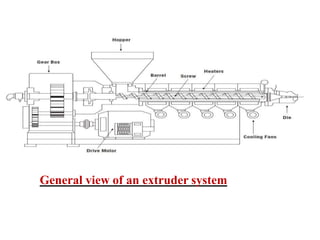

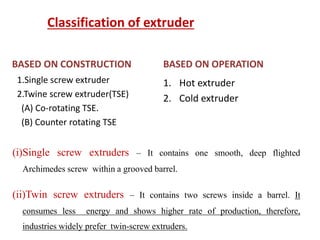

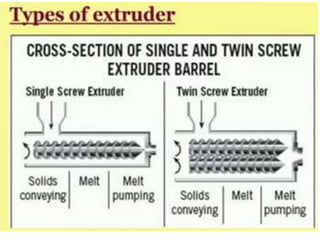

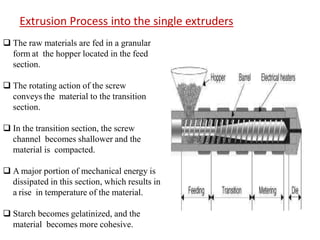

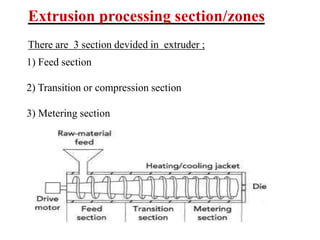

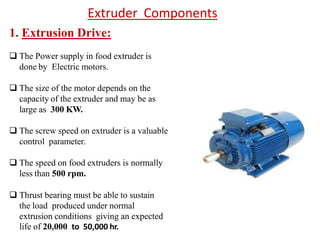

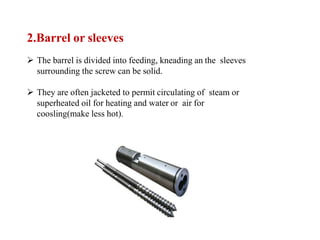

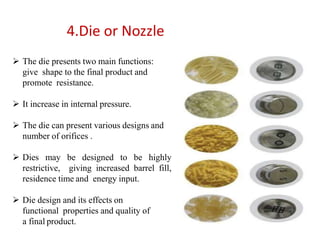

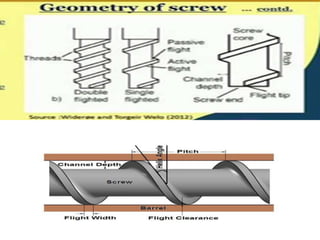

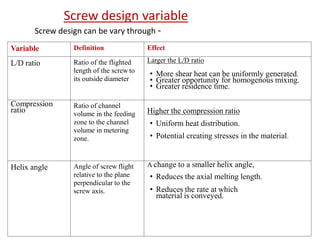

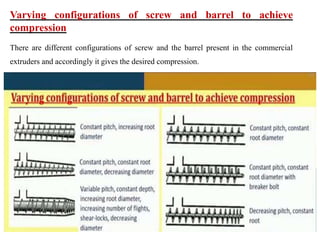

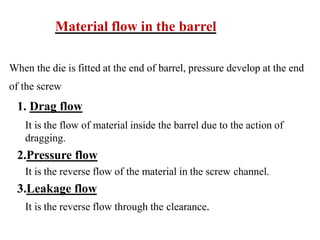

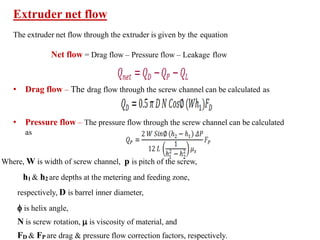

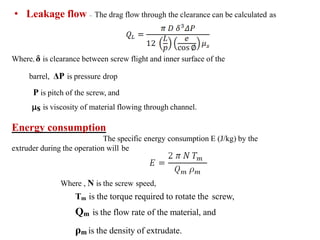

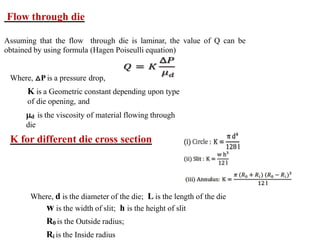

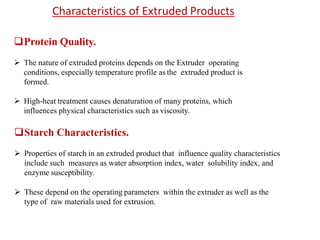

The document summarizes information about extrusion cooking. It begins with an introduction to extrusion cooking and lists its advantages. Examples of extruded products are provided. The document discusses different types of extruders and their components. The extrusion process and factors affecting it are explained. Key aspects of extrusion cooking covered include heating food materials under pressure to form new shapes and textures in a continuous process using an extruder machine.