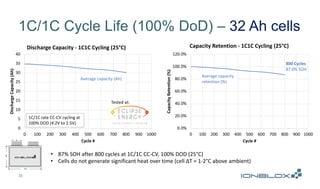

Ionblox has developed high-performance lithium-ion battery cells using a proprietary pre-lithiated silicon-based anode that can deliver up to 400 Wh/kg. Their cells have been validated by US National Labs and Lilium, a leading eVTOL company. Ionblox has received $32M in funding to commercialize their technology. Their silicon anode solves issues like swelling through pre-lithiation and can provide fast charging, high energy, power and long cycle life simultaneously. Ionblox's cells are the only ones that can meet the demanding requirements for electric aerial vehicles and vehicles in general.