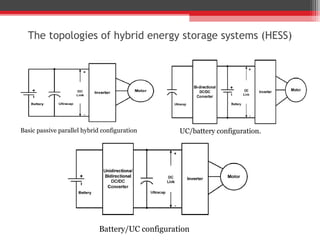

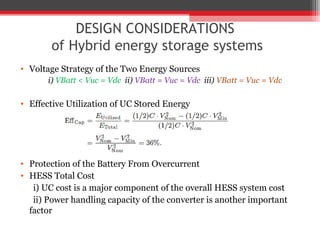

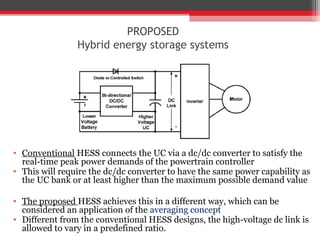

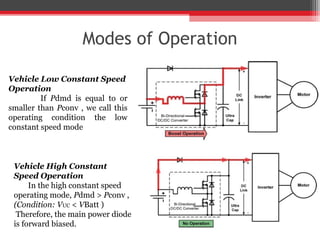

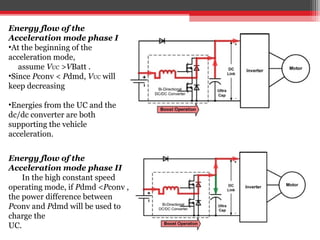

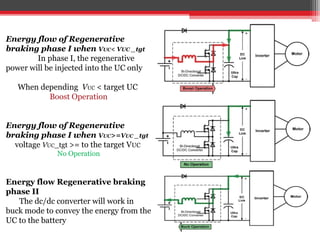

Hybrid energy storage systems (HESS) combine ultracapacitors and batteries to improve performance in hybrid electric vehicles by leveraging the high power density of ultracapacitors alongside the energy density of batteries. New configurations proposed in the document aim to optimize energy flow during different operational phases, including acceleration and regenerative braking, without the need for a matching power DC/DC converter. This design enhances battery longevity, reduces power demand on the battery, and improves vehicle drivability at low temperatures.