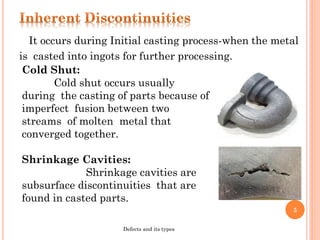

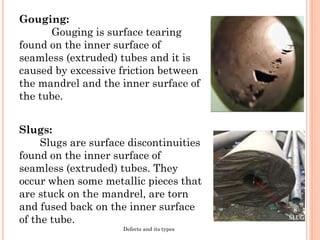

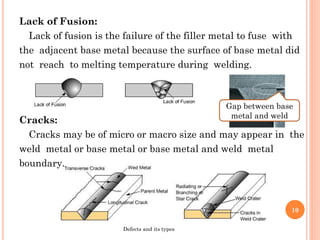

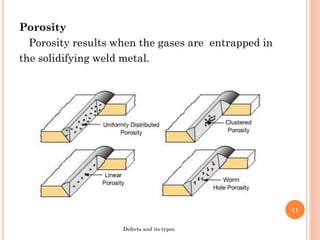

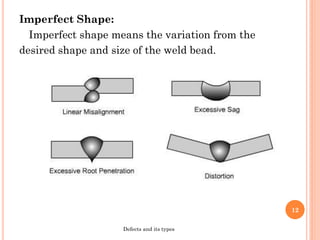

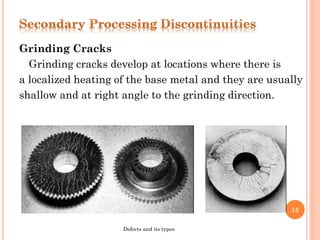

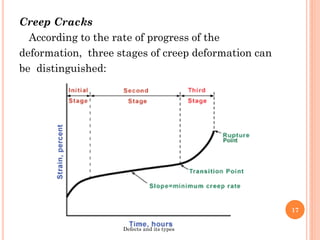

The document discusses defects and discontinuities in materials. It defines a discontinuity as an imperfection in a material's structure, such as a crack or pore, while a defect renders a part unable to meet standards. Discontinuities are categorized based on when they initiate: inherent during casting, primary during hot/cold forming, secondary during welding/machining, or service during use. Various types of discontinuities are described that form from casting, forming, welding, machining and use, such as cold shuts, laminations, pores, cracks and fatigue cracks.