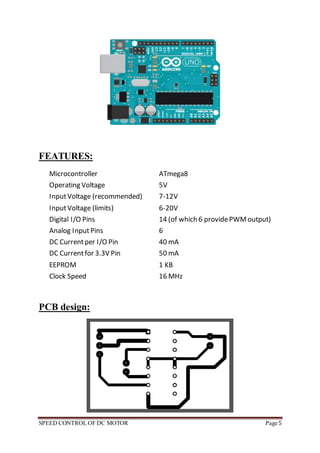

The document discusses a project on controlling the speed of a DC motor using an Arduino controller and PWM technique, incorporating an encoder for RPM feedback. It covers the components involved, including types of DC motors, the Arduino features, PCB design, and the operational functionality of the H-bridge and optocoupler. The project aims to implement a feedback system for precise speed control of the DC motor.