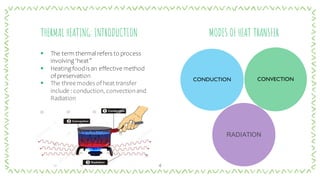

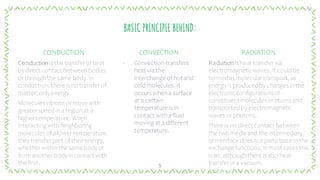

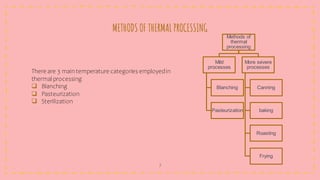

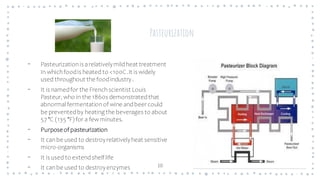

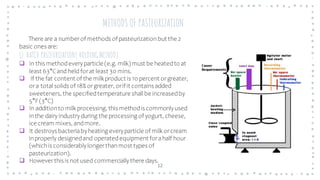

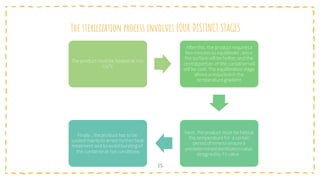

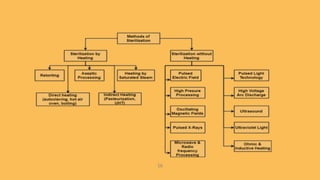

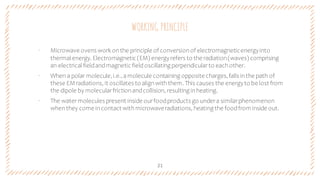

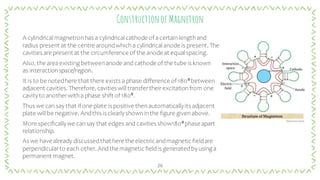

This document provides information on microwave and thermal heating processes. It begins with an introduction to thermal heating, describing the basic principles of conduction, convection and radiation. It then discusses various thermal processes like blanching, pasteurization and sterilization. The document also provides details on the components, working principle and mechanism of microwave heating. It compares the advantages and disadvantages of microwave and thermal heating methods.