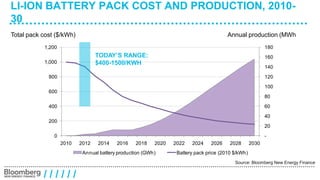

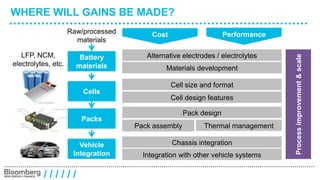

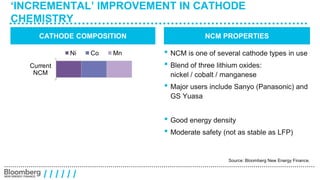

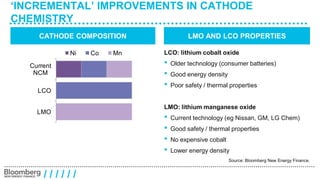

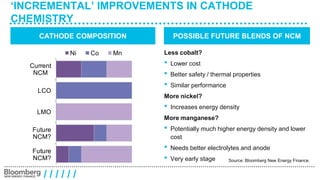

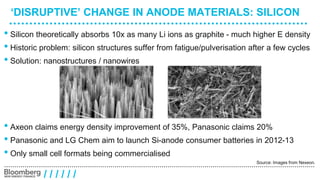

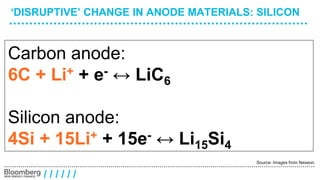

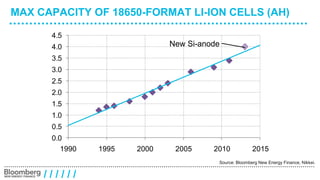

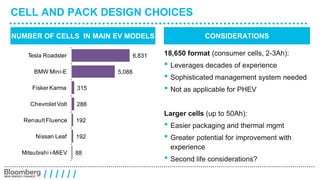

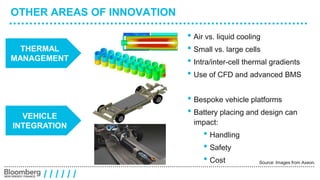

The document discusses battery innovation and whether it is incremental or disruptive. It notes that lithium-ion battery costs have declined significantly from $1000/kWh in 2010 to $400-1500/kWh currently due to improvements in materials, cell design, and manufacturing. Silicon anodes are a promising disruptive technology that could increase energy density by 10-35% but are only being commercialized in small formats currently. Both incremental changes to materials like varying cathode chemistries and disruptive changes like new anode materials will continue to drive innovation across the entire battery value chain.