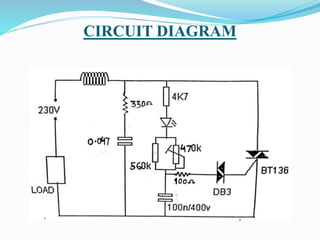

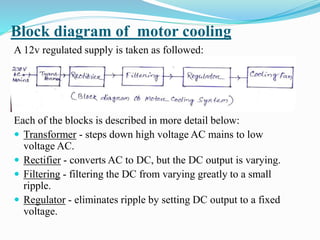

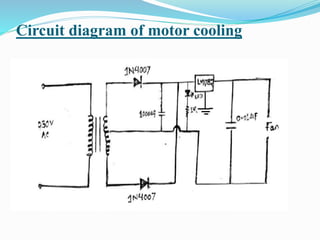

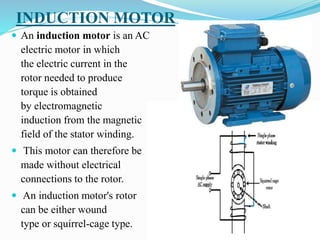

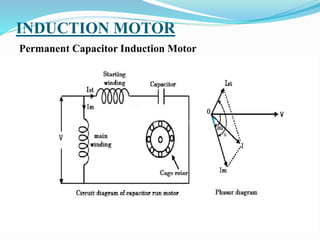

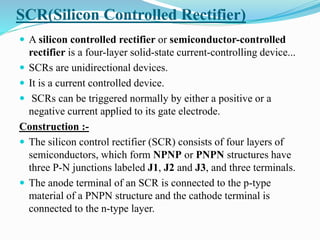

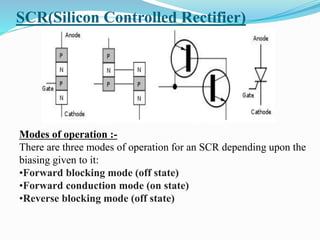

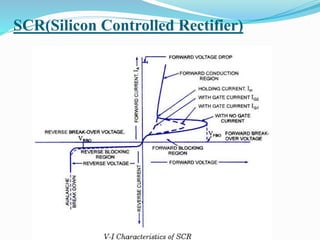

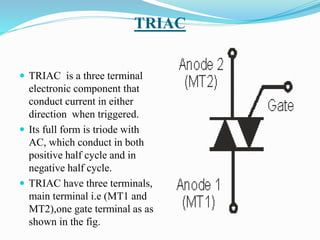

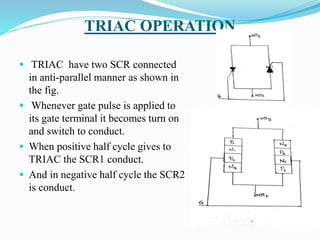

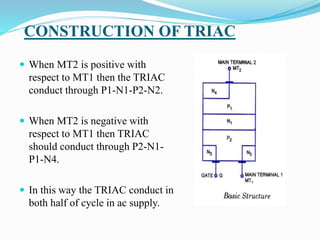

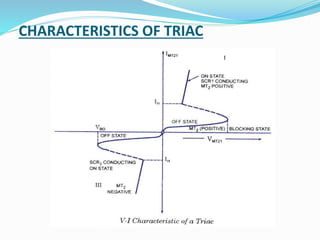

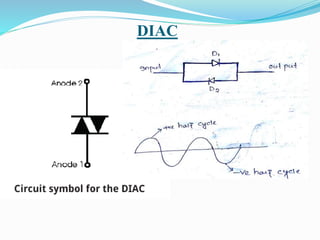

This document describes a project to control the speed of a single-phase induction motor using a TRIAC. It includes sections on the circuit description, induction motor working, SCR, TRIAC, DIAC, applications, advantages and disadvantages. The circuit uses a DIAC to trigger a TRIAC, allowing control of the firing angle to vary the voltage applied to the motor. This provides speed control of the induction motor for applications like pumps, fans and refrigeration.