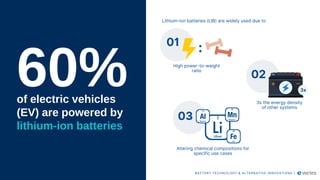

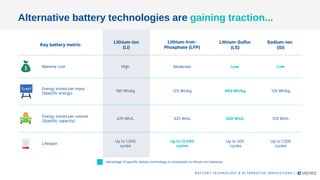

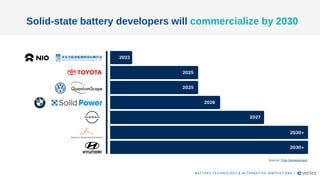

The document discusses advancements in battery technologies, focusing on alternatives to lithium-ion batteries, such as lithium-iron phosphate, lithium-sulfur, and sodium-ion batteries, highlighting their potential advantages in energy density, cost, safety, and sustainability. It also mentions the emergence of solid-state batteries as a promising next-generation technology due to their higher energy density and faster charging times. Furthermore, it emphasizes the need for improved supply chain security and the ongoing innovations in battery design and recycling processes.