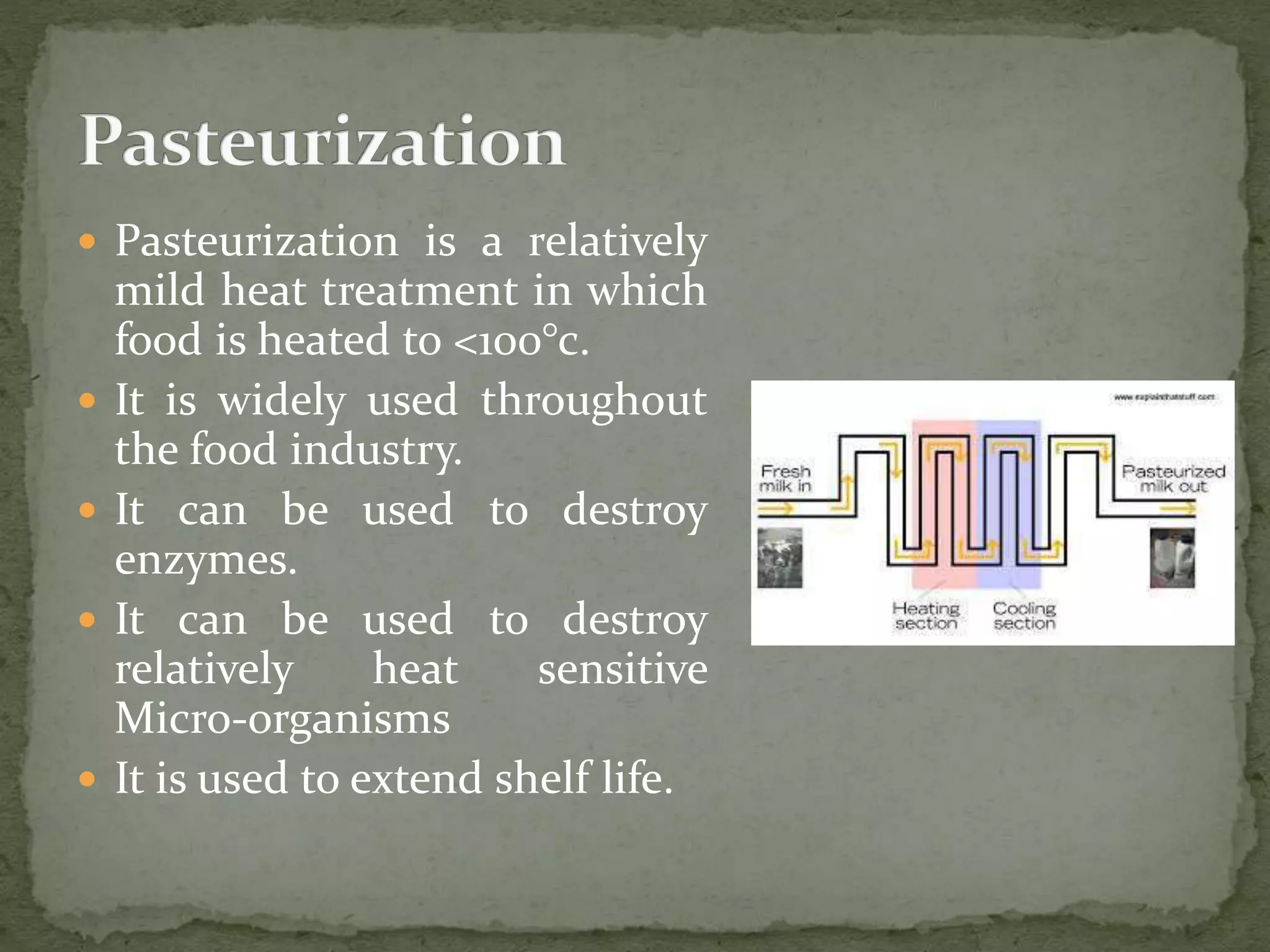

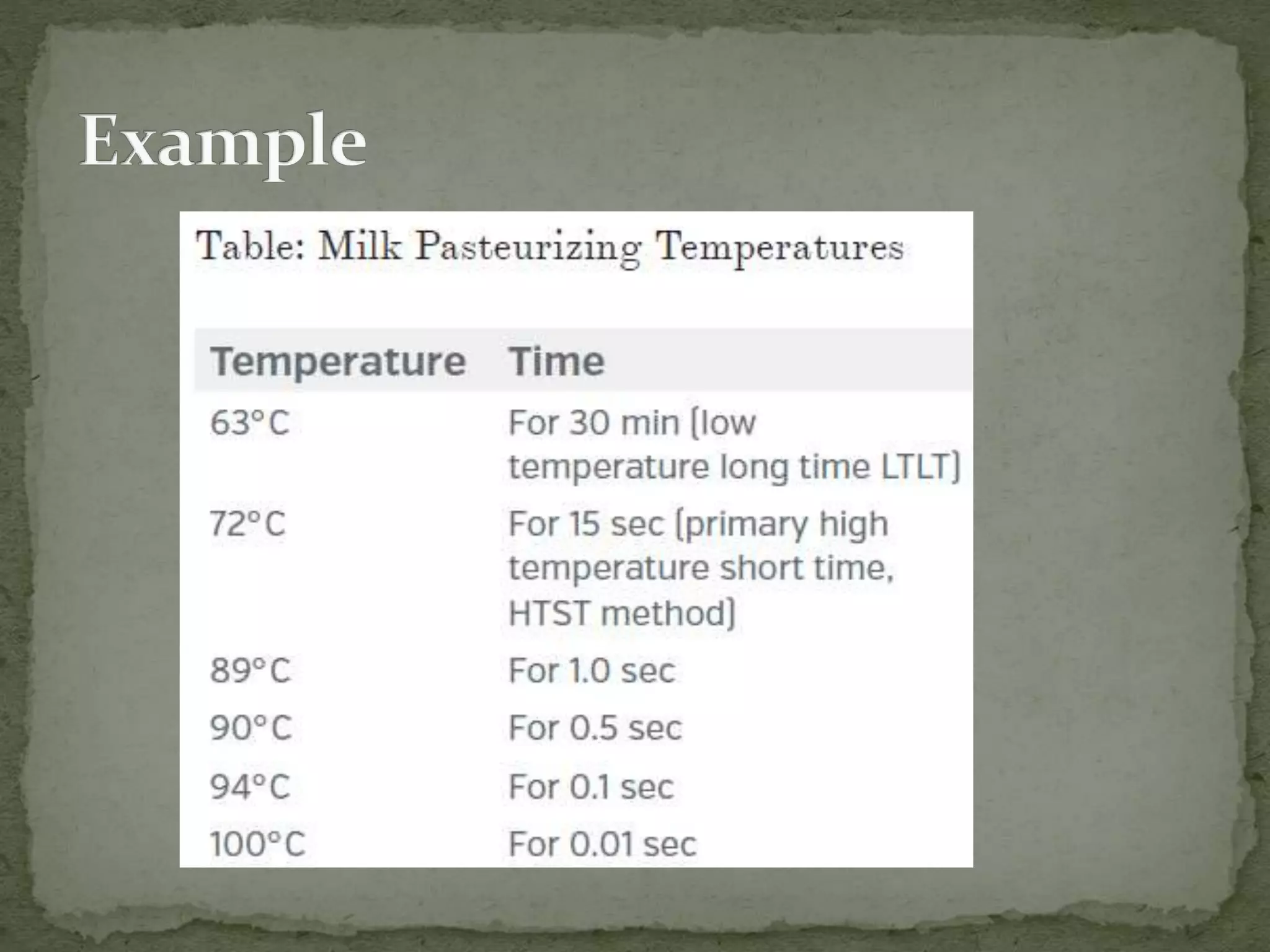

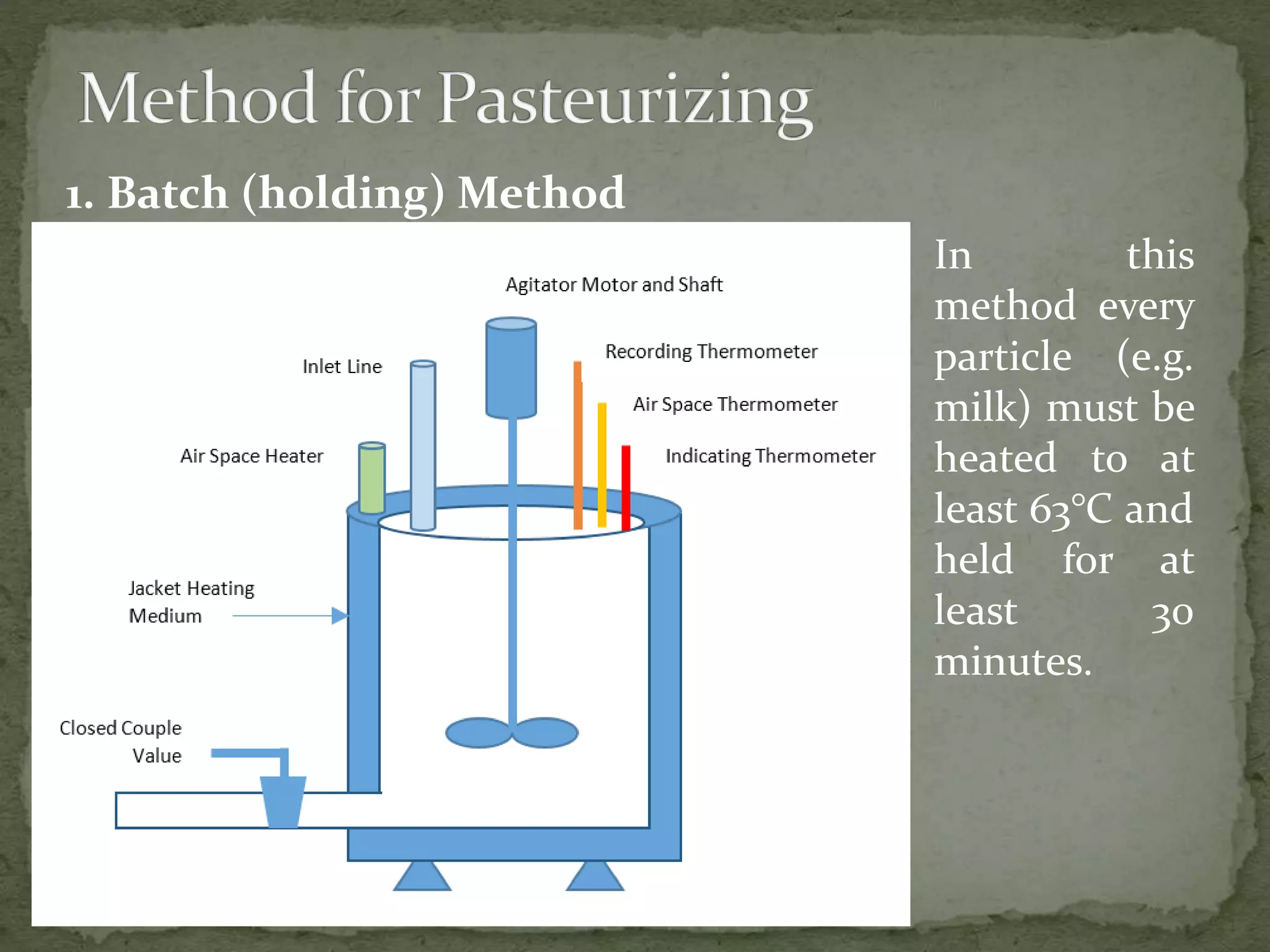

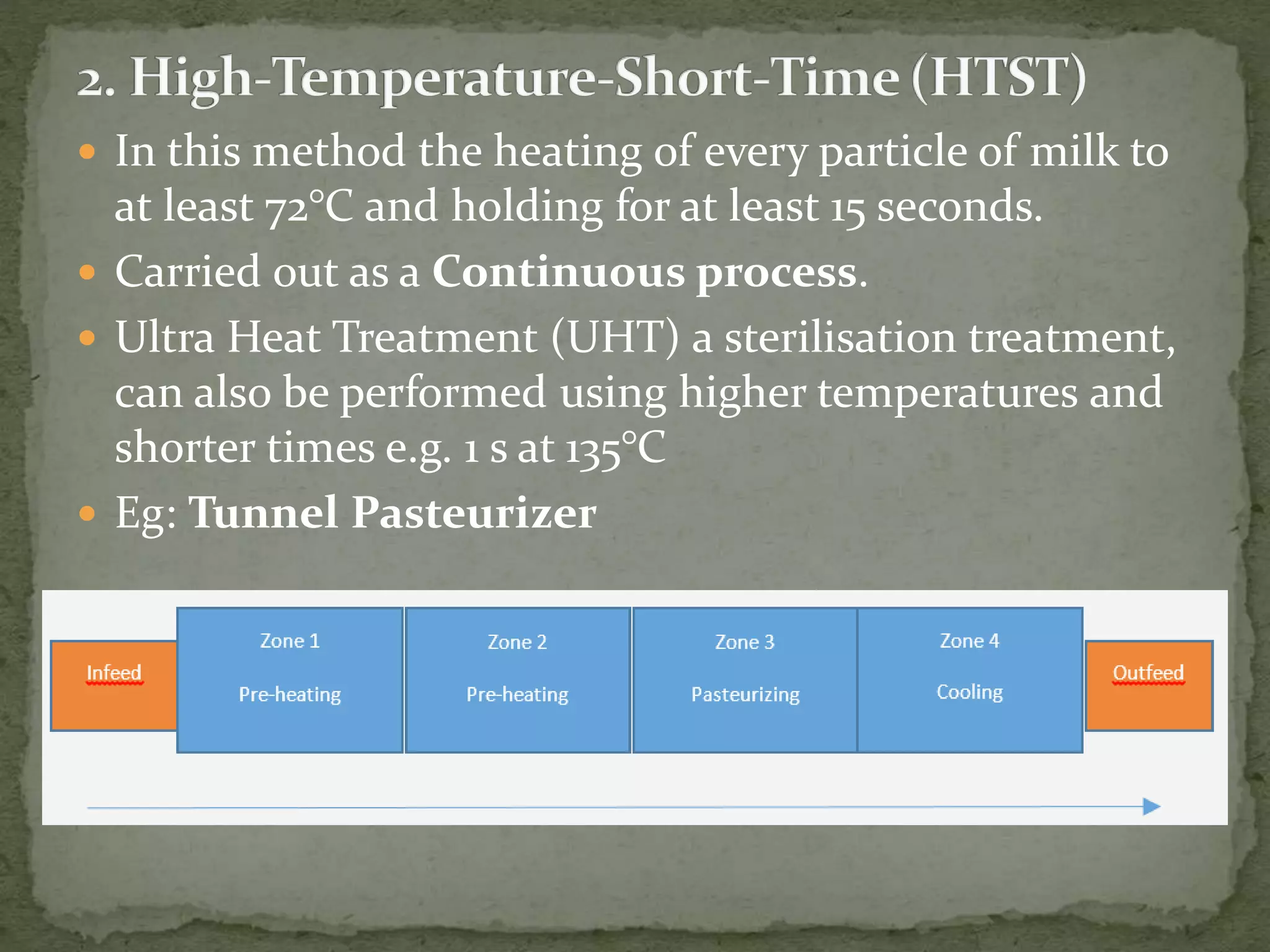

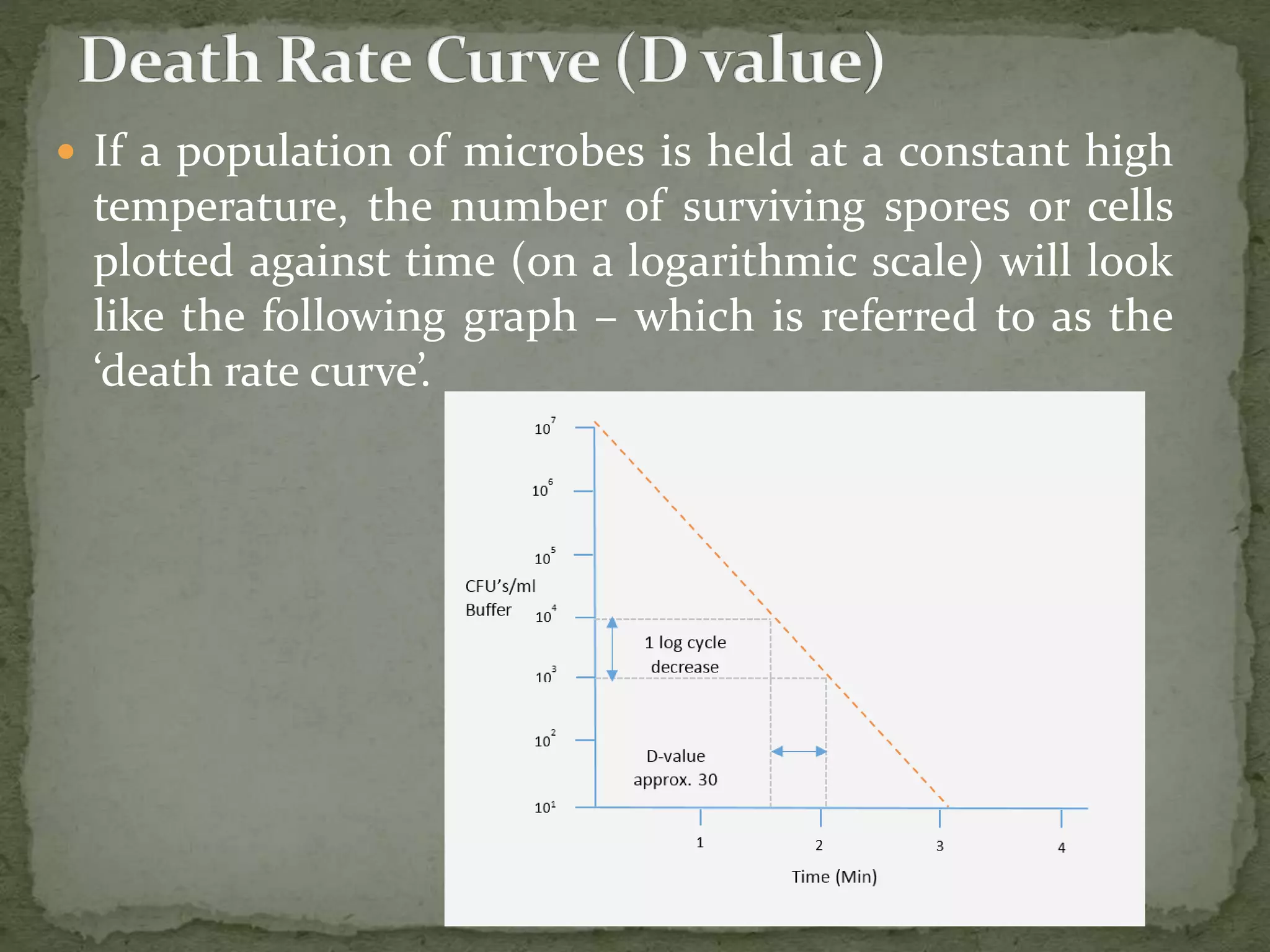

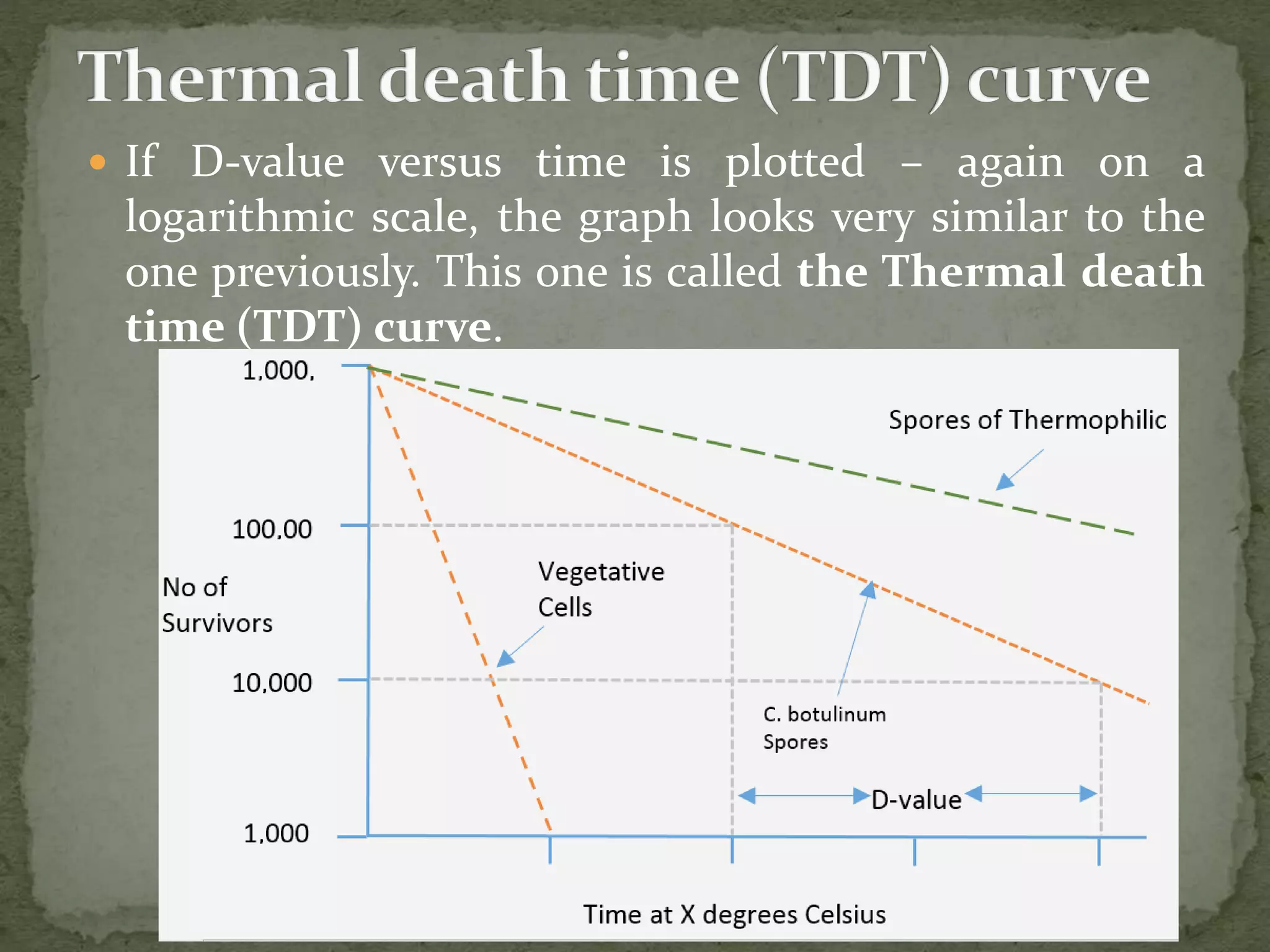

Thermal processing of foods involves applying heat for a specified time to reduce or eliminate microorganisms. There are three main categories: blanching, pasteurization, and sterilization. Blanching uses mild heat (up to 100°C) to inactivate enzymes as a pretreatment for other processes. Pasteurization uses heat below 100°C to destroy heat-sensitive microbes and extend shelf life. Sterilization employs high heat to eliminate all microbes, including spores, through methods like canning. The time and temperature used depends on the thermal resistance of the target organisms.