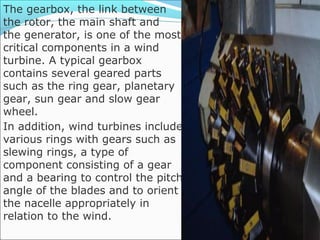

Milling is the process of machining material using a rotating multi-tooth cutter, commonly used for creating flat, angular, or curved surfaces. Gear manufacturing utilizing milling and broaching is vital in wind turbine production, particularly for components like gearboxes that link the rotor and generator. Recent advancements in milling technology emphasize productivity and precision, addressing growing demand in the wind energy sector.