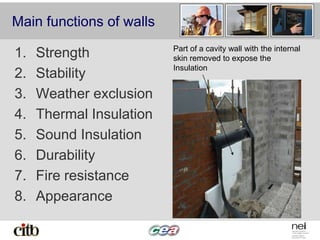

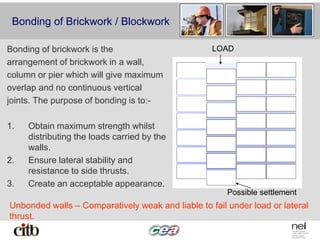

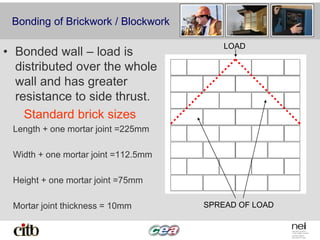

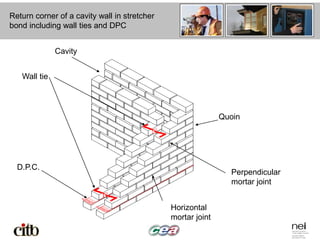

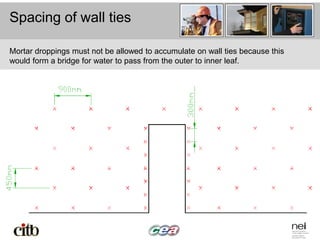

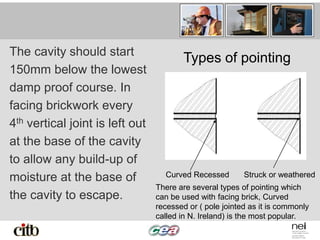

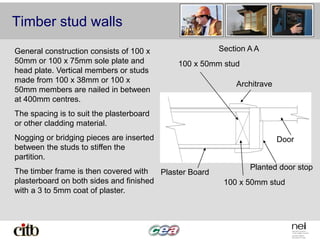

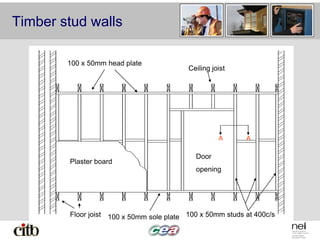

This document discusses different types of wall structures. It describes cavity walls, load bearing vs non-load bearing walls, and the functions of walls including strength, stability, weather exclusion and more. It provides details on bonding brickwork and blockwork, including stretcher bond and corner formations. Additional topics covered include wall ties, spacing of wall ties, cavity walls, and timber stud walls.