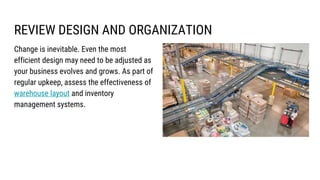

The document outlines strategies for enhancing warehouse efficiency, emphasizing the importance of maintenance plans, organization, and inventory management. It suggests utilizing cycle counts for accurate inventory, securing the warehouse, streamlining receiving processes, and implementing clear labeling systems. Additionally, it encourages dedicating time each day for organization and offers services to help improve warehouse operations.