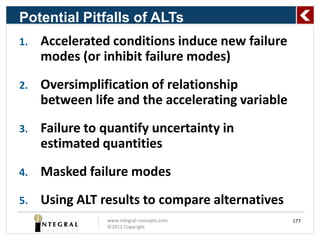

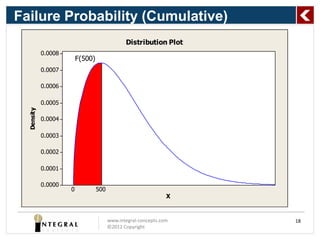

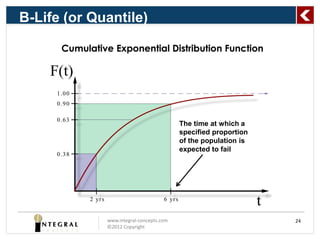

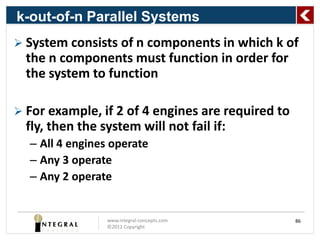

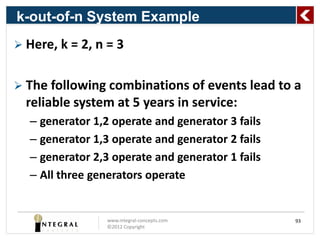

The document presents a comprehensive overview of predicting product life using reliability analysis methods, focusing on various reliability concepts, statistical models, and estimation techniques. It covers topics such as reliability data, types of distributions (like Weibull and exponential), and the significance of censoring in data analysis. The goal is to equip reliability engineers with the knowledge to effectively assess product reliability and improve decision-making in product development.

![Exponential Distribution

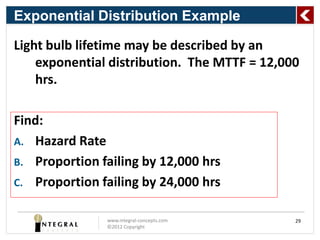

• pdf: f(t) = le-lt

• cdf: F(t) = 1 - e-lt

• Reliability: R(t) = e-lt

• Hazard rate: h(t) = l

• MTTF = 1/l = q

• Quantile: F-1(p) = (1/l)[-ln(1-p)]

www.integral-concepts.com 28

©2012 Copyright](https://image.slidesharecdn.com/predictingproductlifeusingreliabilityanalysismethods09apr2012rev1-120316112325-phpapp01/85/Predicting-product-life-using-reliability-analysis-methods-30-320.jpg)

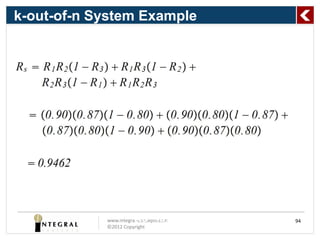

![ReliaSoft AL TA 7 - www.ReliaSoft.com

R el i abi l i ty vs Ti me

1.000

Reliability

CB@90% 2-Sided [R]

Data 1

Inverse Power Law

Lognormal

50

F= | S=

36 0

0.800 Data Points

Reliability Line

Top CB-II

Bottom CB-II

0.600

R e lia b ilit y

0.400

0.200

Steven Wachs

integral Concepts, Inc.

8/19/2011

3:25:11 PM

0.000

0.000 60000.000 120000.000 180000.000 240000.000 300000.000

Time

Std=1.0498; K=1.1494E-12; n=4.2891

www.integral-concepts.com 156

©2012 Copyright](https://image.slidesharecdn.com/predictingproductlifeusingreliabilityanalysismethods09apr2012rev1-120316112325-phpapp01/85/Predicting-product-life-using-reliability-analysis-methods-158-320.jpg)