Embed presentation

Downloaded 129 times

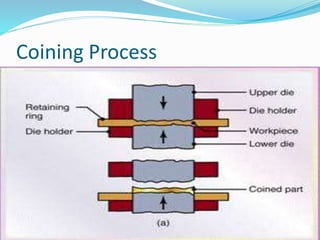

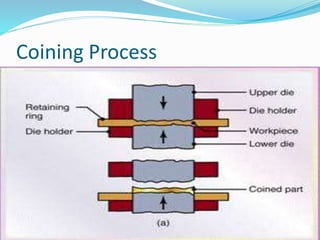

Coining is a cold working process that uses high pressure to plastically deform a workpiece between two closed dies to conform to their shapes. It provides a finer, more detailed surface finish than other processes like stamping. Coining does not require cutting or expensive machinery. It work hardens the surface of the material, making the finished parts more impact and abrasion resistant and eliminating the need for further finishing steps. Industrial applications of coining include minting coins and medals, making jewelry, precision springs, electronic parts, and other complex parts requiring polished surfaces.