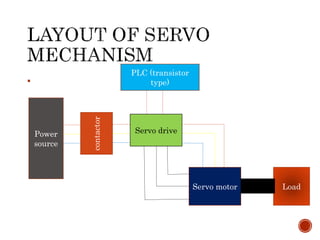

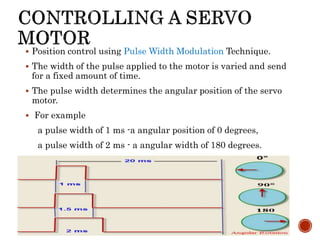

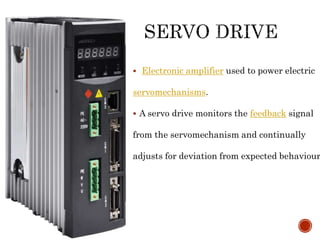

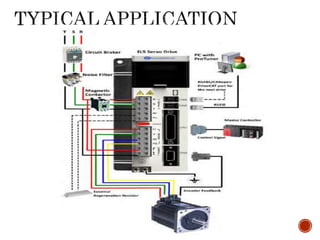

A servomotor is a precise actuator for controlling angular or linear position, consisting of an electric motor, feedback device, and electronic controller. It can be AC or DC, with options for brushed or brushless variants, and utilizes techniques like pulse width modulation for position control. Applications include robotics, conveyor systems, CNC machines, and more.