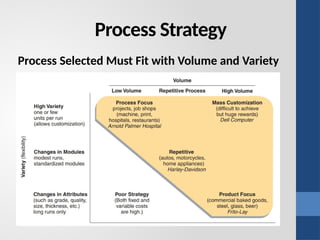

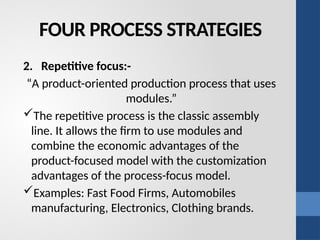

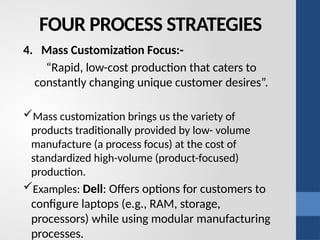

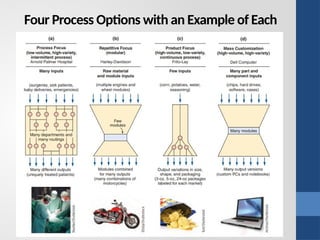

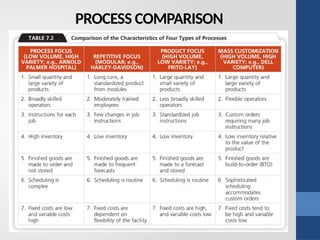

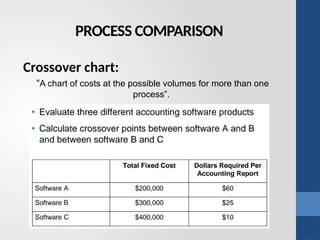

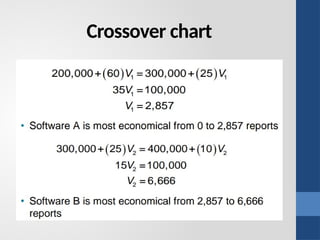

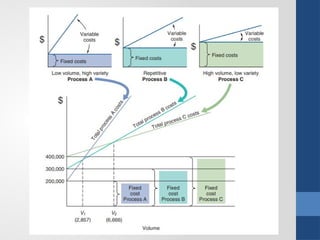

Chapter 7 discusses process strategy, which is an organization's method for transforming resources into goods and services to meet customer and product specifications while managing costs. It outlines four main process strategies: process focus for low-volume, high-variety production; repetitive focus for assembling products in modules; product focus for high-volume, low-variety production; and mass customization to meet unique customer demands. Additionally, the chapter highlights the importance of process analysis and design, production technology advances, and the need for process redesign to adapt to changing market conditions.