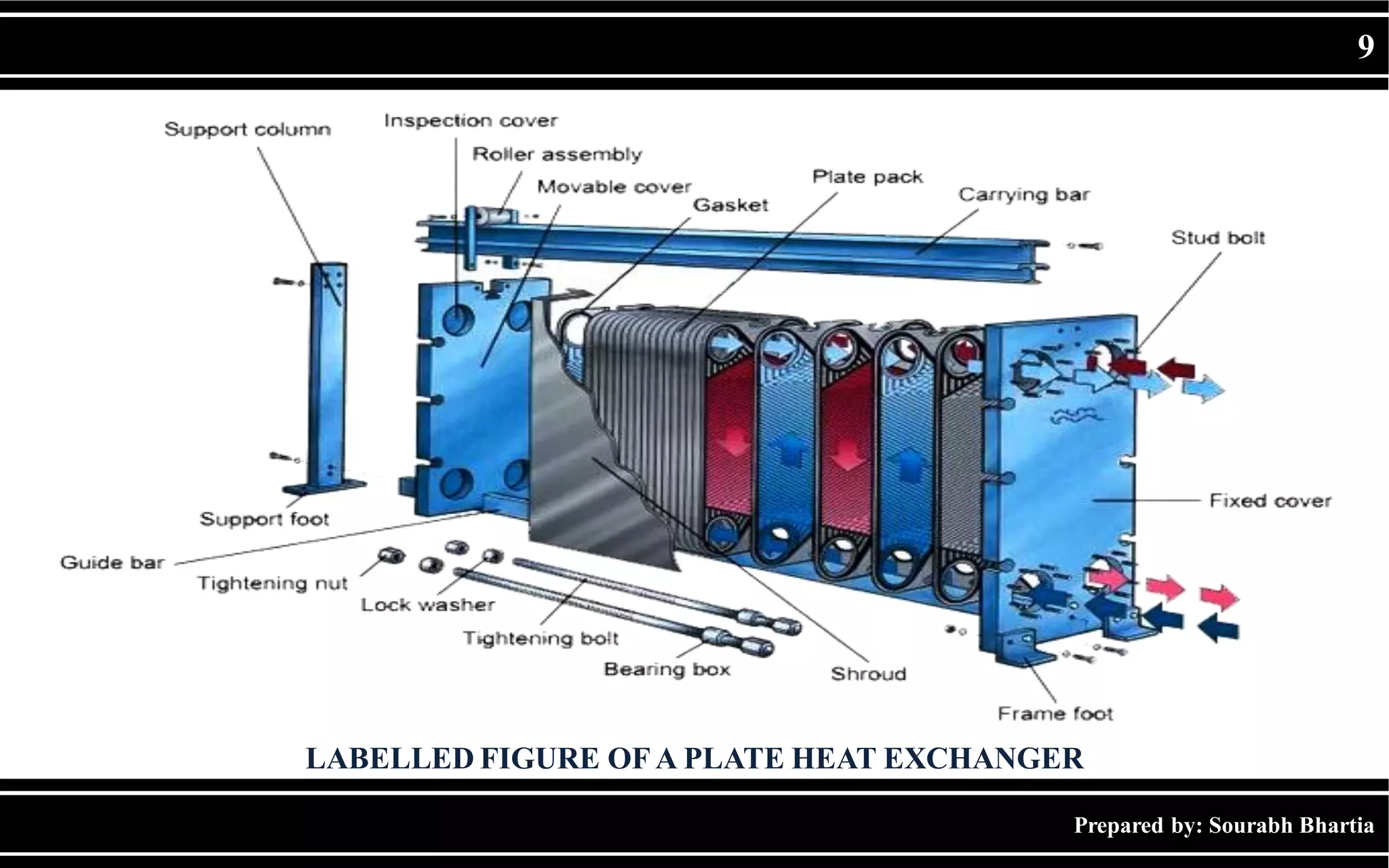

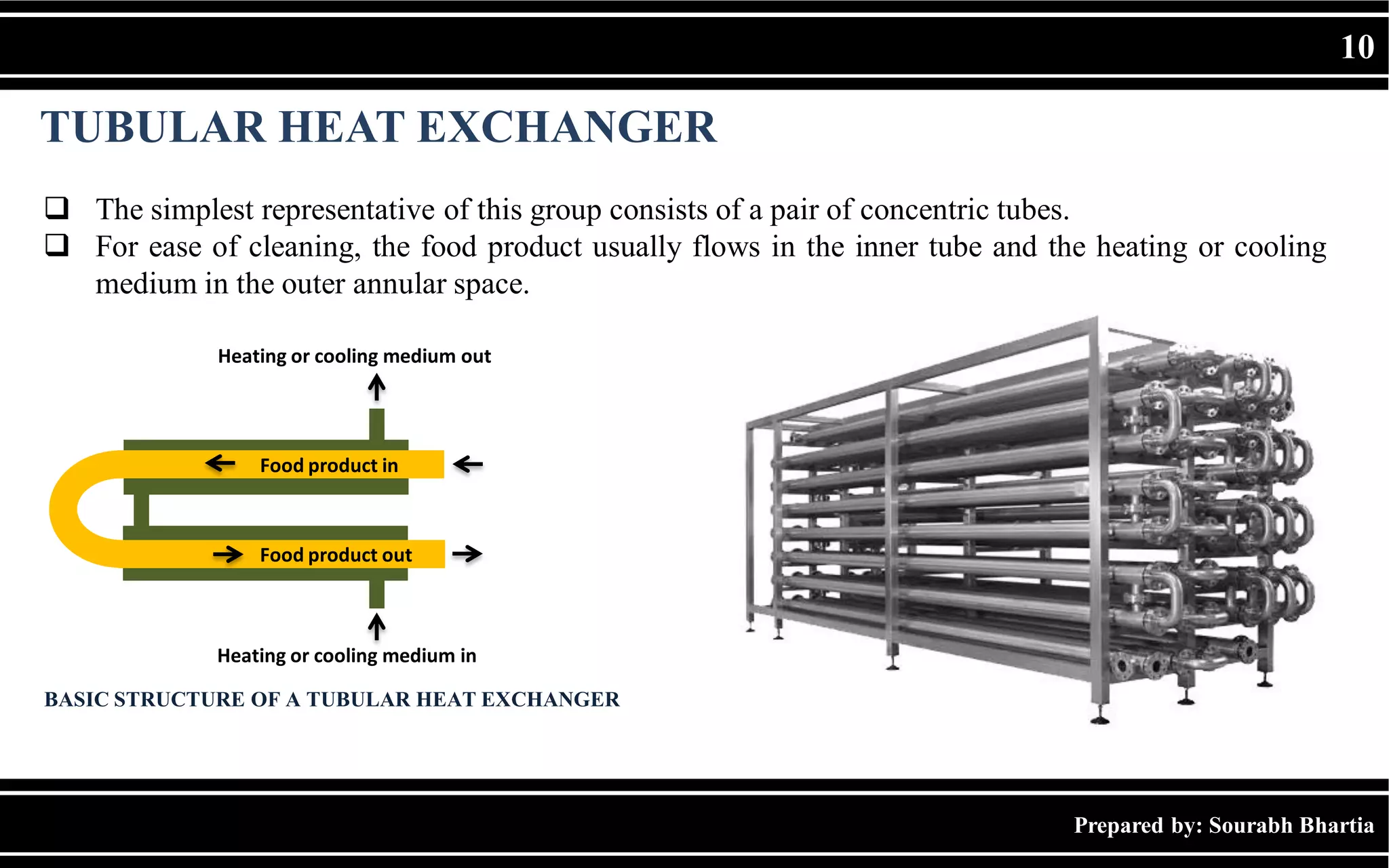

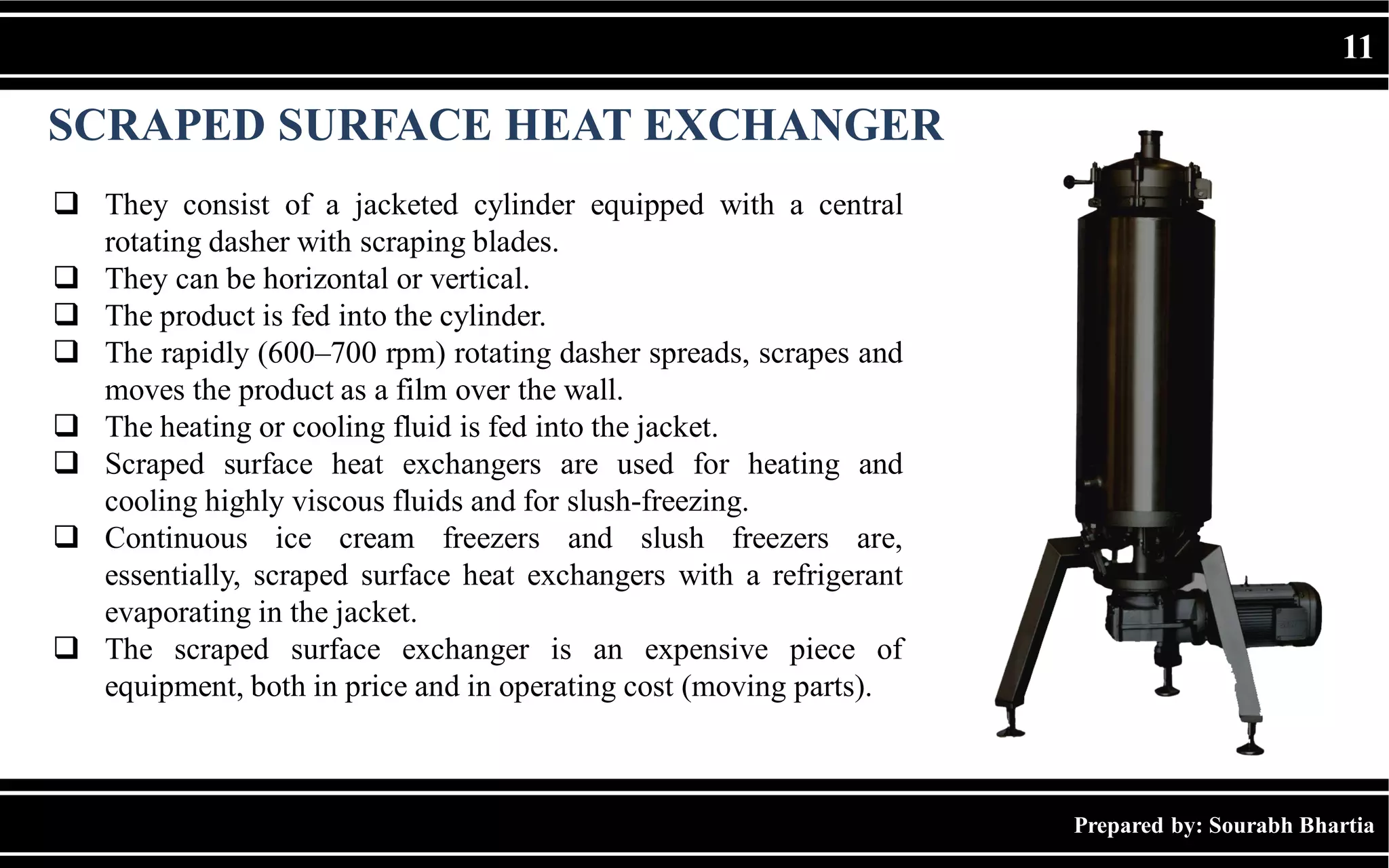

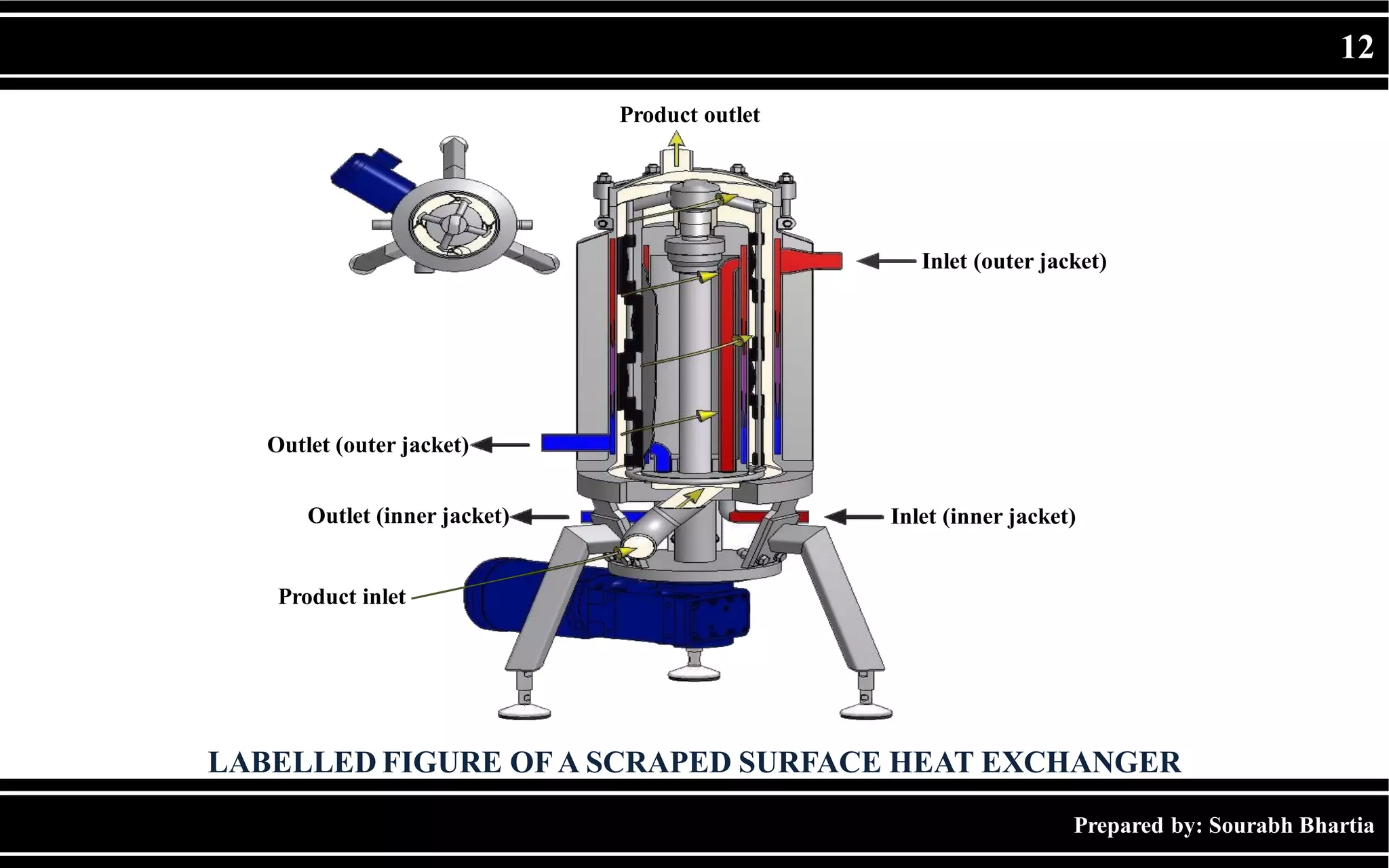

The document discusses ultra high temperature (UHT) processing of food products. UHT processing involves heating food to 135°C for 2-5 seconds to kill microorganisms and spores. This allows for longer shelf life without refrigeration. There are two main methods - direct heating which applies steam directly to the food, and indirect heating which uses a partition between the food and steam. Indirect heating includes plate heat exchangers, tubular heat exchangers, and scraped surface heat exchangers. UHT processing offers benefits like longer shelf life and packaging flexibility but requires complex sterile processing equipment.