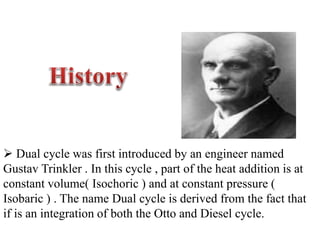

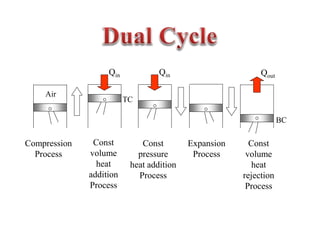

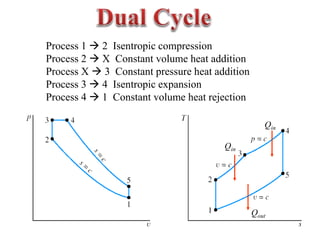

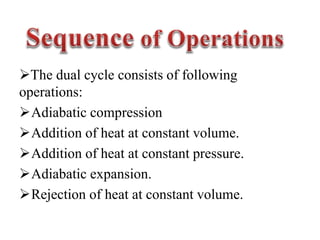

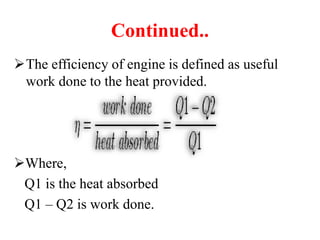

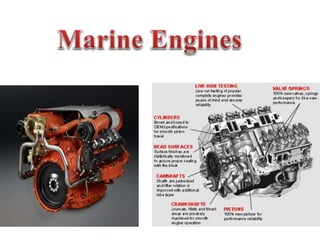

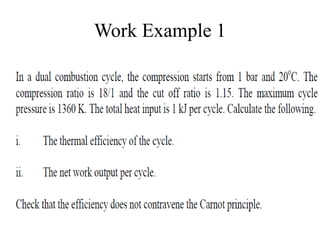

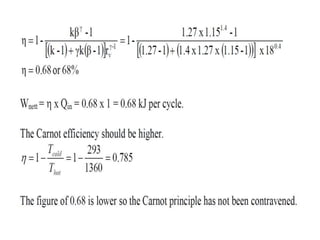

The document discusses the dual combustion engine, highlighting its features, operational cycles, and efficiency compared to traditional diesel engines. This internal combustion four-stroke engine combines elements of both the Otto and diesel cycles for improved performance, making it suitable for various applications including vehicles and portable machinery. The advantages of dual combustion engines include high power-to-weight ratios, cost-effectiveness, and flexible fuel use.