This document provides information about printed circuit boards (PCBs) including:

- PCBs mechanically support and electrically connect electronic components using conductive tracks etched onto a non-conductive substrate. PCBs can be single layer, double layer, or multi-layer.

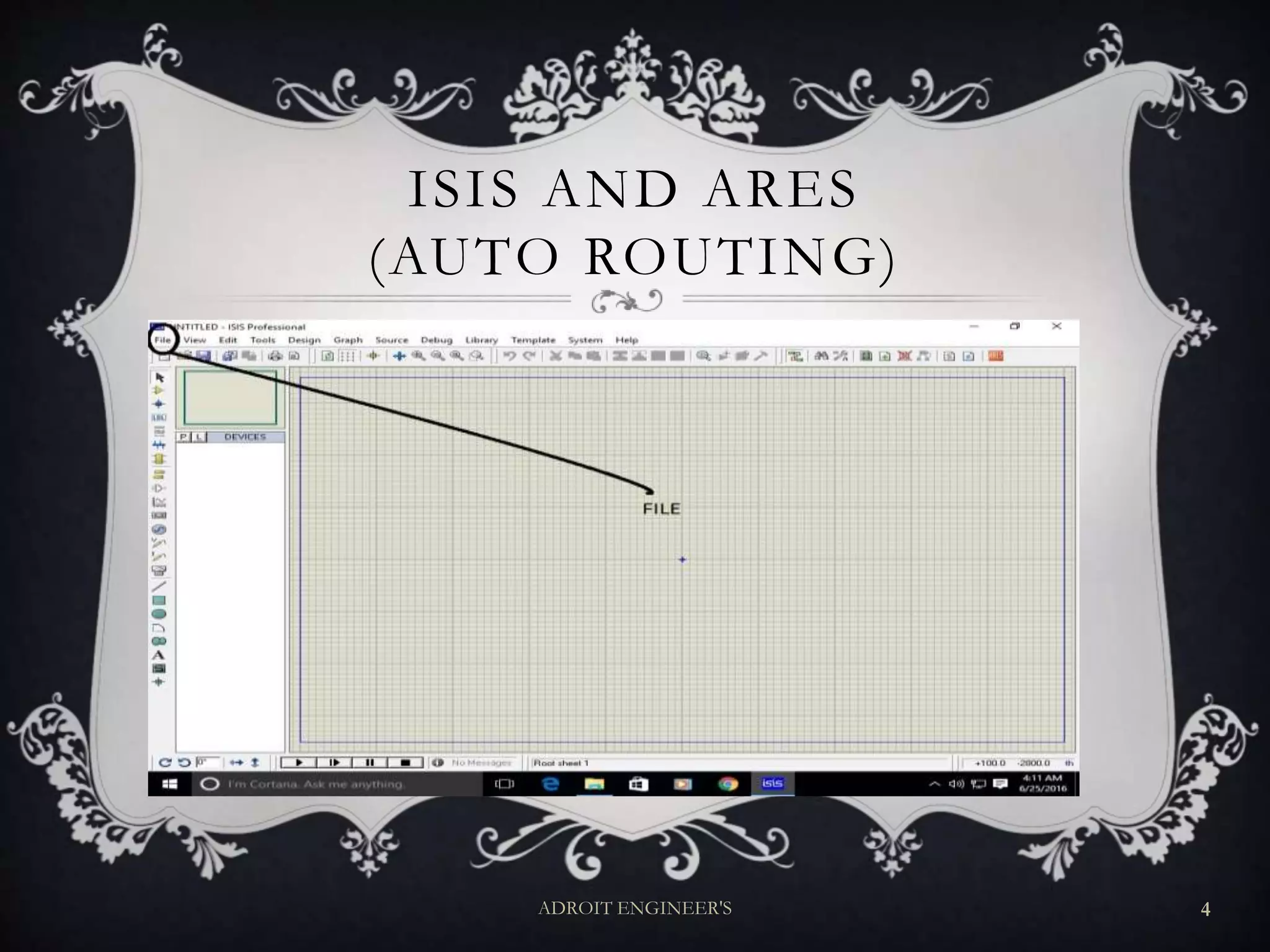

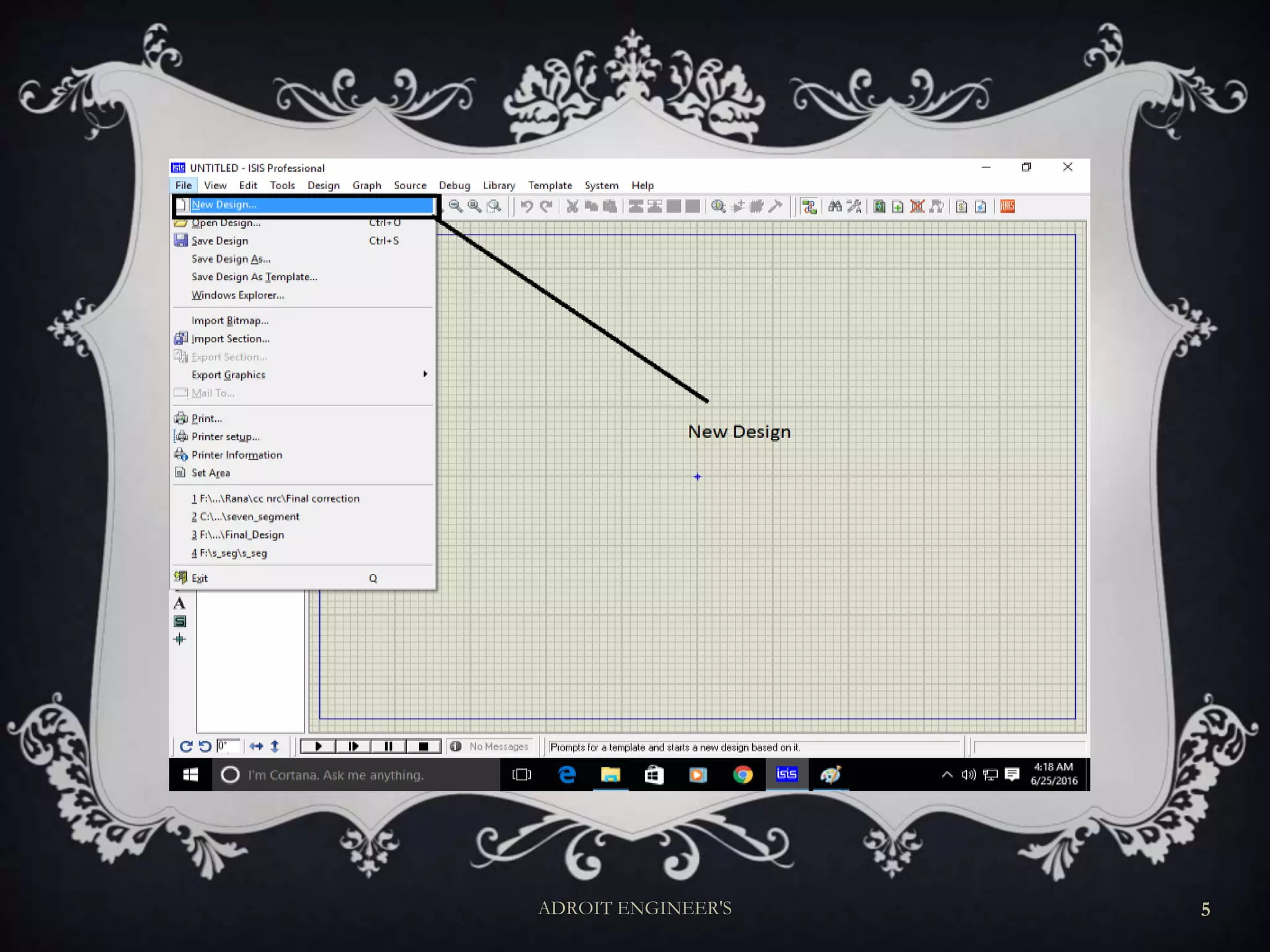

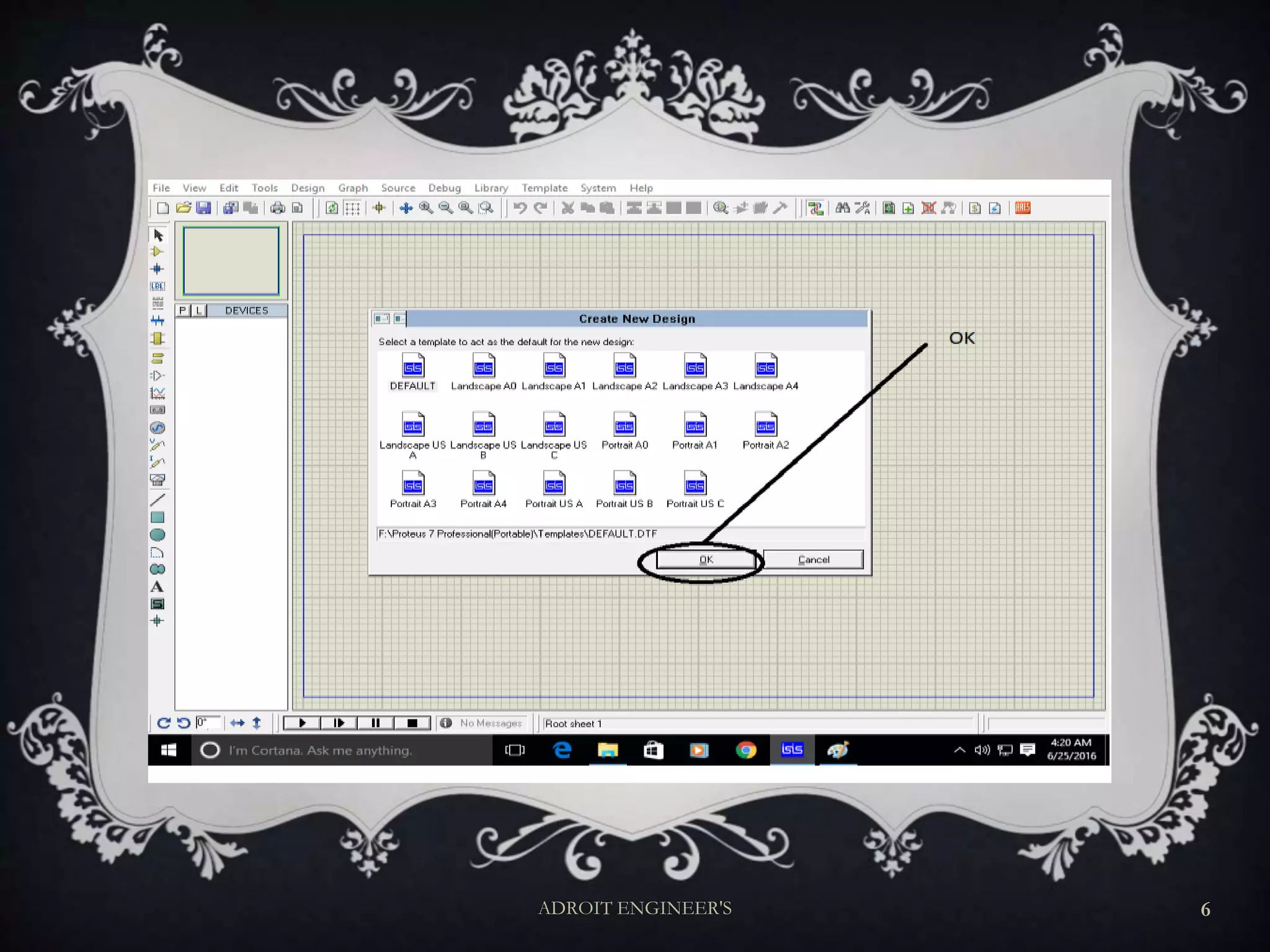

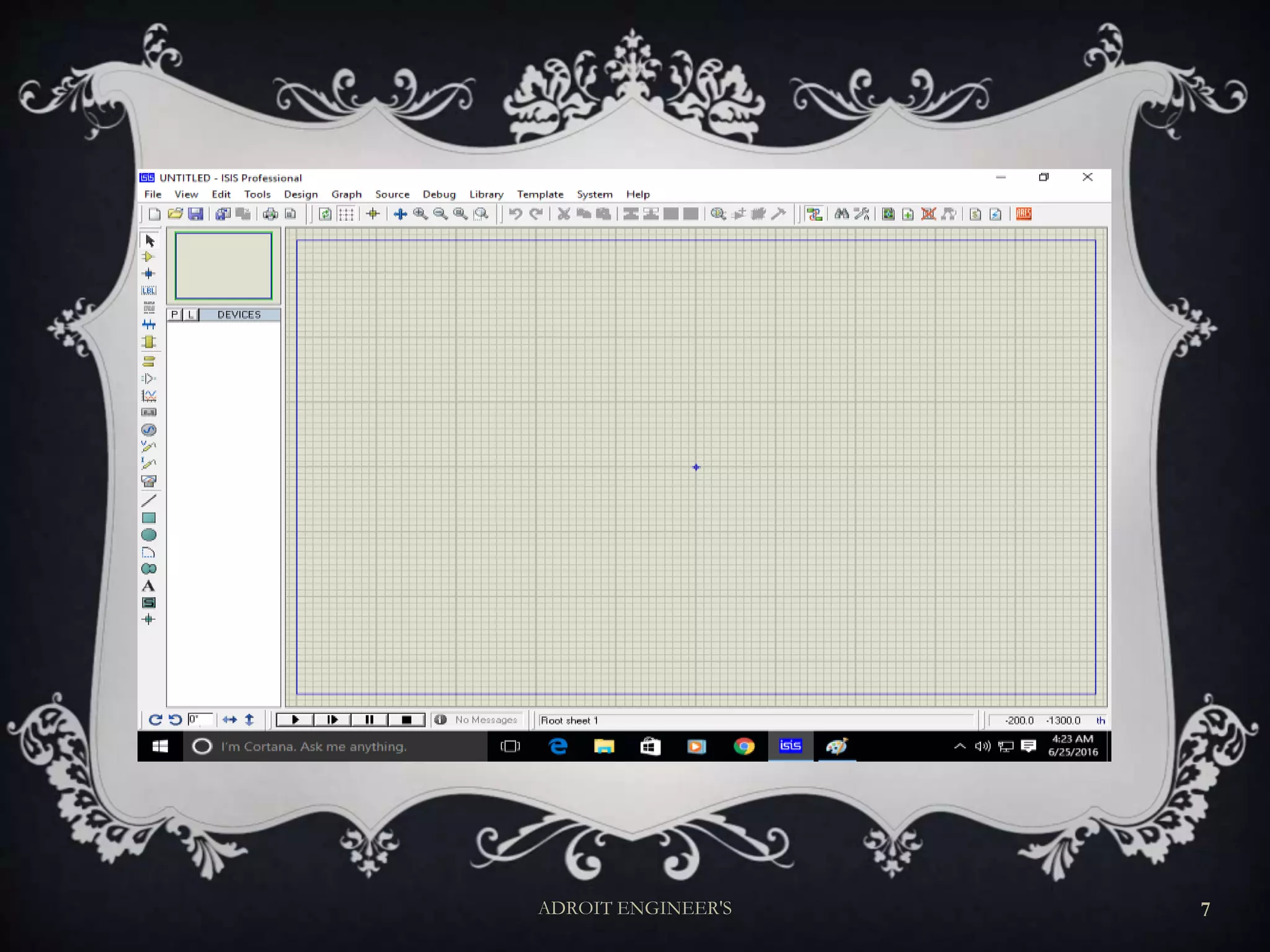

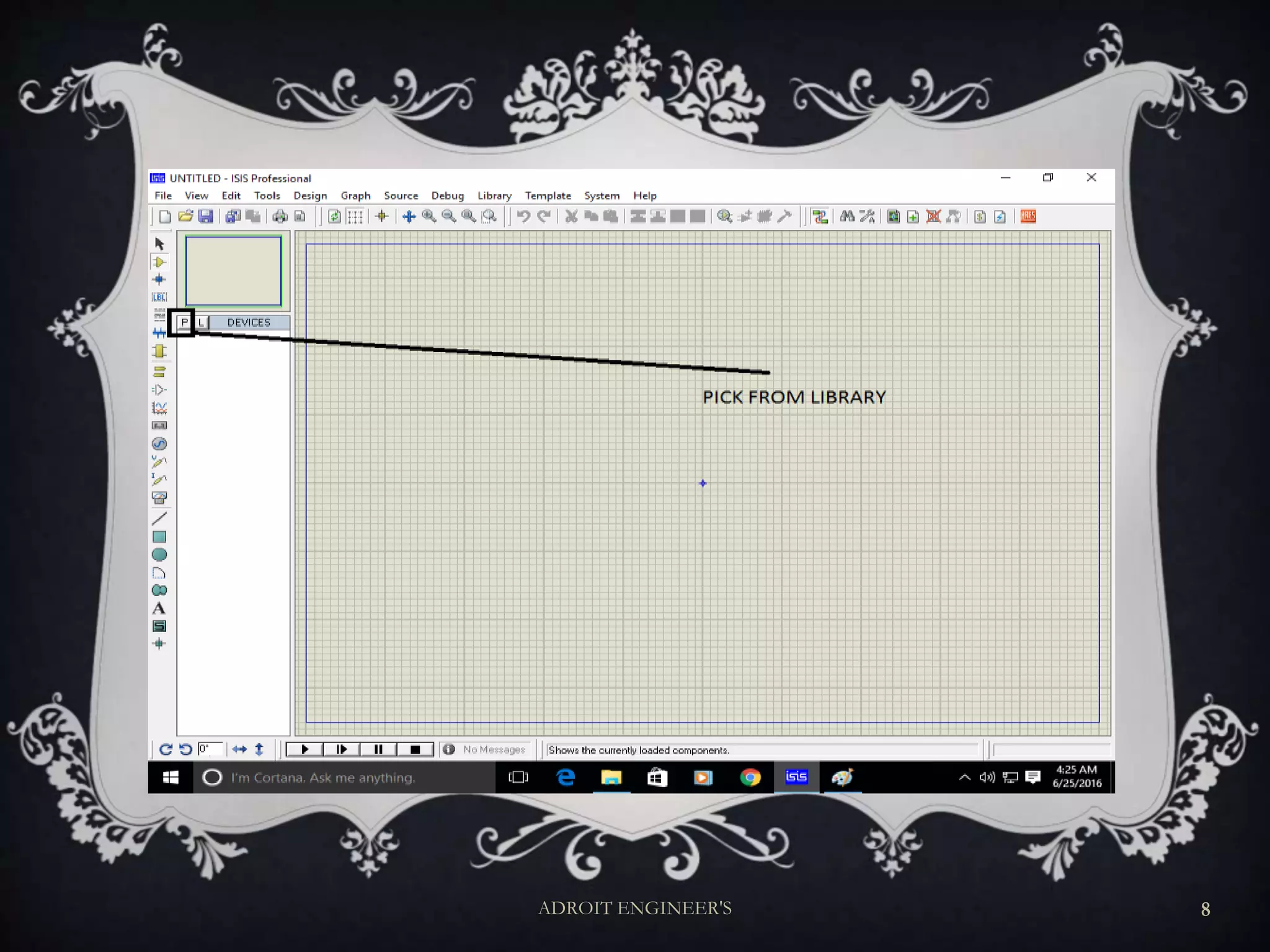

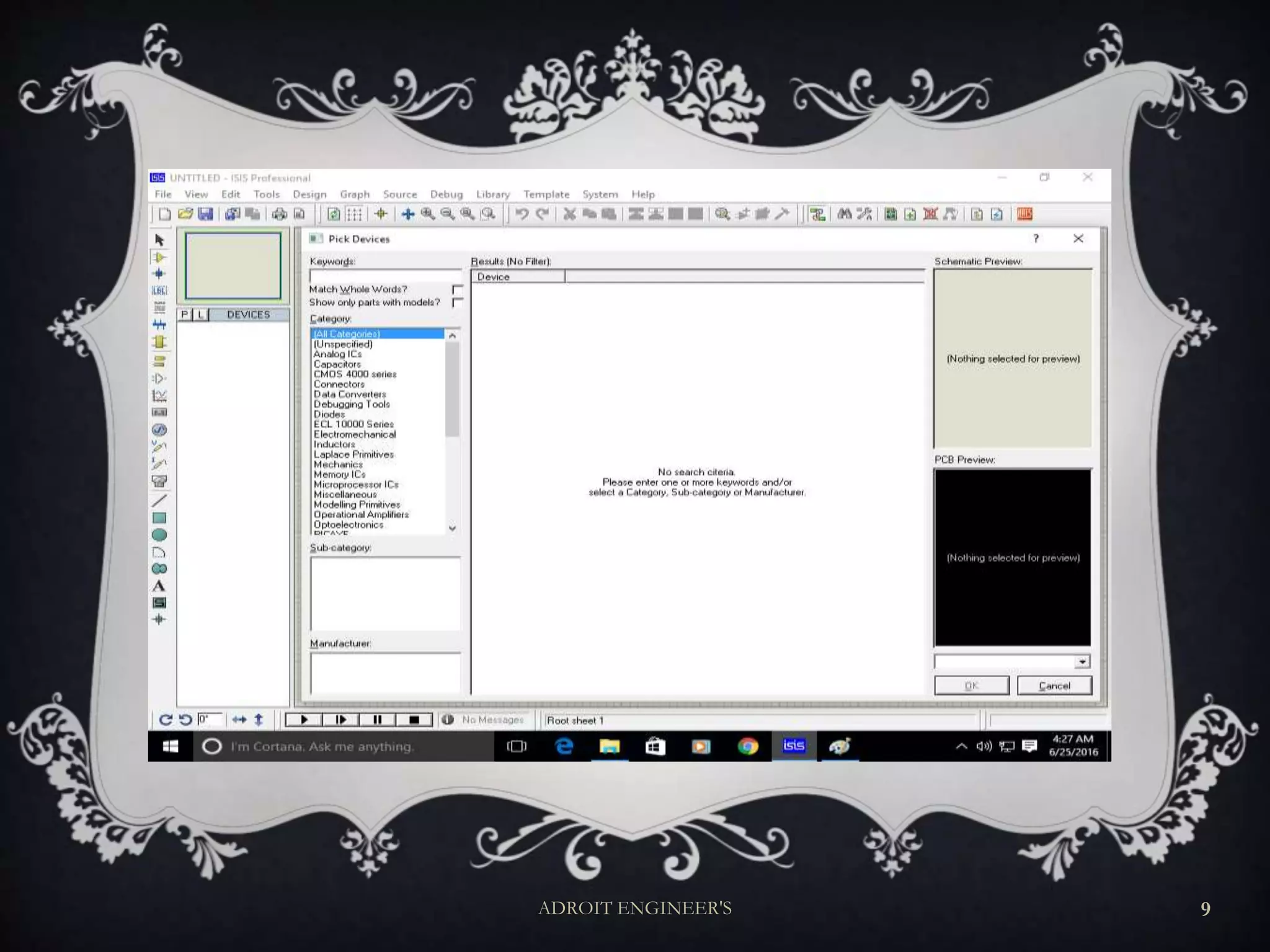

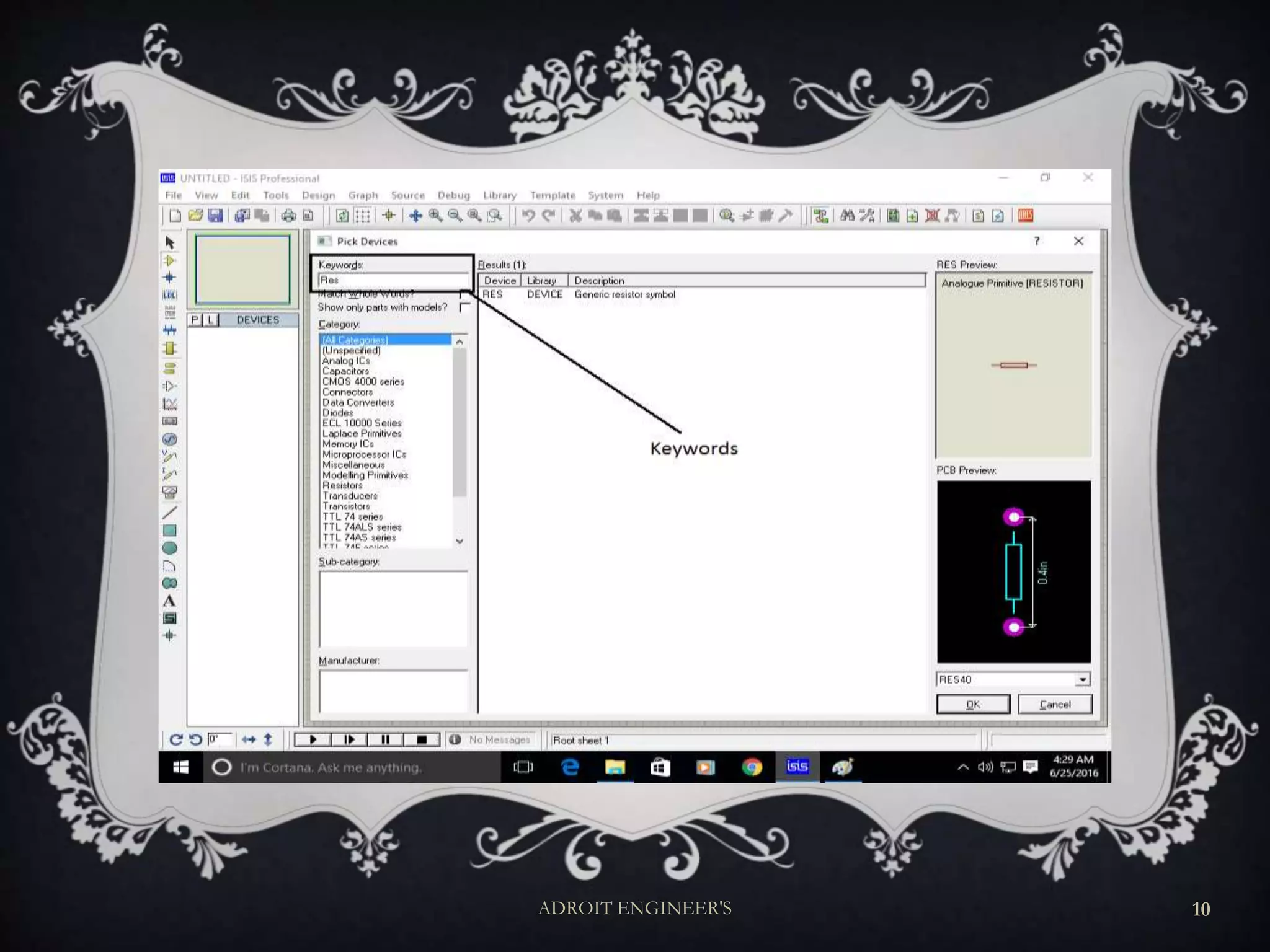

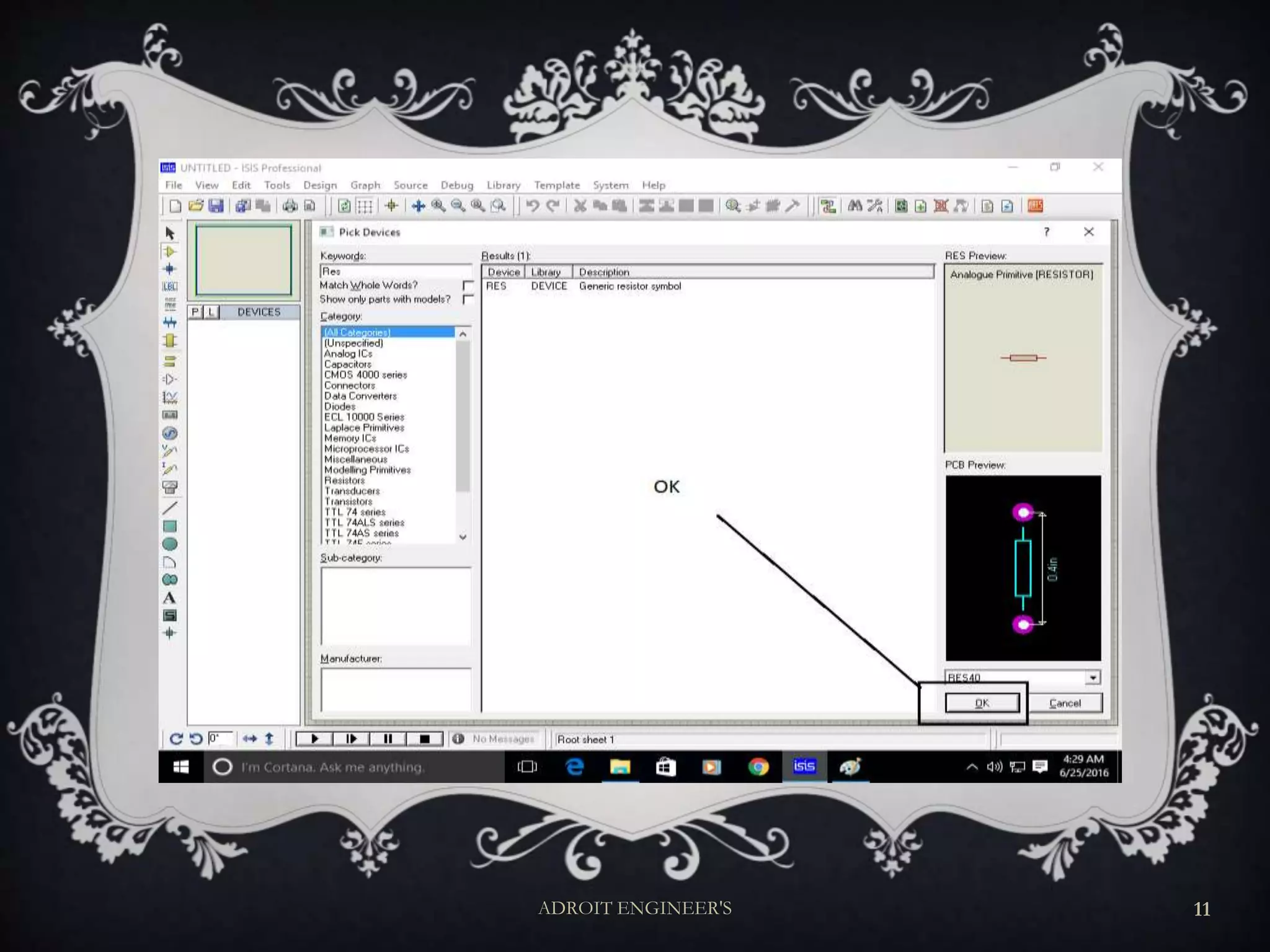

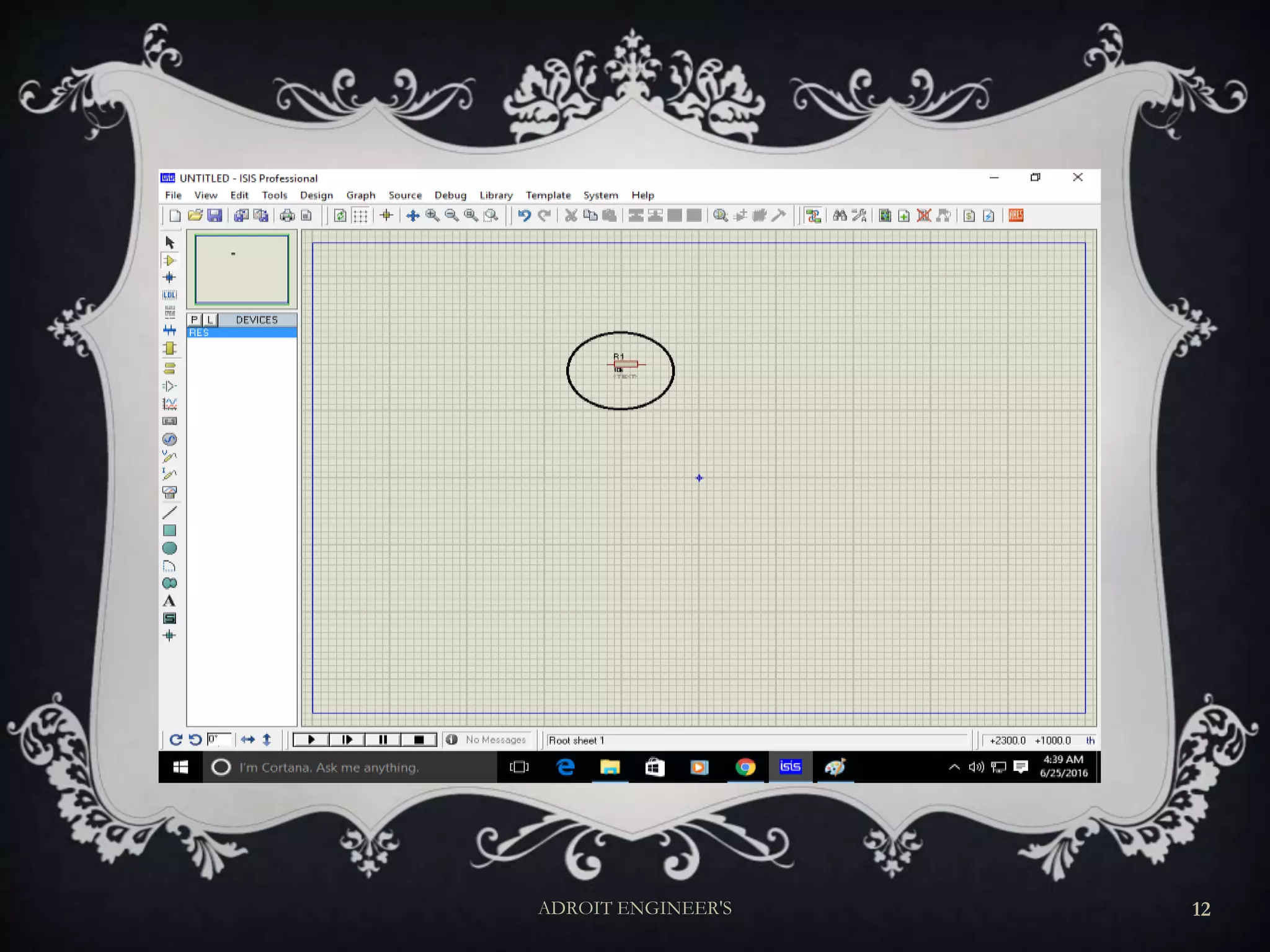

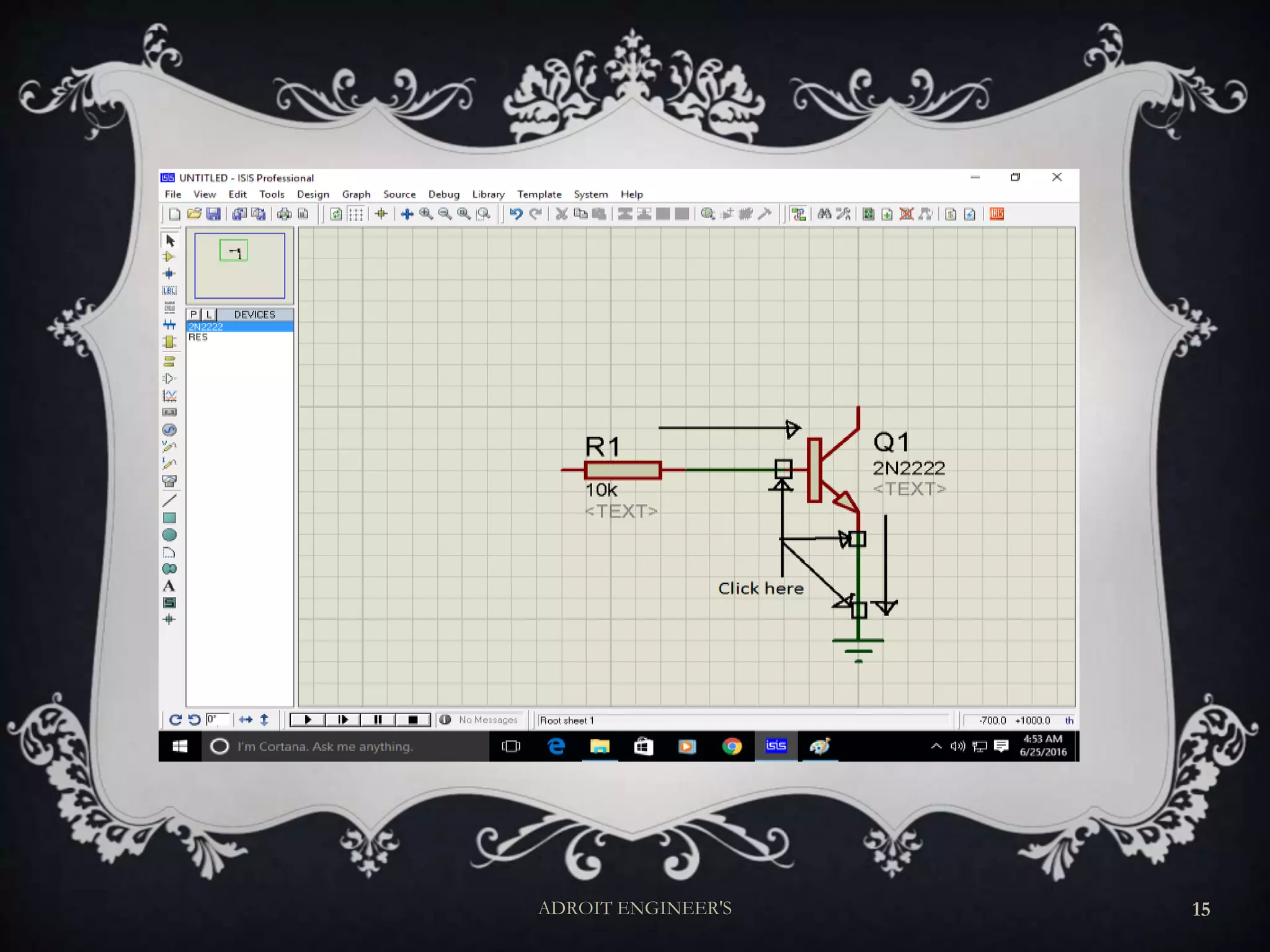

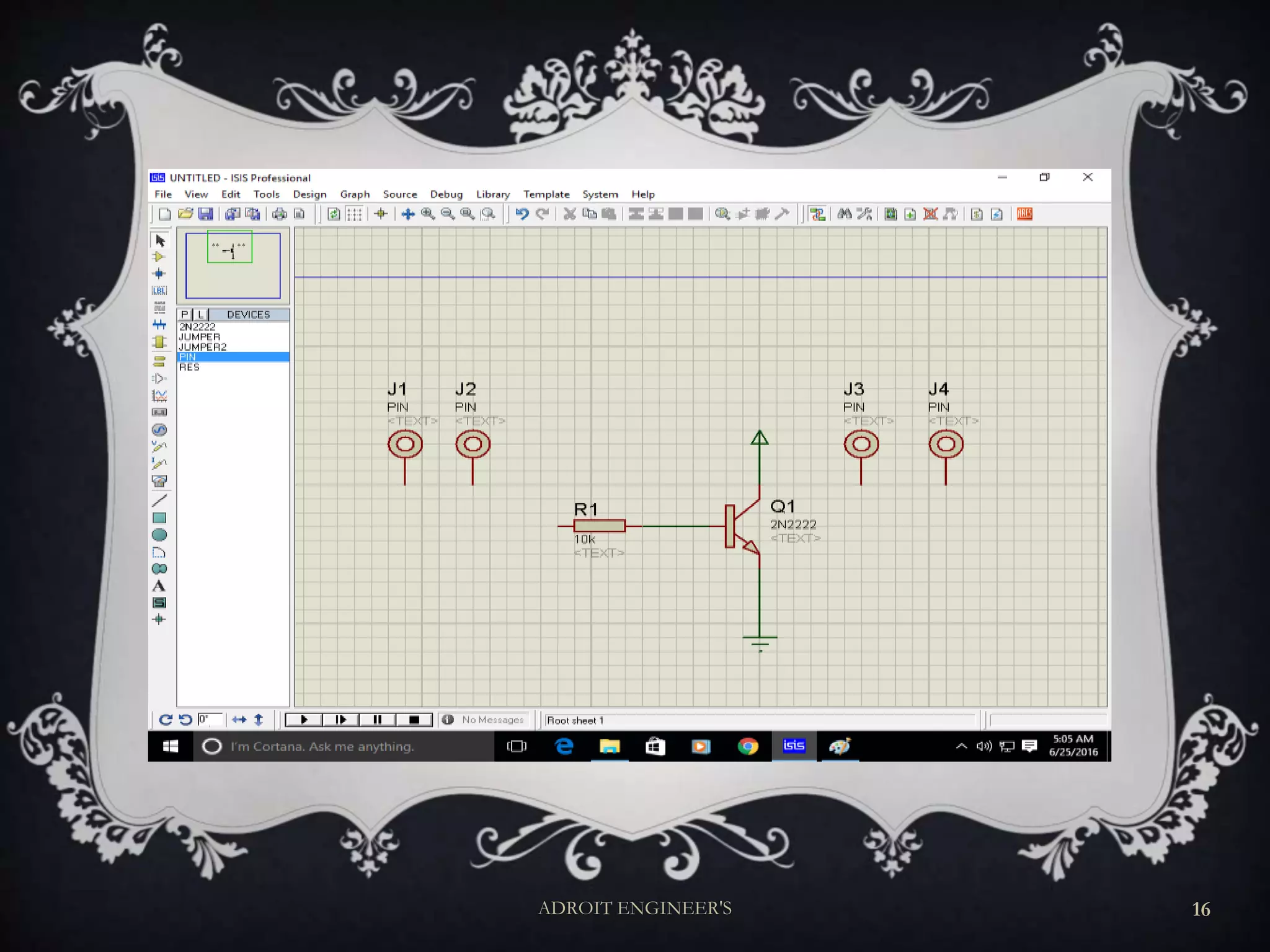

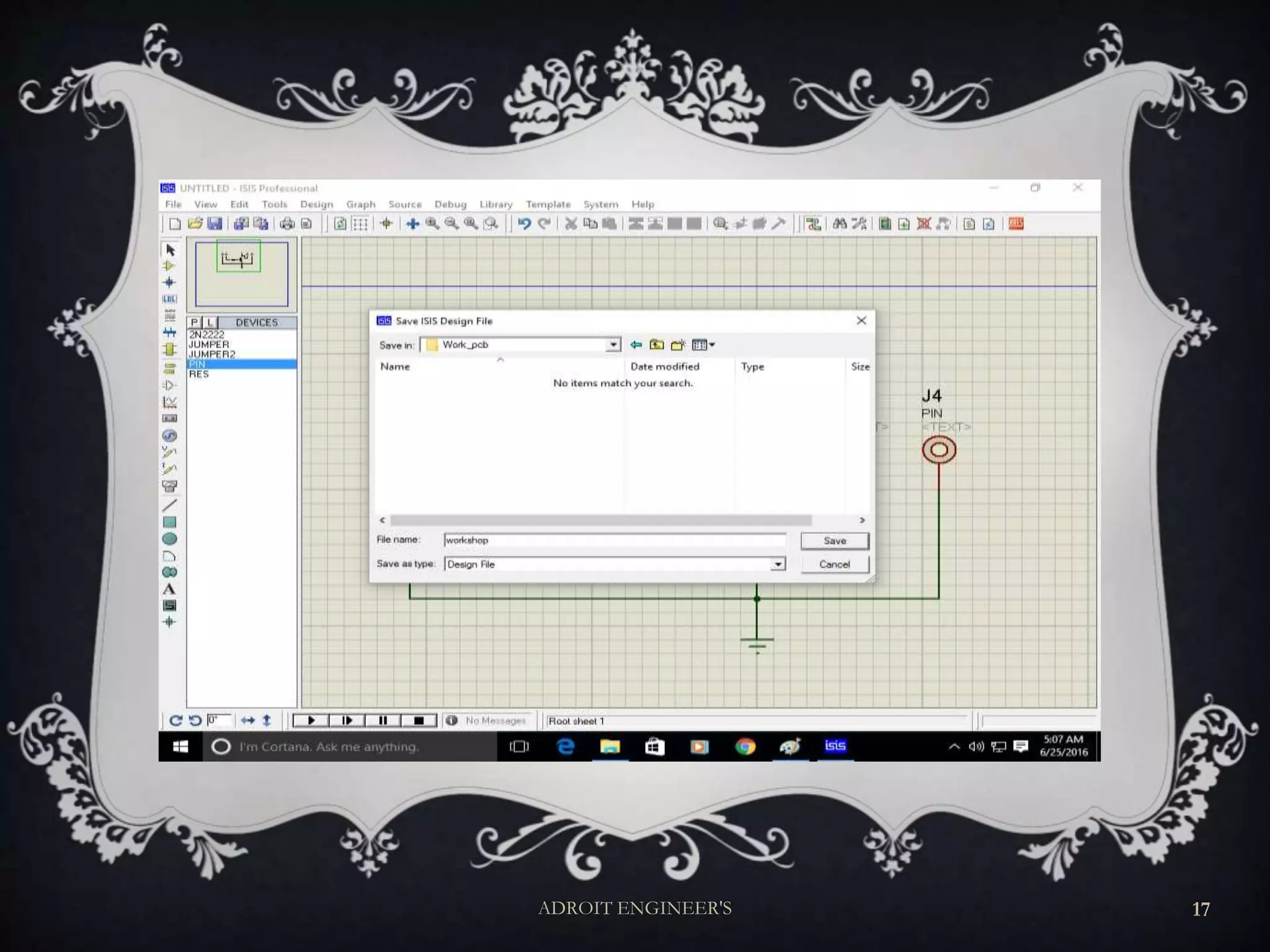

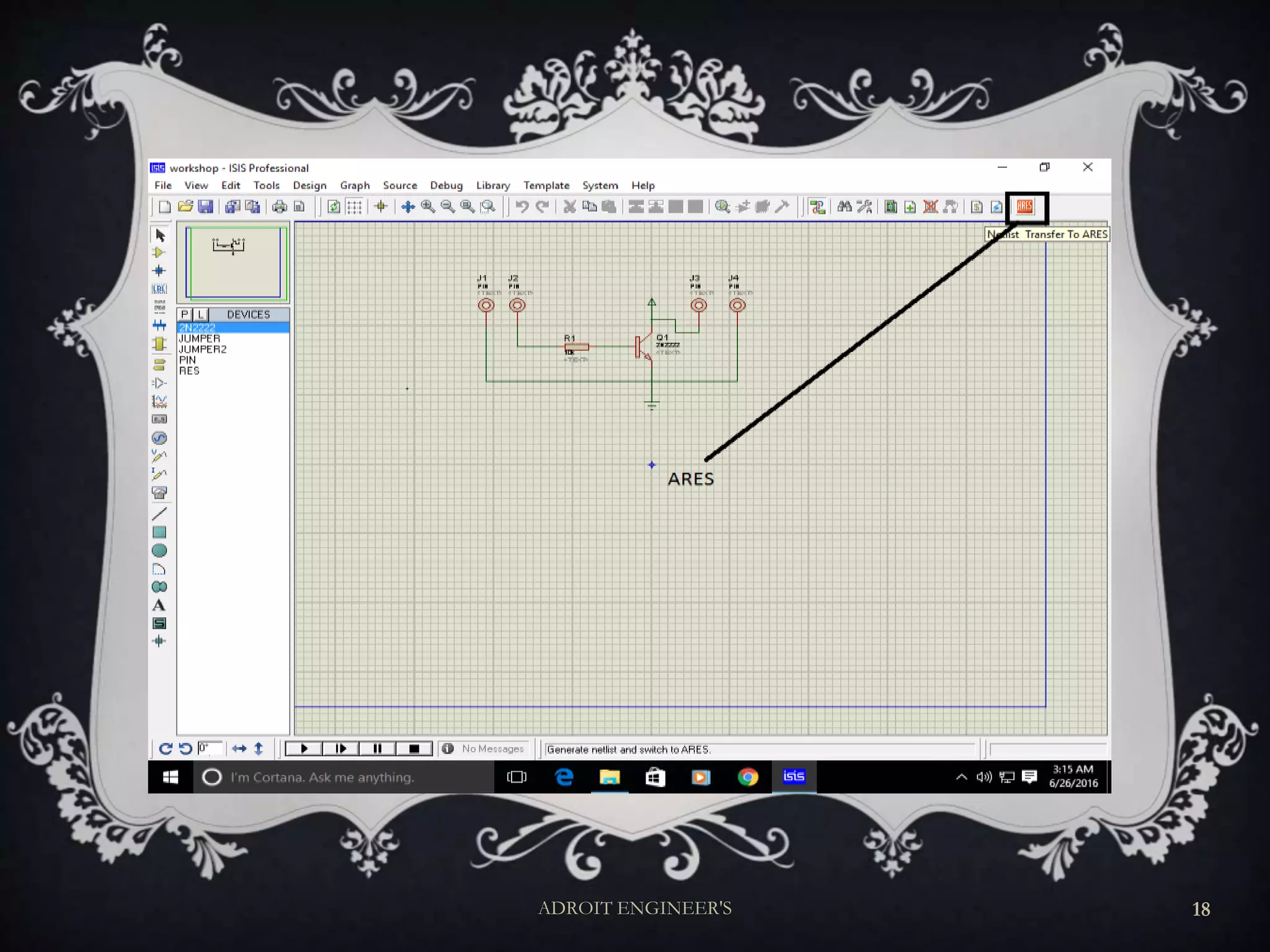

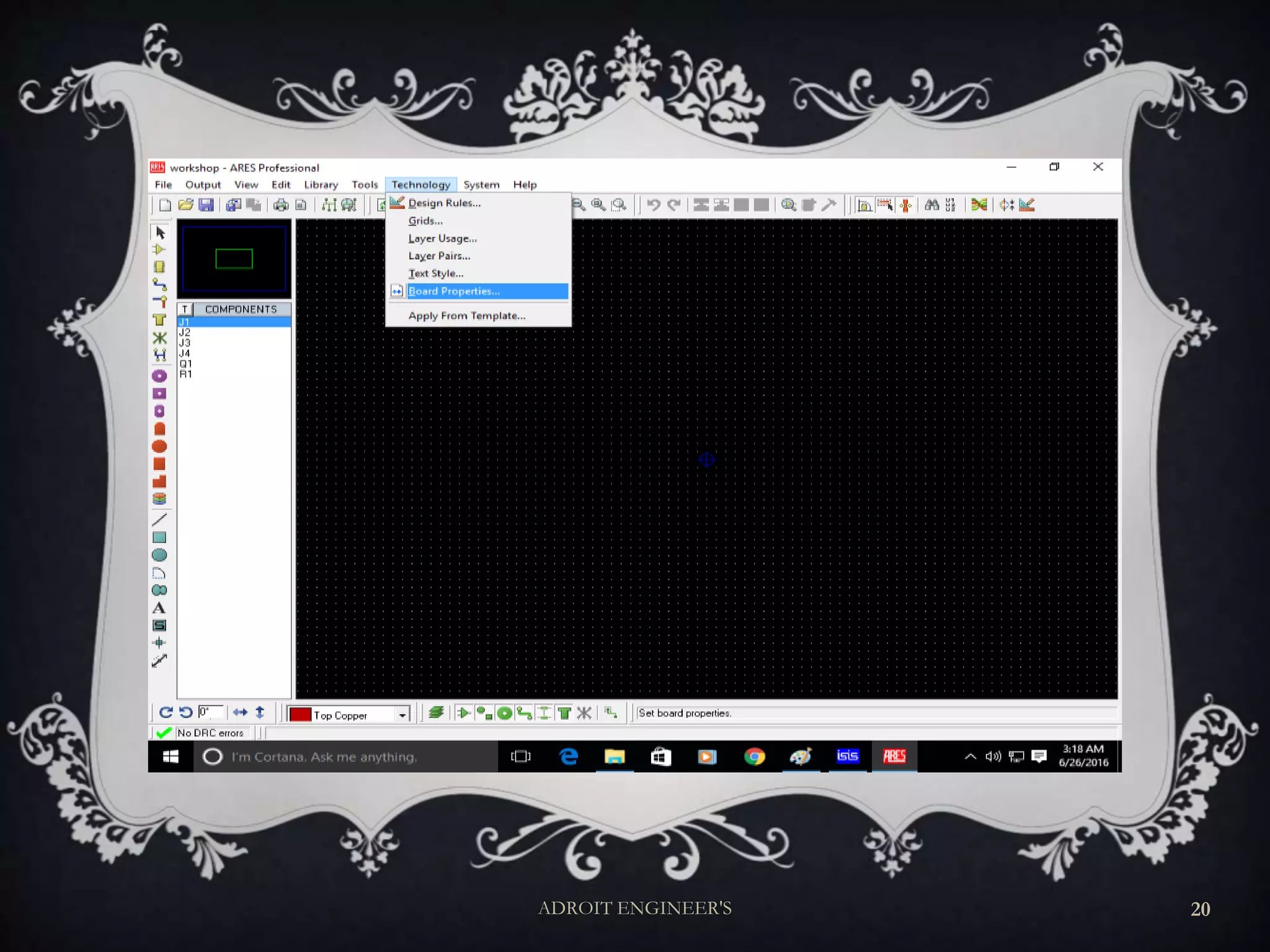

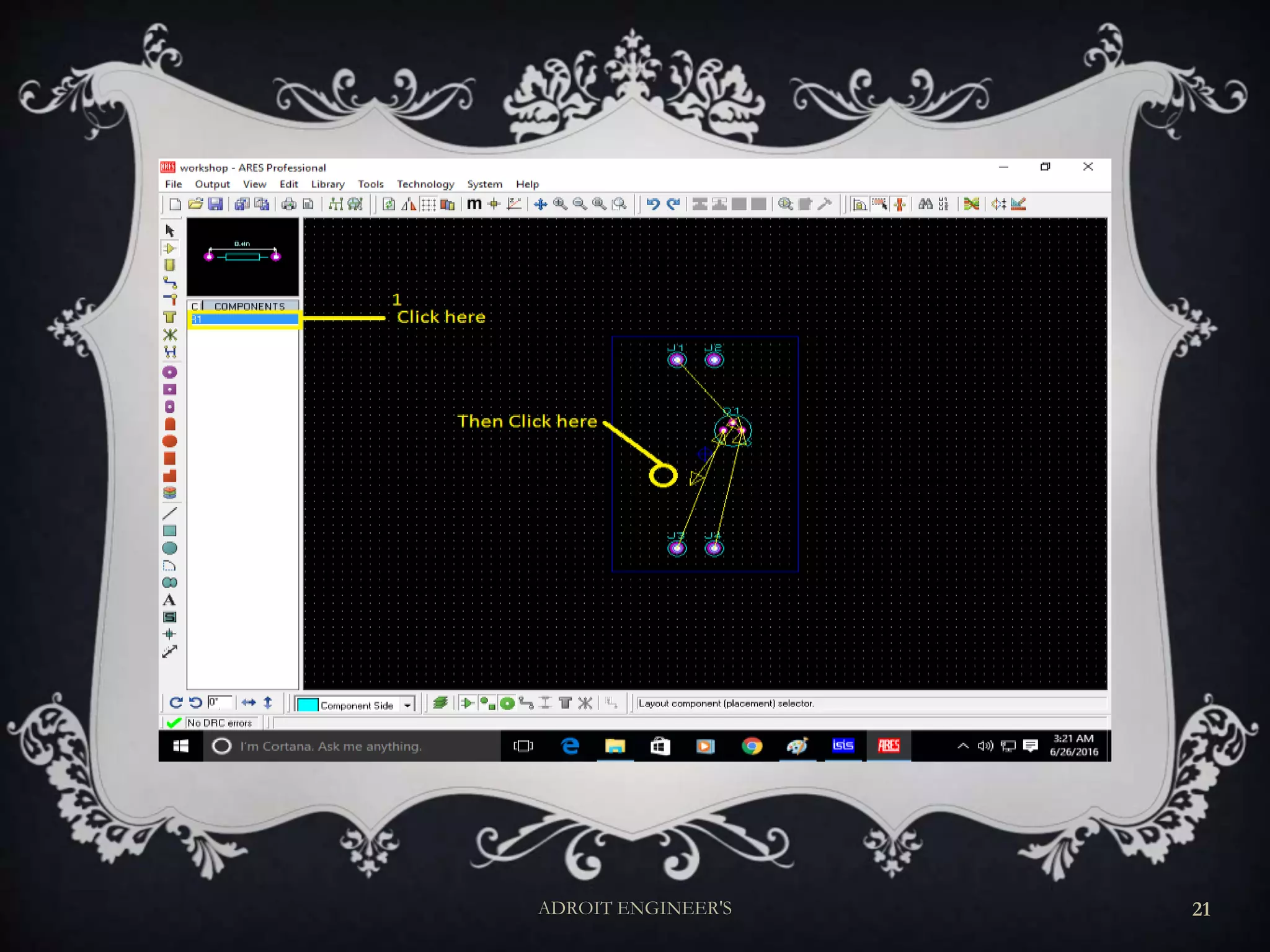

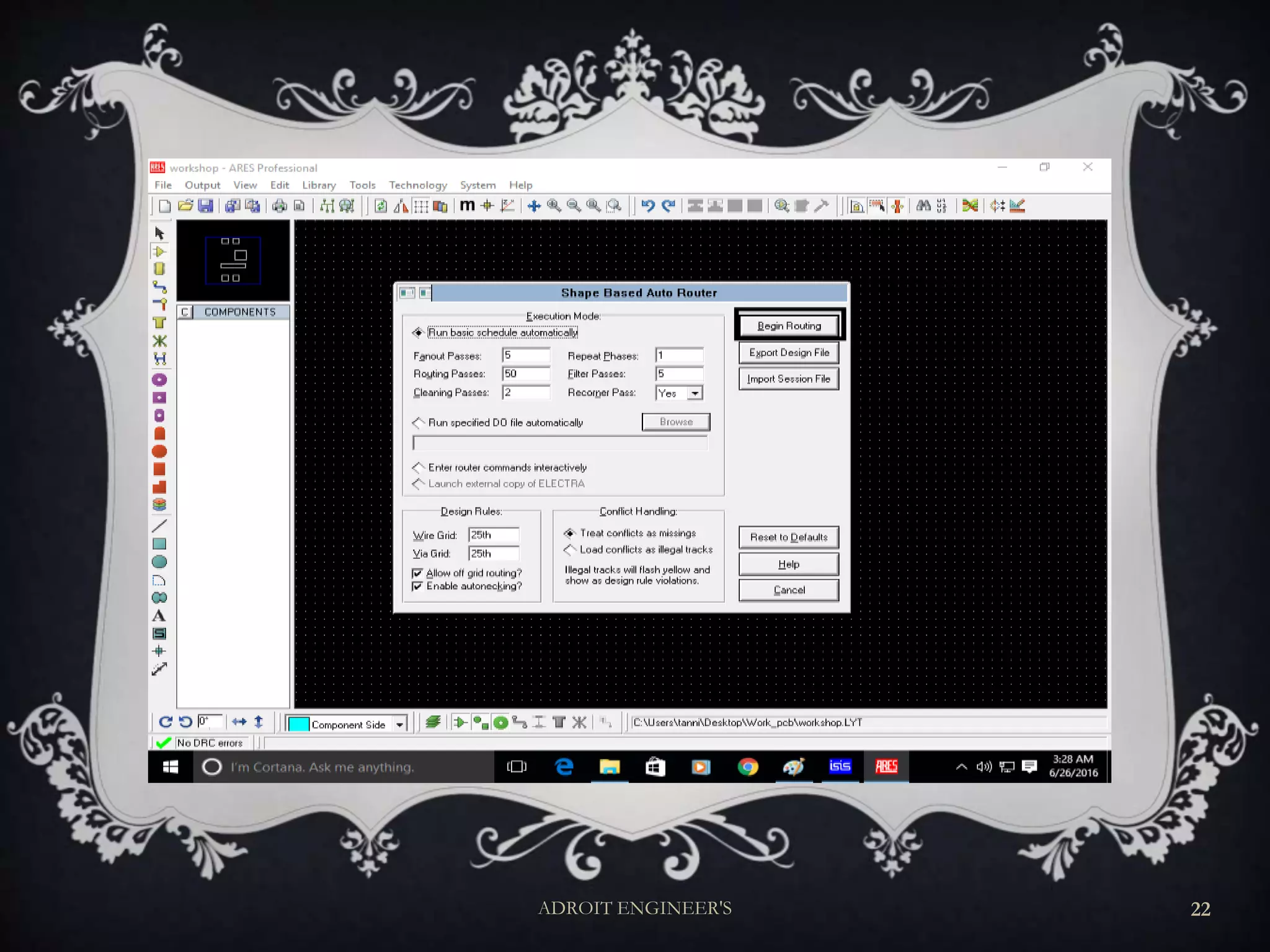

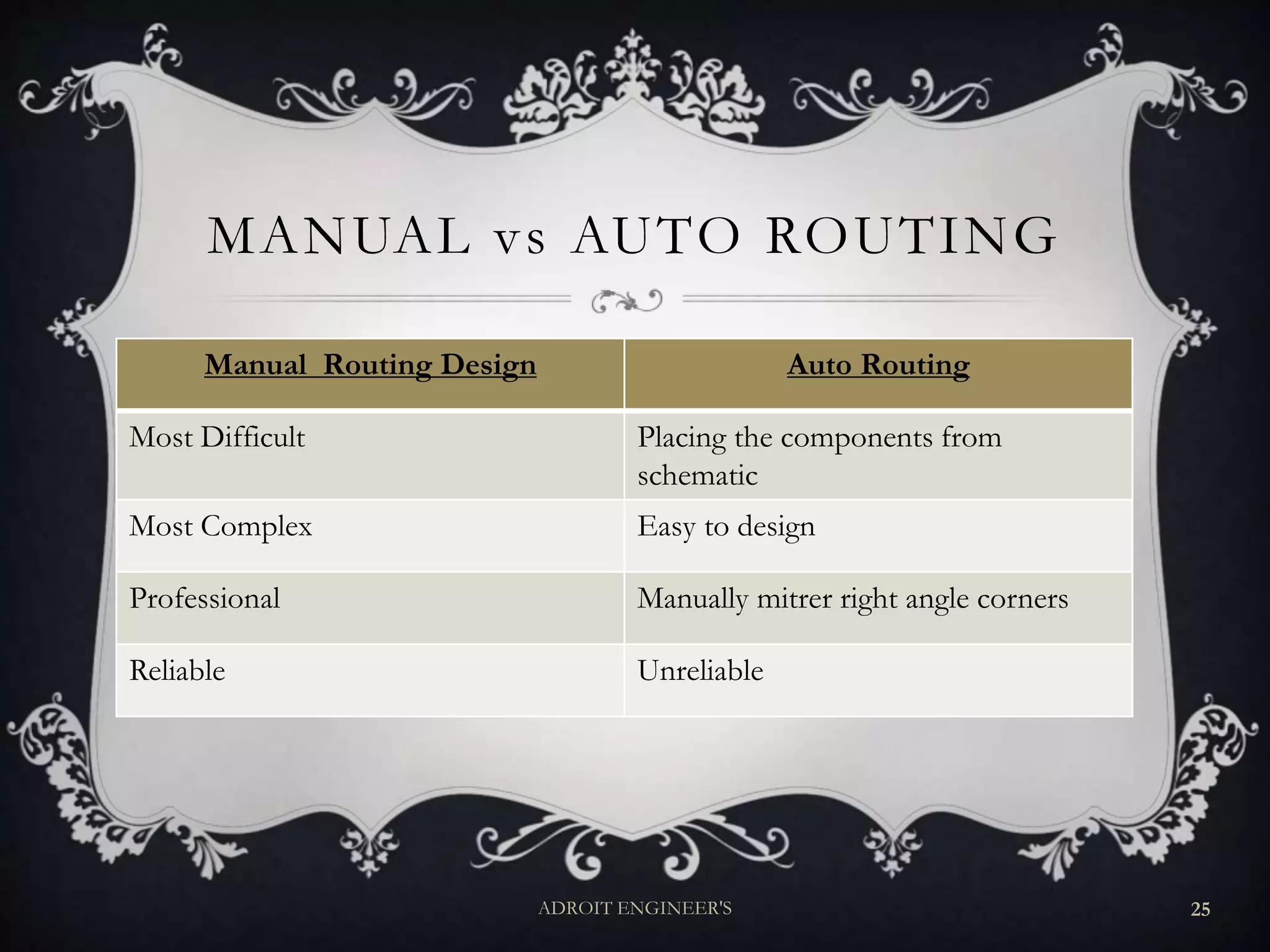

- Auto-routing is an automated design process where components are automatically routed after placement. Software programs like ISIS and ARES are used for auto-routing.

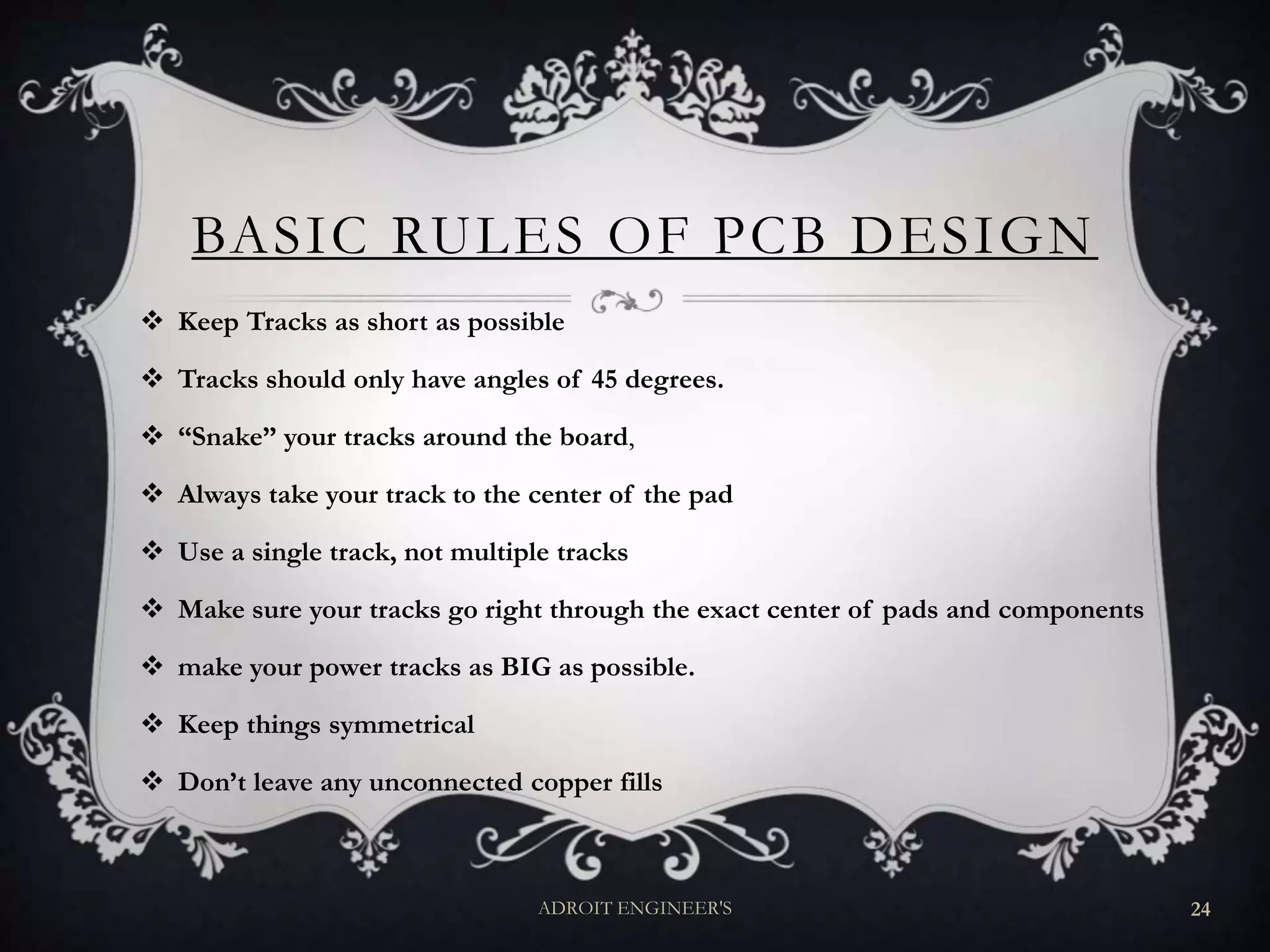

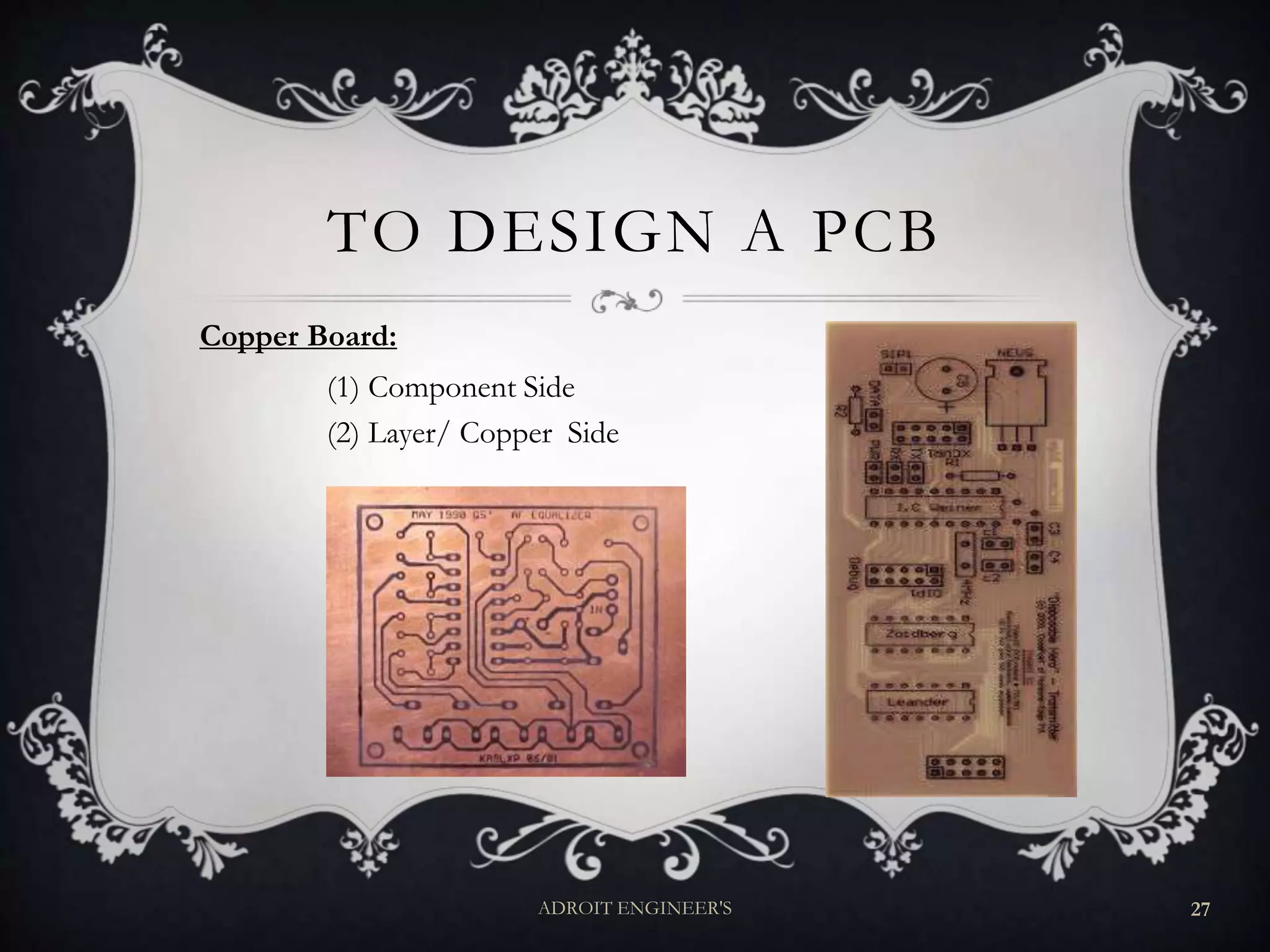

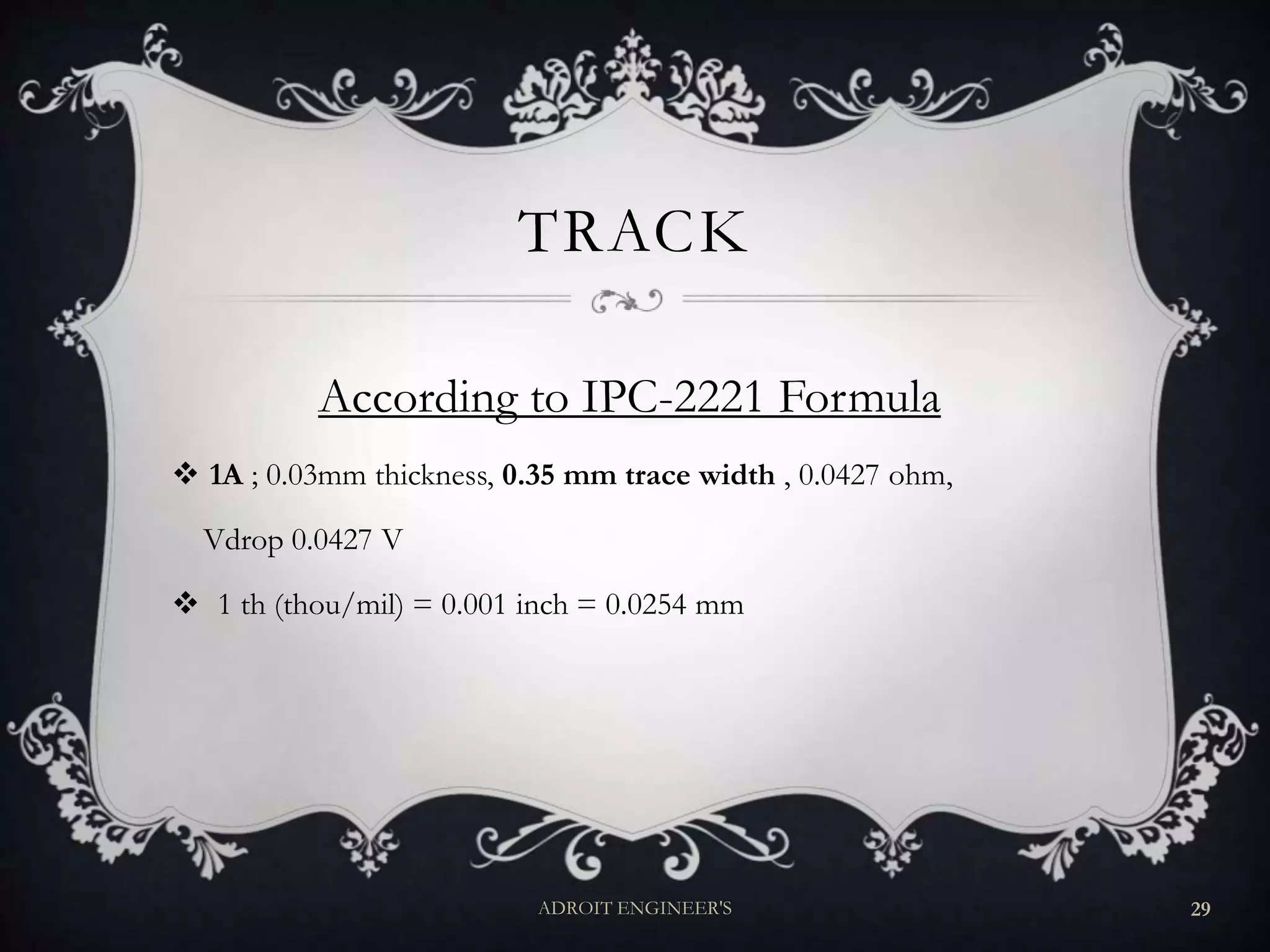

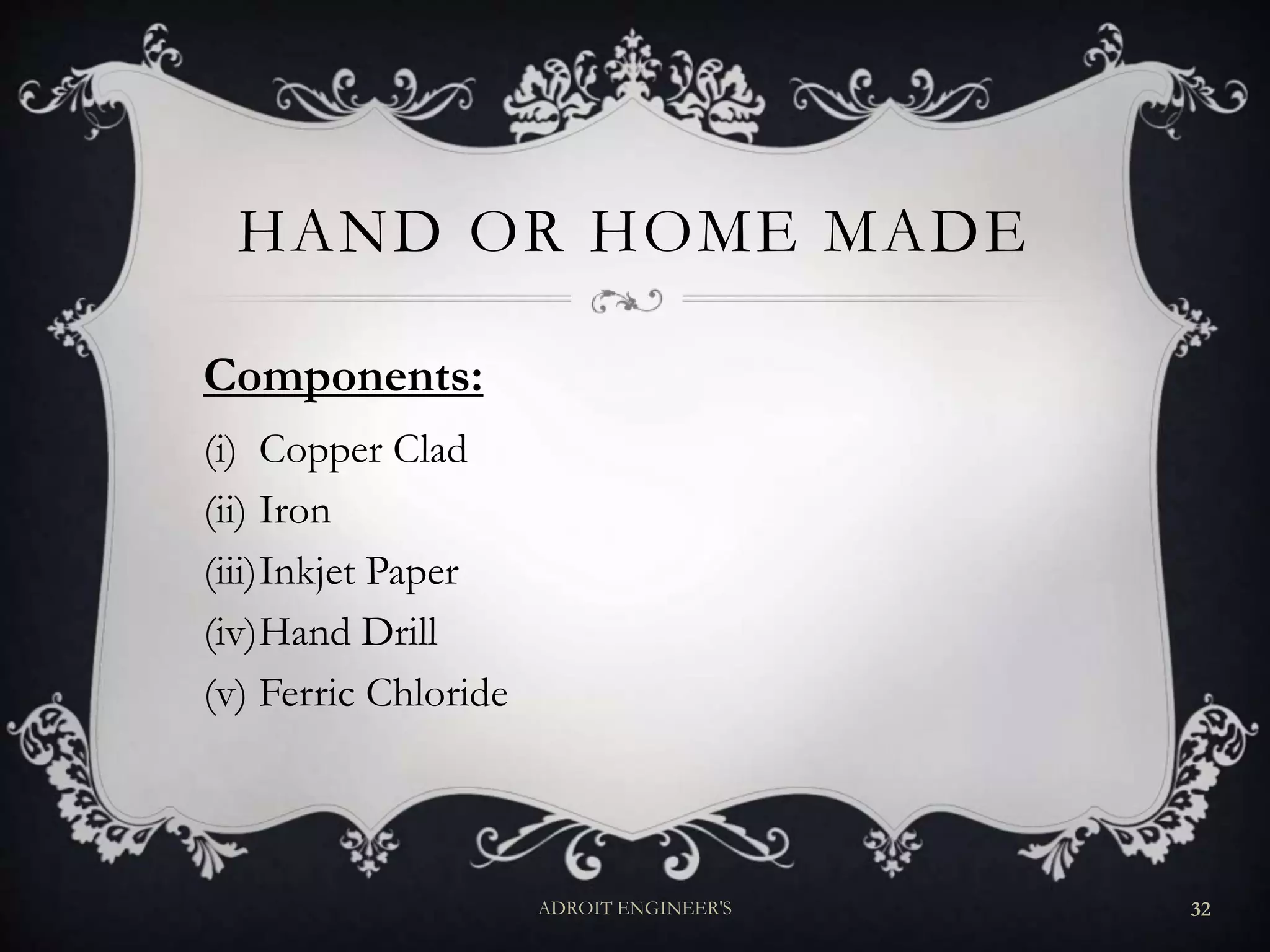

- There are different methods for PCB fabrication including hand/home made, small factories using screen printing processes, and large automated industrial facilities. Basic design considerations include tracks, drills, clearances, and component packages.