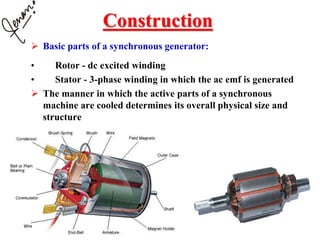

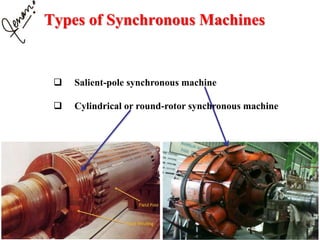

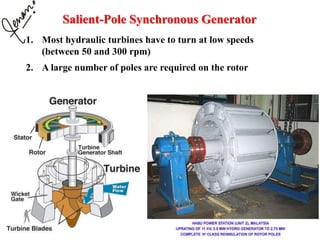

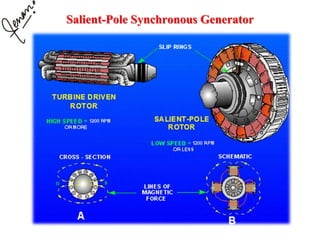

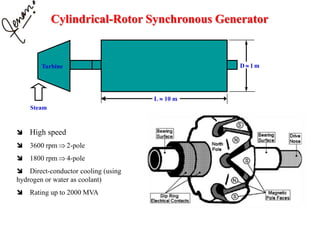

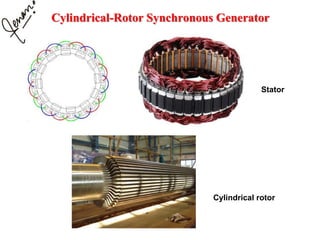

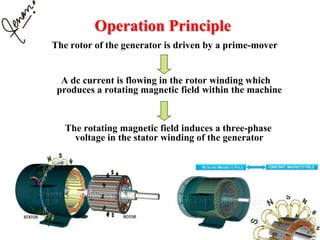

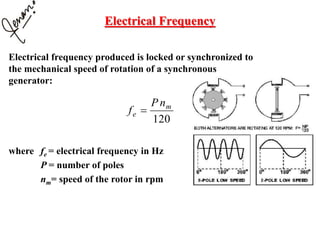

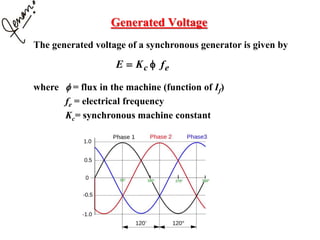

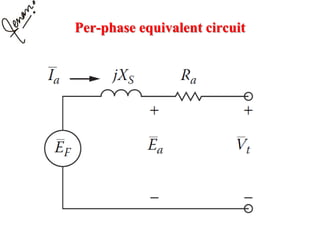

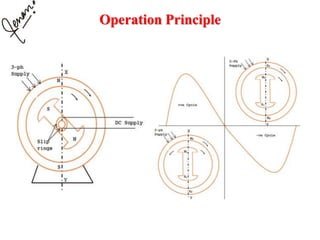

Synchronous machines include generators and motors. Synchronous generators are the primary source of electrical energy and convert mechanical power to AC power. They rely on synchronous motors which are used for constant speed industrial drives. Synchronous generators have a rotor with DC excitation and a stator with a 3-phase winding. They come in salient-pole or cylindrical rotor types. Synchronous motors operate by synchronizing their rotor field to the rotating stator field to convert electric power to mechanical power. They are often used for large, low speed, high power applications like pumps and compressors.