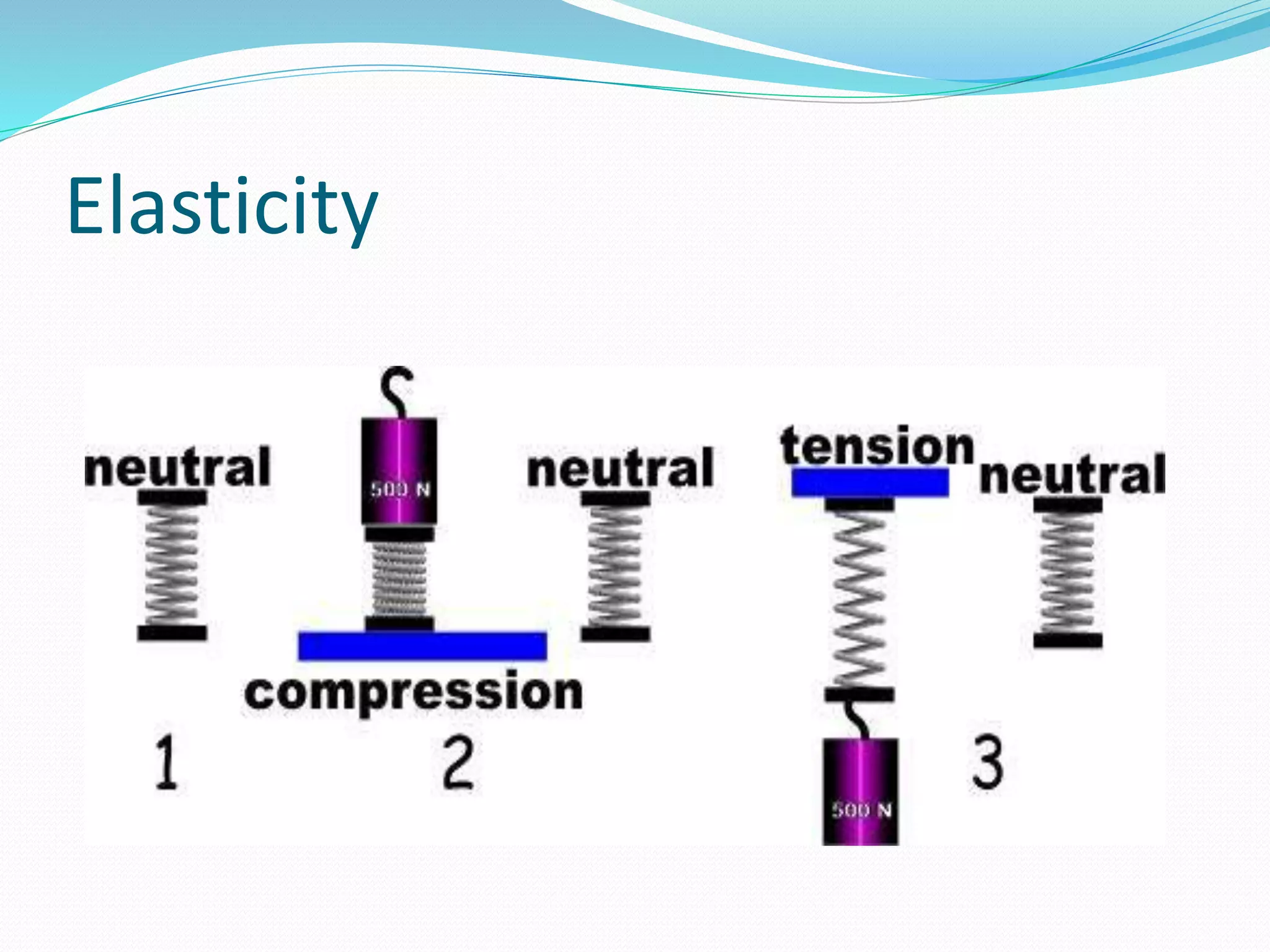

This document discusses various mechanical properties of engineering materials including hardness, creep, elasticity, hardening, and plasticity. It defines each property and describes methods for measuring hardness, factors that influence creep, the hardening process, and how plastic deformation occurs at the atomic level resulting in a permanent change in shape even after removal of stress. Measurement techniques for hardness include Rockwell, Brinell, Vickers, Knoop, and shore hardness tests. Creep is influenced by load, temperature, composition, grain size, and heat treatment. Hardening increases hardness through metallurgical processes.