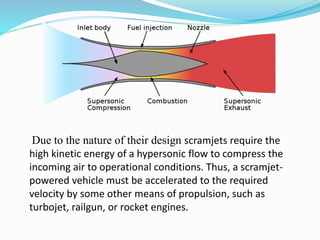

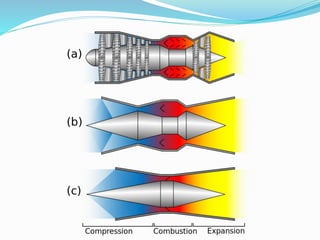

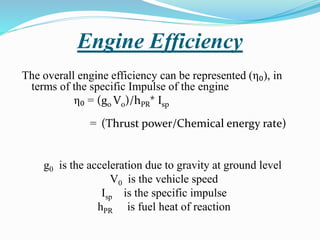

The document presents information about scramjet engines. It discusses the history of scramjet development from World War II to recent test flights reaching Mach 10 speeds. The key components of a scramjet engine are described as a converging inlet to compress incoming air, a combustor where fuel is burned, and a diverging nozzle to accelerate the heated air and produce thrust. Scramjets differ from other jet engines by not using rotating components for compression and relying on high flight speeds to compress air before combustion. Potential applications include hypersonic aircraft that could reduce intercontinental flight times to under 90 minutes.