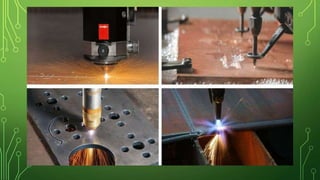

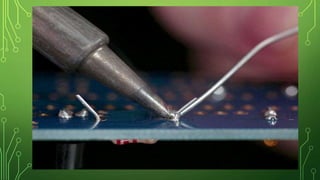

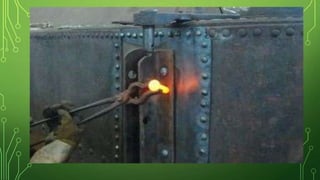

Metalworking is the process of shaping metals into tools and structures, with a rich history dating back thousands of years. Techniques include cutting, joining, and forming, with methods such as welding, soldering, and casting still in use today. Modern applications of metalworking are crucial in various industries, including electronics and transportation.