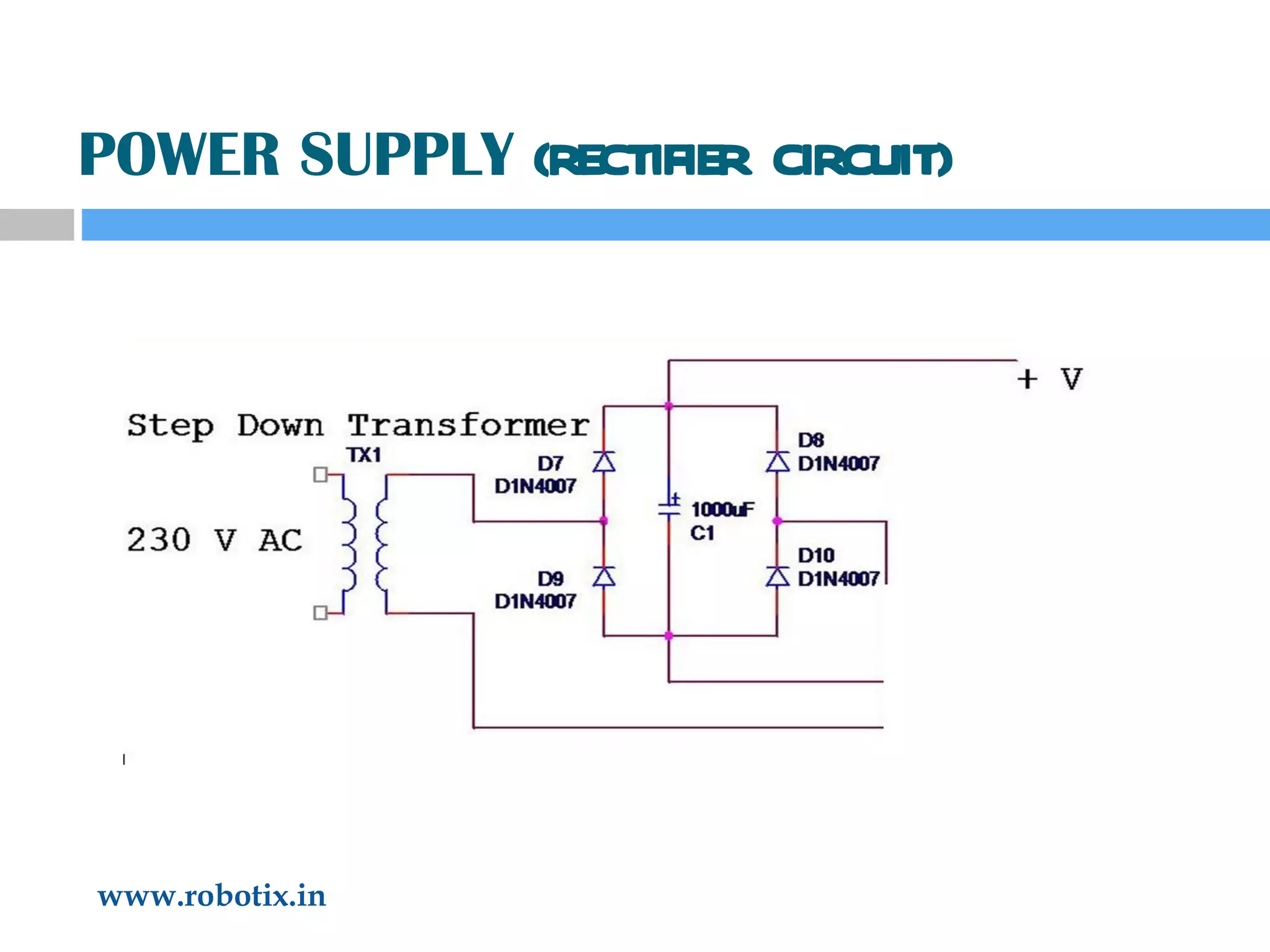

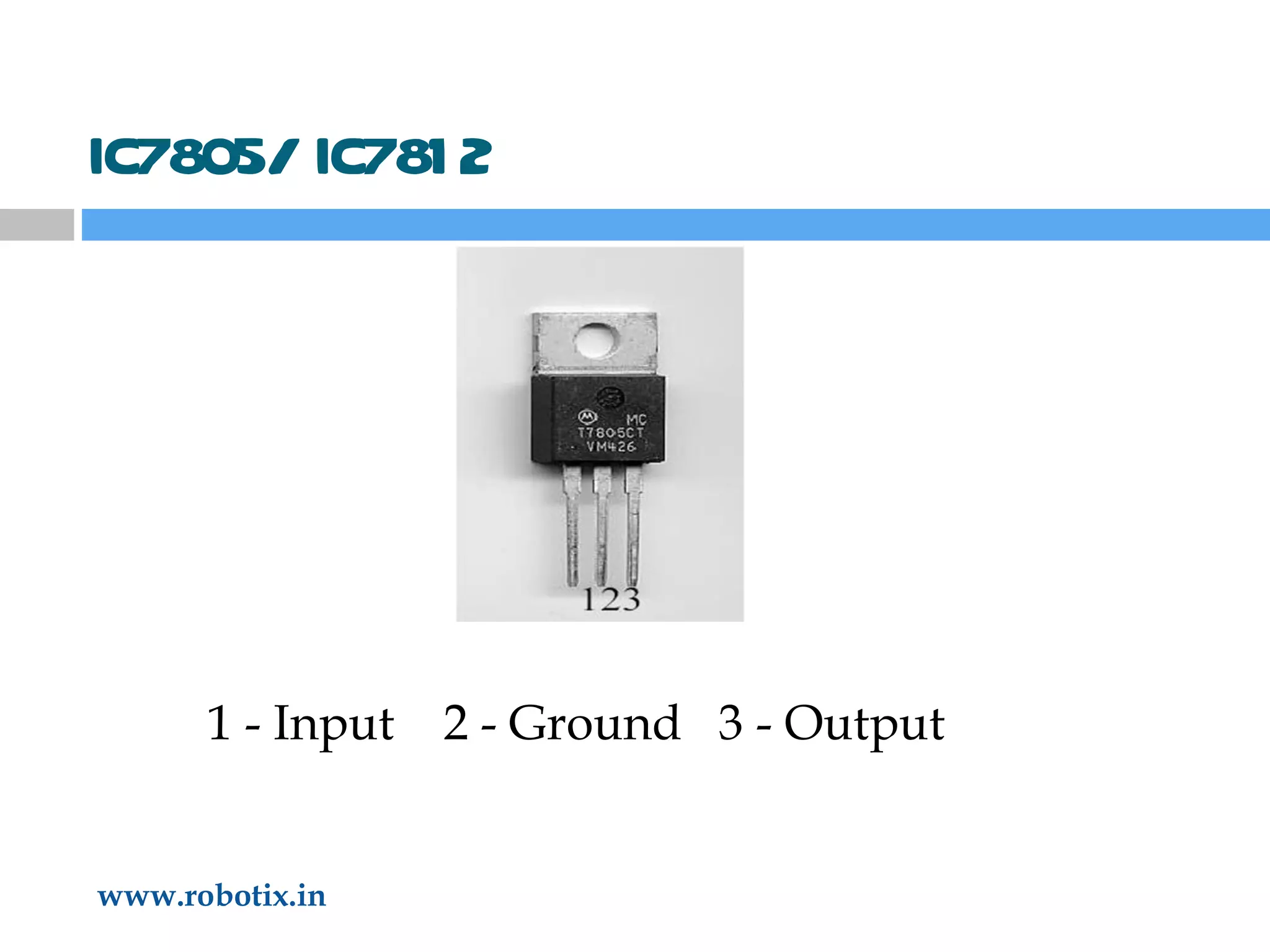

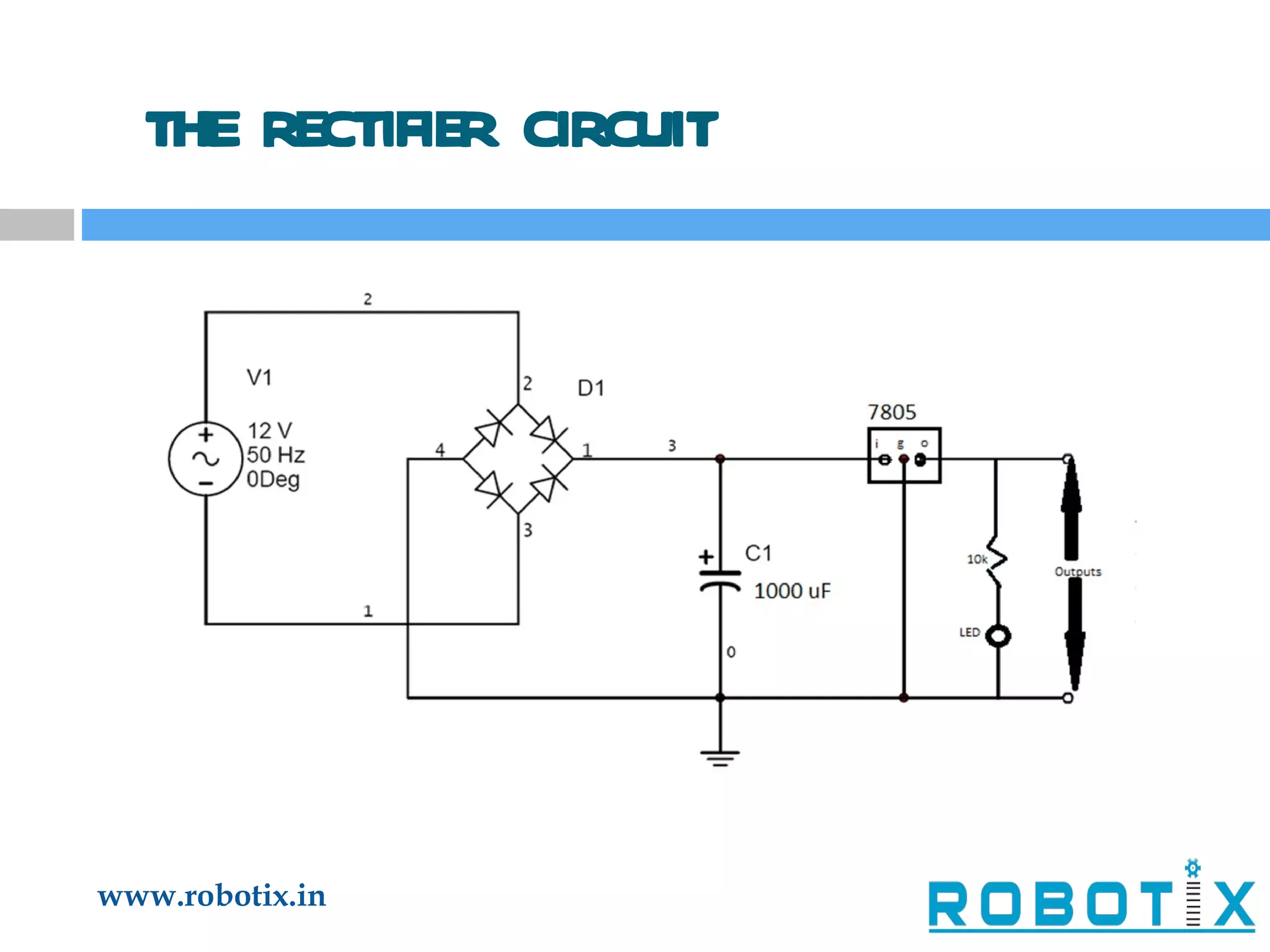

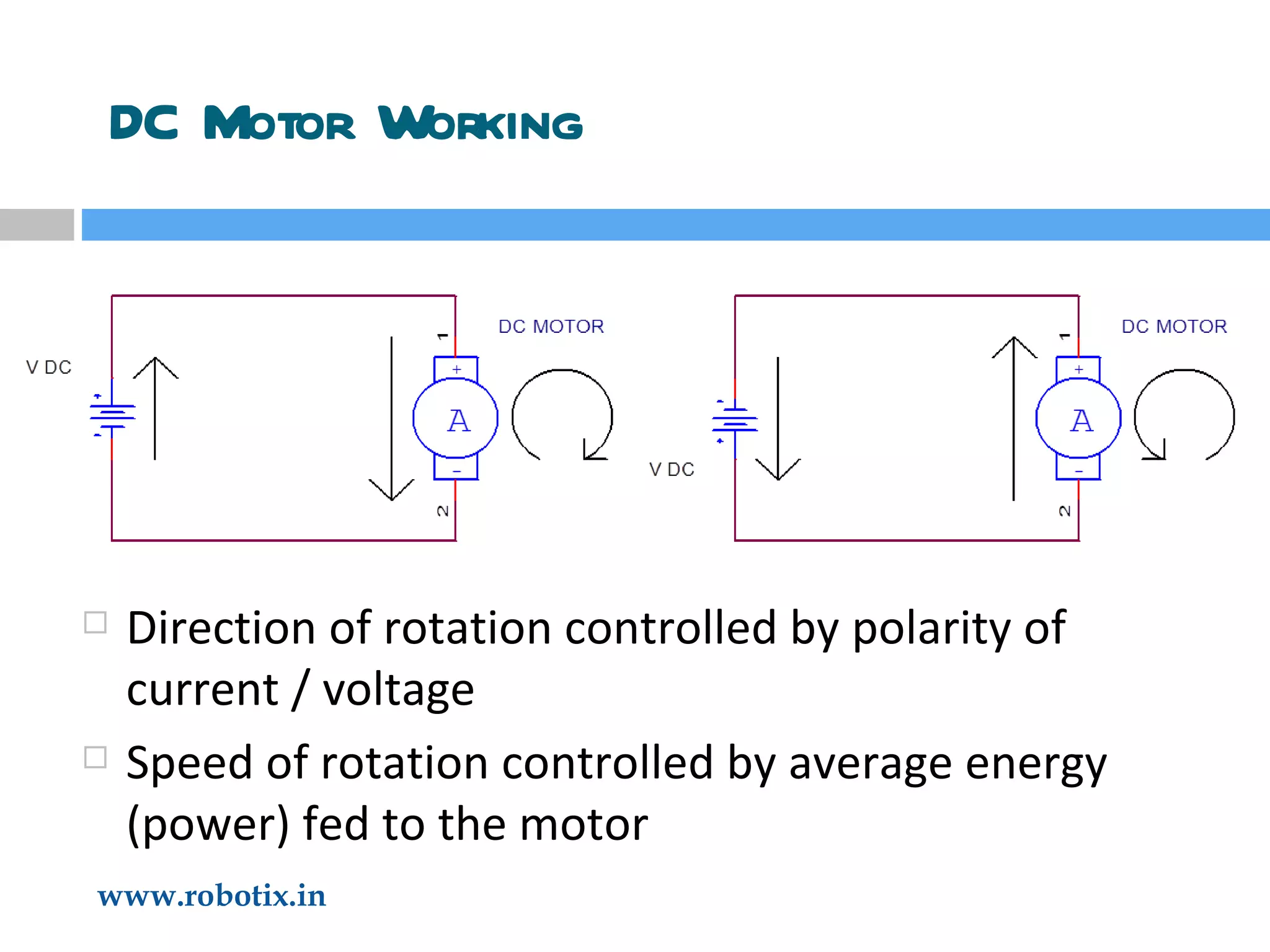

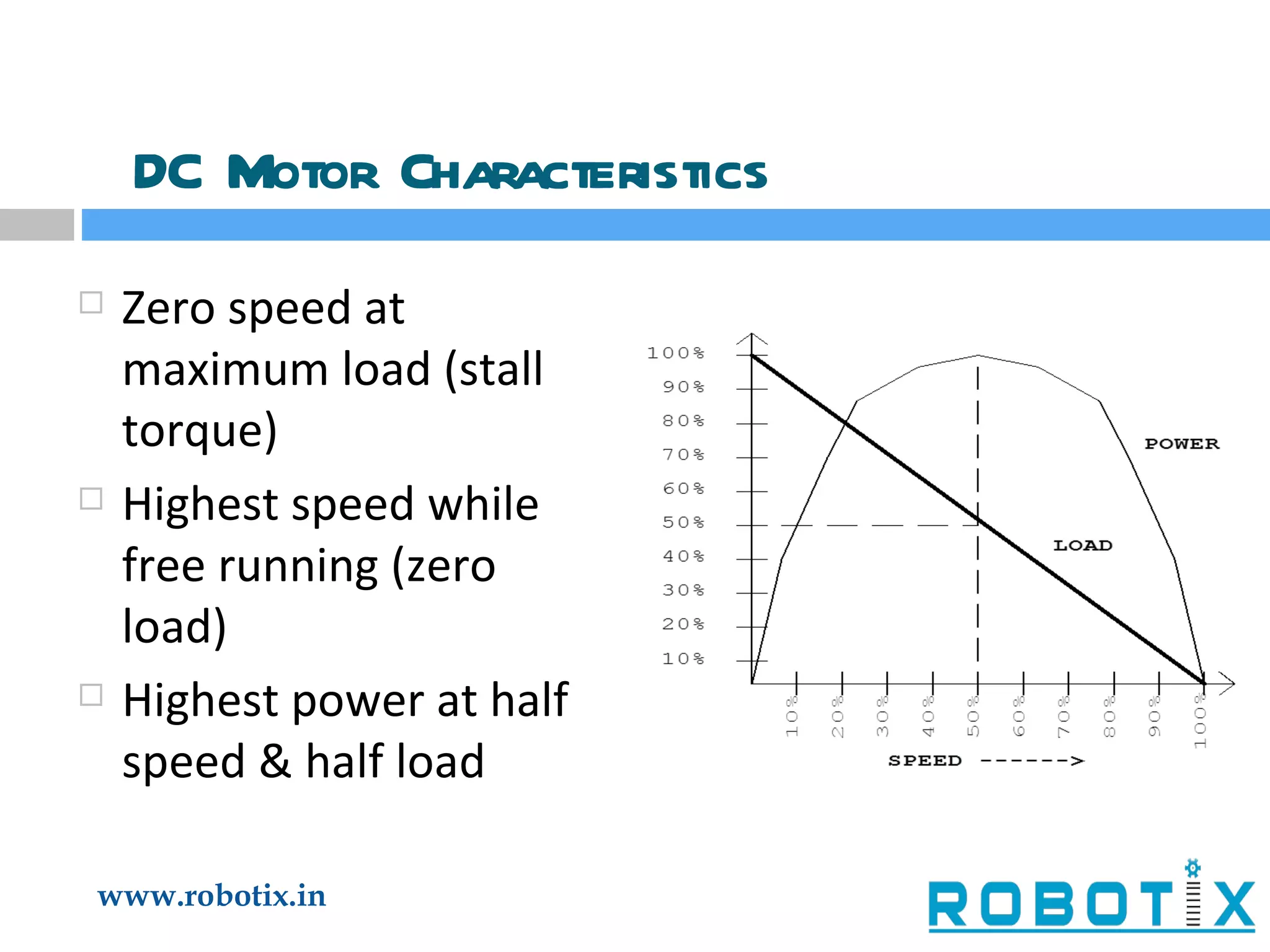

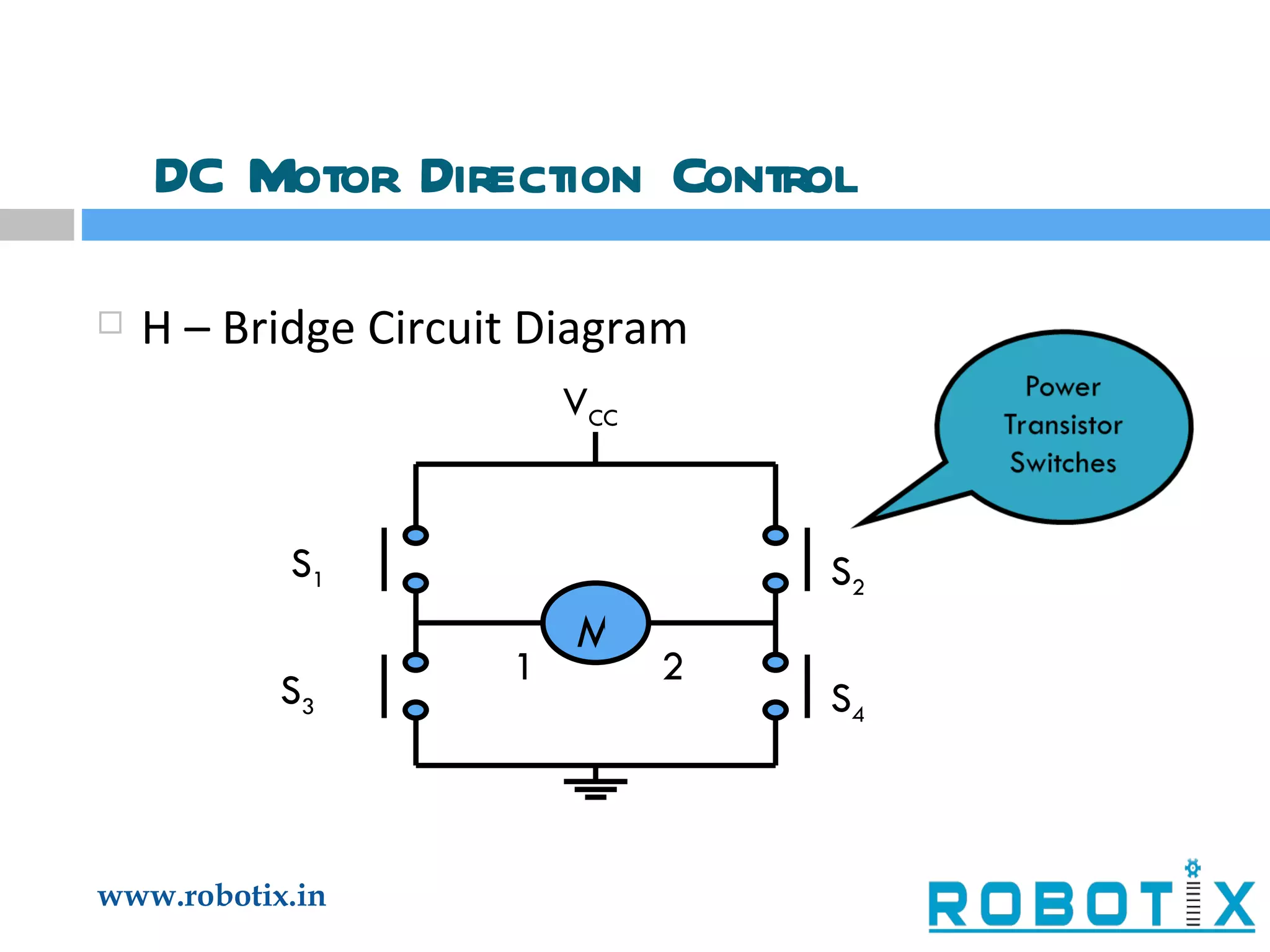

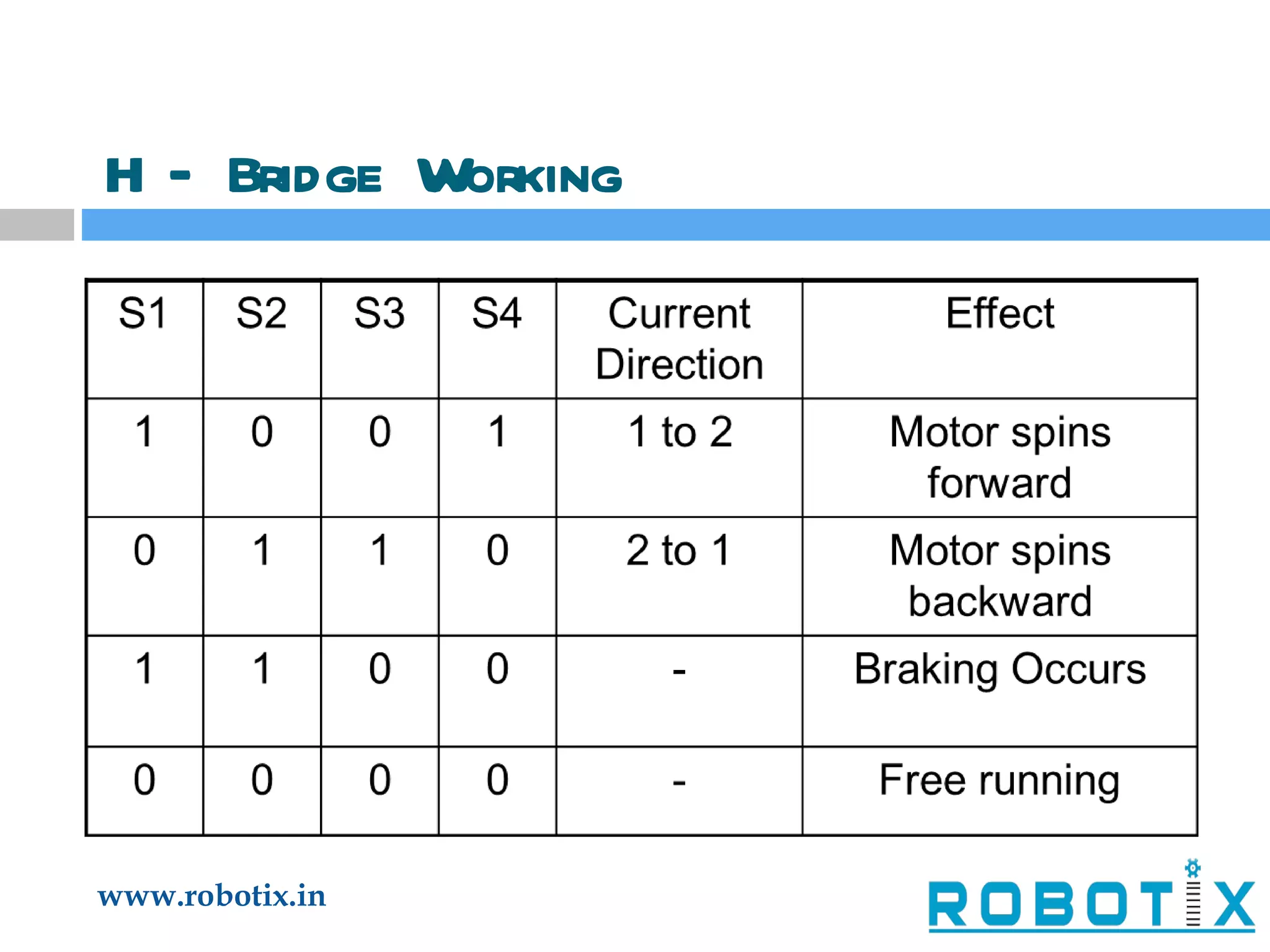

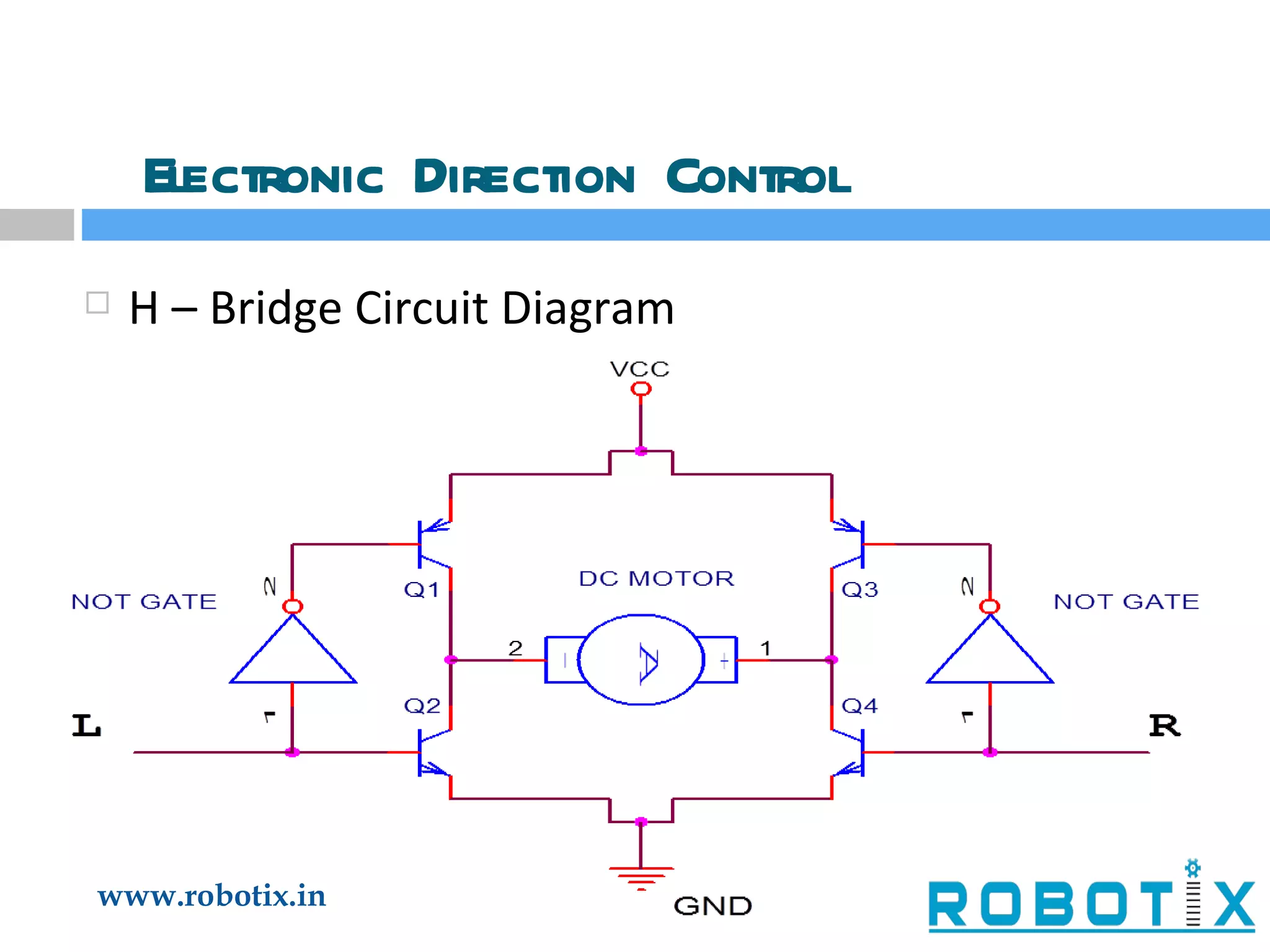

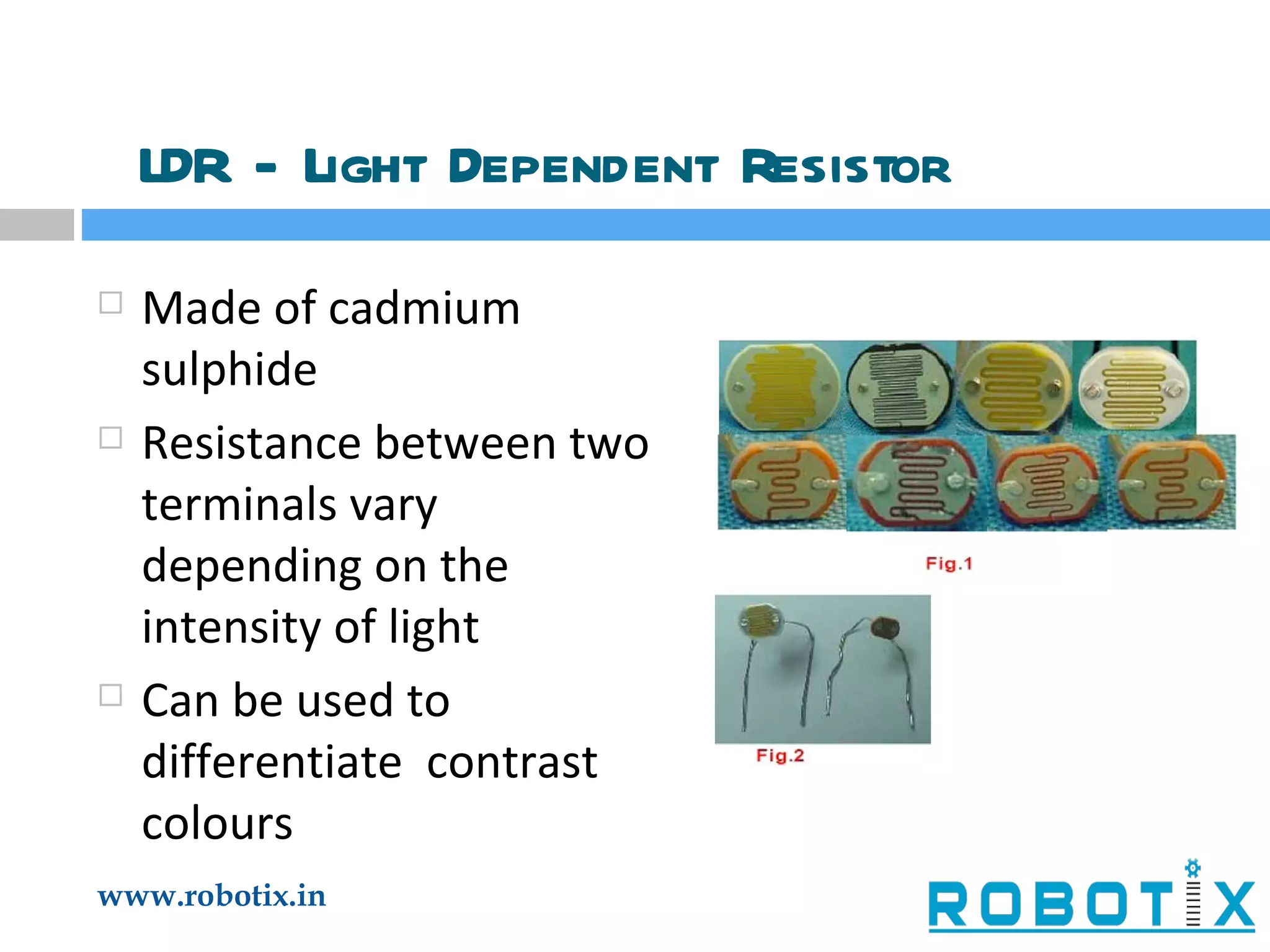

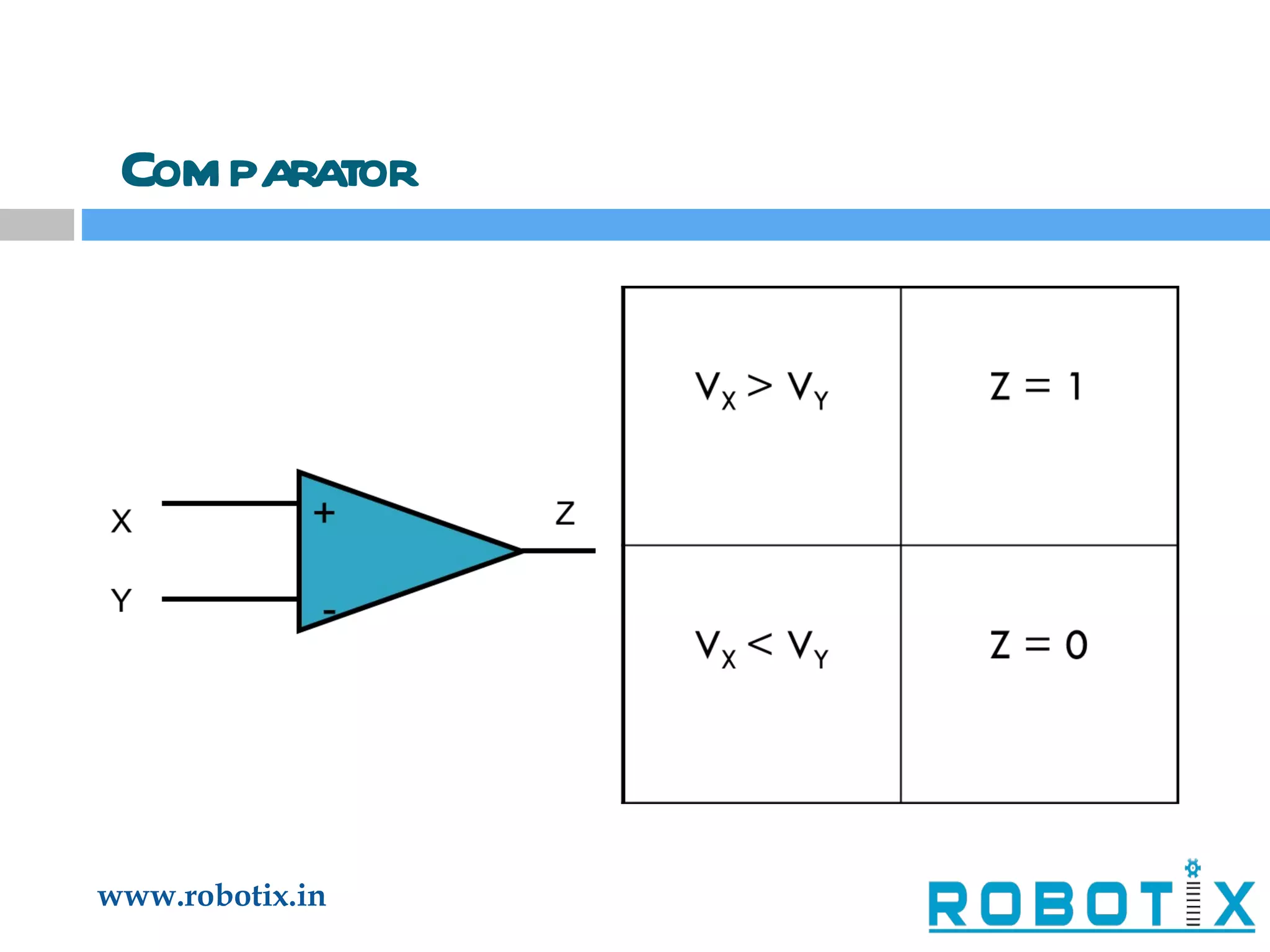

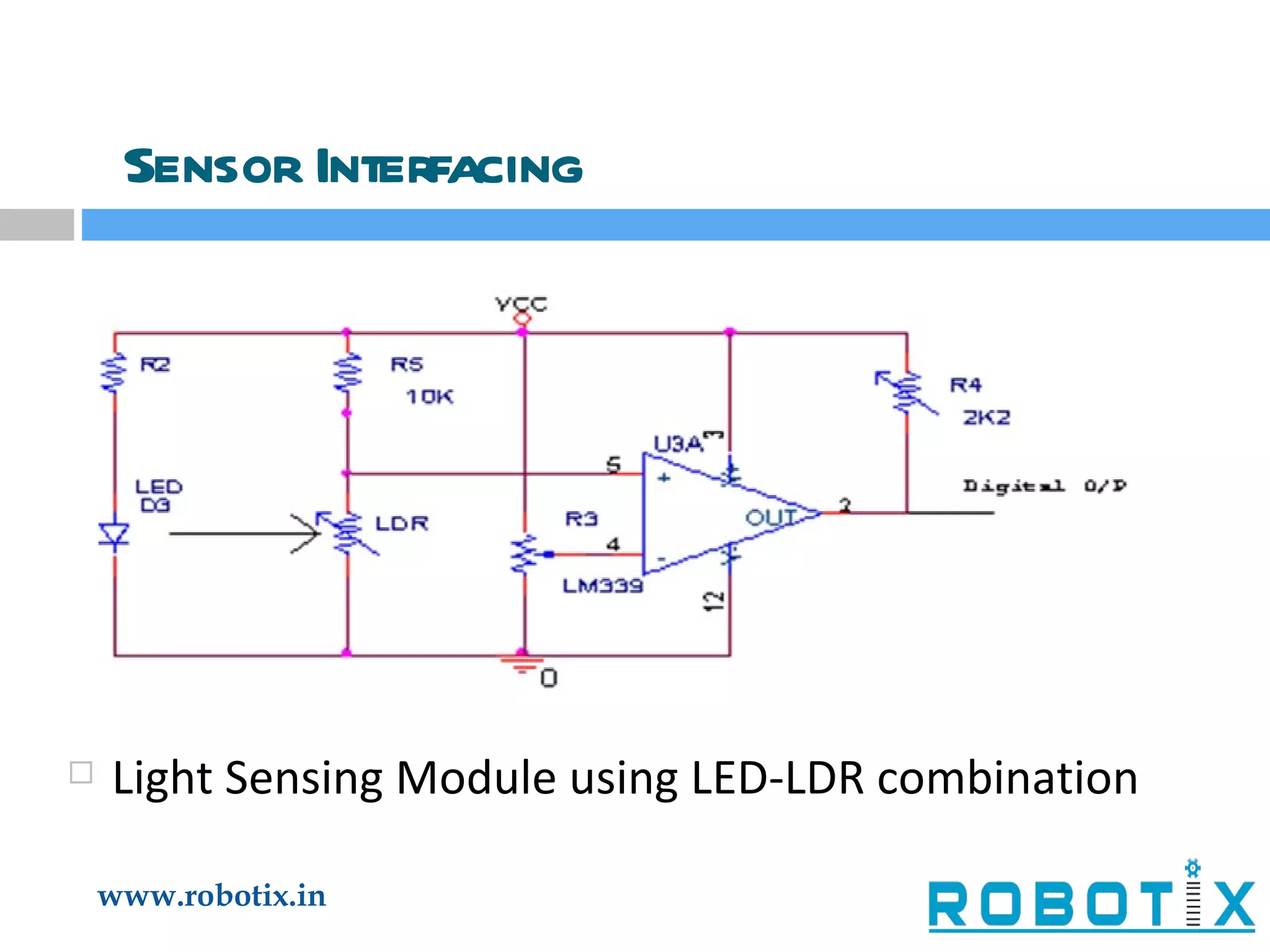

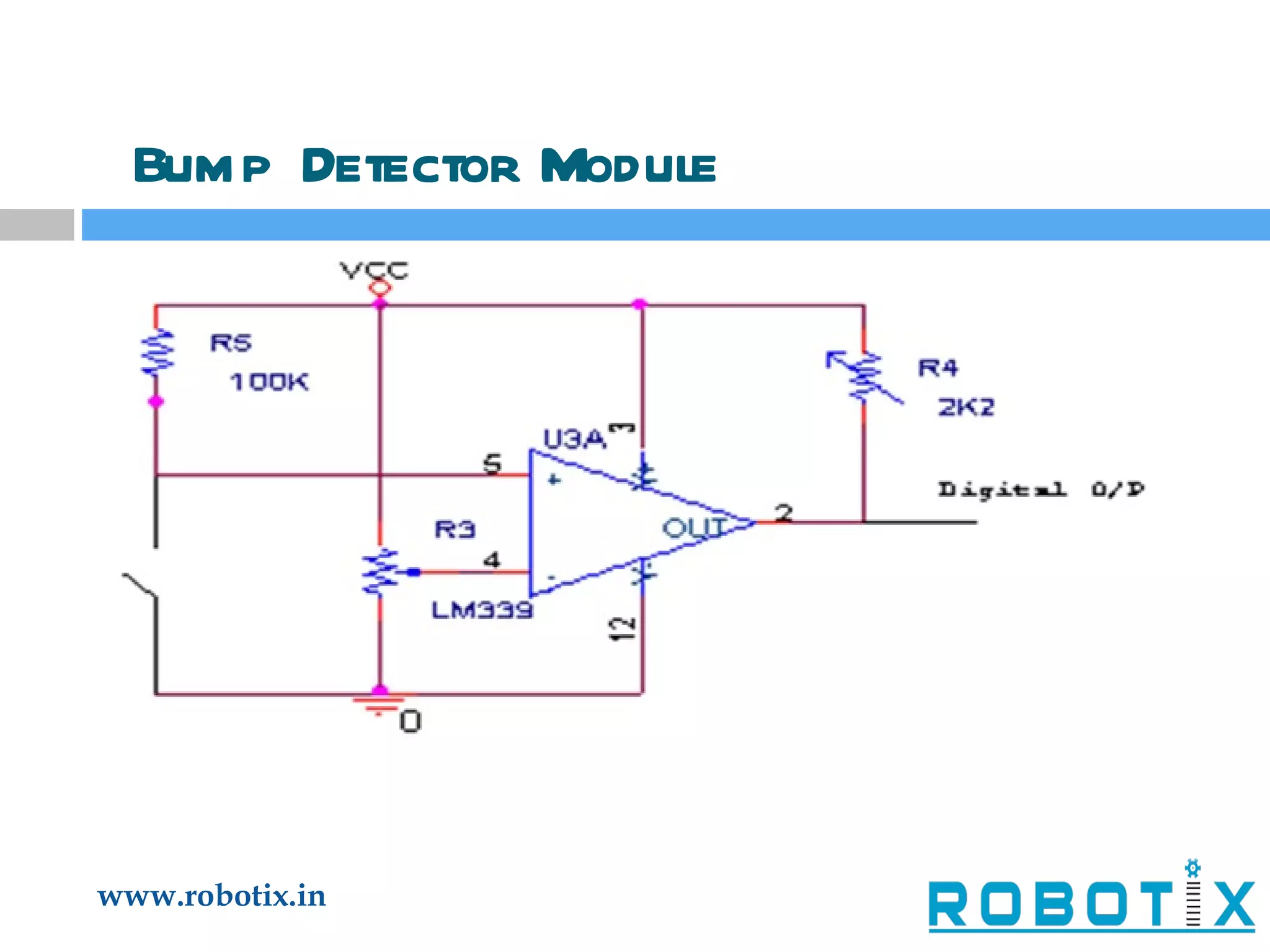

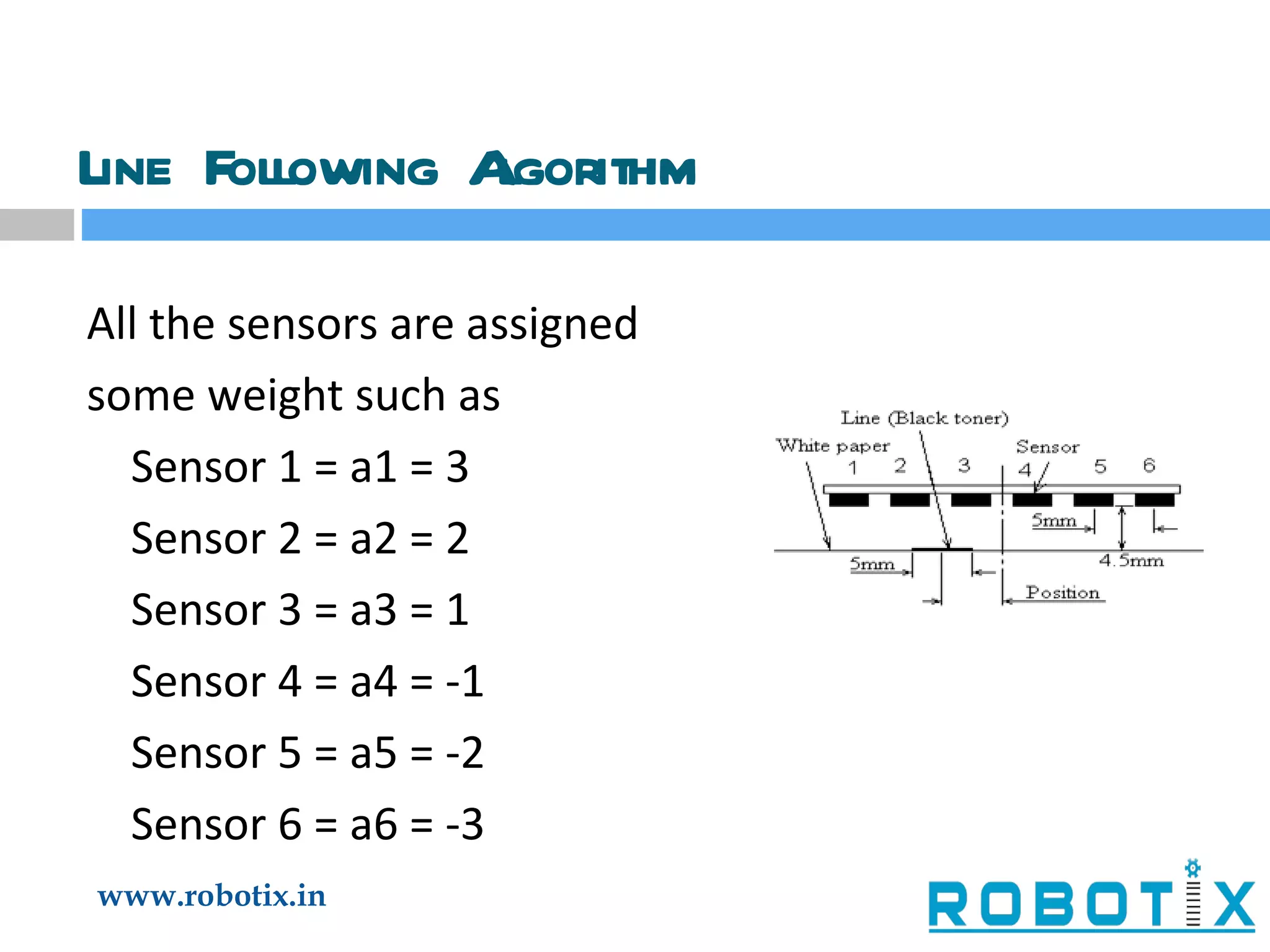

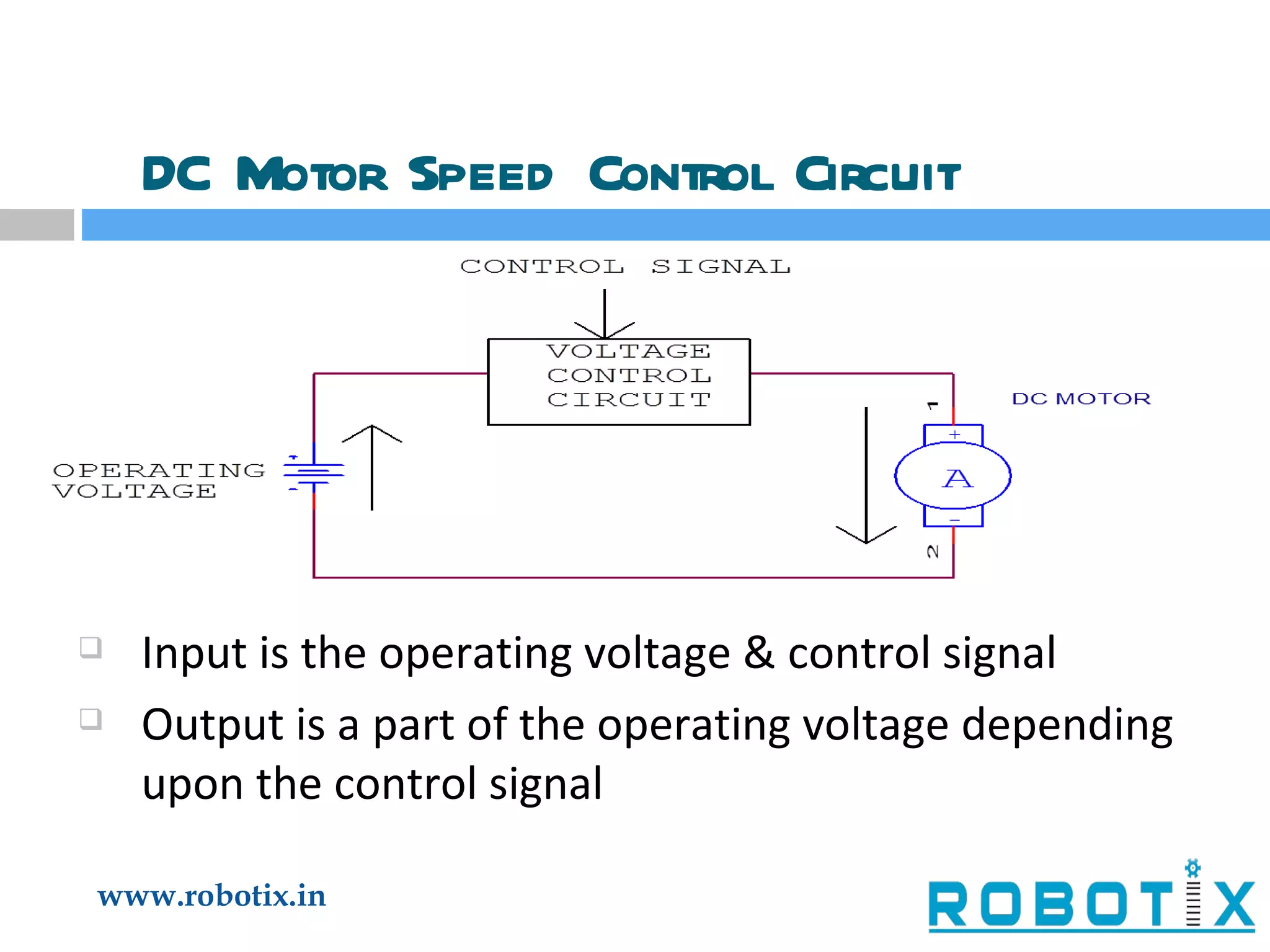

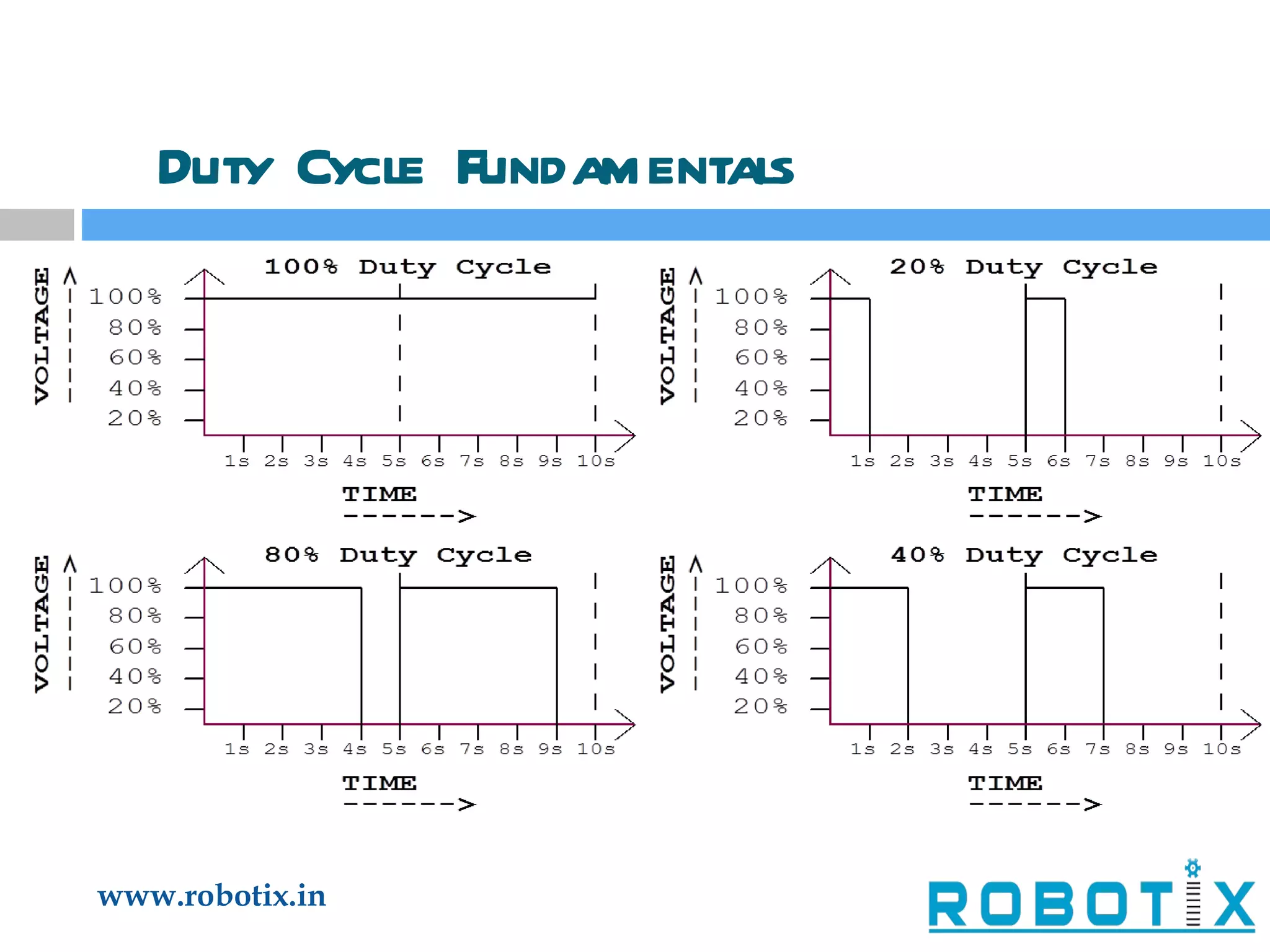

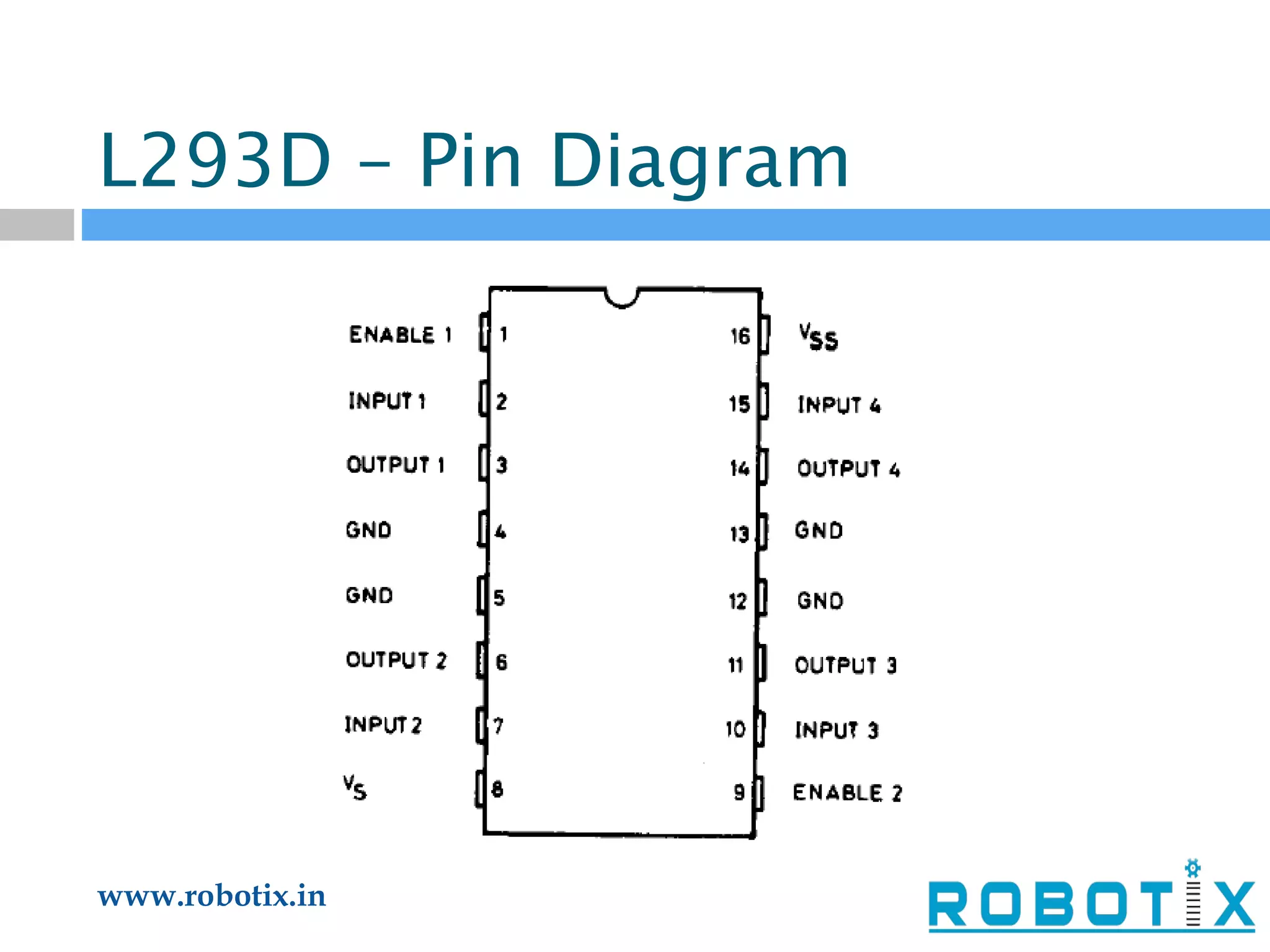

The document summarizes key components of a mobile robot including locomotion systems, power supplies, actuators, sensors, and control systems. It describes specific sensors like light dependent resistors and comparators that provide feedback. It also discusses actuators like DC motors and how their speed and direction can be controlled through H-bridge circuits and pulse width modulation.