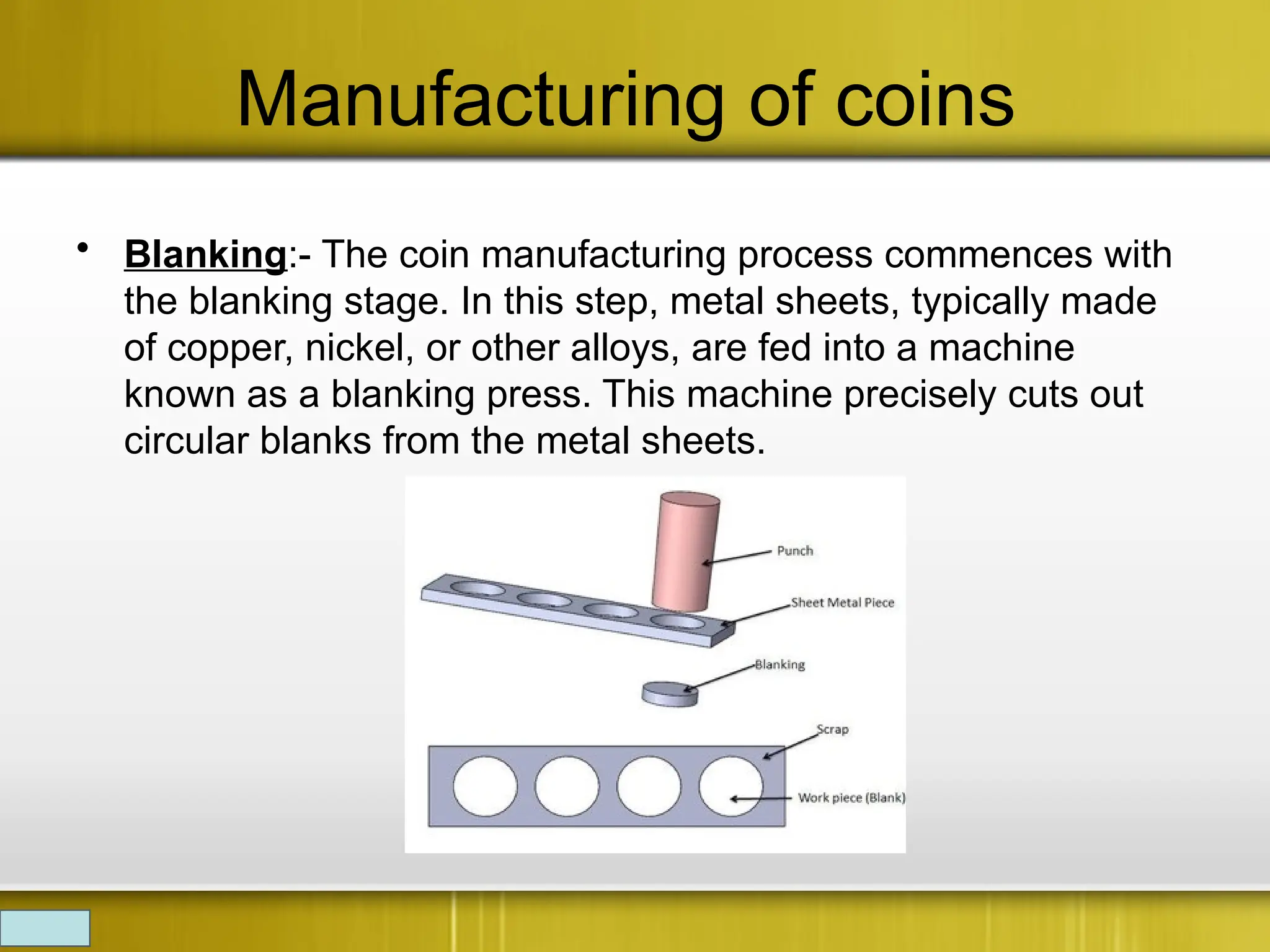

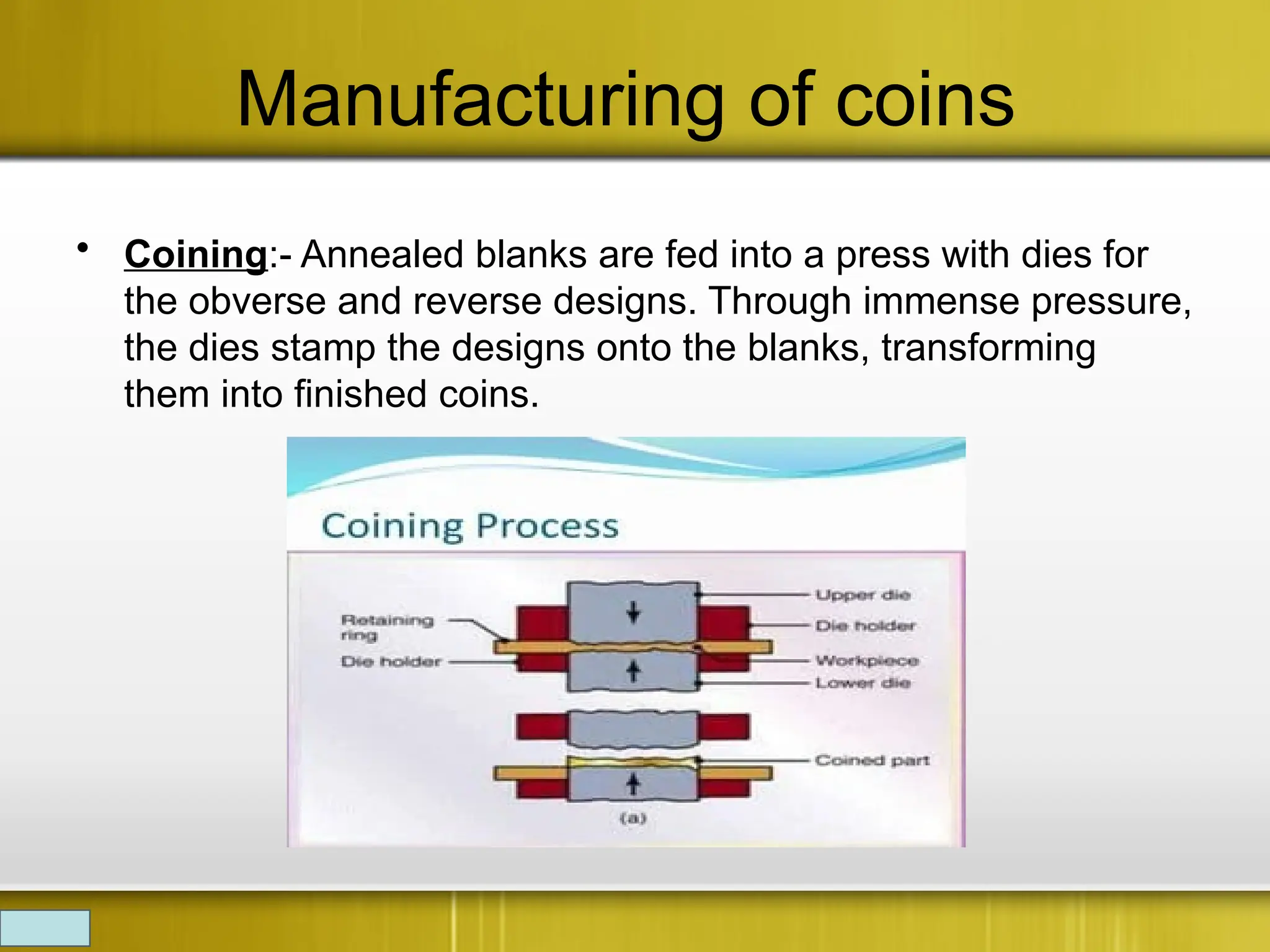

The document outlines the coin manufacturing process, which includes steps like blanking, annealing, coining, inspection, and finishing to produce high-quality coins. It also highlights the utility of coins as a medium of exchange, a store of value, and their portability for daily transactions. Quality control is emphasized to ensure that only perfect coins are circulated.