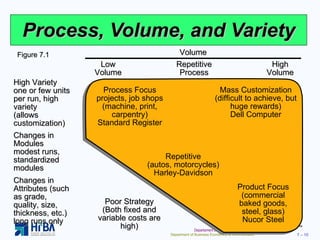

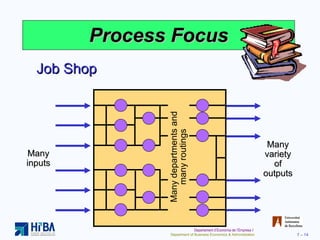

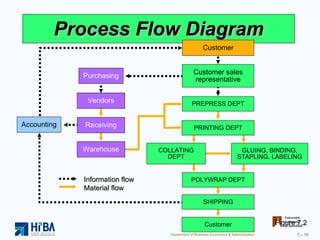

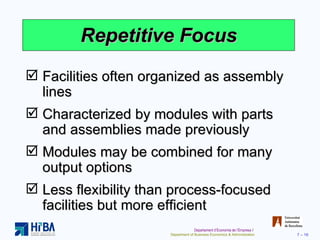

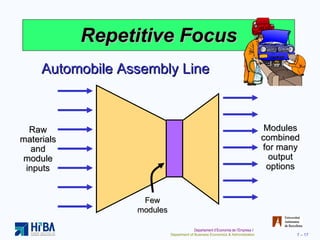

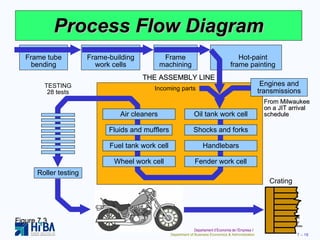

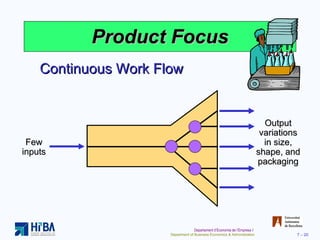

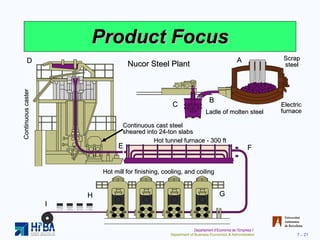

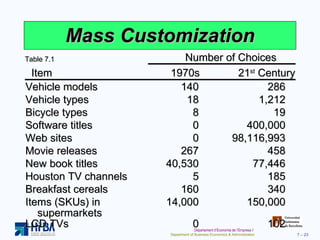

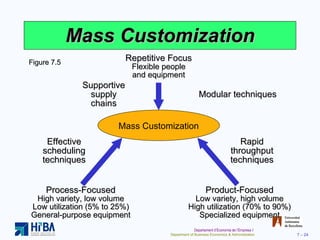

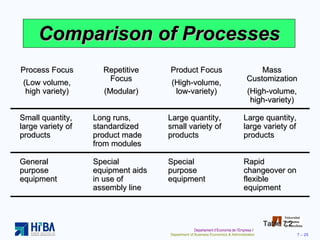

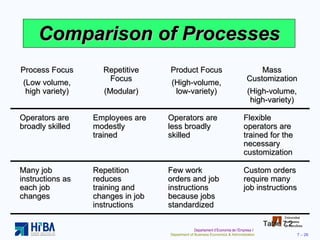

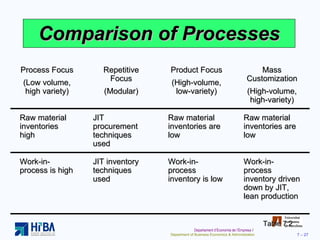

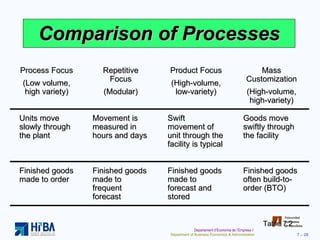

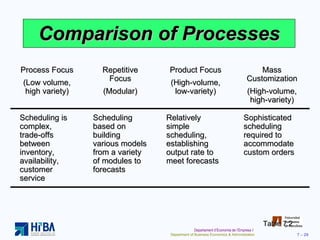

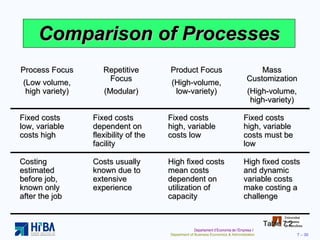

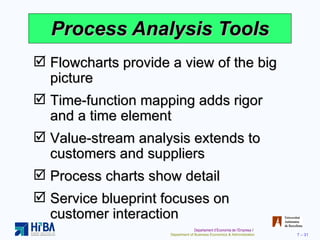

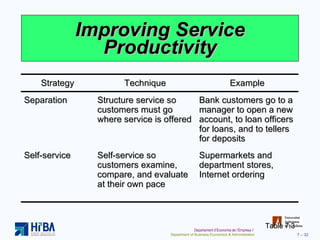

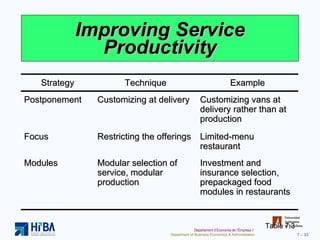

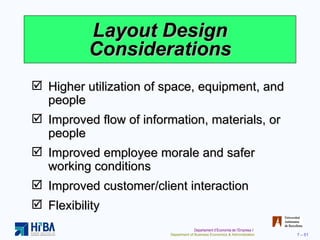

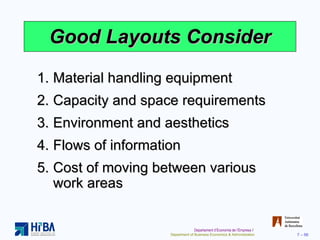

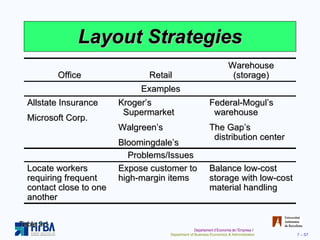

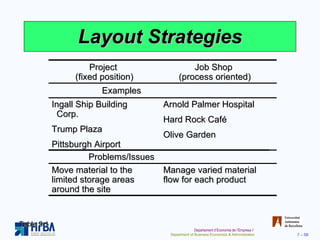

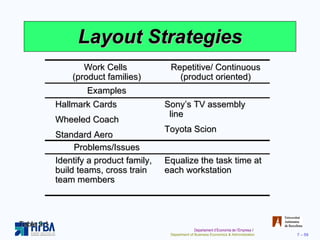

The document outlines key concepts in operations management related to process and layout strategies. It discusses four main process strategies - process focus, repetitive focus, product focus, and mass customization. It also compares the characteristics of different layout types, including office, retail, warehouse, project-oriented, process-oriented, work cell, and product-oriented layouts. The main objectives are to describe different production processes, layout types, and how to analyze and improve processes.