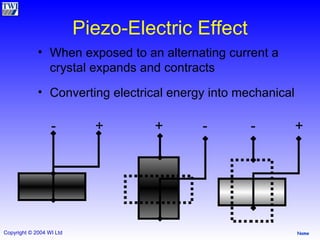

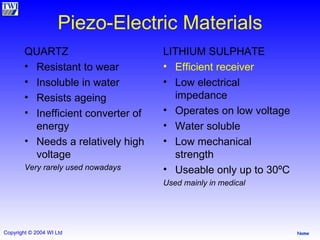

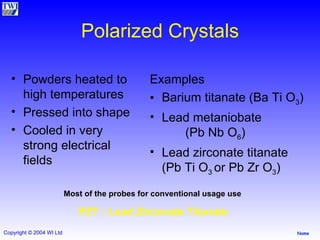

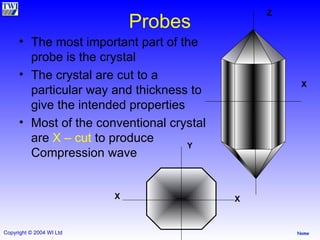

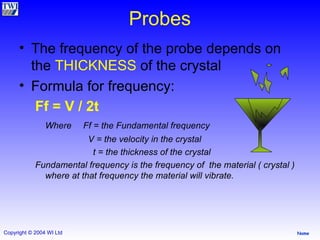

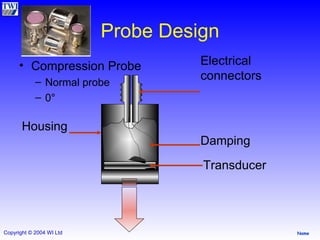

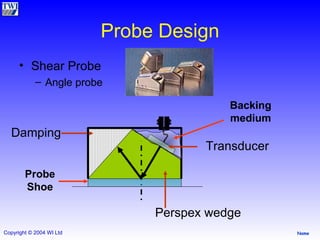

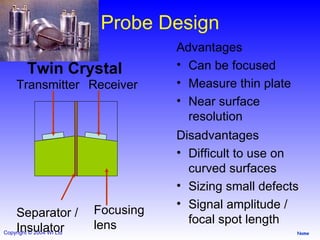

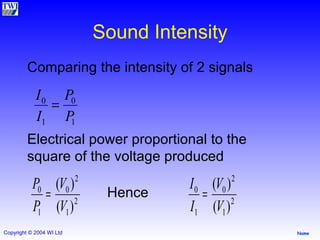

This document discusses ultrasonic testing techniques. It describes different methods for sound generation including hammers, magnetostrictive, and piezoelectric techniques. It then focuses on piezoelectric probes, explaining how they work using polarized crystal materials like lead zirconate titanate. Different probe designs are described for compression and shear waves. Factors that determine probe frequency like crystal thickness are also covered. Finally, automated inspection techniques are briefly outlined.