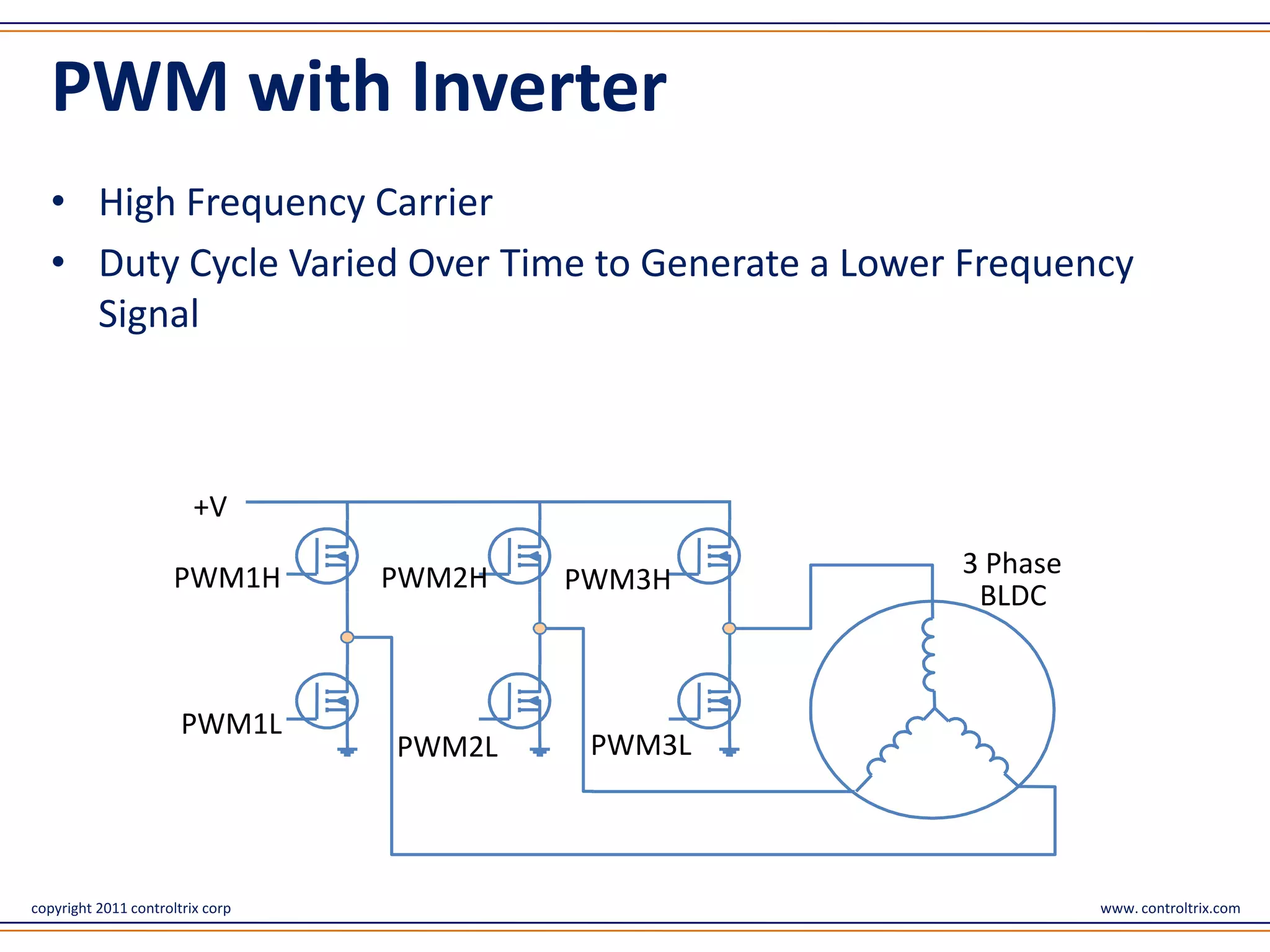

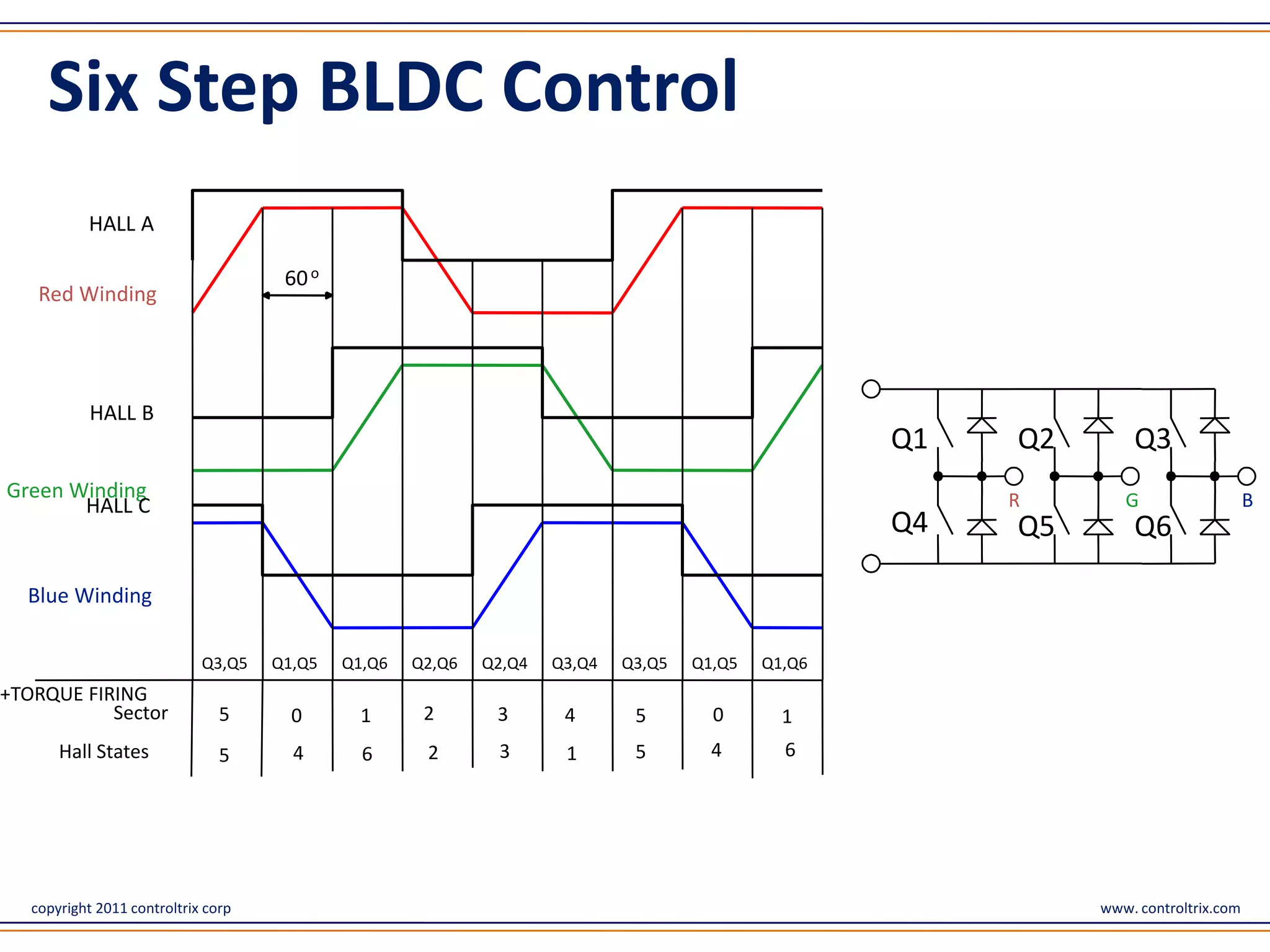

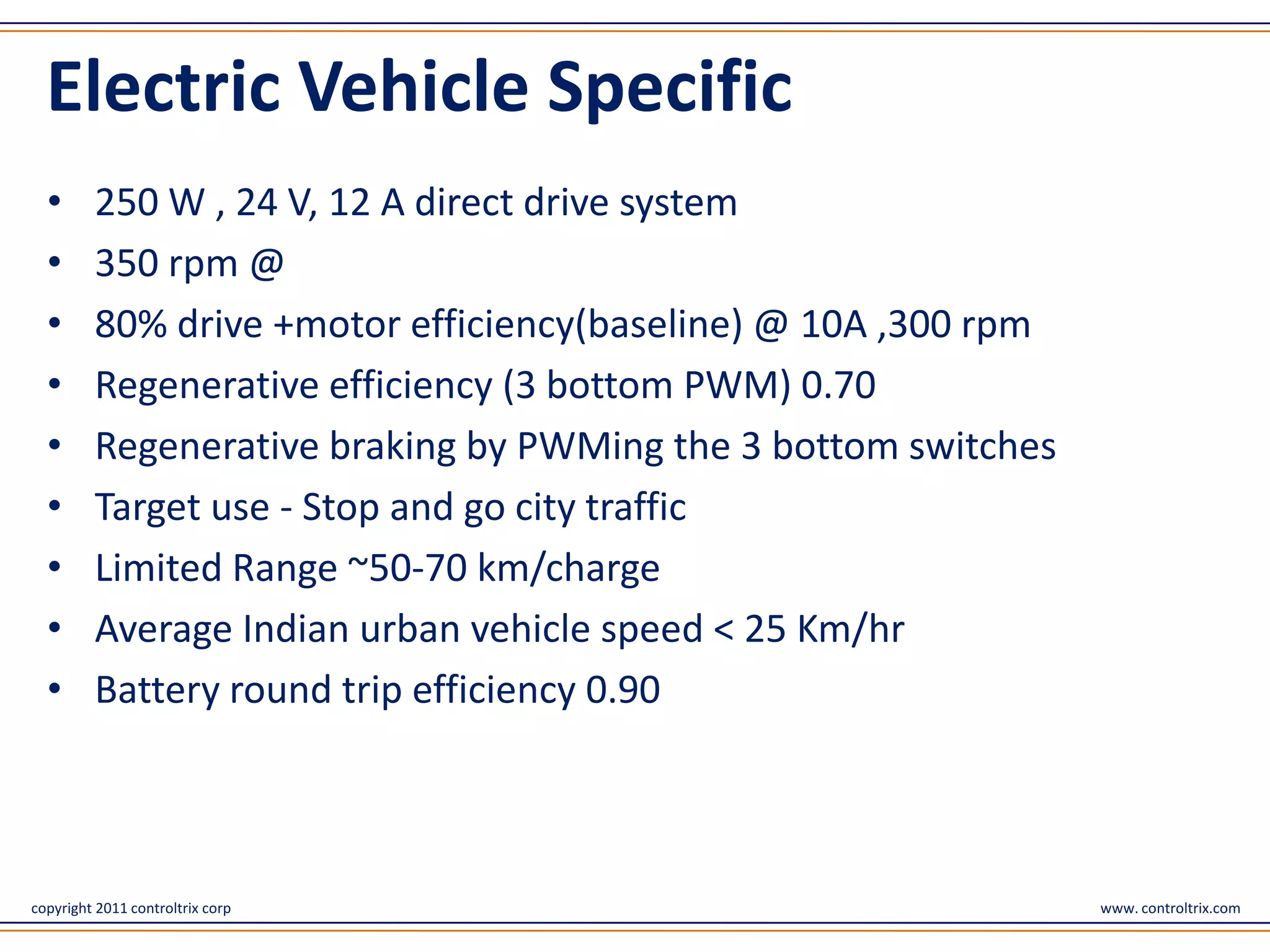

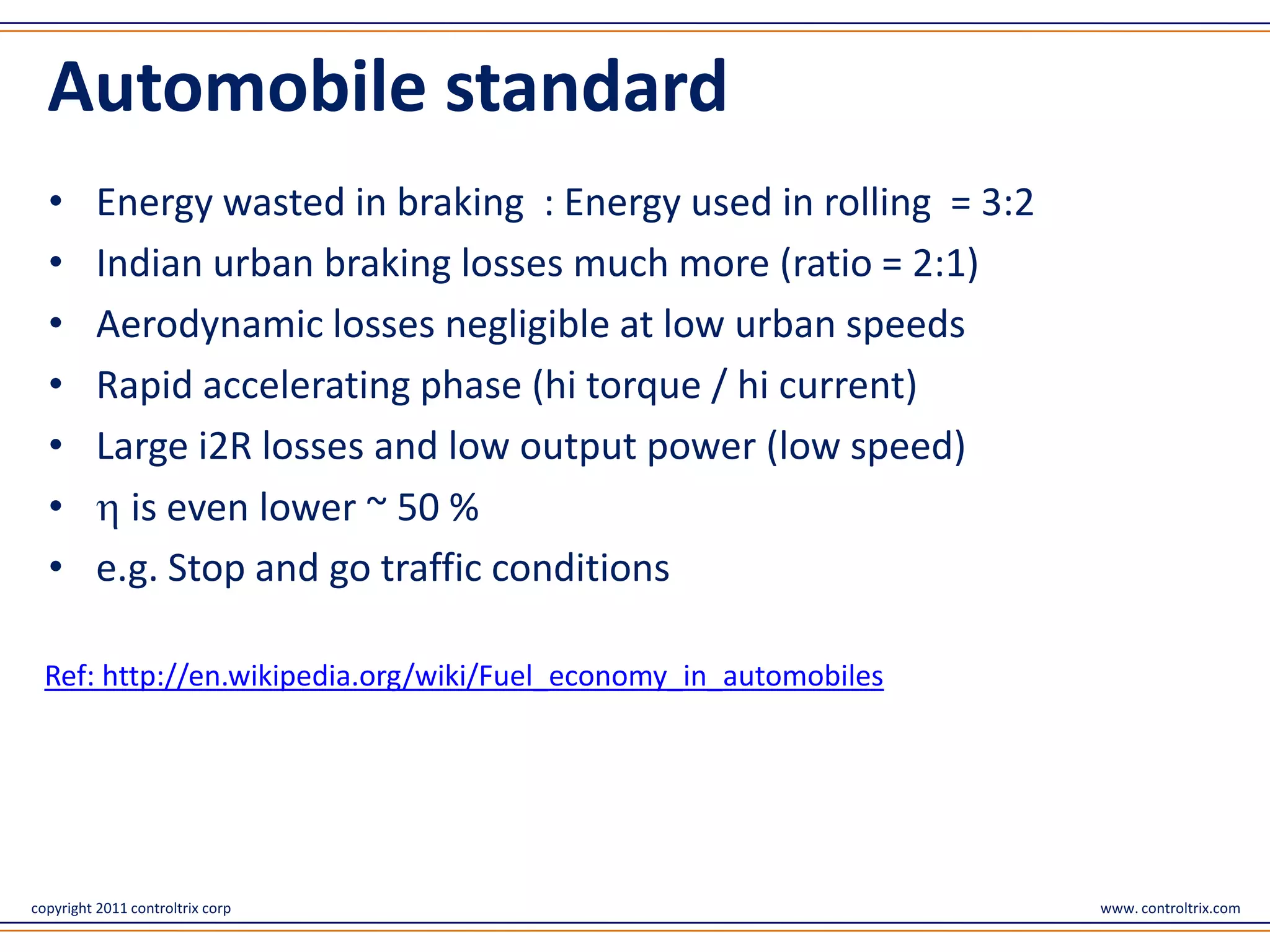

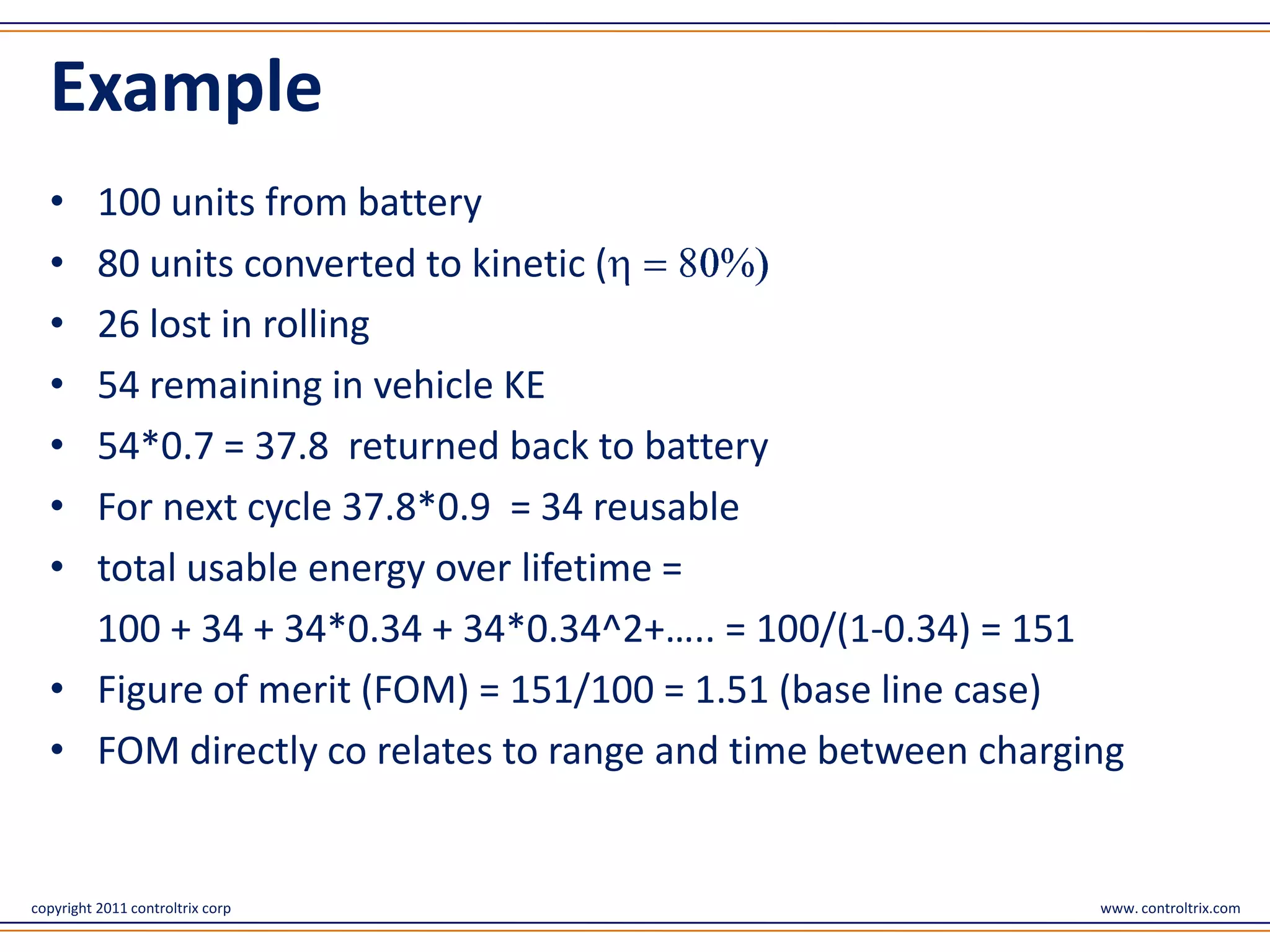

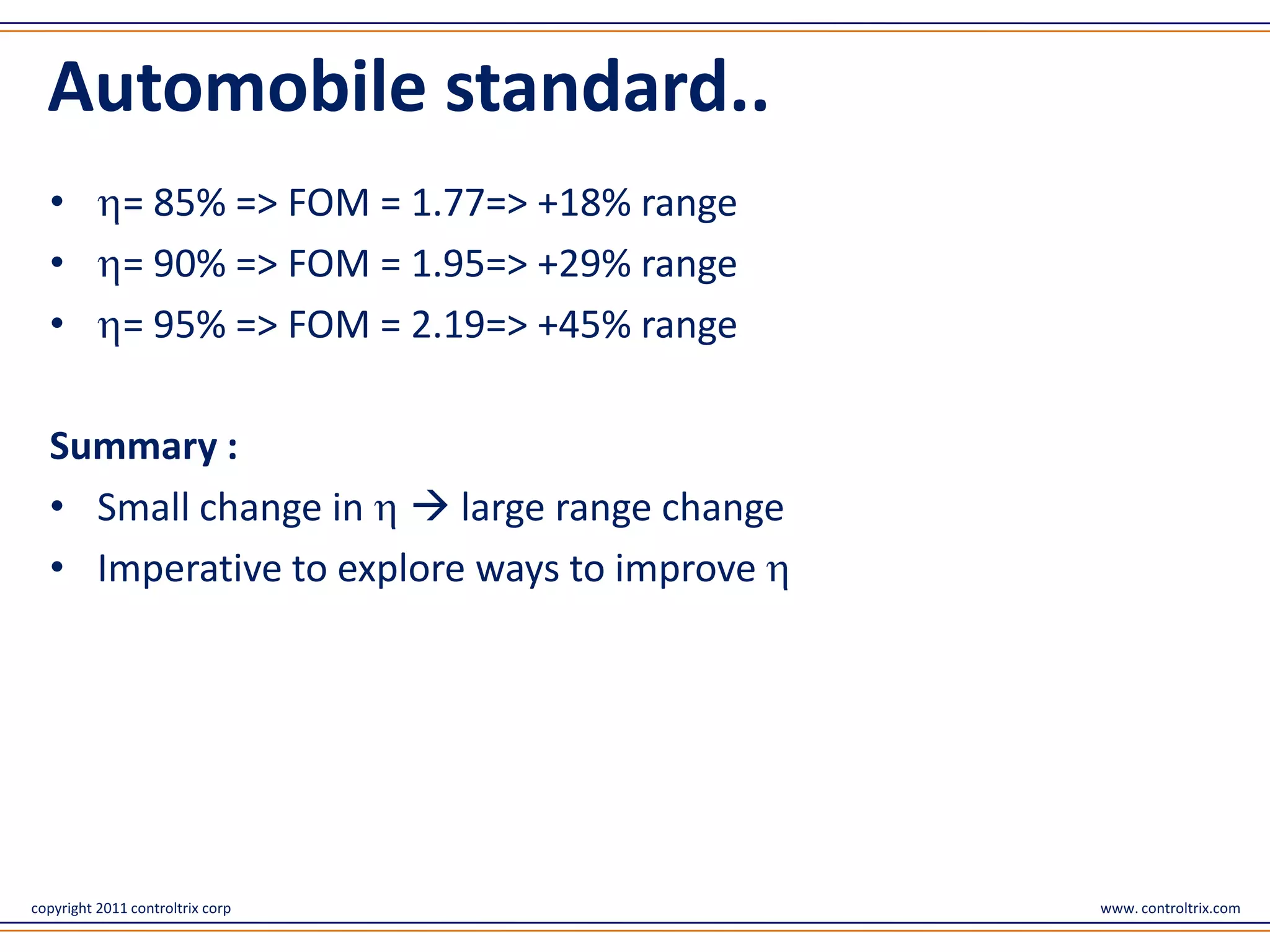

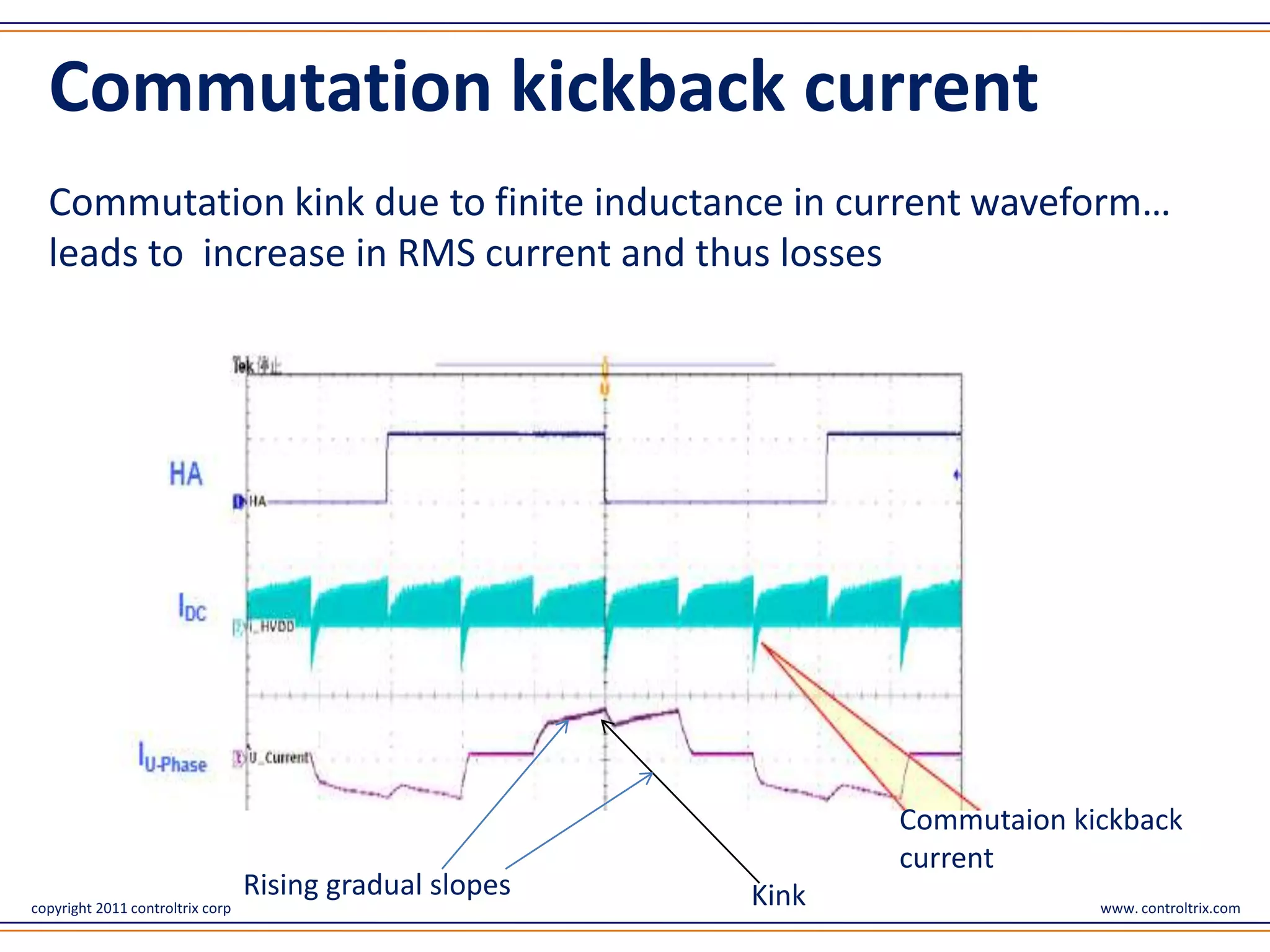

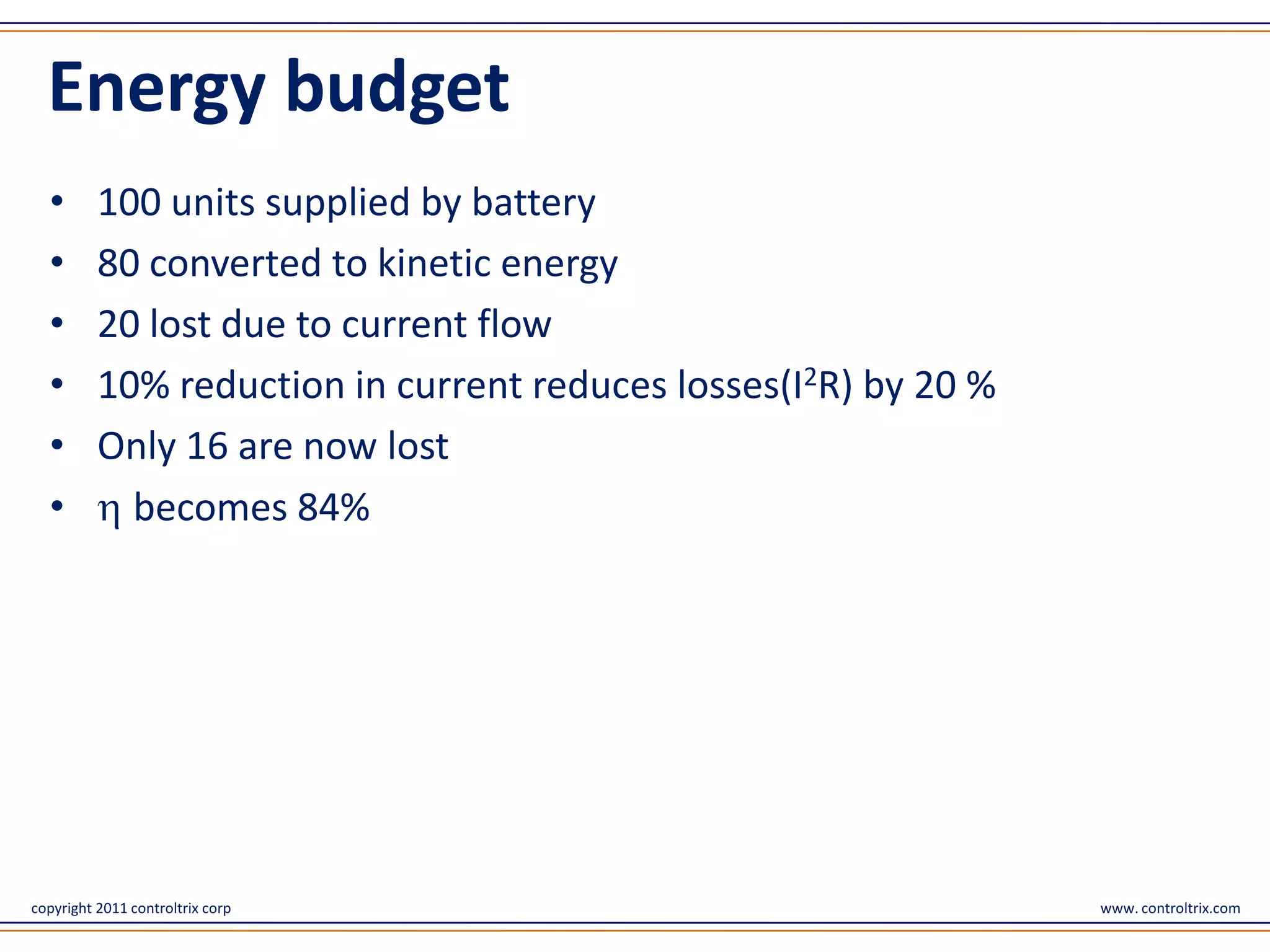

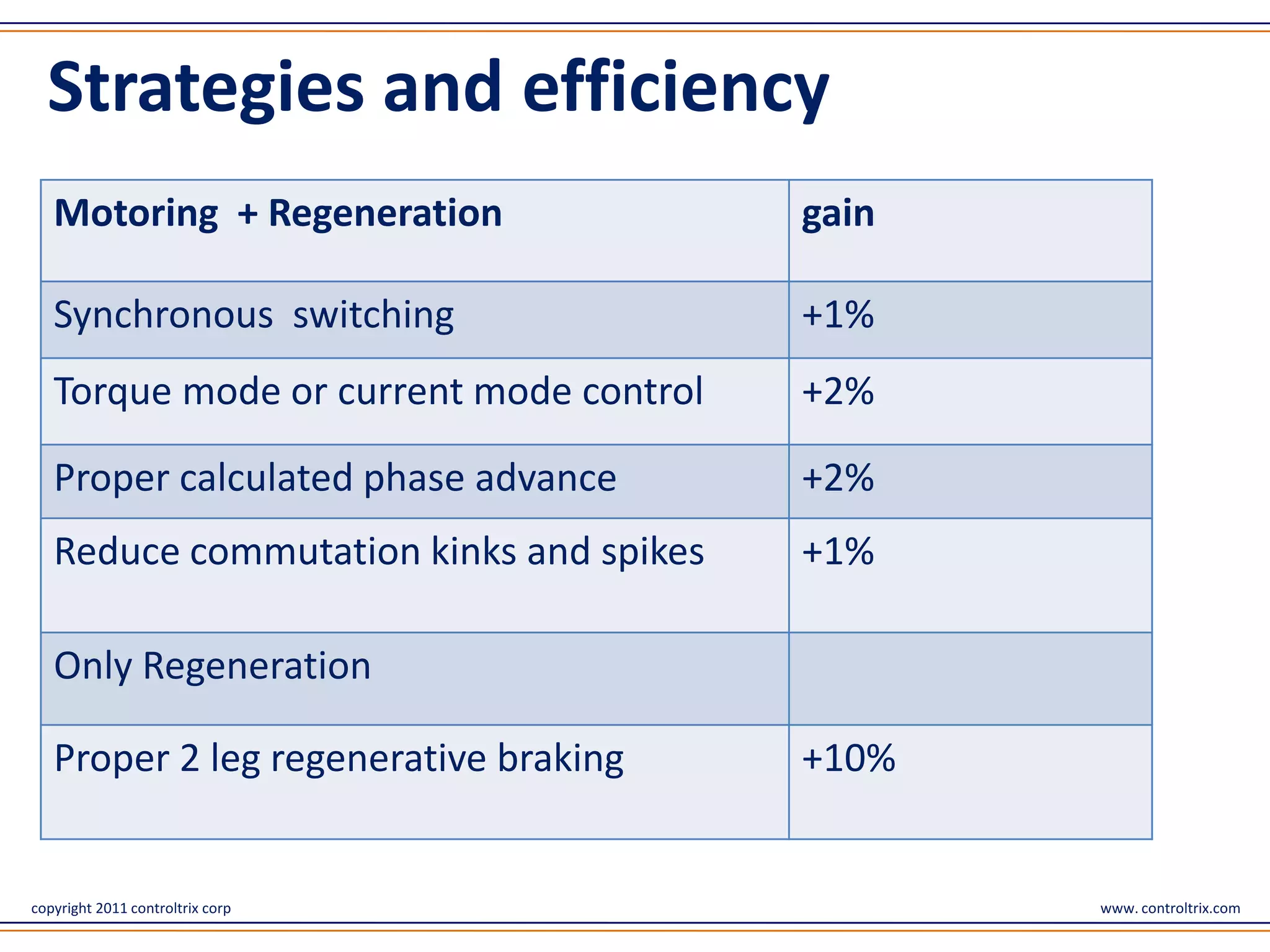

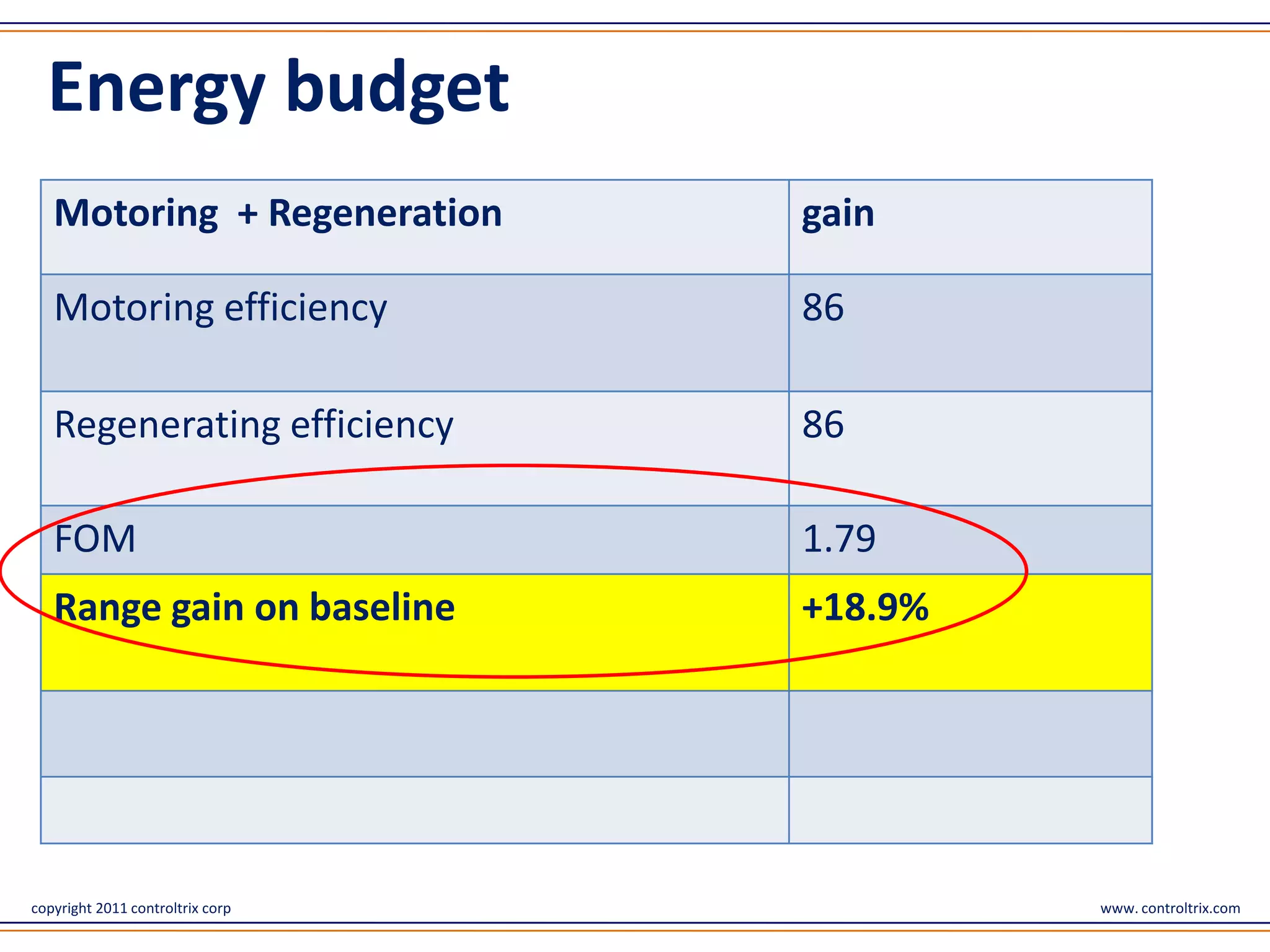

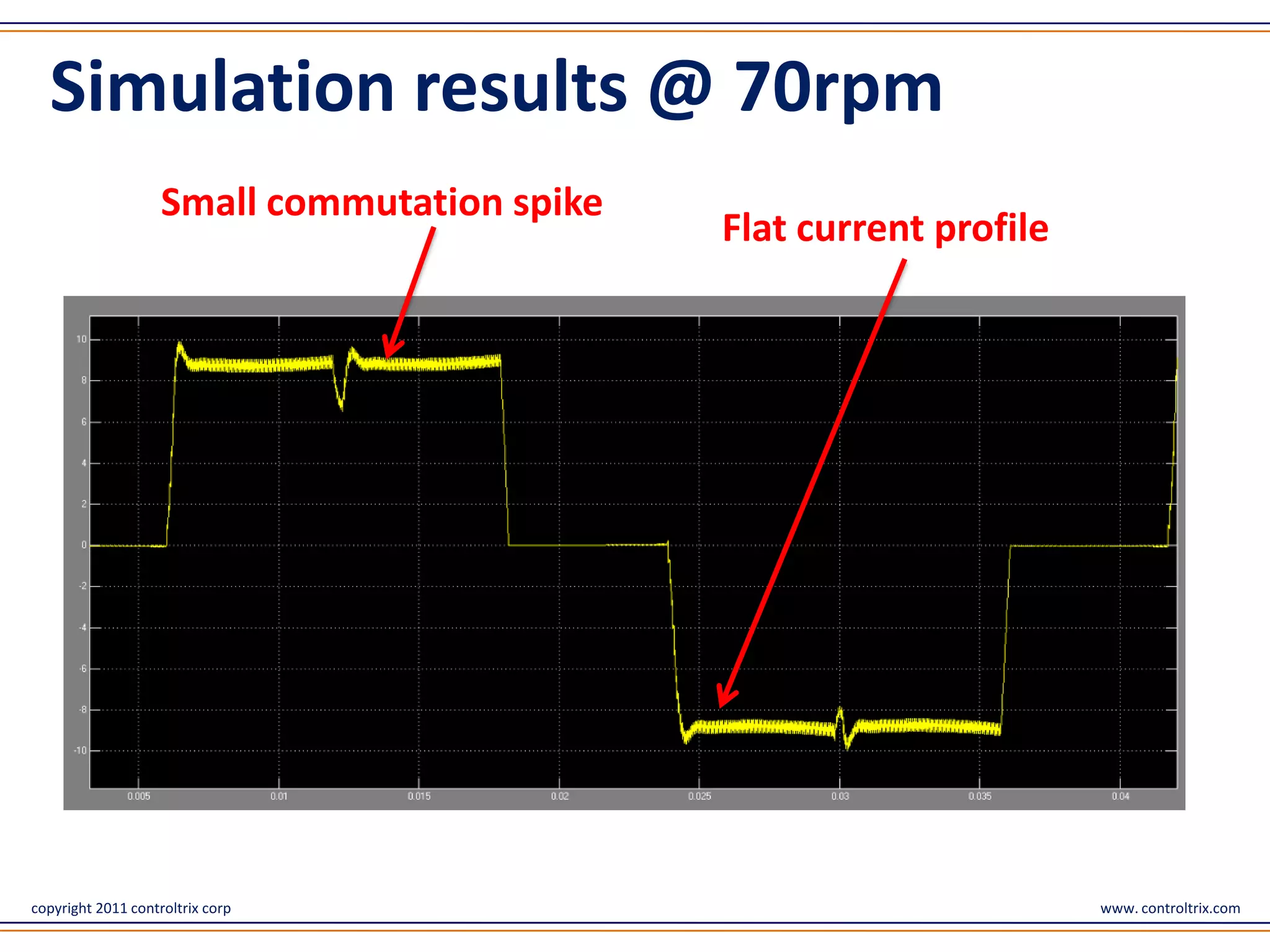

This document discusses improving the efficiency of BLDC motor drive systems for electric vehicles. It describes the basic 6-step hall effect control of the BLDC motor and PWM inverter control. Various strategies are presented to reduce losses and improve efficiency, such as synchronous switching, advanced commutation control to reduce current spikes, optimized regeneration strategies, and improved reliability through hall sensor monitoring. Simulation results show efficiency gains from a flatter current profile at lower speeds. Overall, a 29% potential range increase is estimated through efficiency improvements.