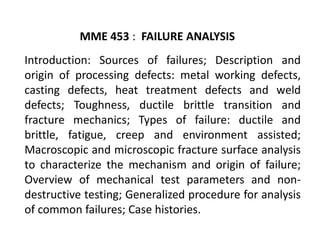

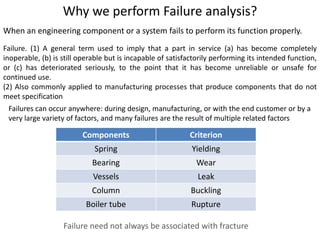

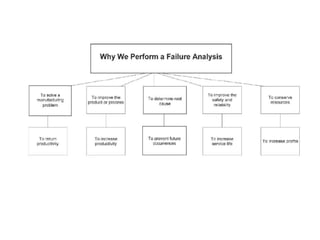

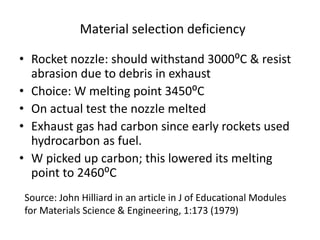

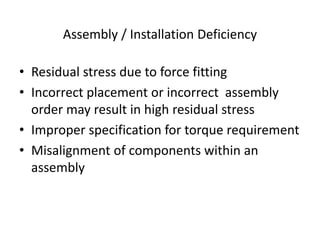

MME 453 is a course on failure analysis that examines the sources, types, and mechanisms of failures in materials and components. The course covers processing defects, fracture analysis, failure testing, and general procedures for analyzing common failures through case studies. Understanding why components fail is important, as failures can result from deficiencies in design, materials selection, processing, assembly, the operating environment, or maintenance. The goal of failure analysis is to determine the root cause of a failure in order to prevent future issues and improve product design and reliability.