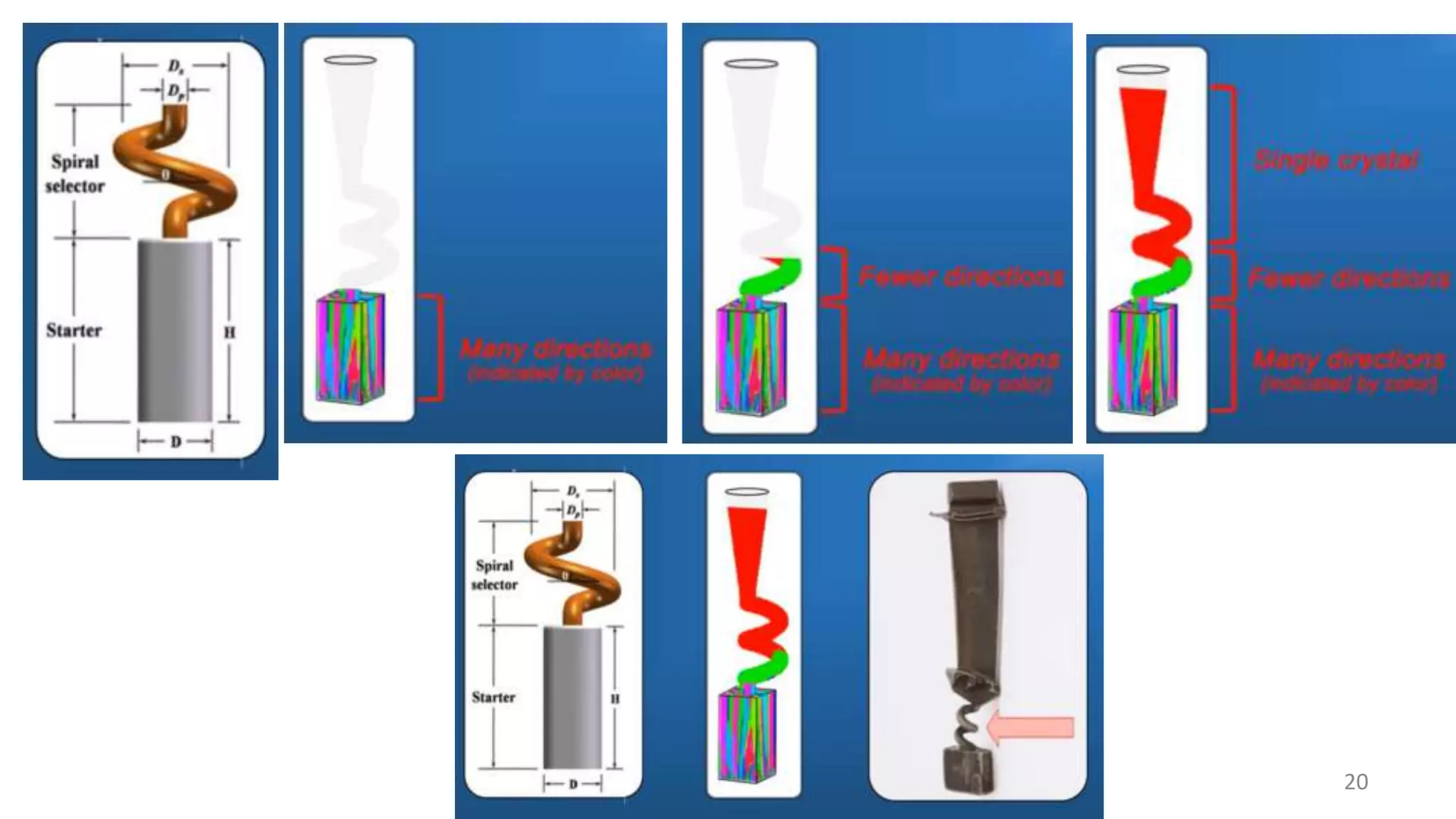

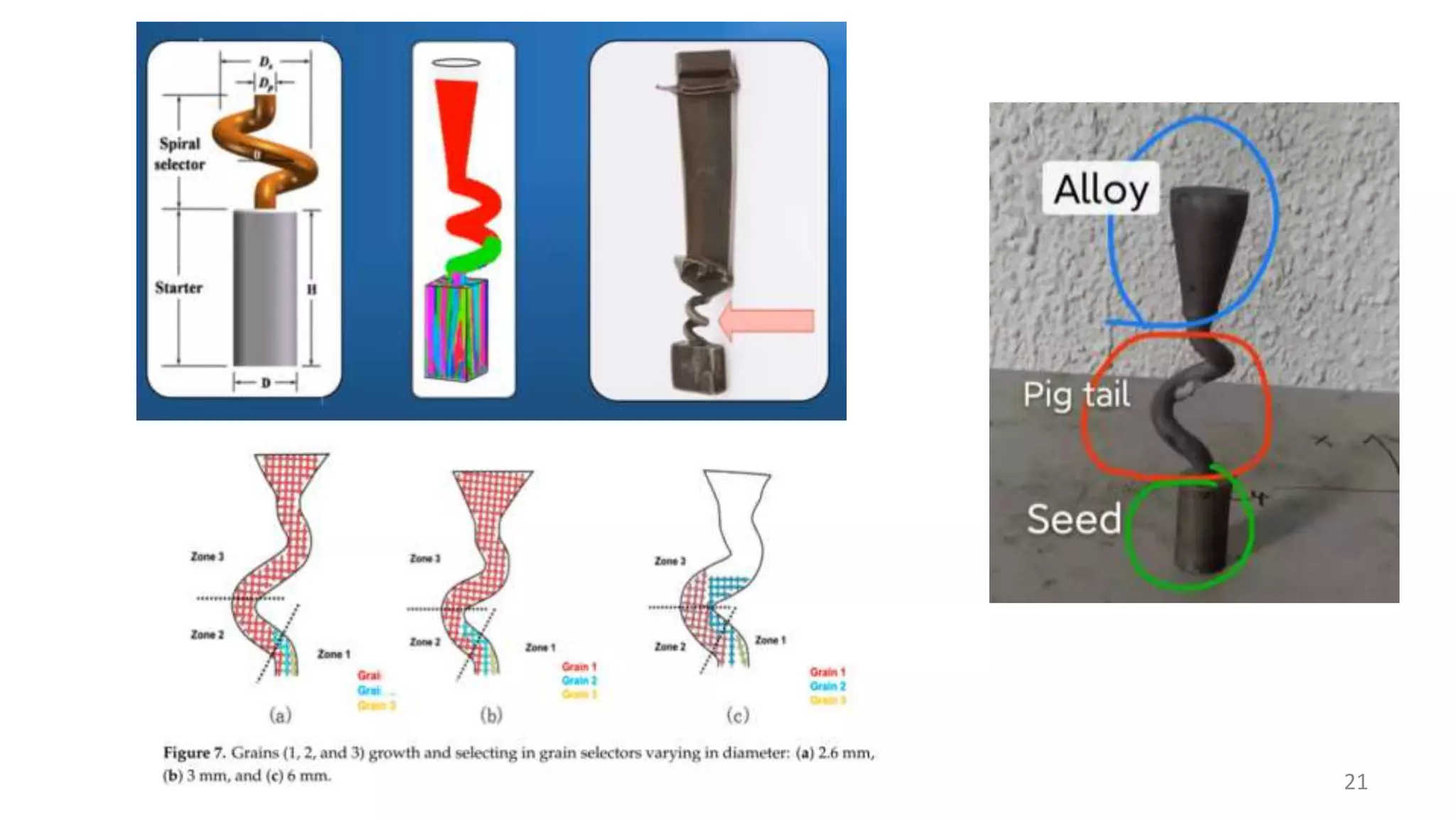

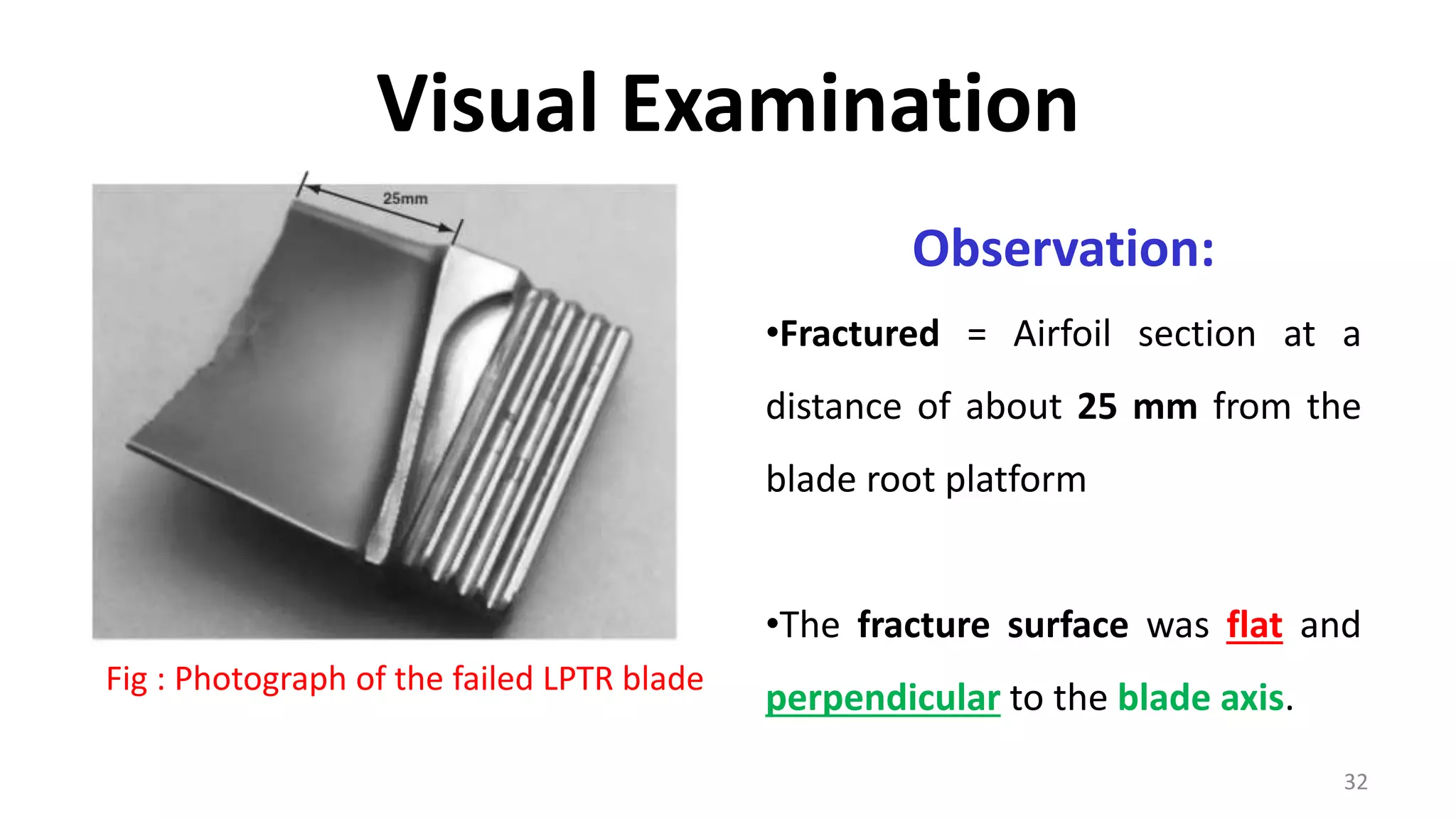

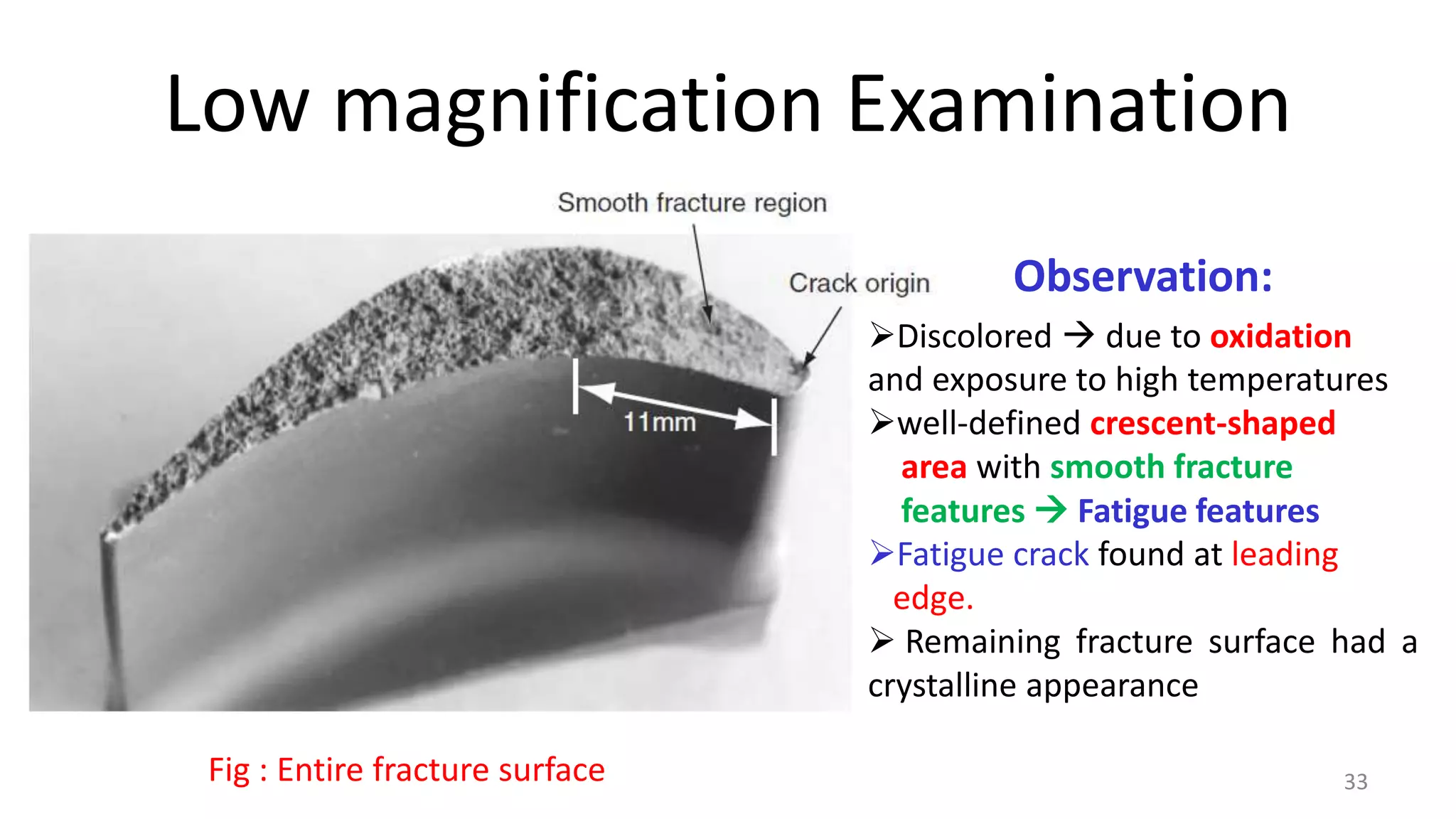

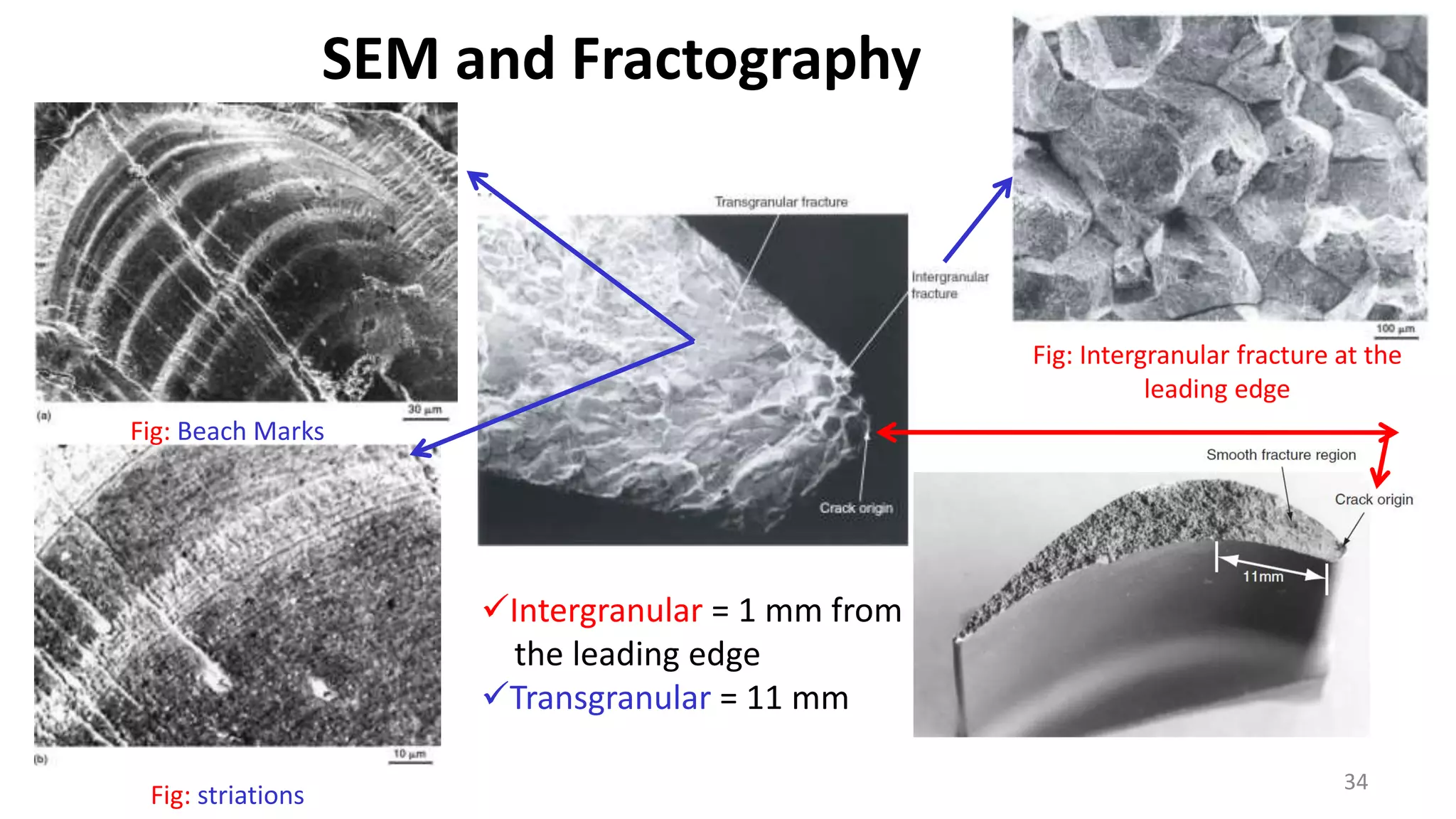

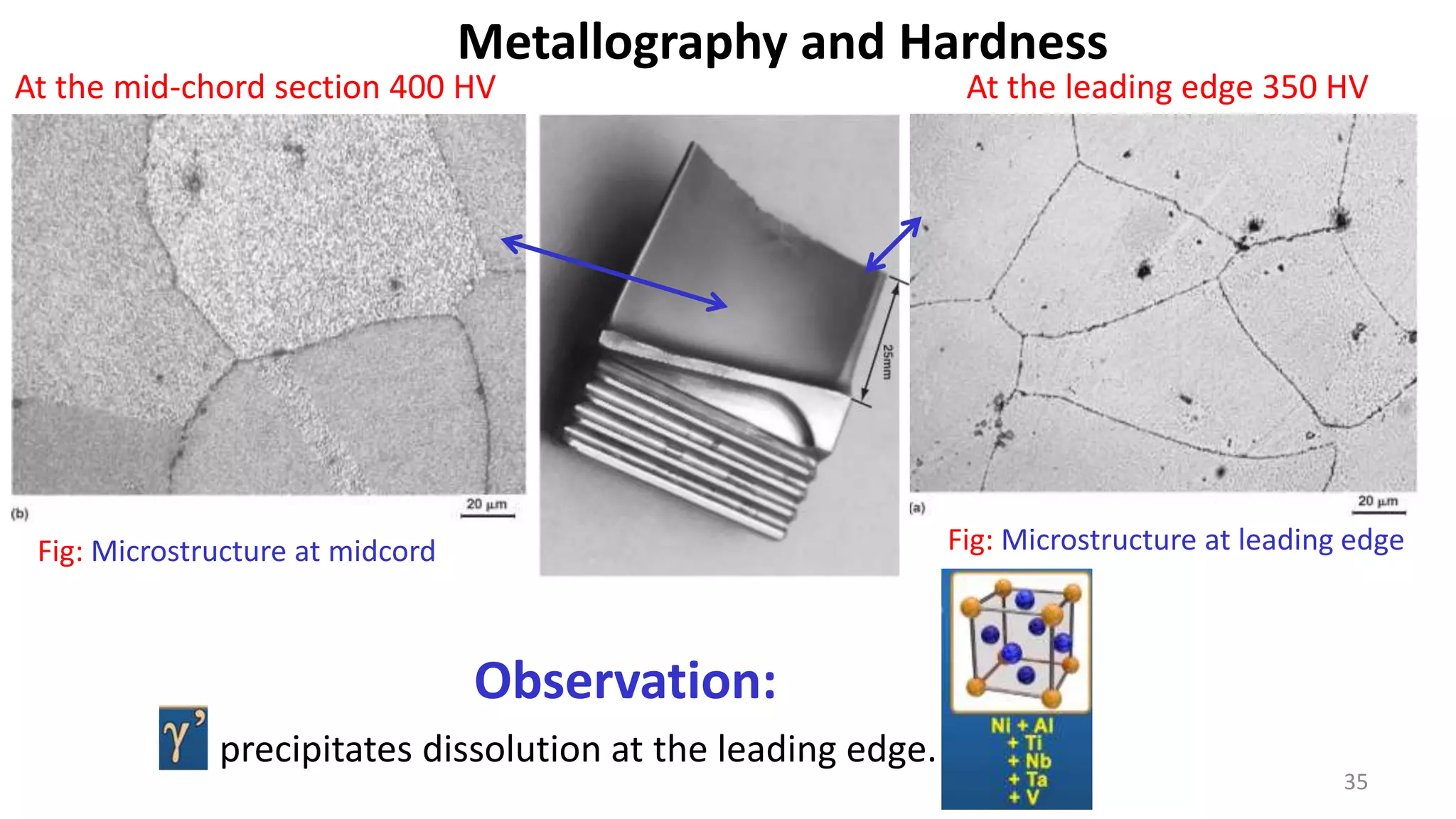

The document summarizes a case study of the failure of a low-pressure turbine rotor (LPTR) blade in a jet engine. Visual examination found a fatigue crack had initiated at the leading edge of the blade and propagated about 1 mm intergranularly and then about 11 mm transgranularly. Testing showed the microstructure at the leading edge had experienced dissolution of gamma prime precipitates, reducing the hardness and creep resistance. The failure mechanism involved initial stress rupture cracking at the leading edge followed by fatigue crack propagation. High operating temperatures caused the failure by dissolving precipitates and degrading the blade's strength properties.