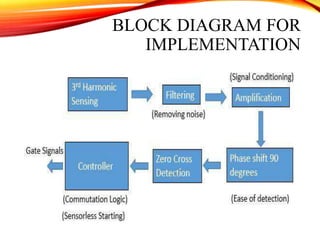

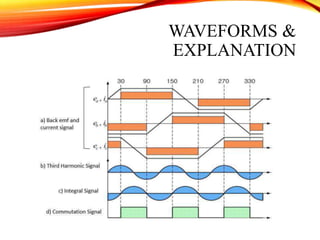

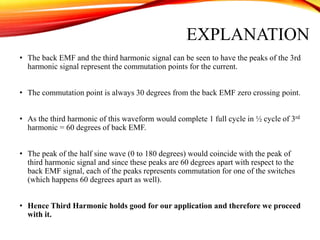

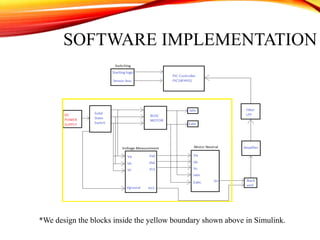

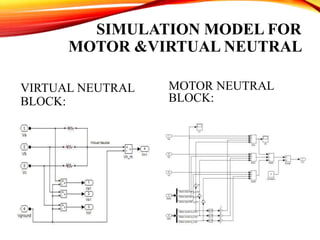

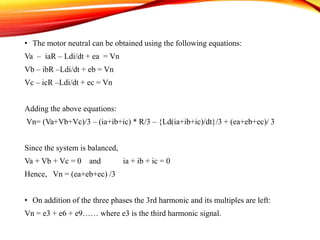

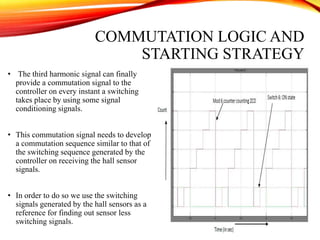

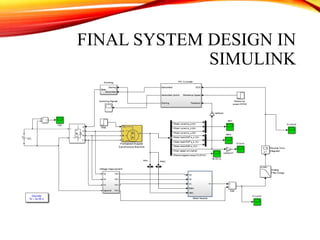

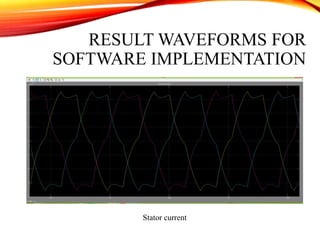

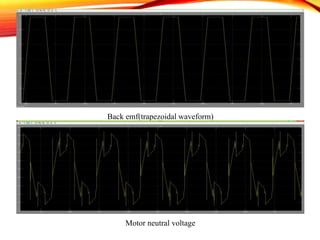

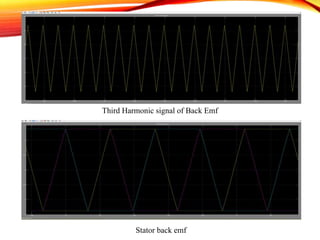

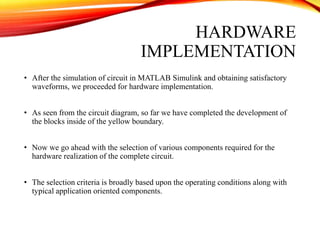

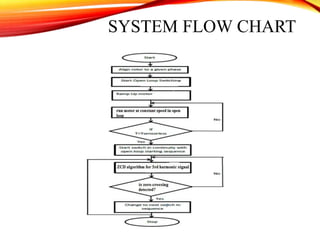

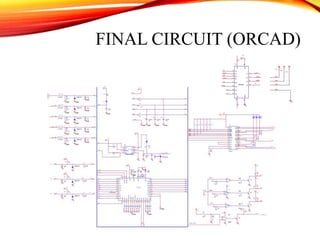

This document summarizes a student project to develop sensorless control of a brushless DC motor using the third harmonic voltage signal method. The objectives are to design a control method, implement it in Simulink, and develop a circuit. BLDC motors are increasingly used due to their efficiency and reliability. Sensorless control can reduce costs by eliminating position sensors. The third harmonic method was chosen because it provides good signal-to-noise ratio and wide speed range. Key steps are extracting the third harmonic from phase voltages, and using its peaks to determine commutation points for switching the motor phases. The project involves modeling the motor and extracting the virtual neutral point in Simulink, and developing the commutation logic and starting strategy.

![4. Sensor less Control of BLDC

Motor Drive Fed by Isolated

DC-DC Converter

Sonia Sunny, Rajesh

Asst. Prof, Department

of EEE, Rajiv Gandhi

Institute of Technology

improved topology of

an isolated DC-DC

converter fed sensor

less BLDC drive

HFT (High Frequency

Transformer) provides

Isolation ensuring safe

operation of the motor

drive.

5. BLDC motor drives using

the unknown input observer

to Sensor less Control

Method for Brushless DC

Motors

Tae-Sung Kim, , Dong-

Myung Lee, and Dong-

Seok Hyun Electrical

Engineering from

Dankook University,

Seoul, Korea,

Line-to line back-

EMF estimation.

detect the rotor position

effectively over a full

speed range, especially at

a low speed range

6. Speed Control of BLDC

Motor Using PID Controller

R.G.Rajesh, C.Balaji

PG Student

[Electronics and

Control], Dept. of ICE,

SRM University,

Chennai

PID controlled

brushless direct

current motor drive

using MATLAB /

SIMULINK

MATLAB/Simulink

environment allows that

many dynamic

characteristics such as

voltage ,rotor speed, phase

current and mechanical

torque can be effectively

Considered.](https://image.slidesharecdn.com/4aecf1f2-bb81-4778-b775-ab74280c0eee-161129033945/85/Final_Presentation-7-320.jpg)

![REFERENCES

[1] Speed Control of BLDC Motor Using PID Controller,” International Journal of Advanced Research in

Electrical, Electronics and Instrumentation Engineering Vol. 3, Issue 4, April 2014”

[2] A New Approach to Sensor-Less Control Method for Brushless DC Motors,” International Journal of

Control, Automation, and Systems, vol. 6, no. 4, pp. 477-487, August 2014”

[3] PWM controlled BLDC Motor, ”International Journal of Scientific and Research Publications, Volume 3,

Issue 4, April 2013 1 ISSN 2250-3153”

[4] Sonia Sunny, Rajesh K, “Sensor-Less Control of BLDC Motor Drive Fed by Isolated DC-DC Converter”,

IJAREEIE (International Journal of Advanced Research in Electrical, Electronics and Instrumentation

Engineering) Vol. 2, Special Issue 1, December 2013

[5] Tae-Sung Kim, Dong-Myung Lee, and Dong-Seok Hyun, “BLDC motor drives using the Line-to line back-

EMF estimation” , International Journal of Control, Automation, and Systems, vol. 6, no. 4, pp. 477-487, August

2008

[6] J. Shao, D. Nolan, M. Teissier, and D. Swanson, “A Novel microcontroller based sensor less brushless DC

(BLDC) motor drive for automotive fuel pumps,” IEEE Trans. Ind. Appl., vol. 39, no. 6, pp. 1734–1740, Nov.

/Dec. 2003.

[7] Charlie Elliott Smart Power Solutions, and Steve Bowling Microchip Technology Inc, “Sensor-less BLDC

control using dsPIC30F” Microchip application note AN901 Sept. 2012.](https://image.slidesharecdn.com/4aecf1f2-bb81-4778-b775-ab74280c0eee-161129033945/85/Final_Presentation-46-320.jpg)