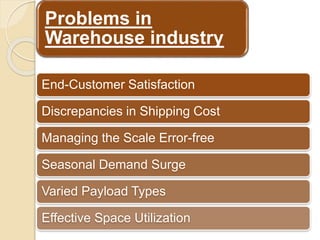

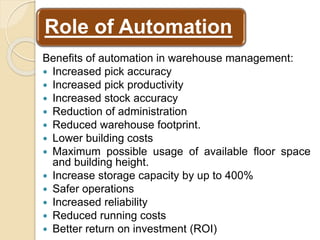

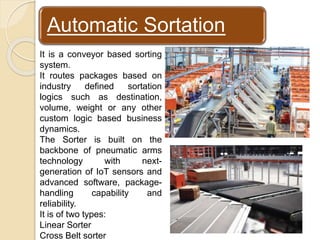

The document discusses a warehouse management system (WMS) that enhances day-to-day warehouse operations by utilizing advanced technologies like RFID and voice recognition to track inventory and materials. It highlights various automation benefits such as increased accuracy, higher productivity, and optimized storage capacity, mentioning specific systems like Profiler and Butler that automate processes effectively. Additionally, it addresses industry challenges and the role of automation in improving operational efficiency and end-customer satisfaction.