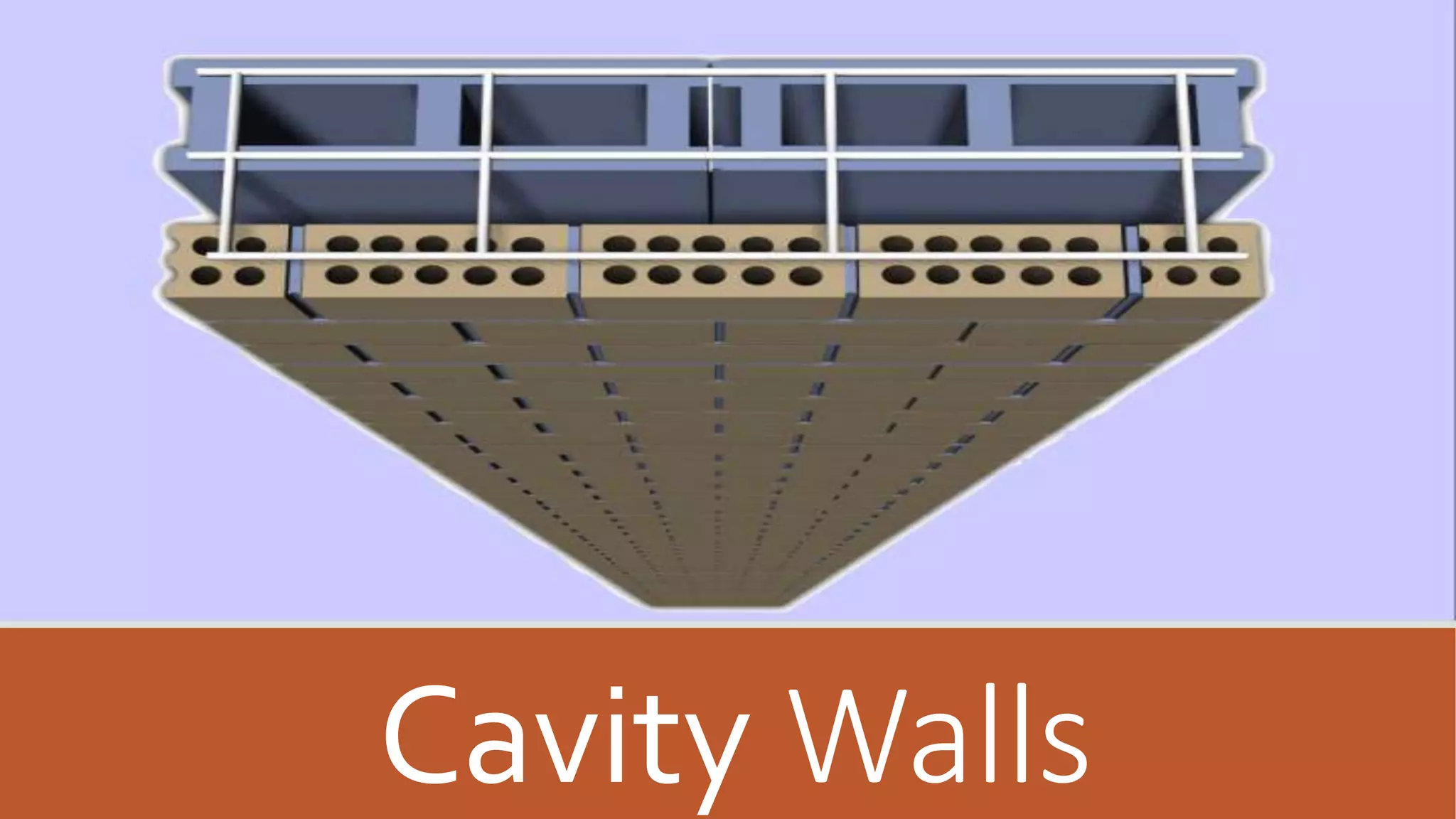

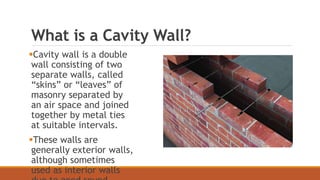

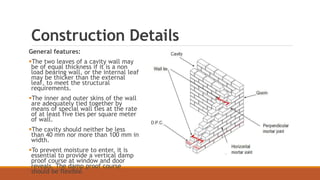

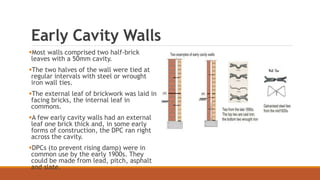

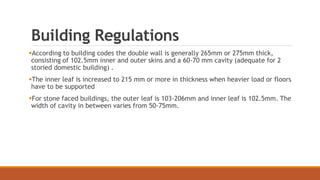

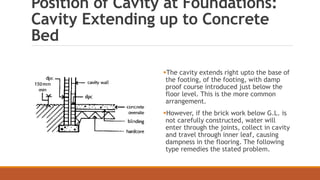

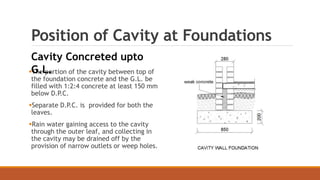

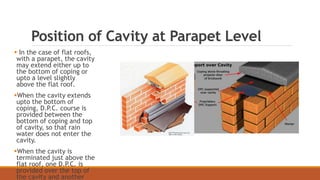

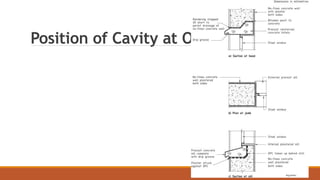

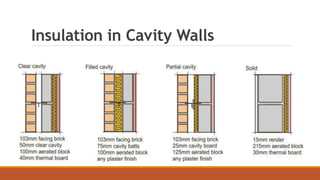

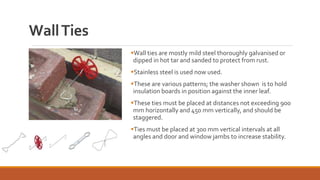

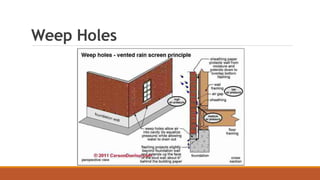

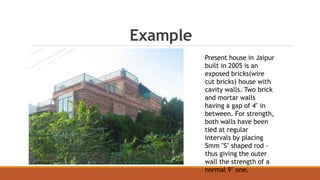

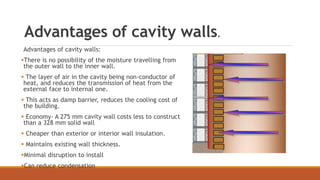

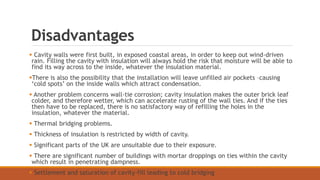

Cavity walls consist of two masonry leaves separated by an air space, providing structural support, moisture protection, and thermal efficiency. Building regulations specify wall thickness, cavity width, and damp proof courses to prevent moisture ingress, while proper insulation and wall ties are essential for stability. Despite their advantages, cavity walls face challenges such as risk of moisture transfer, potential wall tie corrosion, and limitations in insulation thickness.