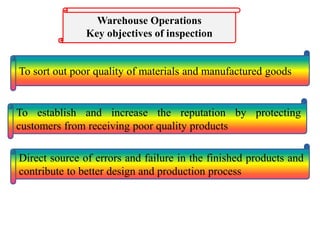

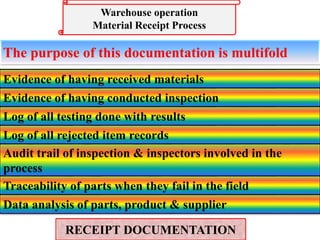

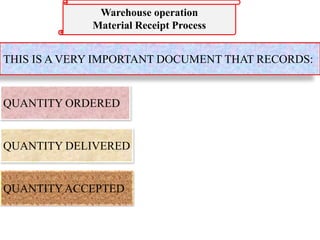

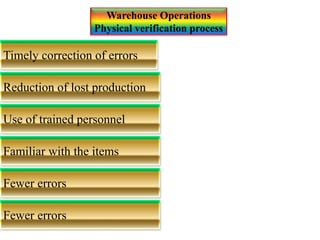

The document discusses key activities and processes in warehouse operations including receiving goods, inspecting goods for quality and quantity, identifying and labeling goods, storing goods in designated locations, picking goods for orders, packing and shipping goods, and managing inventory information through a physical verification process. The receipt, inspection, storage, and dispatch processes are important for maintaining accurate records, complying with requirements, and ensuring high customer service.