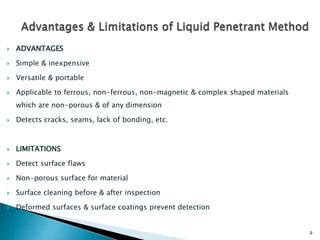

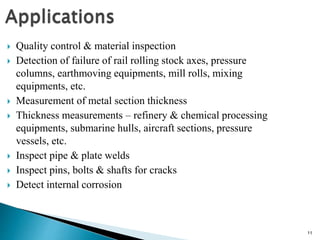

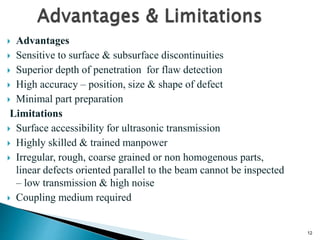

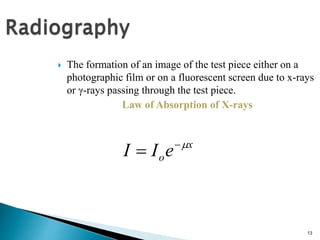

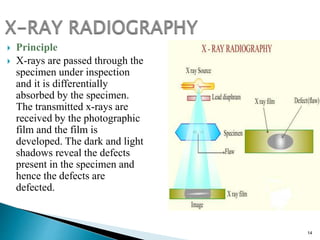

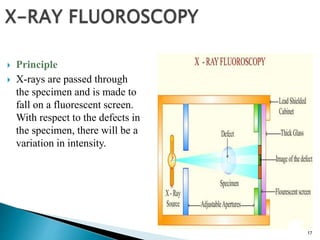

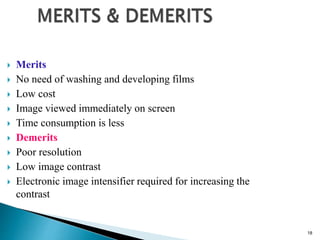

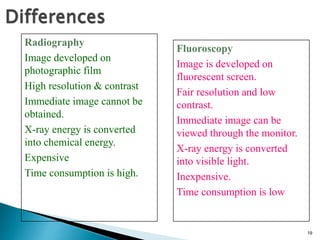

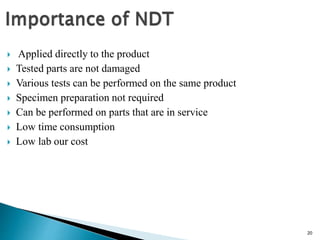

This document summarizes a technical seminar on non-destructive testing (NDT). It defines NDT as techniques used to evaluate materials without causing damage. The objectives of NDT are outlined, including avoiding failures and accidents. Common NDT methods are described at a high level, such as liquid penetrant testing, ultrasonic testing, radiography, and eddy current testing. Specific NDT techniques are then summarized, including advantages and limitations. The document emphasizes that NDT can save costs by detecting flaws without damaging components. Proper training is needed to effectively apply these techniques.