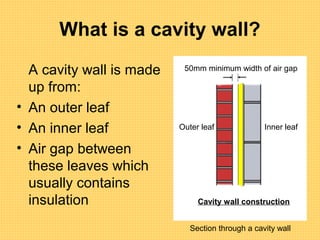

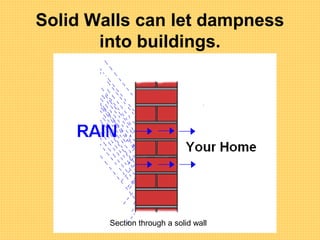

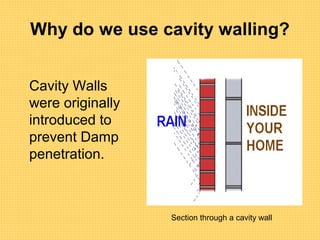

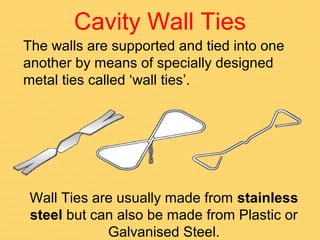

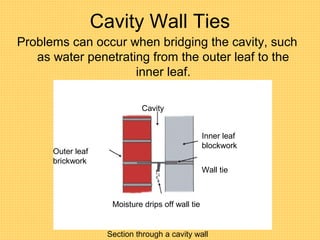

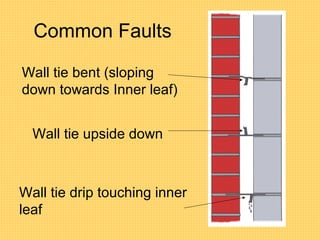

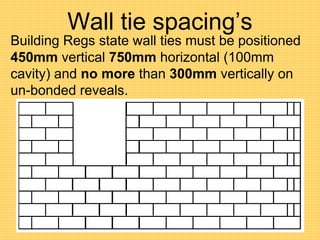

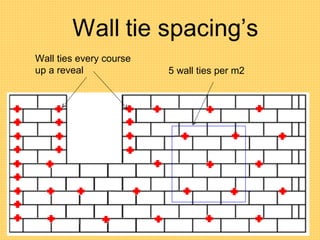

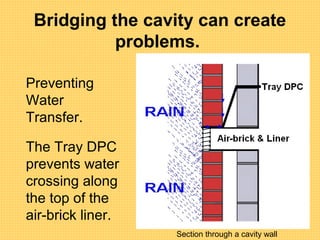

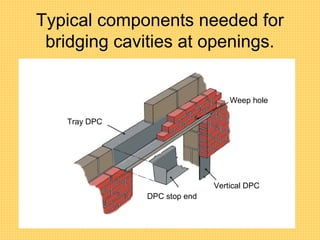

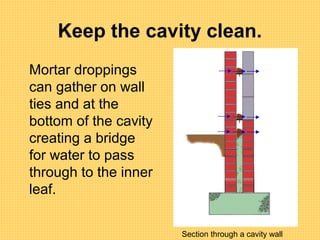

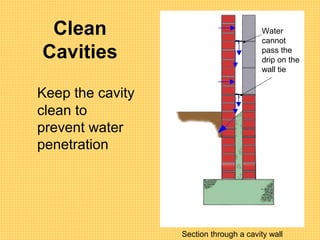

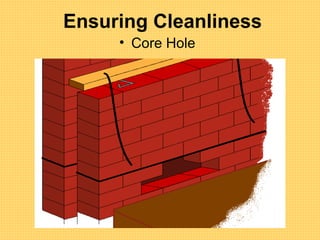

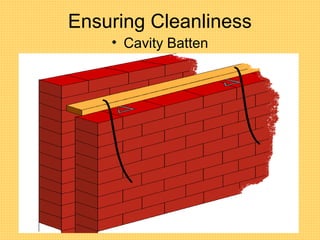

Cavity walls are constructed with an inner and outer leaf separated by an air gap, or cavity. This construction helps prevent dampness by allowing water that enters the outer leaf to drain out before reaching the inner leaf. Cavity walls are reinforced with wall ties to bind the two leaves together. Properly installed wall ties and other components are needed to bridge the cavity at openings while preventing water transfer. Mortar droppings in the cavity can form bridges for water to pass through, so the cavity must be kept clean during and after construction.