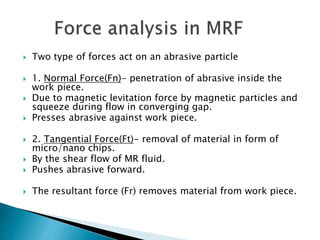

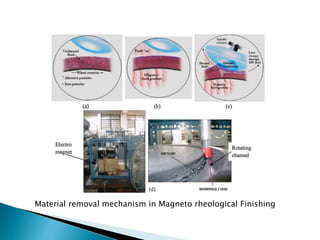

The document discusses magneto rheological finishing (MRF), a fine finishing process that uses magneto rheological fluid to remove material from brittle materials. MRF was developed in 1988 and commercialized in 1996. It relies on carbonyl iron particles and abrasives in a carrier fluid that form chains when exposed to a magnetic field, allowing for controlled removal of material. The document outlines the components of MR fluid, parameters that affect the polishing forces and material removal rate, advantages, and applications for finishing optical lenses and other precision surfaces to nanometer levels of smoothness without damage.