This document discusses materials used in batteries. It begins by introducing primary batteries such as zinc-carbon and alkaline batteries. It describes their characteristics and applications. Secondary batteries like lead-acid, nickel-cadmium, nickel-metal hydride, and lithium-ion batteries are then discussed, outlining their chemistries, characteristics, and uses. The document also provides a case study on the processing of lithium-ion batteries, describing steps such as mixing materials, coating electrodes, compression, drying, assembly, electrolyte filling, formation, grading, and packaging. Key materials used in batteries like various cathode and anode materials are also summarized.

![Primary Batteries

System Characteristics Applications

Zinc-carbon

(Leclanché), Zinc/MnO2

Common, low-cost primary battery; available in a

variety of sizes

Flashlight, portable radios, toys, novelties, instruments

Magnesium (Mg/MnO2) High-capacity primary battery; long shelf life Formerly used for military receiver-transmitters, and aircraft

emergency transmitters (EPIRBs)

Mercury (Zn/HgO) Highest capacity (by volume) of conventional types;

flat discharge; good shelf life

Hearing aids, medical devices (pacemakers), photography,

detectors, military equipment, but in limited use at present

due to environmental hazard of mercury

Mer-cad (Cd/HgO) Long shelf life; good low- and high-temperature

performance; low energy density

Special applications requiring operation under extreme

temperature conditions and long life; in limited use

Alkaline

(Zn/alkaline/MnO2)

Most popular general-purpose battery; good low-

temperature and high-rate performance; low cost

Most popular primary battery; used in a variety of

portable battery operated equipment

Lithium/ soluble

cathode

High energy density; long shelf life; good

performance over wide temperature range

Wide range of applications requiring high energy density,

long shelf life, e.g., from utility meters to military electronics

applications

Lithium/ solid cathode High energy density; good rate capability and low-

temperature performance; long shelf life;

competitive cost

Replacement for conventional button and cylindrical cell

applications, such as digital cameras

Lithium/ solid

electrolyte

Extremely long shelf life; low-power battery Medical electronics

Table 1: Characteristics and applications [1]](https://image.slidesharecdn.com/batterymaterialsreportgroup5final-150413170642-conversion-gate01/85/Battery-materials-6-320.jpg)

![Magnesium Batteries

Twice the service life or capacity of zinc battery

Disadvantages – voltage delay and parasitic corrosion

Potential > 2.8V, but 1.1V is achieved

Battery chemistry, Mg + 2 MnO2 + H2O Mn2O3 + Mg (OH) 2

Figure represents

Magnesium batteries

[2]](https://image.slidesharecdn.com/batterymaterialsreportgroup5final-150413170642-conversion-gate01/85/Battery-materials-7-320.jpg)

![Zinc Carbon batteries

Leclanché and zinc chloride systems

low cost, ready availability, and acceptable performance

Electrolyte – Ammonium chloride and zinc chloride

Carbions with Mg2O- Conductivity

Specific capacity- 75-35 A h/kg

Basic chemistry Zn + 2MnO2 ZnO.Mn2O3

Figure represents Zinc-Carbon

batteries

[3]](https://image.slidesharecdn.com/batterymaterialsreportgroup5final-150413170642-conversion-gate01/85/Battery-materials-8-320.jpg)

![Secondary Batteries [4]

System Characteristics Applications

LEAD-ACID:

Automotive Popular, low-cost secondary battery, low

specific-energy, high-rate, and low-

temperature performance; maintenance-

free designs

Automotive SLI, golf carts, lawn mowers, tractors, aircraft,

marine, micro-hybrid vehicles

Traction (motive power) Designed for deep 6-9 h discharge,

cycling service

Industrial trucks, materials handling, electric and hybrid

electric vehicles, special types for submarine power

Stationary Designed for standby float service, long

life, VRLA designs

Emergency power, utilities, telephone, UPS, load levelling,

energy storage, emergency lighting

Portable Sealed, maintenance-free, low cost, good

float capability, moderate cycle life

Portable tools, small appliances and devices, portable

electronic equipment

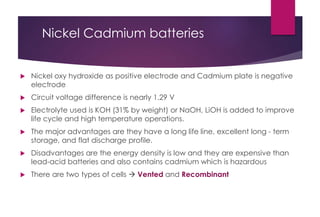

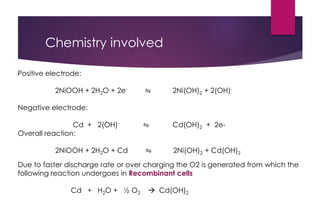

NICKEL-CADMIUM:

Industrial and FNC Good high-rate, low-temperature

capability, flat voltage, excellent cycle life

Aircraft batteries, industrial and emergency power

applications, communication equipment

Portable Sealed, maintenance-free, good high-rate

low-temperature performance, good

cycle life

Consumer electronics, portable tools, pagers, appliances,

photographic equipment, standby power, memory

backup

NICKEL-METAL

HYDRIDE

Sealed, maintenance-free, higher

capacity than nickel-cadmium batteries;

high energy density and power

Consumer electronics and other portable applications;

hybrid electric vehicles

LITHIUM-ION High specific energy and energy density,

long cycle life; high-power capability

Portable and consumer electronic equipment, electric

vehicles (EVs, HEVs, PHEVs), space applications, electrical

energy storage](https://image.slidesharecdn.com/batterymaterialsreportgroup5final-150413170642-conversion-gate01/85/Battery-materials-10-320.jpg)

![Construction of battery

Considering Aircraft battery design consists of steel case containing

identical, individual cells connected in series

And the end of the cells of the series are connected to receptacle located

on the outside of the case

[5] [6]](https://image.slidesharecdn.com/batterymaterialsreportgroup5final-150413170642-conversion-gate01/85/Battery-materials-13-320.jpg)

![Lithium Ion Batteries

Li ions exchange between the positive and negative

electrodes

The major advantages are they are sealed and no

maintenance is required, they have long life cycle, they

have long shelf life, and low self-discharge rate. High power

discharge rate capability

The major disadvantages are that, they degrade at high

temperatures, capacity loss and potential for thermal

runway when charged, possible venting and possible

thermal runway when crushed, and may become unsafe

when rapid charge at low temperature (< 0 0C).

higher specific energy (up to 240 Wh/kg)

energy density (up to 640 Wh/L)

self-discharge rate is around 2-8% per month

The working temperature range is at 0 to 45 0C

Single cell Operating Voltage between 2.5 and 4.3 V

[7]](https://image.slidesharecdn.com/batterymaterialsreportgroup5final-150413170642-conversion-gate01/85/Battery-materials-14-320.jpg)

![Battery materials [7]

Material

Specific

capacity

mAh/g

Comments

LiCoO2 155 Still the most common. Co is expensive.

LiNi1-x-yMnxCoyO2 (NMC) 140-180

Safer and less expensive than LiCoO2. Capacity depends on

upper voltage cut-off.

LiNi0.8Co0.15Al0.05O2 200 About as safe as LiCoO2, high capacity.

LiMn2O4 100-120

Inexpensive, safer than LiCoO2, poor high temperature stability

(but improving with R&D).

LiFePO4 160

Synthesis in inert gas leads to process cost. Very safe. Low

volumetric energy.

Li[Li1/9Ni1/3Mn5/9]O2 275 High specific capacity, R&D scale, low rate capability.

LiNi0.5Mn1.5O4 130 Requires an electrolyte that is stable at a high voltage.](https://image.slidesharecdn.com/batterymaterialsreportgroup5final-150413170642-conversion-gate01/85/Battery-materials-17-320.jpg)

![Battery Manufacturing Process[11]](https://image.slidesharecdn.com/batterymaterialsreportgroup5final-150413170642-conversion-gate01/85/Battery-materials-19-320.jpg)

![REFERENCES

[1] Thomas Reddy. "Chapter 8 - An Introduction to Primary Batteries". Linden's Handbook of Batteries, Fourth

Edition.McGraw-Hill, © 2011. Books24x7. Web. Apr. 7, 2015. http://common.books24x7.com/toc.aspx?bookid=35916

[2] Thomas Reddy. "Chapter 10 - Magnesium and Aluminium Batteries". Linden's Handbook of Batteries, Fourth Edition.

McGraw-Hill. © 2011. Books24x7. http://common.books24x7.com/toc.aspx?bookid=35916 (accessed April 8, 2015)

[3] Thomas Reddy. "Chapter 9 - Zinc-Carbon Batteries—Leclanché and Zinc Chloride Cell Systems". Linden's Handbook of

Batteries, Fourth Edition. McGraw-Hill, © 2011.Books24x7.Web. Apr.7, 2015.

http://common.books24x7.com/toc.aspx?bookid=35916

[4] Thomas Reddy. "Chapter 15 - An Introduction to Secondary Batteries". Linden's Handbook of Batteries, Fourth

Edition. McGraw-Hill, © 2011. Books24x7. Web. Apr. 9, 2015.http://common.books24x7.com/toc.aspx?bookid=35916

[5] D. Vutetakis, “Batteries,” in Digital Avionics Handbook, Third Edition, CRC Press, 2014, pp. 419–442.

[6] Thomas Reddy. "Chapter 19 - Industrial and Aerospace Nickel-Cadmium Batteries". Linden's Handbook of Batteries,

Fourth Edition. McGraw-Hill, © 2011. Books24x7. Web. Apr. 9, 2015. http://common.books24x7.com/toc.aspx?bookid=35916

[7] Thomas Reddy. "Chapter 26 - Lithium-Ion Batteries”. Linden’s Handbook of Batteries, Fourth Edition. McGraw-Hill, ©

2011. Books24x7. Web. Apr. 9, 2015 http://common.books24x7.com/toc.aspx?bookid=35916

[8] A. Manthiram, “Smart Battery Materials,” in Smart Materials, CRC Press, 2008.

[9] D. Vutetakis, “Batteries,” in Digital Avionics Handbook, Third Edition, CRC Press, 2014, pp. 419–442.

[10] Z. Bakenov and I. Taniguchi, “Cathode Materials for Lithium-Ion Batteries,” in Lithium-Ion Batteries, CRC Press, 2011, pp.

51–96.

[11] http://www.industry.siemens.com/topics/global/en/battery-manufacturing/process/pages/default.aspx](https://image.slidesharecdn.com/batterymaterialsreportgroup5final-150413170642-conversion-gate01/85/Battery-materials-31-320.jpg)