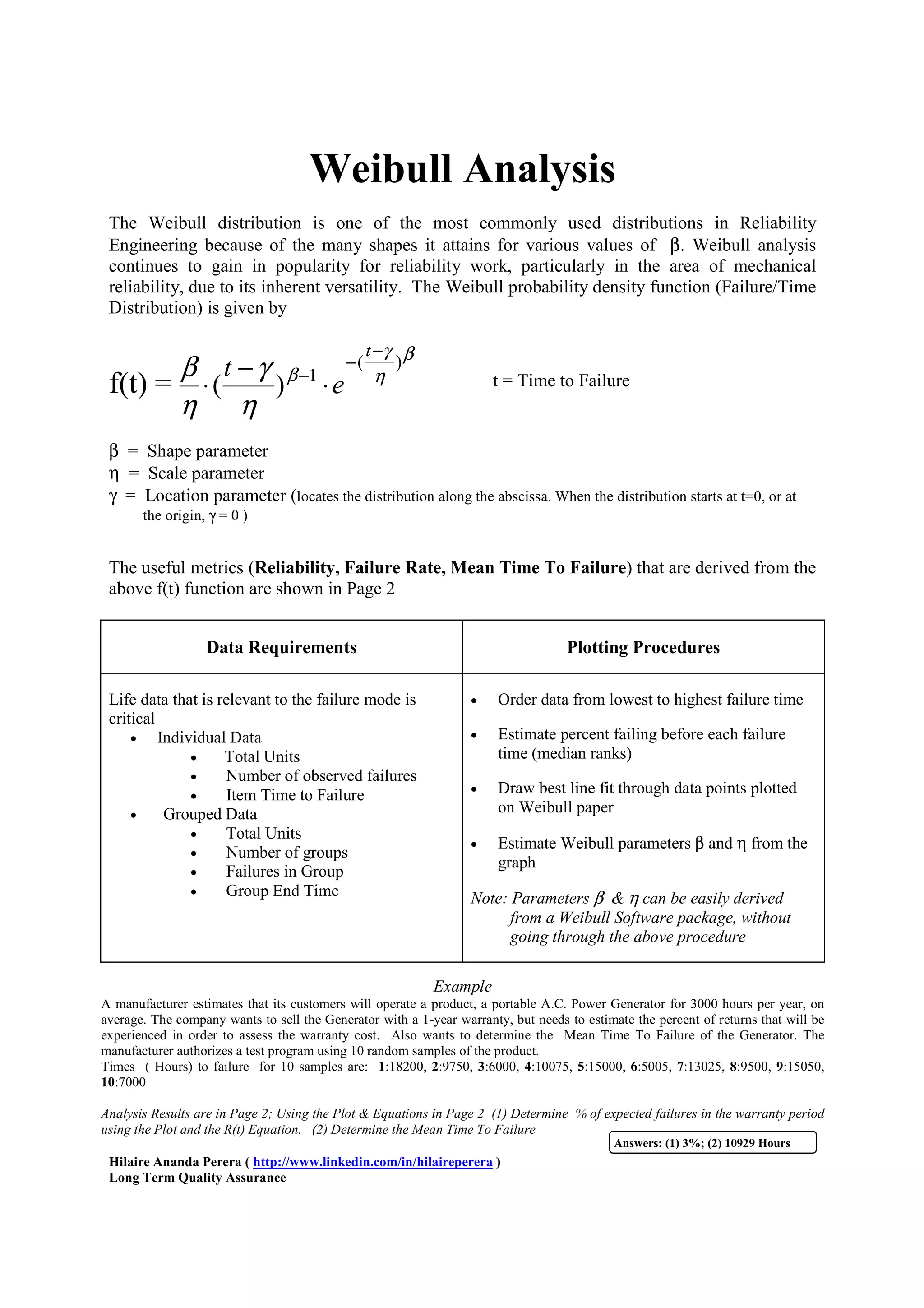

This document discusses Weibull analysis, which is commonly used in reliability engineering. The Weibull distribution can take on many shapes depending on the value of the β parameter. Weibull analysis is useful for mechanical reliability due to its versatility. The document defines the Weibull probability density function and describes how it is used to derive reliability metrics like failure rate and mean time to failure. Examples are provided to demonstrate how Weibull analysis can be used to determine failure percentages and mean time to failure for products.