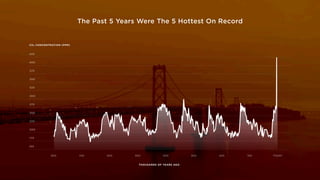

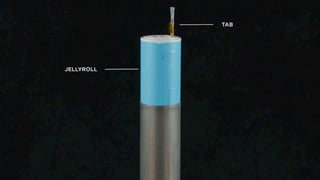

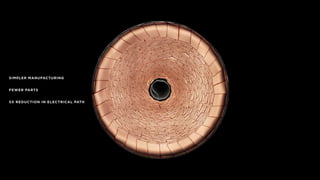

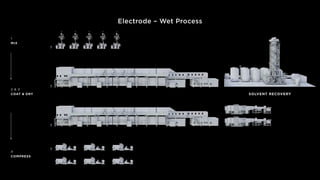

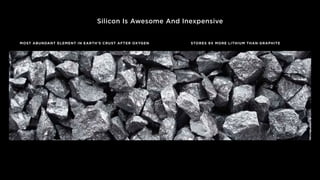

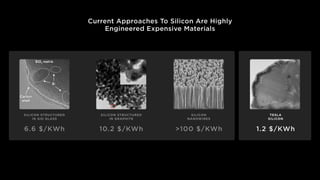

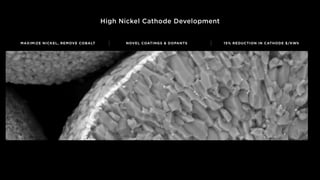

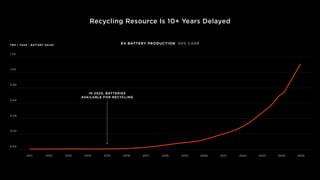

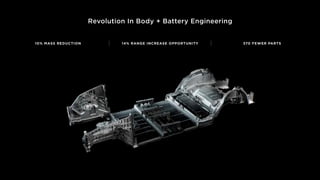

The document summarizes Tesla's plans to significantly reduce battery costs and accelerate the transition to sustainable energy. It outlines Tesla's goal to produce batteries at terawatt-hour scale through new cell designs and manufacturing processes that simplify production and reduce costs. Key areas of focus include increasing energy density with new silicon and high-nickel cathode materials, developing new electrode and cell manufacturing techniques, and further vertically integrating battery and vehicle production. Tesla estimates these developments could reduce battery costs by over 50% while increasing vehicle range by over 50%.