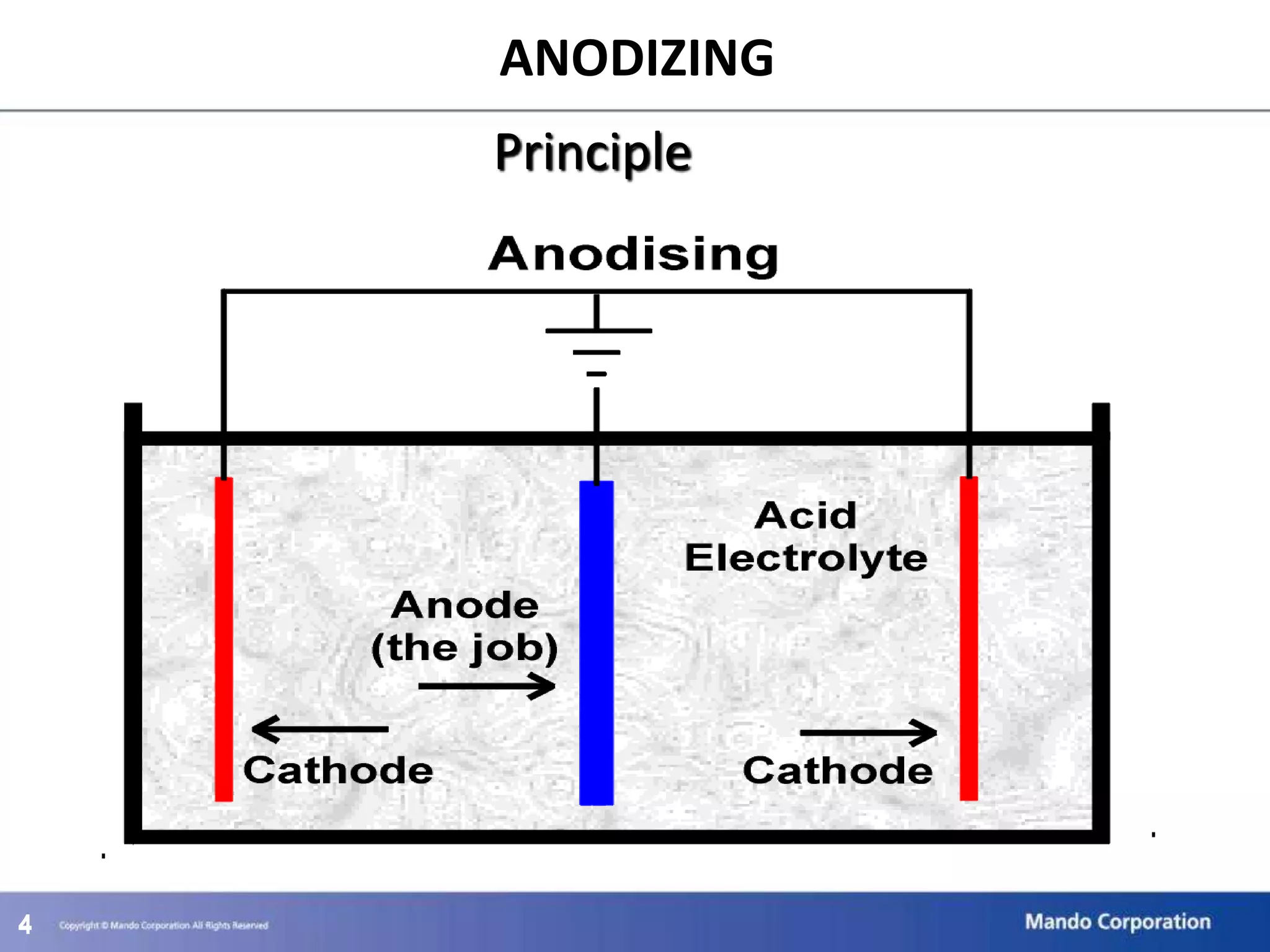

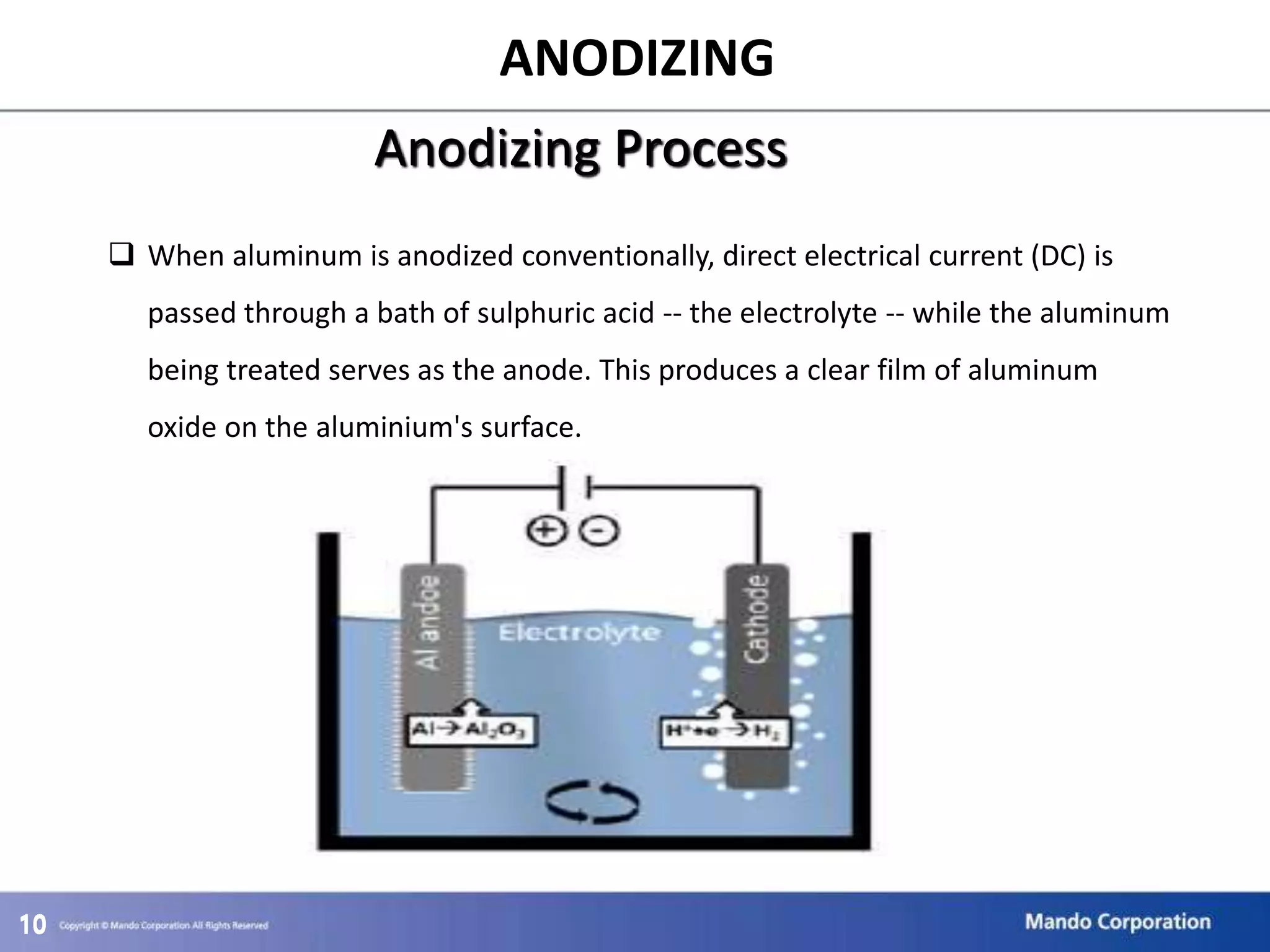

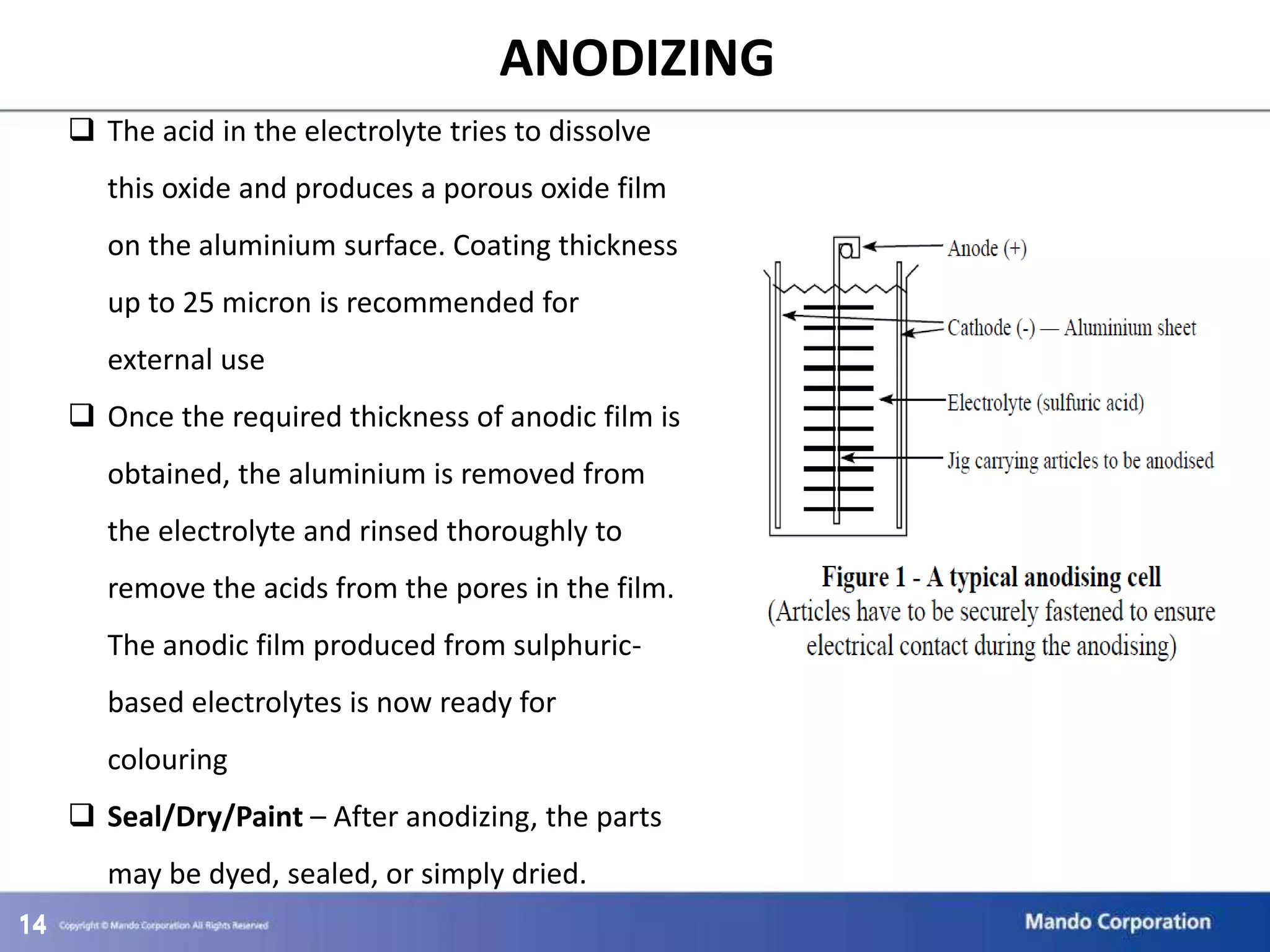

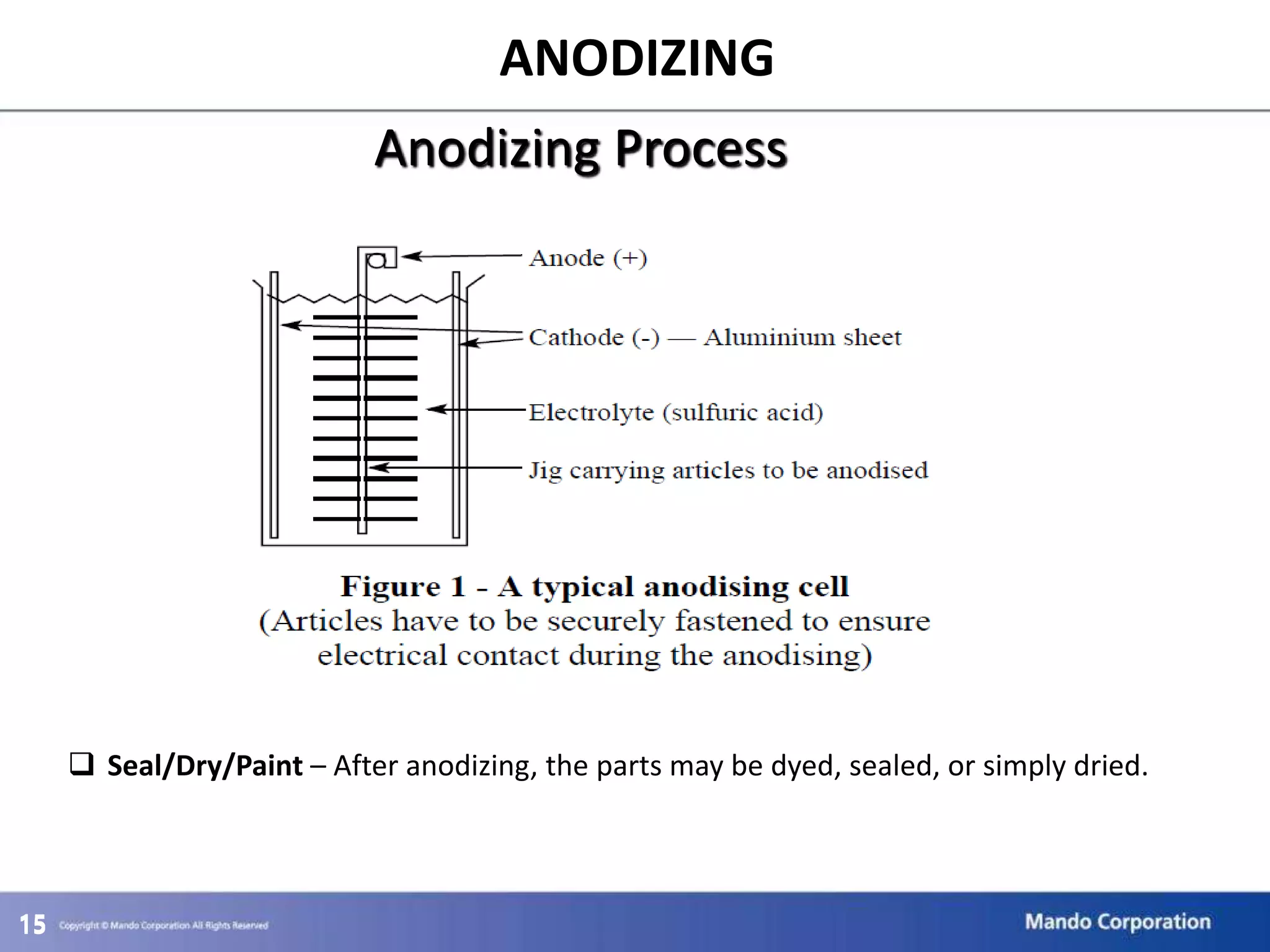

Anodizing is an electrochemical process that converts the surface of metals like aluminum into a decorative, durable, corrosion-resistant finish through controlled oxidation. The metal acts as an anode in an electrolytic solution, forming a hard oxide layer on its surface. Depending on the process, this layer can be thicker than the natural oxide and provides benefits like improved aesthetics, hardness, and longevity. Common applications of anodized aluminum include architectural elements, appliances, vehicles, and aerospace and electronic components.